prEN 18220

(Main)Digital product passport - Data carriers

Digital product passport - Data carriers

This document defines requirements for data carriers used in a digital product passport system. This covers: symbology characteristics, format, error correction codes, encoding methods, printing and production quality, and durability.

This document also defines requirements on graphical or other indicators for easy recognition of DPP data carriers and the indication on the data carrier placement, machine readability, quality checking, links between physical product and digital representation.

The following aspects are out of scope: Architecture and use cases, Secure elements and any other cryptographic security features.

Digitaler Produktpass - Datenträger

Dieses Dokument definiert Anforderungen an Datenträger, die in einem digitalen Produktpasssystem verwendet werden. Dazu gehören: Symbologieeigenschaften, Format, Fehlerkorrekturcodes, Codierverfahren, Druck- und Produktionsqualität und Haltbarkeit.

Dieses Dokument definiert ebenfalls Anforderungen an graphische oder andere Indikatoren für die einfache Erkennung von DPP Datenträgern und die Angabe zu Datenträgerplatzierung, Maschinenlesbarkeit, Qualitätsprüfung und Verbindungen zwischen physischem Produkt und digitaler Darstellung.

Die folgenden Aspekte werden nicht behandelt: Architektur und Anwendungsfälle, sichere Elemente und andere kryptographische Sicherheitsmerkmale.

Passeport numérique des produits - Supports de données

Le présent document définit les exigences relatives aux supports de données utilisés dans un système de passeports numériques des produits. Cela couvre : les caractéristiques de symbologie, le format, les codes de correction d'erreur, les méthodes d’encodage, la qualité d'impression et de production, et la durabilité.

Le présent document définit également les exigences relatives aux indicateurs graphiques ou à d'autres indicateurs pour faciliter la reconnaissance des supports de données de DPP et l'indication sur le positionnement des supports de données, la lisibilité par machine, le contrôle de la qualité, les liens entre le produit physique et la représentation numérique.

Les aspects suivants ne relèvent pas du domaine d’application : Architecture et cas d'utilisation, Éléments sécurisés et toute autre fonction de sécurité cryptographique.

Digitalni potni list izdelka - Nosilci podatkov

General Information

- Status

- Not Published

- Publication Date

- 27-May-2026

- Technical Committee

- JTC 24 - Digital Product Passport (DPP)

- Drafting Committee

- WG 2 - Unique identifiers and data carriers

- Current Stage

- 4599 - Dispatch of FV draft to CMC - Finalization for Vote

- Start Date

- 23-Jan-2026

- Due Date

- 21-Nov-2025

- Completion Date

- 23-Jan-2026

Overview

The prEN 18220:2025 standard, published by CEN, establishes comprehensive requirements for data carriers used in Digital Product Passport (DPP) systems. Focusing specifically on the physical and technical attributes of data carriers, this standard outlines specifications that ensure consistent identification, durability, and interoperability of DPP data carriers across products within the European Union and beyond.

This document plays a critical role in supporting the European Green Deal's vision of sustainability and circular economy by detailing how product information can be effectively linked to physical items through reliable data carriers. It does not cover system architecture, use cases, or cryptographic security features, maintaining a clear focus on data carrier technology and its performance.

Key Topics

Data Carrier Characteristics

Defines the symbology, format, encoding methods, and error correction codes necessary for effective and error-tolerant encoding of digital product passport data.Printing and Production Quality

Specifies durability and quality standards for printing, labels, and embedded data carriers to ensure long-lasting readability throughout a product’s lifecycle.Machine Readability and Scanning

Addresses performance requirements for barcode readers, NFC, HF RFID, and UHF RFID technologies, detailing the scanning and decoding process for each type.Graphical and Recognition Indicators

Establishes guidelines for visual signage or indicators that facilitate easy identification of DPP data carriers by operators and automated systems.Placement and Accessibility

Recommends optimal placement of data carriers on products, packaging, or accompanying documents to balance usability with physical and aesthetic product constraints.Data Encoding and Syntax

Covers the data content, syntax, and character sets for encoding, helping ensure interoperability with industry-standard identification schemes like GS1 Digital Link URIs.Quality Verification and Testing

Includes verification procedures and performance criteria to maintain data integrity, reliability, and readability of data carriers in real-world conditions.

Applications

The prEN 18220 standard supports wide-ranging applications related to sustainable product management and traceability:

Sustainable Product Compliance

Facilitates compliance with the Ecodesign for Sustainable Product Regulation (ESPR) by enabling transparent and accessible product data.Circular Economy Enablement

Allows manufacturers, retailers, recyclers, and consumers to identify product material composition, repairability, and end-of-life instructions through reliable data carriers.Supply Chain Traceability

Enhances supply chain transparency by providing machine-readable linkage between physical products and their digital records.Product Authentication and Anti-Counterfeiting

Assists in preventing fraud with durable data carriers that can be easily scanned and verified across multiple touchpoints.Consumer Engagement

Empowers consumers with immediate access to detailed product information by scanning QR codes, NFC tags, or RFID labels.

Related Standards

ISO/IEC 18975: Provides guidance on product identification methods referenced in data syntax encoding examples in prEN 18220.

GS1 Digital Link URI: An established scheme used within this standard for web-enabled, structured product identification via QR codes and other carriers.

Ecodesign for Sustainable Product Regulation (ESPR): The EU regulatory framework that prEN 18220 supports by specifying data carriers for digital passports.

Barcode and RFID International Standards: Applicable standards detailing the technical specifications for data matrix, QR codes, NFC, HF RFID, and UHF RFID technologies.

By standardizing data carrier requirements for digital product passports, prEN 18220:2025 ensures reliable linkage between the physical product and its digital identity, empowering stakeholders across industries to benefit from enhanced data accessibility, product sustainability, and regulatory compliance. This focal document is essential for manufacturers, regulators, and technology providers advancing sustainable and circular product innovations.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

prEN 18220 is a draft published by the European Committee for Standardization (CEN). Its full title is "Digital product passport - Data carriers". This standard covers: This document defines requirements for data carriers used in a digital product passport system. This covers: symbology characteristics, format, error correction codes, encoding methods, printing and production quality, and durability. This document also defines requirements on graphical or other indicators for easy recognition of DPP data carriers and the indication on the data carrier placement, machine readability, quality checking, links between physical product and digital representation. The following aspects are out of scope: Architecture and use cases, Secure elements and any other cryptographic security features.

This document defines requirements for data carriers used in a digital product passport system. This covers: symbology characteristics, format, error correction codes, encoding methods, printing and production quality, and durability. This document also defines requirements on graphical or other indicators for easy recognition of DPP data carriers and the indication on the data carrier placement, machine readability, quality checking, links between physical product and digital representation. The following aspects are out of scope: Architecture and use cases, Secure elements and any other cryptographic security features.

prEN 18220 is classified under the following ICS (International Classification for Standards) categories: 35.240.63 - IT applications in trade. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 18220 is associated with the following European legislation: Standardization Mandates: M/604, M/604 AMD 1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 18220 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Digitalni potni list za proizvode - Nosilci podatkov

Digital product passport - Data carriers

Digitaler Produktpass - Datenträger

Passeport numérique des produits - Supports de données

Ta slovenski standard je istoveten z: prEN 18220

ICS:

35.240.63 Uporabniške rešitve IT v IT applications in trade

trgovini

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2025

ICS 35.240.63

English version

Digital product passport - Data carriers

Passeport numérique des produits - Supports de Digitaler Produktpass - Datenträger

données

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/CLC/JTC 24.

If this draft becomes a European Standard, CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal

Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any

alteration.

This draft European Standard was established by CEN and CENELEC in three official versions (English, French, German). A

version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language

and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.Recipients of this draft are invited to submit, with their comments, notification

of any relevant patent rights of which they are aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2025 CEN/CENELEC All rights of exploitation in any form and by any means

Ref. No. prEN 18220:2025 E

reserved worldwide for CEN national Members and for

CENELEC Members.

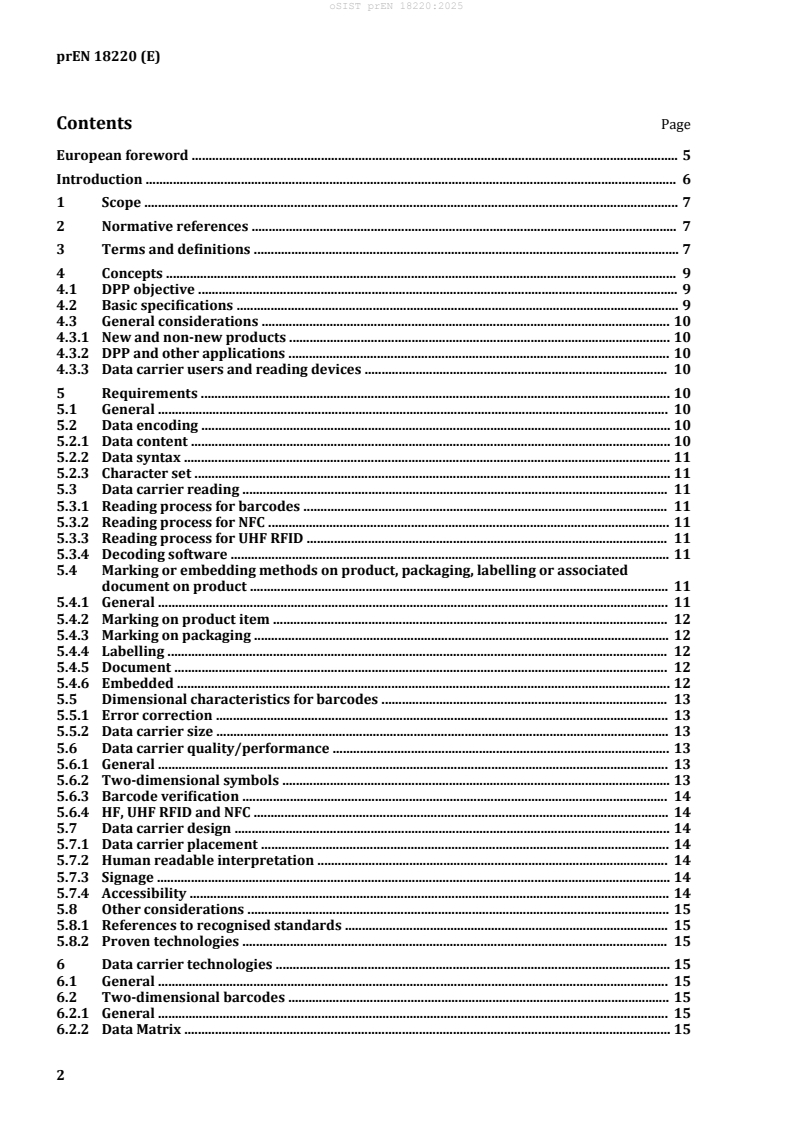

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Concepts . 9

4.1 DPP objective . 9

4.2 Basic specifications . 9

4.3 General considerations . 10

4.3.1 New and non-new products . 10

4.3.2 DPP and other applications . 10

4.3.3 Data carrier users and reading devices . 10

5 Requirements . 10

5.1 General . 10

5.2 Data encoding . 10

5.2.1 Data content . 10

5.2.2 Data syntax . 11

5.2.3 Character set . 11

5.3 Data carrier reading . 11

5.3.1 Reading process for barcodes . 11

5.3.2 Reading process for NFC . 11

5.3.3 Reading process for UHF RFID . 11

5.3.4 Decoding software . 11

5.4 Marking or embedding methods on product, packaging, labelling or associated

document on product . 11

5.4.1 General . 11

5.4.2 Marking on product item . 12

5.4.3 Marking on packaging . 12

5.4.4 Labelling . 12

5.4.5 Document . 12

5.4.6 Embedded . 12

5.5 Dimensional characteristics for barcodes . 13

5.5.1 Error correction . 13

5.5.2 Data carrier size . 13

5.6 Data carrier quality/performance . 13

5.6.1 General . 13

5.6.2 Two-dimensional symbols . 13

5.6.3 Barcode verification . 14

5.6.4 HF, UHF RFID and NFC . 14

5.7 Data carrier design . 14

5.7.1 Data carrier placement . 14

5.7.2 Human readable interpretation . 14

5.7.3 Signage . 14

5.7.4 Accessibility . 14

5.8 Other considerations . 15

5.8.1 References to recognised standards . 15

5.8.2 Proven technologies . 15

6 Data carrier technologies . 15

6.1 General . 15

6.2 Two-dimensional barcodes . 15

6.2.1 General . 15

6.2.2 Data Matrix . 15

6.2.3 QR Code . 16

6.2.4 Two-dimensional barcodes characteristics . 16

6.3 Radio frequency data carriers . 17

6.3.1 General . 17

6.3.2 HF RFID . 17

6.3.3 NFC . 18

6.3.4 UHF RFID . 19

Annex A (normative) Criteria for selection of data carriers - Mandatory criteria . 21

Annex B (informative) List of criteria to be considered when selecting a data carrier to

ensure success . 22

Annex C (informative) Examples of Data Syntax . 24

C.1 Example as described in ISO/IEC 18975 . 24

C.2 Example as described in [6] and [7] . 24

C.3 Example of [6] . 25

C.4 Example of [7] . 25

C.5 Examples of syntax with MH-10 . 26

C.6 Example of QR code embedding an identifier in URI a link, ISO/IEC 18975

compliant: GS1 Digital Link URI . 27

Annex D (informative) Data carriers and ID schemes for products . 28

D.1 General . 28

D.2 ID Scheme 5.1.2.1 Web enabled structured path identification for products . 28

D.2.1 General . 28

D.2.2 Example with a QR Code . 28

D.2.3 Example of QR Code with [53] using GS1 Digital Link URI syntax for ECC L . 29

D.2.4 Example with a Data Matrix . 29

D.2.5 Example of Data Matrix with [53] using GS1 Digital Link URI syntax . 29

D.2.6 Example of Data in an NFC tag . 29

D.3 ID Scheme 5.1.2.2 Web enabled query string ID for products, without structure . 29

D.3.1 Web enabled query string ID for products . 30

D.4 Example with a QR Code . 30

D.5 ID scheme 5.2.2.1: Identification Link (IL) with structure . 30

D.5.1 Example of Identification Link (IL) with structure, with graphical frame to indicate

item . 30

D.5.2 QR Code size of IL with graphical marking . 31

D.6 ID scheme 5.2.2.2: Identification Link (Structured ID Link) . 31

D.6.1 Example of Identification Link (IL) with structure and graphical frame to indicate

item . 32

D.6.2 QR Code size of IL with graphical marking . 32

D.6.3 Model Identification IL (product level with optional reuse of existing ID solutions)

QR Code size with graphical marking . 33

D.6.4 Example Model Identification (Product Code Level with optional reuse of existing

ID solutions) . 34

D.7 ID scheme 5.3: Decentralized Identifiers . 34

D.7.1 General . 34

D.7.2 Example with a QR Code . 35

D.8 ID scheme 5.4.2.1: Product and group identification, RFID . 36

D.9 ID scheme 5.4.1.2 Product and group identification, 2D-symbols . 36

D.9.1 Example with a QR Code . 37

D.10 ID scheme 5.5: Digital Object Identifier for products . 38

D.10.1 Example of DOI with a QR Code . 39

Annex E (informative) DPP data carrier recognition . 41

E.1 Example of Data carrier multiple use with implicit recognition . 41

E.2 Examples of data carrier with explicit recognition . 41

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of 2024/1781 . 43

Bibliography . 44

European foreword

This document (prEN 18220:2025) has been prepared by Technical Committee CEN/CENELEC/JTC 24

Digital product passport – Framework and systems ", the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

Introduction

In 2019, the European Commission introduced the European Green Deal, a detailed strategic plan aimed

at sustainable growth. A key component of this plan is the Ecodesign for Sustainable Product Regulation

(ESPR)[1], which is designed to guide the European Union towards achieving climate neutrality by 2050.

The ESPR promotes a vision of a society that is equitable and thriving, functioning within a modern,

competitive, and circular economy, all while preserving a toxin-free environment.

In detail, the ESPR mandates the adoption of production and consumption patterns that are in harmony

with the Union’s comprehensive sustainability goals related to climate change, environmental

protection, energy use, resource efficiency, and biodiversity conservation, all within defined planetary

boundaries. To achieve these goals, the regulation introduces a set of stringent ecodesign requirements.

These are specifically crafted to enhance the durability, reliability, repairability, upgradability,

reusability, and recyclability of products. Such measures are vital for reducing waste, diminishing the

presence of hazardous substances in products, and improving their energy and resource efficiency.

Collectively, these requirements establish a rigorous framework for sustainability within the industry,

pivotal for supporting the Union's transition to sustainability.

To support the implementation of these comprehensive requirements, the ESPR highlights Digital

Product Passports (DPP) as a key element and a pivotal tool to ensure that all stakeholders in the value

chain—manufacturers, distributors, consumers, and recyclers— have access to essential, traceable, and

reliable product information, supporting informed consumer choices, and promoting better resource

management and sustainability practices.

The roll-out of the digital product passport (DPP) concept is set to occur gradually over the coming

years. Specific details, including what will be included in the DPP for various product groups and

intermediate products, will be outlined in delegated acts. This approach ensures a comprehensive

strategy that balances environmental objectives with regulatory requirements and stakeholder

expectations.

To support the implementation of the DPP concept, this document addresses suitable data carriers and

show how they meet the requirements. The ESPR defines ‘data carrier’ as a linear barcode symbol, a

two-dimensional symbol or other automatic identification data capture medium that can be read by a

device. It further stipulates that delegated acts will specify one or more data carriers to be used. This

document specifies common rules for how to construct the automatic identification and data capture

(AIDC) media to be used as data carrier linked to the product passport. These rules are based on the

requirements derived from the ESPR and from the subsequent standardisation request issued by the

European Commission. The requirements relate to the encoding capability, the dimensional

characteristics, quality, persistence and durability as applicable. This document includes data carriers

and shows how they meet the requirements.

1 Scope

This document defines requirements for data carriers used in a digital product passport system. This

covers: symbology characteristics, format, error correction codes, encoding methods, printing and

production quality, and durability.

This document also defines requirements on graphical or other indicators for easy recognition of DPP

data carriers and the indication on the data carrier placement, machine readability, quality checking,

links between physical product and digital representation.

The following aspects are out of scope: Architecture and use cases, Secure elements and any other

cryptographic security features.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

ISO/IEC 15961-1:2021, Information technology — Data protocol for radio frequency identification (RFID)

for item management — Part 1: Application interface

ISO/IEC 15961-2:2019, Information technology — Data protocol for radio frequency identification (RFID)

for item management — Part 2: Registration of RFID data constructs

ISO/IEC 15961-3:2019, Information technology — Data protocol for radio frequency identification (RFID)

for item management — Part 3: RFID data constructs

ISO/IEC 18046-1:2011, Information technology — Radio frequency identification device performance test

methods — Part 1: Test methods for system performance

ISO/IEC 18046-2:2020, Information technology — Radio frequency identification device performance test

methods — Part 2: Test methods for interrogator performance

ISO/IEC 18046-3:2020, Information technology — Radio frequency identification device performance test

methods — Part 3: Test methods for tag performance

ISO/IEC 19762:2025, Information technology — Automatic identification and data capture (AIDC)

techniques — Vocabulary

ISO/IEC 29158:2020, Information technology — Automatic identification and data capture techniques

— Direct Part Mark (DPM) Quality Guideline

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 19762:2025 and the

terms and definitions defined in clause 3 apply.

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

additional software

additional application, program, or tool that a user will install or access separately from the default

setup of most smartphones or similar devices to interact with the digital product passport

EXAMPLE Proprietary applications, plugins or extensions, dedicated apps, specialized middleware, or

customized software readers.

Note 1 to entry: Standard functionalities, such as web browsers, camera-based QR readers, and universal

communication protocols (e.g. DNS, HTTP, HTTPS), are not considered as additional software.

3.2

barcode

printed data carrier indicating either a reference to a linear or a 2D matrix

Note 1 to entry: It excludes RFID data carriers.

3.3

batch

subset of a model that is grouped by the economic operator based on the identical properties

3.4

consumer

individual member of the general public purchasing or using goods, property or services for private

purposes

[SOURCE: [2]]

3.5

data carrier

device or medium used to store data as a relay mechanism in an automatic identification and data

capture system

3.6

digital product passport

DPP

digital record of product characteristics throughout its life cycle

Note 1 to entry: Example characteristics include environmental sustainability, environmental impact, and

recyclability.

3.7

economic operator

manufacturer, authorized representative, importer, distributor, dealer or fulfilment service provider

3.8

item

single unit of a model

3.9

life cycle

consecutive and interlinked stages of a product system, from raw material acquisition or generation

from natural resources to final disposal

[SOURCE: [3]]

3.10

model

version of a product of which all units share the same technical characteristics and the same model

identifier

3.11

NFC

near field communication

subset of HF passive radio-frequency identification with low range

3.12

persistence

existence, and ability to be used in services outside the direct control of the issuing assigner, without a

stated time limit

[SOURCE: [4]]

3.13

product

physical goods placed on the market or put into service

3.14

radio-frequency identification

RFID

identification technology that uses electromagnetic fields to automatically identify and track tags

attached to objects

3.15

RAIN

radio identification

UHF passive radio-frequency identification (3.14)

3.16

two-dimensional symbol

code representing data in machine-readable form by a collection of polygonal or circular cells in a regular

pattern which are read optically by scanning

3.17

unique identifier

identifier which is guaranteed to be unique among all identifiers used for those objects and for a specific

purpose

Note 1 to entry: A unique identifier refers to unique product identifier, unique economic operator identifier and

unique facility identifier.

[SOURCE: ISO 29404:2015 (Modified: Note 1 added)]

4 Concepts

4.1 DPP objective

The general objective of the DPP is to ensure that all value chain stakeholders have access to essential,

traceable, and reliable product information. This is done through a link to the web or a lookup

mechanism associated with the product. The identifier is represented in a data carrier that can be read

automatically. In cases where the lookup mechanism through an identifier is temporarily not available,

and there is sufficient space (barcode) or memory (RFID tag), additional information may be made

available in the data carrier.

4.2 Basic specifications

This document specifies the basic rules applicable to the data carriers. Additional legislations determine

precisely the level of identification (model, batch, item) and the data carriers that apply to a given

product group.

4.3 General considerations

4.3.1 New and non-new products

The DPP will apply to different product groups available on the market. The circular economy will

facilitate products to be sold, used, re-sold and re-used multiple times. In some cases, the identifier and

associated data carrier will remain unchanged through the lifecycle of the product. In other cases, if a

new digital product passport is needed, then a new identifier and the associated data carrier will be

required. The fact that a data carrier has to remain usable after several used-reused-repair cycles has

an impact on the durability of the support of the data carrier associated to the product.

4.3.2 DPP and other applications

Unique identification and associated data carrier technologies are widely used in some sectors for trade

and logistic applications, consumer communication via the web and support for other regulatory

requirements. Depending on the requirements set for a given product group, it may be that the existing

data carriers related to the product meet the DPP requirements, at least partially. The data carrier

specification for DPP should thus take into consideration the state of identification and data carriers'

usage in the product group and this usage includes production specifications established by existing

industry standards (eg: barcode module size, print quality and location, RFID tag frequency or memory

constraints). This is to say that DPP implementation will not necessarily imply the use of a new data

carrier.

4.3.3 Data carrier users and reading devices

It is expected that the DPP concept will be used by a large number of parties, where consumers are a

key target. Consumers will have the ability to discover relevant information about a product, which

might influence the purchasing decision. After purchase, the DPP will enable finding useful information

such as user manuals, safety instructions or guidelines for recycling.

The DPP will also be used by manufacturers, distributors, resellers, recyclers, etc., for example to verify

the availability and accuracy of information related to products, and to enable the reuse, repair, and

recycling of products. In addition, governmental agencies, such as customs, will use the DPP to access

relevant information about products.

The devices used to read the data carrier and access DPP information are smart devices and other AIDC

devices (e.g: industrial barcode scanners and RFID readers in the supply chain).

5 Requirements

5.1 General

This chapter describes the requirements that data carriers should meet, as stipulated in the ESPR

regulation.

A product item shall have at least one data carrier either on the product itself, on the packaging or on

documentation according to this document.

5.2 Data encoding

5.2.1 Data content

The data carrier shall encode the unique identifier that allows to access the DPP. The data carrier shall

comply with the rules of the unique ID to enable a smooth interoperability between systems, including

the syntax when used.

5.2.2 Data syntax

The data syntax refers to the way data is represented and structured within a data carrier. Each data

carrier type has a specific set of rules for encoding data, which ensures that readers and software can

interpret the data correctly. These rules include the sequence of data elements, the character sets

allowed, and the inclusion of start/stop characters or check digits for validation.

Data syntaxes as specified in Module 1 are in [5] or [6] or [7] or [8] or [9]

For examples of data syntax, see Annex C.

5.2.3 Character set

The unique product identifier should be presentable in a URI, using the character set specified by IETF

RFC 3986 (Uniform Resource Identifier (URI): Generic Syntax).

Other data can be encoded using characters specified in [10] (Information technology — 8-bit single-

byte coded graphic character sets — Part 1: Latin alphabet No. 1) or [11] (Information technology —

7-bit coded character set for information interchange.

5.3 Data carrier reading

5.3.1 Reading process for barcodes

The process of reading the DPP data carrier is usually performed by a human operator, handling one

product at a time. The reading distance of the DPP data carrier will typically be between 2 and 30

centimetres. For barcodes, this distance can vary depending on several factors, such as barcode quality,

lighting conditions, barcode size.

5.3.2 Reading process for NFC

NFC technologies operate in a one-to-one communication mode between a reader and a tag. The DPP

data carrier reading process is thus similar to the process used when the DPP data carrier is a bar code.

5.3.3 Reading process for UHF RFID

UHF RFID (RAIN RFID) technology is designed to read multiple tags simultaneously over a distance of

several meters. Different techniques can be used to read only a specific tag, such as filtering by

communications protocol, adjusting the power output of the reader and the placement of the antenna,

filtering by software or letting the user choose (in a list).

5.3.4 Decoding software

For end consumer usage, the unique product identifier shall be useable to access DPP public information

without the need to register, download DPP-specific software, or add user credentials. For smart devices,

this implies that the decoding software should ideally be natively available in the operating system.

Significant research is underway to enable singulation of UHF tags by consumer smart devices. It is

expected this standard will be updated as international standards are established for this use of UHF

RFID.

5.4 Marking or embedding methods on product, packaging, labelling or associated

document on product

5.4.1 General

There shall be at least one data carrier containing the product identifier of the DPP provided either on

the product (preferred), embedded in the product (preferred), on the packaging or in the

documentation.

5.4.2 Marking on product item

This method refers to the process of permanently marking or engraving information directly onto a part

or product. There are several techniques that could be used to permanently identify a product

throughout its lifetime.

The advantage of product marking is that the identifier stays in principle with the product throughout

its complete lifetime.

5.4.3 Marking on packaging

The representation of the identifier with a data carrier is often part of the packaging of the product. This

approach is used commonly for consumer goods.

Here are some of the techniques used for packaging marking:

— Laser Marking utilises lasers to engrave information onto a part's surface. It offers high precision,

readability, and durability.

— Thermal Transfer which is a printing method where a thermal print head applies heat to a ribbon,

transferring ink onto the substrate, usually label or film. It is commonly used for high-quality and

durable printing, such as barcodes, images and texts on labels.

— Inkjet Printing can be used for product marking, especially on surfaces where other techniques

may not be suitable.

If the product is re-sold, possibly refurbished, and re-used, there is a high probability that the original

packaging is damaged or no longer available. The data carrier encoding the link between the physical

product and its identifier is then lost.

5.4.4 Labelling

Another method is to attach a label with the data carrier on the product or on the product packaging.

Label media should be selected to endure for the full life of the product and the environment of the

product.

5.4.5 Document

The DPP product identifier may be included in a document accompanying the product. The document

may be physical or digital.

If the documentation is the only source of the DPP product identifier the data carrier shall be included

in the documentation accompanying the product.

— Examples of physical documentation: User manual, warranty documents customer printed receipt,

conformity documents…

— Examples of digital documentation: E-commerce web page, Digital customer receipt, Digital

Customer account, e-mail… We speak in this case of a digital copy of the data carrier.

5.4.6 Embedded

A data carrier used for digital product passport can be embedded into the product itself. Example: textile

products or tyres".

The main interest to permanently attach data carrier to the product is to ensure DPP will provide at any

time of its life cycle relevant information related to the product (consumer, authorities, recyclers.) to

increase circular economy.

5.5 Dimensional characteristics for barcodes

5.5.1 Error correction

Error correction code (ECC) is a crucial feature that helps 2D symbols, such as QR Codes and Data Matrix

codes, remain readable even if they are partially damaged, obscured, or dirty. ECC involves adding extra

data to the barcode a higher error correction level will in theory make the code more robust, but it will

also make the code larger. The error correction level will not necessarily make a barcode easier to read,

if the barcode print quality is poor.

5.5.2 Data carrier size

Several factors influence the size of the data carrier:

— the type of symbology;

— the X dimension that applies for the application;

— The selected error correction rate for data carrier technologies that support error correction;

— the amount of data encoded;;

— the encoding methods of characters and character sets

— the size of the product to which the dpp data carrier applies;

— the print method and the media.

Different industries and applications may have specific standards or recommendations for the X-

dimension to ensure compatibility with their scanning and printing equipment. The X-dimension shall

be chosen carefully to ensure that the barcode can be scanned accurately by the intended scanning

environments (e.g., Point-of-Sale and consumer mobile devices). The combination of the above factors

will determine the size of the data carrier. Opting for a smaller X-dimension to reduce the overall size

based on the required encoded data may lead to a higher-density barcode, which can be challenging for

lower-resolution scanners to read. The X-dimension also impacts printing. Printers need to have the

appropriate resolution to produce clear and distinct bars or modules at the chosen X-dimension.

5.6 Data carrier quality/performance

5.6.1 General

The DPP data carrier shall reach a minimum level of quality/performance to ensure seamless usage in

different environments. This section specifies the different standards that define good implementation

of different data carrier technology.

Data carriers (UHF, NFC, …) should be write protected.

5.6.2 Two-dimensional symbols

The applicable standard for 2D barcode symbols is [12], Bar code symbol print quality test specification

— Two-dimensional symbols. This standard defines the methodology for grading the quality of printed

2D barcodes. The grade includes a grade level, measuring aperture and the wavelength of light used for

the measurement.

The minimum quality grade is typically 1,5 / 80%/ 660, where:

— 1,5 is the overall symbol quality grade;

— 80% is the measuring aperture related to the measured X dimension;

— illumination 660 is the peak response wavelength in nanometres.

ISO/IEC 29158:2020, Direct Part Mark (DPM) Quality Guideline shall be used to assess the symbol

quality of direct marked parts, where the mark is applied directly to the surface of the item and the

reading device is a two-dimensional imager.

Consult industry application standards, where available, for minimum print quality specifications per

the intended scanning environment for the product.

5.6.3 Barcode verification

The principle is that it is important to verify the barcodes quality, using conformant verifiers.

References to:

— [13], Bar code verifier conformance specification — Part 2: Two-dimensional symbols

5.6.4 HF, UHF RFID and NFC

In case the quality/performance is to be assessed, the quality/performance of RFID (UHF or NFC) shall

use the following standards:

— ISO/IEC 18046-1:2011: Information technology — Radio frequency identification device

performance test methods — Part 1: Test methods for system performance

— ISO/IEC 18046-2:2020: Information technology — Radio frequency identification device

performance test methods — Part 2: Test methods for interrogator performance

— ISO/IEC 18046-3:2020: Information technology — Radio frequency identification device

performance test methods — Part 3: Test methods for tag performance

5.7 Data carrier design

5.7.1 Data carrier placement

To facilitate the choice of more sustainable products, DPP data carriers should be displayed in a clearly

visible and identifiable way such as the only visible data carrier. In the case it is not possible to have a

visible data carrier, a specific marking can inform the consumer of the presence of a data carrier. They

should be identifiable as the labels, containers or tags belonging to the product in question, without

customers, including potential customers, having to read the brand name and model number on the

labels.

5.7.2 Human readable interpretation

Human readable interpretation (HRI) is the information encoded in the DPP data carrier presented

close to it in a clearly legible font, such as OCR-B specified in [14]. Different industries may have specific

recommendations for HRI. Additional legislations may specify rules applicable to different product

groups.

5.7.3 Signage

A 2D data carrier that links to a DPP may have a graphical marking to distinguish it from other data

carriers.

When an optional graphical marking is used, it should comply with [15][16], symbol 6452 or 6452-1.

5.7.4 Accessibility

The design of the data carrier shall take into consideration the possible disabilities of consumers willing

to access the DPP information.

5.8 Other considerations

5.8.1 References to recognised standards

Data carrier and quality standards used for digital product passport (DPP) applications shall be

recognized by ISO and IEC. Where necessary, other specifications may be considered in the following

order of preference: existing European standards, national standards, and specifications developed by

industry fora. The use of additional software to enhance accessibility may also be considered.

5.8.2 Proven technologies

The data carriers selected for DPP applications shall have proven implementations on the market, both

for the production of the data carrier and for the capture and processing of the encoded data.

6 Data carrier technologies

6.1 General

This chapter introduces 2D barcodes and radio-frequency technologies. It provides an overview of their

technical characteristics and shows how they meet the requirements specified in chapter 5. New data

carriers emerging in the future could be included in a new version of this document and be subject to

the same assessment against the identified requirements.

The detailed list of requirements expressed in the ESPR is available in Annex A and Annex B.

They are summarized as follows:

1. data capacity for URI and additional data;

2. ability to use ISO/IEC 15459 conformant identifier;

3. granularity: ability to id

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...