EN 10244-2:2009

(Main)Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings

Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings

This part of this European Standard specifies the requirement for coating mass, other properties and testing of zinc and zinc alloy coatings on steel wire and steel wire products of circular or other section.

Stahldraht und Drahterzeugnisse - Überzüge aus Nichteisenmetall auf Stahldraht - Teil 2: Überzüge aus Zink und Zinklegierungen

Dieser Teil der vorliegenden Europäischen Norm legt Anforderungen an Masse, andere Eigenschaften und

Prüfung von Überzügen aus Zink und Zinklegierungen auf Stahldraht und Stahldrahterzeugnissen mit rundem

oder anderem Querschnitt fest.

Fils et produits tréfilés en acier - Revêtements métalliques non ferreux sur fils d'acier - Partie 2 : Revêtement de zinc ou d'alliage de zinc

La présente partie de cette Norme européenne spécifie les exigences en matière de masse de revêtement,

des autres caractéristiques et d’essai des revêtements de zinc et d’alliage de zinc sur fils en acier et produits

dérivés, de section circulaire ou autre.

Jeklena žica in žični izdelki - Neželezne kovinske prevleke na jekleni žici - 2. del: Prevleke iz cinka in cinkovih zlitin

General Information

- Status

- Withdrawn

- Publication Date

- 14-Apr-2009

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- ECISS/TC 106 - Wire rod and wires

- Drafting Committee

- ECISS/TC 106 - Wire rod and wires

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Jun-2023

- Completion Date

- 21-Jan-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 16-Mar-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 10244-2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings". This standard covers: This part of this European Standard specifies the requirement for coating mass, other properties and testing of zinc and zinc alloy coatings on steel wire and steel wire products of circular or other section.

This part of this European Standard specifies the requirement for coating mass, other properties and testing of zinc and zinc alloy coatings on steel wire and steel wire products of circular or other section.

EN 10244-2:2009 is classified under the following ICS (International Classification for Standards) categories: 25.220.40 - Metallic coatings; 77.140.65 - Steel wire, wire ropes and link chains. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10244-2:2009 has the following relationships with other standards: It is inter standard links to EN 10244-2:2001, EN 10244-2:2023, EN 1179:2003, EN 10257-1:2011, EN 10270-1:2011+A1:2017, EN 10257-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10244-2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

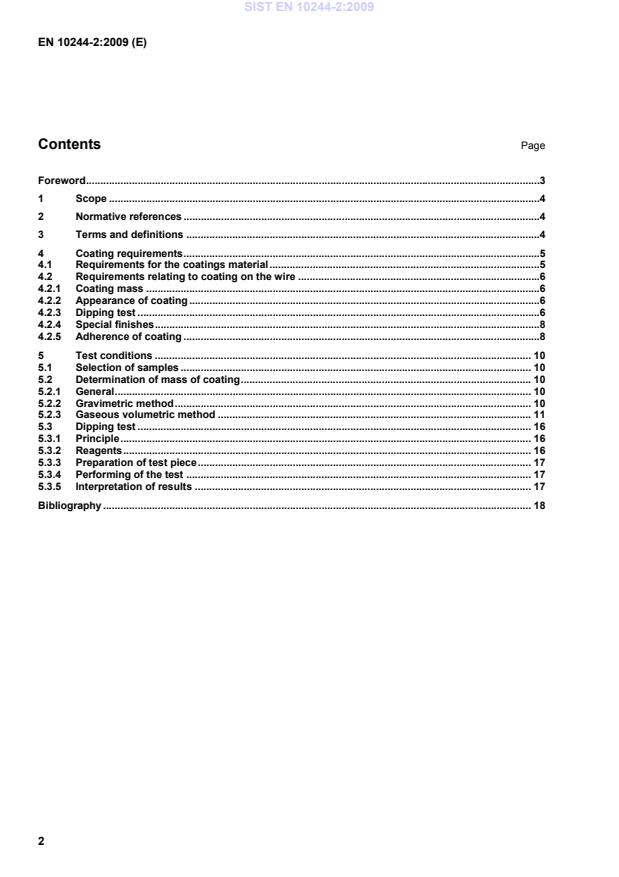

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stahldraht und Drahterzeugnisse - Überzüge aus Nichteisenmetall auf Stahldraht - Teil 2: Überzüge aus Zink und ZinklegierungenFils et produits tréfilés en acier - Revêtements métalliques non ferreux sur fils d'acier - Partie 2 : Revêtement de zinc ou d'alliage de zincSteel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings77.140.65Jeklene žice, jeklene vrvi in verigeSteel wire, wire ropes and link chains25.220.40Kovinske prevlekeMetallic coatingsICS:Ta slovenski standard je istoveten z:EN 10244-2:2009SIST EN 10244-2:2009en,de01-junij-2009SIST EN 10244-2:2009SLOVENSKI

STANDARDSIST EN 10244-2:20021DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10244-2April 2009ICS 25.220.40; 77.140.65Supersedes EN 10244-2:2001

English VersionSteel wire and wire products - Non-ferrous metallic coatings onsteel wire - Part 2: Zinc or zinc alloy coatingsFils et produits tréfilés en acier - Revêtements métalliquesnon ferreux sur fils d'acier - Partie 2 : Revêtement de zincou d'alliage de zincStahldraht und Drahterzeugnisse - Überzüge ausNichteisenmetall auf Stahldraht - Teil 2: Überzüge aus Zinkund ZinklegierungenThis European Standard was approved by CEN on 20 December 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10244-2:2009: ESIST EN 10244-2:2009

Part 3: Aluminium coatings

Part 4: Tin coatings

Part 5: Nickel coatings Part 6: Copper, bronze or brass coatings According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 10244-2:2009

1) Mischmetal is a mixture of rare earth metals (La and others) which is a by product from zinc production. SIST EN 10244-2:2009

The requirements for zinc-aluminium coatings of type Zn95Al 5 are given in Table 2. For other zinc alloy coatings, the manufacturer and supplier shall agree on the required coating mass. 4.2.2 Appearance of coating The coating applied to the wire shall be reasonably smooth and as evenly distributed as industrial technology allows and not show discontinuities such as bare patches, dross contamination, etc. NOTE The Zn95Al5 zinc-aluminium alloy might show difference in colour and become darker with time. This does not affect the corrosion protection performance. 4.2.3 Dipping test When specified the dipping (immersion) test shall be carried out according to the procedure detailed in 5.3. However, it should be pointed out that there is no correlation between the number of dips and the mass of the coating and that the result is influenced as much by the conditions of manufacture of the coating as by the uniformity of the coating. Table 3 gives the minimum number of immersions for coatings of classes A and AB. The dipping test does not apply to class B, C and D. SIST EN 10244-2:2009

mm Mass of coating a

g/m2

A AB B E b 0,20 ≤ d < 0,25 — 20 20

40 0,25 ≤ d < 0,40 — 30 30 0,40 ≤ d < 0,50 85 55 40 0,50 ≤ d < 0,60 100 70 50 0,60 ≤ d < 0,70 115 80 60 0,70 ≤ d < 0,80 130 90 60 0,80 ≤ d < 0,90 145 100 70 0,90 ≤ d < 1,00 155 110 70 1,00 ≤ d < 1,20 165 115 80 1,20 ≤ d < 1,40 180 125 90

60 1,40 ≤ d < 1,65 195 135 100 1,65 ≤ d < 1,85 205 145 100 1,85 ≤ d < 2,15 215 155 115 2,15 ≤ d < 2,50 230 170 125 2,50 ≤ d < 2,80 245 185 125 2,80 ≤ d < 3,20 255 195 135 3,20 ≤ d < 3,80 265 210 135 3,80 ≤ d < 4,40 275 220 135 4,40 ≤ d < 5,20 280 220 150 5,20 ≤ d < 8,20 290 — — 8,20 ≤ d < 10,00 300 — — a The coating class with a designation starting with A relates to thick coatings (generally final coating). Designations ending in B relate to classes usually but not always obtained by (zinc coating) and subsequent drawing. b the corrosion resistance of this class E must be at least equivalent of these from a zinc coating according Table 1 class B

Table 3 — Minimum number of dips Nominal diameter mm Class A of coating Class AB of coating Number of dips Number of dips of 1 min of 1/2 min of 1min of 1/2 min 0,40 ≤ d < 0,60 — 1 — — 0,60 ≤ d < 0,90 1 — — 1 0,90 ≤ d < 1,00 1 1 — 1 1,00 ≤ d < 1,40 1 1 1 — 1,40 ≤ d < 1,65 2 — 1 — 1,65 ≤ d < 1,85 2 — 1 — 1,85 ≤ d < 2,15 2 — 1 1 2,15 ≤ d < 2,80 2 1 1 1 2,80 ≤ d < 4,40 3 — 2 — 4,40 ≤ d < 5,20 3 1 2 — 5,20 ≤ d < 8,20 3 1 — — 8,20 ≤ d < 10,00 4 — — — SIST EN 10244-2:2009

EN 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...