prEN IEC 61284:2025

(Main)Overhead lines - Requirements and tests for fittings

Overhead lines - Requirements and tests for fittings

Freileitungen - Anforderungen und Prüfungen für Armaturen

Lignes aériennes - Exigences et essais pour le matériel d'équipement

Nadzemni vodi - Zahteve in preskusi za obesno opremo

General Information

- Status

- Not Published

- Publication Date

- 13-Jun-2027

- Technical Committee

- CLC/TC 11 - Overhead electrical lines exceeding 1 kV a.c. (1,5 kV d.c.)

- Drafting Committee

- IEC/TC 11 - IEC_TC_11

- Current Stage

- 4060 - Enquiry results established and sent to TC, SR, BTTF - Enquiry

- Start Date

- 13-Feb-2026

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 30-Mar-2021

Overview

The prEN IEC 61284:2025 standard, titled "Overhead lines - Requirements and tests for fittings," is developed by the CLC (European Committee for Electrotechnical Standardization) and focuses on the essential requirements and testing protocols for overhead line fittings. This standard addresses a broad range of fittings used in power transmission and distribution lines to ensure safety, durability, and performance under operational stresses. Expected to be stable by 2026, this standard provides vital guidelines for manufacturers, engineers, and utility companies involved in overhead power infrastructure.

Key Topics

Design and Material Requirements

Covers design standards for mechanical integrity and resilience. Materials are classified into metallic and non-metallic categories with an emphasis on corrosion protection methods such as hot dip galvanizing and alternative corrosion-resistance techniques.Dimensions, Tolerances, and Markings

Specifies precise dimensional tolerances and mandatory marking requirements to support traceability and proper installation.Quality Assurance and Testing Classification

Encompasses type tests, sample tests, and routine tests ensuring products consistently meet safety and performance criteria.Mechanical and Thermal Testing

Detailed protocols outline how to conduct mechanical damage tests, failure load tests, slip tests for clamps, tensile tests, and thermal preconditioning for high-temperature (HT) conductors. These tests simulate operational conditions to validate fitting durability.Corrosion and Non-Destructive Tests

Procedures for verifying corrosion resistance and detecting internal defects without damaging the fittings.Heat Cycle and Electrical Performance Tests

Includes heat cycle testing of joints to determine long-term thermal resilience and tests for corona discharge and radio interference voltage (RIV) to ensure electrical safety and limit interference.Specific Fitting Categories

Requirements vary for insulator sets, suspension clamps, tension clamps, repair sleeves, earth wire fittings, and insulator protective fittings, each with tailored test methodologies according to their function in overhead lines.

Applications

This standard is critical for all stakeholders involved in the design, manufacture, and maintenance of overhead power lines. Key applications include:

Power Transmission and Distribution

Ensures fittings used in overhead cables maintain integrity under mechanical loads, temperature fluctuations, and environmental conditions, promoting reliable electricity delivery.Utility and Infrastructure Projects

Facilitates compliance with international best practices and enhancing the safety and lifespan of overhead line installations.Manufacturing and Quality Control

Guides manufacturers in producing fittings that consistently meet international safety and performance standards through rigorous testing.Engineering Design and Installation

Provides technical criteria for selecting and assembling fittings that withstand mechanical forces and electrical stresses during operation.

Related Standards

prEN IEC 61284:2025 aligns with and references standards related to power transmission equipment, electrical safety, and material specifications, including:

- IEC standards on overhead line components and electrical testing methods.

- Corrosion protection and material standards relevant to outdoor electrical fittings.

- Standards for electrical performance tests such as corona and RIV to safeguard against electrical noise and losses.

By adhering to prEN IEC 61284:2025, organizations ensure enhanced durability, safety, and reliability of overhead line fittings - contributing to overall power system resilience and operational excellence.

Keywords: overhead lines, fittings requirements, overhead line fittings tests, power transmission standards, mechanical testing overhead lines, corrosion protection fittings, IEC 61284, overhead power line safety, electrical insulation fittings, fitting durability tests

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

prEN IEC 61284:2025 is a draft published by CLC. Its full title is "Overhead lines - Requirements and tests for fittings". This standard covers: Overhead lines - Requirements and tests for fittings

Overhead lines - Requirements and tests for fittings

prEN IEC 61284:2025 is classified under the following ICS (International Classification for Standards) categories: 29.240.20 - Power transmission and distribution lines. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 61284:2025 has the following relationships with other standards: It is inter standard links to EN 61284:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN IEC 61284:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Nadzemni vodi - Zahteve in preskusi za obesno opremo

Overhead lines - Requirements and tests for fittings

Freileitungen - Anforderungen und Prüfungen für Armaturen

Lignes aériennes - Exigences et essais pour le matériel d'équipement

Ta slovenski standard je istoveten z: prEN IEC 61284:2025

ICS:

29.240.20 Daljnovodi Power transmission and

distribution lines

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

11/321/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 61284 ED3

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-11-21 2026-02-13

SUPERSEDES DOCUMENTS:

11/315/CD, 11/318A/CC

IEC TC 11 : OVERHEAD LINES

SECRETARIAT: SECRETARY:

South Africa Mr John Dlamini

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 7,TC 36,TC 42,TC 78,TC 99,TC 115,TC 122

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft for

Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of which t hey

are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some Countries”

clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the final stage for

submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Overhead lines - Requirements and tests for fittings

PROPOSED STABILITY DATE: 2026

NOTE FROM TC/SC OFFICERS:

electronic file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions.

You may not copy or "mirror" the file or printed version of the document, or any part of it, for any other purpose without

permission in writing from IEC.

IEC CDV 61284 © IEC 2025

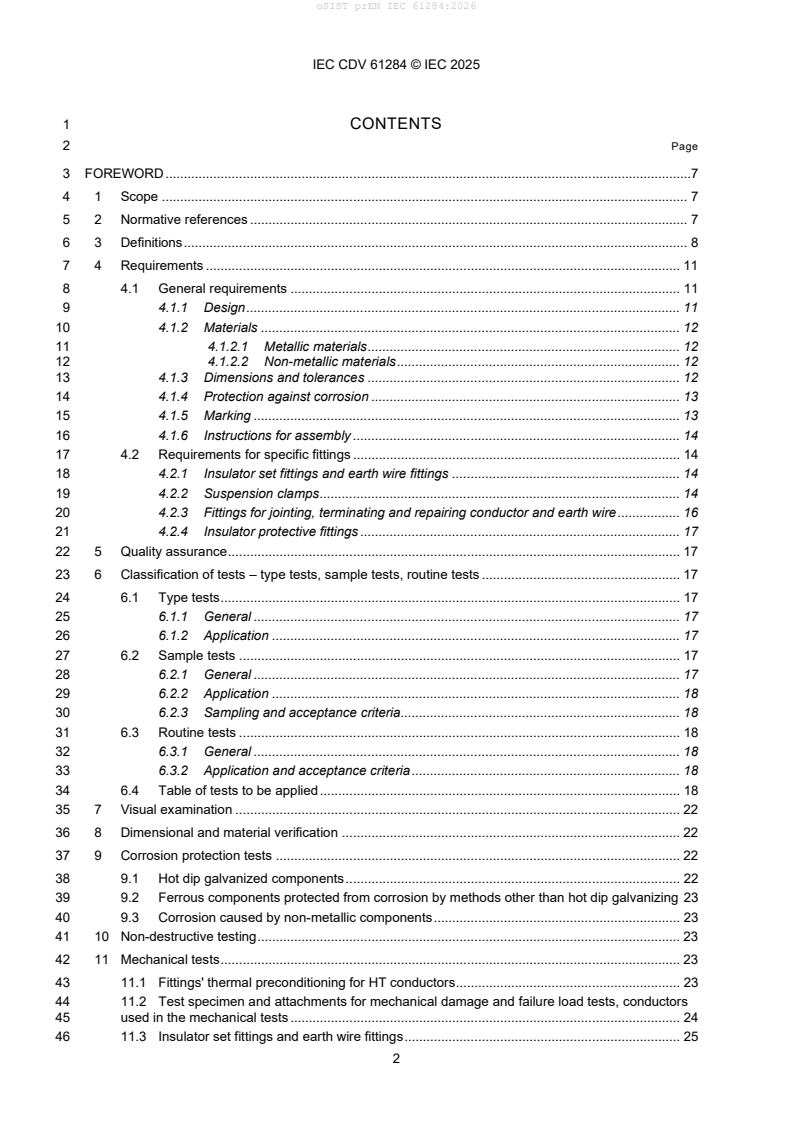

1 CONTENTS

2 Page

3 FOREWORD .7

4 1 Scope . 7

5 2 Normative references . 7

6 3 Definitions . 8

7 4 Requirements . 11

8 4.1 General requirements . 11

9 4.1.1 Design . 11

10 4.1.2 Materials . 12

11 4.1.2.1 Metallic materials . 12

12 4.1.2.2 Non-metallic materials . 12

13 4.1.3 Dimensions and tolerances . 12

14 4.1.4 Protection against corrosion . 13

15 4.1.5 Marking . 13

16 4.1.6 Instructions for assembly . 14

17 4.2 Requirements for specific fittings . 14

18 4.2.1 Insulator set fittings and earth wire fittings . 14

19 4.2.2 Suspension clamps . 14

20 4.2.3 Fittings for jointing, terminating and repairing conductor and earth wire . 16

21 4.2.4 Insulator protective fittings . 17

22 5 Quality assurance . 17

23 6 Classification of tests – type tests, sample tests, routine tests . 17

24 6.1 Type tests . 17

25 6.1.1 General . 17

26 6.1.2 Application . 17

27 6.2 Sample tests . 17

28 6.2.1 General . 17

29 6.2.2 Application . 18

30 6.2.3 Sampling and acceptance criteria. 18

31 6.3 Routine tests . 18

32 6.3.1 General . 18

33 6.3.2 Application and acceptance criteria . 18

34 6.4 Table of tests to be applied . 18

35 7 Visual examination . 22

36 8 Dimensional and material verification . 22

37 9 Corrosion protection tests . 22

38 9.1 Hot dip galvanized components . 22

39 9.2 Ferrous components protected from corrosion by methods other than hot dip galvanizing 23

40 9.3 Corrosion caused by non-metallic components . 23

41 10 Non-destructive testing . 23

42 11 Mechanical tests . 23

43 11.1 Fittings' thermal preconditioning for HT conductors . 23

44 11.2 Test specimen and attachments for mechanical damage and failure load tests, conductors

45 used in the mechanical tests . 24

46 11.3 Insulator set fittings and earth wire fittings . 25

IEC CDV 61284 © IEC 2025

47 11.3.1 Mechanical damage and failure load test . 25

48 11.3.2 Mechanical damage and failure load test of the attachment point used during

49 erection. 25

50 11.4 Suspension clamps . 27

51 11.4.1 Vertical damage load and failure load test . 27

52 11.4.2 Slip test on standard clamps with a specified minimum and maximum slip load . 27

53 11.4.2.1 Slip test after thermal cycles preconditioning . 29

54 11.4.3 Slip test on standard clamps with only specified minimum slip load . 29

55 11.4.3.1 Slip test after thermal cycles preconditioning . 30

56 11.4.4 Slip test on controlled slippage clamps . 30

57 11.4.4.1 Slip test after thermal cycles preconditioning . 31

58 11.4.5 Clamp bolt tightening test . 31

59 11.4.5.1 Clamp bolt tightening test after thermal cycles preconditioning . 32

60 11.4.6 Turning angle test . 32

61 11.5 Tension clamps, dead-end tension joints and mid-span tension joints . 33

62 11.5.1 Tensile test . 33

63 11.5.1.1 Tensile test after thermal cycles preconditioning . 35

64 11.5.2 Mechanical damage and failure load test (except compressed clamps) . 35

65 11.5.3 Mechanical damage and failure load test of the attachment point used during

66 erection. 36

67 11.5.4 Clamp bolt tightening test . 36

68 11.5.4.1 Clamp bolt tightening test after thermal cycles preconditioning . 36

69 11.6 Partial tension fittings . 36

70 11.6.1 Partial tension fittings other than T joints . 36

71 11.6.1.1 Tensile test . 36

72 11.6.1.1.1 Tensile test after thermal cycles preconditioning . 36

73 11.6.2 T joints . 37

74 11.6.2.1 Tensile test with mechanical tension between main conductor and branch

75 conductor 37

76 11.6.2.1.1 Tensile test after thermal cycles preconditioning . 37

77 11.6.2.2 Tensile test with mechanical tension on the main conductor . 37

78 11.6.2.2.1 Tensile test after thermal cycles preconditioning . 37

79 11.6.3 Clamp bolt tightening test . 37

80 11.6.3.1 Clamp bolt tightening test after thermal cycles preconditioning . 37

81 11.7 Repair sleeves . 37

82 11.7.1 Tensile test . 37

83 11.7.1.1 Tensile test after thermal cycles preconditioning . 38

84 11.8 Mechanical damage and failure load test for insulator protective fittings . 38

85 12 Magnetic losses test . 38

86 12.1 General. 38

87 12.2 Test procedure . 38

88 13 Heat cycle tests . 40

89 13.1 Purpose . 40

90 13.2 Joints . 40

91 13.2.1 General . 40

92 13.2.2 Classification for test purposes . 40

93 13.3 Test specimens . 40

94 13.3.1 General . 40

95 13.3.2 Multi-conductor joints . 40

96 13.3.3 Preparation . 41

97 13.3.4 Data on test specimens . 41

98 13.4 Test arrangements . 41

IEC CDV 61284 © IEC 2025

99 13.4.1 Test conditions . 41

100 13.4.2 Reference conductor . 41

101 13.4.3 Potential points . 41

102 13.4.4 Installation of test loop . 41

103 13.4.5 Measurements . 42

104 13.4.5.1 Resistance measurement . 42

105 13.4.5.2 Temperature measurements . 42

106 13.4.5.3 Measurement of short-time overcurrent (class B joints) . 43

107 13.5 Procedure for type 0 conductors . 43

108 13.5.1 General . 43

109 13.5.2 Joints of class A . 43

110 13.5.2.1 Test procedure . 43

111 13.5.2.2 Acceptance criteria (class A joints) . 44

112 13.5.3 Joints of class B . 44

113 13.5.3.1 Test procedure . 44

114 13.5.3.2 Acceptance criteria (class B) . 45

115 13.6 Procedure for HT conductors . 45

116 13.6.1 Method 1 . 45

117 13.6.1.1 Joints of class A . 45

118 13.6.1.1.1 Test procedure . 45

119 13.6.1.1.2 Acceptance criteria (Method 1 - class A joints) . 45

120 13.6.1.2 Joints of class B . 45

121 13.6.1.2.1 Test procedure . 45

122 13.6.1.2.2 Acceptance criteria (Method 1 - class B joints) . 46

123 13.6.2 Method 2 (only joints of class A) . 46

124 13.6.2.1 Test procedure . 46

125 13.6.2.2 Acceptance criteria (Method 2 - class A joints) . 46

126 13.6.3 Method 3 (only joints of class A) . 46

127 13.6.3.1 Test procedure . 46

128 13.6.3.2 Acceptance criteria (Method 3 - class A joints) . 47

129 13.7 Test report . 47

130 14 Corona and radio interference voltage (RIV) tests . 48

131 14.1 Purpose . 48

132 14.2 Description of test methods . 48

133 14.3 General. 48

134 14.4 Test circuit and instruments . 49

135 14.5 Corona and RIV test procedures . 50

136 14.6 Acceptance criteria . 50

137 14.7 Test report . 50

138 14.8 Voltage method . 51

139 14.8.1 Adjacent conductors in a three-phase system . 51

140 14.8.1.1 Test set-up and dimensions (see from Figure 22 to Figure 27) . 51

141 14.8.1.2 Critical variant . 54

142 14.8.1.3 Distance from wall (reflection plane) W . 54

143 14.8.1.4 Minimum clearance from adjacent live components . 55

144 14.8.1.5 Metallic wall . 55

145 14.9 Voltage gradient method . 55

146 14.9.1 Conductor voltage on three-phase system . 55

147 14.9.2 Test set-up and dimensions . 55

148 14.9.3 Test method . 56

149 15 Fittings’ thermal profile . 57

150 16 Characterization of elastomers . 57

151 Annexes

IEC CDV 61284 © IEC 2025

152 Annex A (normative) Minimum technical details to be agreed between purchaser and supplier . 59

153 Annex B (informative) Alternative fittings' thermal preconditioning . 61

154 Annex C (normative) Typical joint types . 62

155 Annex D (informative) Temperature sensing devices . 64

156 Annex E (informative) Potential points . 65

157 Annex F (normative) Typical test circuit – Class A joints . 66

158 Annex G (normative) Typical test circuit – Class B joints . 67

159 Annex H (normative) Diagrammatic representation of heat cycle test sequence . 68

160 Annex I (normative) Mathematical acceptance criterion . 69

161 Annex J (normative) Heat cycles test for HT conductors - Method 3 . 71

162 Annex K (informative) Aeolian vibration test . 76

163 Annex L (informative) Examples of international standards and recommendations for fitting materials

164 . 79

165 Annex M (informative) Test voltage calibration device . 81

166 Annex N (informative) Example of sampling with inspection by attributes . 84

167 Annex O (informative) Example of sampling with inspection by variables . 85

168 Annex P (informative) Practical inspection method by attributes . 86

170 Figures

171 Figure 1 – Tolerance on holes subjected to mechanical stress . 15

172 Figure 2 – Different articulation of suspension clamps . 15

173 Figure 3 – Different types of metal-to-metal suspension clamps . 16

174 Figure 4 – Different types of rubber/elastomer-lined (ES) clamps . 16

175 Figure 5 – Different types of HAES clamps . 17

176 Figure 6 – Thermal cycles preconditioning . 25

177 Figure 7 – Insulator set fittings and earth wire fittings – damage load and failure load test: diagrams

178 showing the typical application of load . 27

179 Figure 8 – Insulator set fittings and earth wire fittings – mechanical damage and failure load test: rate

180 of increase of load . 27

181 Figure 9 – Suspension clamp – vertical damage load and failure load test: diagram showing the typical

182 application of load . 28

183 Figure 10 – Suspension clamp – slip test: Check points for slippage of the different types of

184 suspension clamps . 30

185 Figure 11 – Suspension clamp (standard type) – slip test: diagram showing the typical application of

186 load . 31

187 Figure 12 – Suspension clamp (controlled slippage type) – slip test: diagram showing the typical

188 application of load . 32

189 Figure 13 – Suspension clamp – Turning angle test: diagram showing the typical application of load 33

190 Figure 14 – Tension clamps, dead-end tension joints and tension joints – tensile test: diagram

191 showing the typical application of load . 35

192 Figure 15 – Tension clamps, dead-end tension joints and tension joints – tensile test: Recommended

193 Check points for slippage of the different types of tension clamps . 35

194 Figure 16 – Tension clamps, dead-end tension joints and tension joints – tensile test: rate of increase

195 of load . 36

196 Figure 17 – Tension clamps and tension joints – mechanical damage and failure load test: diagram

197 showing the typical application of load . 36

198 Figure 18 – Tension clamp and tension joints – mechanical damage and failure load test of the

199 attachment point used during erection: diagram showing the typical application of load . 37

200 Figure 19 – Magnetic losses test . 40

201 Figure 20 – Heat cycles test for HT conductors - Method 3 - Typical test circuit . 48

202 Figure 21 – Typical relationship between observed corona and RIV . 49

203 Figure 22 – Suspension test arrangement, critical variant b) . 52

204 Figure 23 – Tension test arrangement, critical variant b) . 53

205 Figure 24 – Tension test arrangement, critical variant b), hanging vertically from the ceiling . 53

206 Figure 25 – Tension test arrangement, critical variant c) . 54

207 Figure 26 – Tension test arrangement, critical variant c), hanging vertically from the ceiling . 54

208 Figure 27 – Test arrangement for in-span fittings, critical variant b) or c) . 55

209 Figure 28 – Typical test arrangement – suspension assembly . 57

210 Figure 29 – Typical test arrangement – tension assembly . 57

IEC CDV 61284 © IEC 2025

212 Tables

213 Table 1 – Tests on fittings . 20

214 Table 2 – Current magnitudes for magnetic losses test . 40

215 Table 3 – Conditions for heat cycle test . 44

216 Table 4 – Test voltages and dimensions for Corona and RIV tests . 56

IEC CDV 61284 © IEC 2025

219 INTERNATIONAL ELECTROTECHNICAL COMMISSION

220 –––––––––

221 OVERHEAD LINES –

222 REQUIREMENTS AND TESTS FOR FITTINGS

224 FOREWORD

225 1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

226 all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

227 international co-operation on all questions concerning standardization in the electrical and electronic fields. To

228 this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

229 entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

230 participate in this preparatory work. International, governmental and non-governmental organizations liaising with

231 the IEC also participate in this preparation. The IEC collaborates closely with the International Organization for

232 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

233 2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

234 international consensus of opinion on the relevant subjects since each technical committee has representation

235 from all interested National Committees.

236 3) The documents produced have the form of recommendations for international use and are published in the form

237 of standards, technical reports or guides and they are accepted by the National Committees in that sense.

238 4) In order to promote international unification, IEC National Committees undertake to apply IEC International

239 Standards transparently to the maximum extent possible in their national and regional standards. Any divergence

240 between the IEC Standard and the corresponding national or regional standard shall be clearly indicated in the

241 latter.

242 5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

243 equipment declared to be in conformity with one of its standards.

244 6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

245 of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

246 International Standard IEC 61284 has been prepared by IEC technical committee 11: Overhead

247 lines.

248 This third edition cancels and replaces the second edition published in 1997 and constitutes a

249 technical revision.

250 The text of this standard is based on the following documents:

FDIS Report on voting

251 Full information on the voting for the approval of this standard can be found in the report on

252 voting indicated in the above table.

253 Annexes A, C, F, G, H, I and J form an integral part of this standard.

254 Annexes B, D, E, K, L, M, N, O and P are for information only.

255 The contents of the corrigenda of September 1998 have been included in this copy.

256 OVERHEAD LINES –

257 REQUIREMENTS AND TESTS FOR FITTINGS

259 1 Scope

260 This International Standard applies to fittings for overhead lines of nominal voltage above 45

261 kV. Fittings concerned particularly are all fittings except those that have a specific standard

262 dedicated like spacers (IEC 61854), dampers (IEC 61897) and end fittings for insulators (IEC

263 61466-1). It may also be applied to fittings for overhead lines of lower nominal voltage and to

264 similar fittings for substations. Moreover, fittings designed for use with High Temperature (HT)

265 conductors are included.

IEC CDV 61284 © IEC 2025

266 In some cases, test procedures and test values are left to agreement between purchaser and

267 supplier and are stated in the procurement contract. The purchaser is best able to evaluate the

268 intended service conditions, which should be the basis for establishing the test severity.

269 In Annex A, the minimum technical details to be agreed between purchaser and supplier are

270 listed.

271 2 Normative references

272 The following documents are referred to in the text in such a way that some or all of their content

273 constitutes requirements of this document. For dated references, only the edition cited applies.

274 For undated references, the latest edition of the referenced document (including any

275 amendments) applies.

276 IEC 60050, International Electrotechnical Vocabulary (IEV) – Chapter 466: Overhead lines

277 (available at www.electropedia.org))

278 IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

279 IEC 60120, Dimensions of ball and socket couplings of string insulator units - Dimensions

280 IEC 60372, Locking devices for ball and socket couplings of string insulator units – Dimensions

281 and tests

282 IEC 60437, Radio interference test on high-voltage insulators

283 IEC 60471, Clevis and tongue couplings of string insulator units - Dimensions

284 IEC 60794-1-2, Optical fibre cables - Part 1-2: Generic specification - Basic optical cable test

285 procedures - General guidance

286 IEC 60794-4, Optical fibre cables - Part 4: Sectional specification - Aerial optical cables along

287 electrical power lines

288 IEC 60826, Loading and strength of overhead transmission lines

289 IEC 61089, Round wire concentric lay overhead electrical stranded conductors

290 IEC 61466-1, Composite string insulator units for overhead lines with a nominal voltage greater

291 than 1000 V - Part 1: Standard strength and end fittings

292 IEC 61467, Insulators for overhead lines - Insulator strings and sets for lines with a nominal

293 voltage greater than 1000 V - AC power arc tests

294 IEC 61854, Overhead lines – Requirements and tests for spacers

295 IEC 61897, Overhead lines – Requirements and tests for Aeolian vibration dampers

296 IEC 62641:2022, Conductors for overhead lines - Aluminium and aluminium alloy wires for

297 concentric lay stranded conductors

298 IEC 63248, Conductors for overhead lines - Coated or cladded metallic wire for concentric lay

299 stranded conductors

300 CISPR 16-1, Specification for radio disturbance and immunity measuring apparatus and

301 methods – Part 1: Radio disturbance and immunity measuring apparatus

302 CISPR TR 18-2, Radio interference characteristics of overhead power lines and high-voltage

303 equipment – Part 2: Methods of measurement and procedure for determining limits

304 ISO 1461:2022, Hot dip galvanized coatings on fabricated ferrous products – Specifications

305 ISO 9000, Quality management systems – Fundamentals and vocabularies

306 ISO 9001, Quality management systems – Requirements

IEC CDV 61284 © IEC 2025

307 ISO 9004, Managing for the sustained success of an organization – A quality management

308 approach

309 ISO 2859-1, Sampling procedures for inspection by attributes – Part 1: Sampling schemes

310 indexed by acceptable quality limit (AQL) for lot-by-lot inspection

311 ISO 2859-2, Sampling procedures for inspection by attributes – Part 2: Sampling plans indexed

312 by limiting quality (LQ) for isolated lot inspection

313 ISO 3951-1, Sampling procedures for inspection by variables – Part 1: Specification for single

314 sampling plans indexed by acceptance quality limit (AQL) for lot-by-lot inspection for a single

315 quality characteristic and a single AQL

316 ISO 3951-2, Sampling procedures for inspection by variables – Part 2: General specification for

317 single sampling plans indexed by acceptance quality limit (AQL) for lot-by-lot inspection of

318 independent quality characteristics

319 3 Definitions

320 For the purpose of this document, the following terms and definitions apply. The term and the

321 definitions listed here are those which differ or do not appear in IEC 60050-466.

322 ISO and IEC maintain terminological databases for use in standardization at the following

323 addresses:

324 • IEC Electropedia: available at http://www.electropedia.org

325 • ISO Online browsing platform: available at http://www.iso.org/obp

326 3.1

327 characteristic dimension

328 Dimension of a component of the test circuit or of a fitting which characterizes its effect on the

329 electric field. In the case of a bundle, this dimension is approximately the diameter of an

330 enclosing circle; in the case of a corona ring or sphere, it is its largest dimension, etc.

331 3.2

332 conductor classification

333 The following last four types are generally called High Temperature (HT) conductors, being able

334 to withstand operating temperatures above the limits of conventional aluminium alloy or hard -

335 drawn aluminium wires without significant reduction of mechanical strength during its expected

336 lifetime. These conductors are usually designed to achieve an higher ampacity than

337 conventional conductors (Type 0) of the same size or to reduce size keeping the same ampacity.

338 Type 0

339 Conductors made up of hard-drawn aluminium or aluminium alloy wires (Ax or ALx as per IEC

340 62641, except A0 or AL0) with or without an inner core made up of steel wires (as per IEC

341 63248); conductors made up of only steel wires (as per IEC 63248).

342 NOTE – In case of optical fibre conductors, the maximum operating temperature shall be agreed between

343 purchaser and supplier.

344 Type 1

345 Conductors made up of thermal resistant aluminium alloy wires (ATx as per IEC 62641) with

346 or without an inner core made up of steel wires (as per IEC 63248).

347 Type 2

348 Conductors made up of annealed aluminium wires (A0 or AL0 as per IEC 62641) supported

349 by an inner core made up of steel wires (as per IEC 63248).

350 Type 3

351 Conductors made up of thermal resistant aluminium alloy wires (ATx as per IEC 62641)

352 supported by an inner core made up of metal-matrix composite (MMC).

IEC CDV 61284 © IEC 2025

353 Type 4

354 Conductors made up of annealed aluminium wires (A0 or AL0 as per IEC 62641) or thermal

355 resistant aluminium alloy wires (ATx as per IEC 62641) supported by an inner core made up

356 of polymer-matrix composite (PMC).

357 3.3

358 corona discharge

359 Electric discharge that only partially breaks down the gas insulation around the fittings under

360 test.

361 3.4

362 corona extinction

363 Voltage or conductor voltage gradient at which corona discharges cease during a decreasing

364 test voltage sequence.

365 3.5

366 corona inception

367 Voltage or conductor voltage gradient at which corona discharges initiate during an increasing

368 test voltage sequence.

369 3.6

370 earth wire fitting

371 Any component of an assembly for attaching an earth wire to a supporting structure other than

372 a suspension clamp, a tension fitting or a mechanical protective fitting.

373 3.7

374 factory-formed helical conductor fitting

375 Fitting consisting of helically formed rods which provide the force necessary to grip the

376 conductor by self-tightening.

377 3.8

378 insulator set fitting

379 Any component of a suspension or tension insulator set other than a string insulator unit, a

380 suspension clamp, a conductor tension fitting, an insulator protective fitting or a mechanical

381 protective fitting.

382 3.9

383 non-tension joint / partial tension fitting

384 A fitting for the connection of two consecutive pieces of conductor which are to be held, but not

385 at the full line tension. Typical non-tension joints are the T joint [IEV 461-11-06], the lug

386 terminal [IEV 442-06-16], the branch-joint [IEV 461-11-17] and the fittings installed on slack

387 spans.

388 NOTE – In branch joints, the connection is not subjected to line tension although the conductor to which the fitting

389 is applied on its length may be at the line tension.

390 3.10

391 tension joint

392 A fitting for the connection of two consecutive pieces of conductor which are to be held at the

393 full line tension. Typical tension joints are the dead-end tension joint [IEV 466-11-04] and the

394 mid-span tension joint [IEV 466-11-03].

395 3.11

396 mechanical damage load

397 Maximum load which can be applied to a fitting without an unacceptable permanent deformation

398 when the fitting is tested under specified test conditions.

IEC CDV 61284 © IEC 2025

399 NOTE – The unacceptable permanent deformation should be agreed upon between purchaser and supplier.

400 3.12

401 mechanical failure load

402 Maximum load which can be applied to a fitting under specified test conditions.

403 3.13

404 mechanical protective fitting

405 Any device attached to a conductor or to an earth wire for their mechanical protection.

406 3.14

407 operating temperatures

408 The operating temperatures are the temperatures, as below detailed, at which the conductor

409 can be operated satisfying the conditions agreed between purchaser and conductor

410 manufacturer.

411 NOTE - The following definitions will be in accordance with the similar ones introduced in the relevant IEC

412 standards and which take precedence over this standard. In fact, these temperatures (as well as the RTS below

413 defined) are peculiar characteristics of conductors and it is not the task of this standard to verify them; instead,

414 they must be seen as parameters required to make the test protocols described here applicable.

415 maximum conductor continuous operating temperature (T )

c

416 Maximum continuous temperature at which the conductor can be operated without significant

417 reduction of its rated tensile strength during its expected lifetime.

418 maximum conductor peak load (emergency operating) temperature (T )

p

419 Maximum temperature at which the conductor can be exposed without significant reduction of

420 its rated tensile strength during a cumulative period of time (peak loads).

421 3.15

422 radio-interference voltage (RIV)

423 Voltage in the radio frequency range produced by an electromagnetic disturbance and which

424 can be measured in accordance with CISPR 16 on the test circuit equipped with the fitting.

425 3.16

426 rated tensile strength (RTS)

427 Using the specified tensile properties of its elementary components, the calculated maximum

428 load value at which a conductor or earth wire may be subjected before one or more of its

429 elementary components break.

430 NOTE – The value is indicated in the manufacturer’s datasheet and/or calculated according to the applicable IE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...