EN 1755:2000+A2:2013

(Main)Safety of industrial trucks - Operation in potentially explosive atmospheres - Use in flammable gas, vapour, mist and dust

Safety of industrial trucks - Operation in potentially explosive atmospheres - Use in flammable gas, vapour, mist and dust

This European Standard applies to self-propelled and pedestrian controlled manual and semi-manual industrial trucks as specified in the European Standards

EN 1459, Safety of industrial trucks - Self propelled variable reach trucks

EN 1551, Safety of industrial trucks - Self propelled trucks over 10 000 kg capacity

EN 1726-1, Safety of industrial trucks - Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N - Part 1: General requirements

EN 1726-2, Safety of industrial trucks - Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N - Part 2: Additional requirements for trucks with elevating operator position and trucks specifically designed to travel with elevated load

EN 1757-1, Safety of industrial trucks - Pedestrian propelled trucks - Part 1: Stacker trucks

EN 1757-2, Safety of industrial trucks - Pedestrian propelled trucks - Part 2: Pallet trucks

EN 1757-3, Safety of industrial trucks - Pedestrian controlled manual and semi-manual trucks - Part 3: Platform trucks

EN 1757-4, Safety of industrial trucks - Pedestrian controlled manual and semi-manual trucks - Part 4: Scissor lift pallet-trucks

and gives additional requirements for industrial trucks of equipment group II and equipment category 2G respectively 3G, 2D and 3D including their load handling devices as defined in Annex A.

This European Standard covers the technical requirements necessary to avoid or minimize the significant hazards listed in Clause 4 which could occur during normal operation, maintenance or foreseeable misuse (in accordance with the data given by the manufacturer or his authorised representative) of industrial trucks.

Trucks for group II suitable for explosive atmospheres of gas, vapour or mist shall be subdivided in accordance with the respective mixture of the potentially explosive atmospheres in which they are intended to operate. The subdivision is in accordance with #!4.2 of EN 13463-1:2009.

Trucks marked IIB are suitable for application required for Group IIA trucks. Trucks marked IIC are suitable for application required for subgroup IIA and subgroup IIB trucks, but are not suitable to be used in areas with flammable gas and vapour atmospheres containing carbon disulfide (CS2).

Where hybrid mixtures are present, the requirements for gas, vapour and mist as well as for dust shall be fulfilled.

Fork arms, load platforms or integrated attachments are part of the truck. Attachments mounted on the load carrier or fork arms are not part of the truck.

Sicherheit von Flurförderzeugen - Einsatz in explosionsgefährdeten Bereichen - Verwendung in Bereichen mit brennbaren Gasen, Dämpfen, Nebeln oder Stäuben

Sécurité des chariots de manutention - Fonctionnement en atmosphères explosibles - Utilisation dans des atmosphères inflammables dues à la présence de gaz, de vapeurs, brouillards ou poussières inflammables

Vozila za talni transport - Obratovanje v potencialno eksplozivnih atmosferah - Uporaba v območju vnetljivega plina, pare, megle in prahu

Ta dokument določa osnovne varnostne zahteve za izdelavo, preverjanje in označevanje vozil za talni transport skupine II, kategorij skladnosti 2 in 3 (glej direktivo 94/9/EGS), vključno z napravo za upravljanje z bremenom, ki je namenjeno za uporabo na območjih z morebitnimi eksplozivnimi atmosferami v obliki plinov, hlapov in kapljic, kot je opredeljeno v conah 1 in 2, ali vnetljivih plinov, kot je opredeljeno v conah 21 in 22.

General Information

- Status

- Withdrawn

- Publication Date

- 26-Mar-2013

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 150 - Industrial trucks - Safety

- Drafting Committee

- CEN/TC 150/WG 7 - Potentially explosive atmosheres

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Nov-2015

- Completion Date

- 21-Jan-2026

Relations

- Effective Date

- 23-Jan-2013

- Effective Date

- 23-Jan-2013

- Effective Date

- 17-Apr-2013

- Effective Date

- 23-Jan-2013

Frequently Asked Questions

EN 1755:2000+A2:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of industrial trucks - Operation in potentially explosive atmospheres - Use in flammable gas, vapour, mist and dust". This standard covers: This European Standard applies to self-propelled and pedestrian controlled manual and semi-manual industrial trucks as specified in the European Standards EN 1459, Safety of industrial trucks - Self propelled variable reach trucks EN 1551, Safety of industrial trucks - Self propelled trucks over 10 000 kg capacity EN 1726-1, Safety of industrial trucks - Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N - Part 1: General requirements EN 1726-2, Safety of industrial trucks - Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N - Part 2: Additional requirements for trucks with elevating operator position and trucks specifically designed to travel with elevated load EN 1757-1, Safety of industrial trucks - Pedestrian propelled trucks - Part 1: Stacker trucks EN 1757-2, Safety of industrial trucks - Pedestrian propelled trucks - Part 2: Pallet trucks EN 1757-3, Safety of industrial trucks - Pedestrian controlled manual and semi-manual trucks - Part 3: Platform trucks EN 1757-4, Safety of industrial trucks - Pedestrian controlled manual and semi-manual trucks - Part 4: Scissor lift pallet-trucks and gives additional requirements for industrial trucks of equipment group II and equipment category 2G respectively 3G, 2D and 3D including their load handling devices as defined in Annex A. This European Standard covers the technical requirements necessary to avoid or minimize the significant hazards listed in Clause 4 which could occur during normal operation, maintenance or foreseeable misuse (in accordance with the data given by the manufacturer or his authorised representative) of industrial trucks. Trucks for group II suitable for explosive atmospheres of gas, vapour or mist shall be subdivided in accordance with the respective mixture of the potentially explosive atmospheres in which they are intended to operate. The subdivision is in accordance with #!4.2 of EN 13463-1:2009. Trucks marked IIB are suitable for application required for Group IIA trucks. Trucks marked IIC are suitable for application required for subgroup IIA and subgroup IIB trucks, but are not suitable to be used in areas with flammable gas and vapour atmospheres containing carbon disulfide (CS2). Where hybrid mixtures are present, the requirements for gas, vapour and mist as well as for dust shall be fulfilled. Fork arms, load platforms or integrated attachments are part of the truck. Attachments mounted on the load carrier or fork arms are not part of the truck.

This European Standard applies to self-propelled and pedestrian controlled manual and semi-manual industrial trucks as specified in the European Standards EN 1459, Safety of industrial trucks - Self propelled variable reach trucks EN 1551, Safety of industrial trucks - Self propelled trucks over 10 000 kg capacity EN 1726-1, Safety of industrial trucks - Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N - Part 1: General requirements EN 1726-2, Safety of industrial trucks - Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N - Part 2: Additional requirements for trucks with elevating operator position and trucks specifically designed to travel with elevated load EN 1757-1, Safety of industrial trucks - Pedestrian propelled trucks - Part 1: Stacker trucks EN 1757-2, Safety of industrial trucks - Pedestrian propelled trucks - Part 2: Pallet trucks EN 1757-3, Safety of industrial trucks - Pedestrian controlled manual and semi-manual trucks - Part 3: Platform trucks EN 1757-4, Safety of industrial trucks - Pedestrian controlled manual and semi-manual trucks - Part 4: Scissor lift pallet-trucks and gives additional requirements for industrial trucks of equipment group II and equipment category 2G respectively 3G, 2D and 3D including their load handling devices as defined in Annex A. This European Standard covers the technical requirements necessary to avoid or minimize the significant hazards listed in Clause 4 which could occur during normal operation, maintenance or foreseeable misuse (in accordance with the data given by the manufacturer or his authorised representative) of industrial trucks. Trucks for group II suitable for explosive atmospheres of gas, vapour or mist shall be subdivided in accordance with the respective mixture of the potentially explosive atmospheres in which they are intended to operate. The subdivision is in accordance with #!4.2 of EN 13463-1:2009. Trucks marked IIB are suitable for application required for Group IIA trucks. Trucks marked IIC are suitable for application required for subgroup IIA and subgroup IIB trucks, but are not suitable to be used in areas with flammable gas and vapour atmospheres containing carbon disulfide (CS2). Where hybrid mixtures are present, the requirements for gas, vapour and mist as well as for dust shall be fulfilled. Fork arms, load platforms or integrated attachments are part of the truck. Attachments mounted on the load carrier or fork arms are not part of the truck.

EN 1755:2000+A2:2013 is classified under the following ICS (International Classification for Standards) categories: 53.060 - Industrial trucks. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1755:2000+A2:2013 has the following relationships with other standards: It is inter standard links to EN 1755:2000+A1:2009/FprA2, EN 1755:2000+A1:2009, EN 1755:2015, EN 1755:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1755:2000+A2:2013 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 94/9/EC; Standardization Mandates: M/396, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1755:2000+A2:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Flurförderzeugen - Einsatz in explosionsgefährdeten Bereichen - Verwendung in Bereichen mit brennbaren Gasen, Dämpfen, Nebeln oder StäubenSécurité des chariots de manutention - Fonctionnement en atmosphères explosibles - Utilisation dans des atmosphères inflammables dues à la présence de gaz, de vapeurs, brouillards ou poussières inflammablesSafety of industrial trucks - Operation in potentially explosive atmospheres - Use in flammable gas, vapour, mist and dust53.060Industrijski tovornjakiIndustrial trucksICS:Ta slovenski standard je istoveten z:EN 1755:2000+A2:2013SIST EN 1755:2001+A2:2013en,fr,de01-junij-2013SIST EN 1755:2001+A2:2013SLOVENSKI

STANDARDSIST EN 1755:2001+A1:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1755:2000+A2

March 2013 ICS 53.060 Supersedes EN 1755:2000+A1:2009

English Version

Safety of industrial trucks - Operation in potentially explosive atmospheres - Use in flammable gas, vapour, mist and dust

Sécurité des chariots de manutention - Fonctionnement en atmosphères explosibles - Utilisation dans des atmosphères inflammables dues à la présence de gaz, de vapeurs, brouillards ou poussières inflammables

Sicherheit von Flurförderzeugen - Einsatz in explosionsgefährdeten Bereichen - Verwendung in Bereichen mit brennbaren Gasen, Dämpfen, Nebeln oder Stäuben This European Standard was approved by CEN on 16 August 1999 and includes Amendment 1 approved by CEN on 1 May 2009 and Amendment 2 approved by CEN on 20 January 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1755:2000+A2:2013: E SIST EN 1755:2001+A2:2013

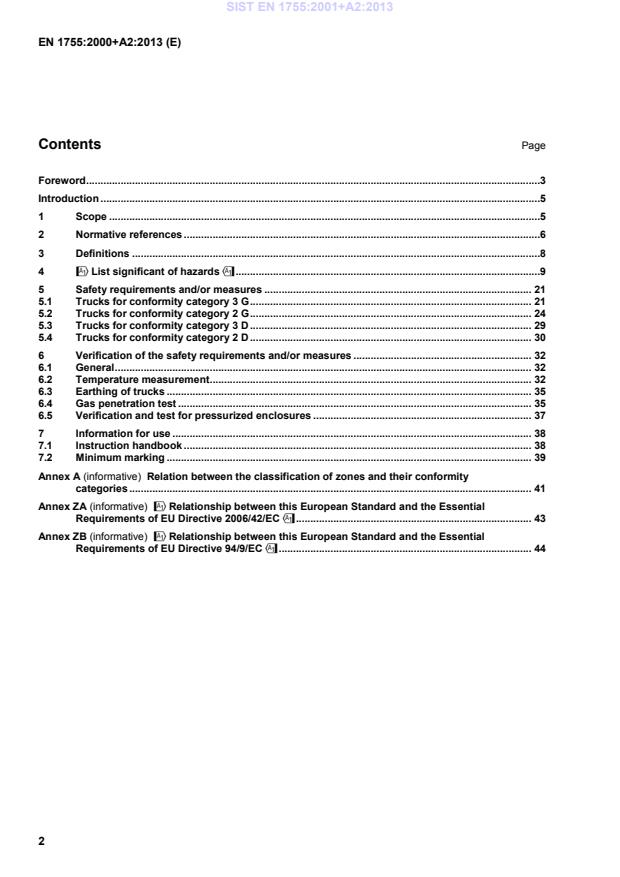

Relation between the classification of zones and their conformity categories . 41 Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 43 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC" . 44

!EN 1459, Safety of industrial trucks — Self propelled variable reach trucks EN 1551, Safety of industrial trucks — Self propelled trucks over 10 000 kg capacity EN 1726-1, Safety of industrial trucks — Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N — Part 1: General requirements EN 1726-2, Safety of industrial trucks — Self propelled trucks up to and including 10 000 kg capacity and tractors with a drawbar pull including 20 000 N — Part 2: Additional requirements for trucks with elevating operator position and trucks specifically designed to travel with elevated load EN 1757-1, Safety of industrial trucks — Pedestrian propelled trucks — Part 1: Stacker trucks EN 1757-2, Safety of industrial trucks — Pedestrian propelled trucks — Part 2: Pallet trucks EN 1757-3, Safety of industrial trucks — Pedestrian controlled manual and semi-manual trucks — Part 3: Platform trucks EN 1757-4, Safety of industrial trucks — Pedestrian controlled manual and semi-manual trucks — Part 4: Scissor lift pallet-trucks" !and gives additional requirements for industrial trucks of equipment group II and equipment category 2G respectively 3G, 2D and 3D including their load handling devices as defined in Annex A." !deleted text" !This European Standard covers the technical requirements necessary to avoid or minimize the significant hazards listed in Clause 4 which could occur during normal operation, maintenance or foreseeable misuse (in accordance with the data given by the manufacturer or his authorised representative) of industrial trucks." SIST EN 1755:2001+A2:2013

3.5 tyre outer part of a wheel which is of a different material from the wheel center 3.6 categories the definitions of categories are covered in clause 6.4.1 of EN 1127-1:1997 3.7 automatic monitoring a back-up safety function which ensures that a safety measure is initiated if the ability of a component or an element to perform its function is diminished, or if the process conditions are changed in such a way that hazards are generated 3.8 emergency stop (function) Function which is intended: to avert arising or to reduce existing hazards to persons, damage to machinery or to work in process; to be initiated by a single human action. 3.9 emergency stop (device) a normally actuated control device used to initiate an emergency stop function 3.10 normal operating conditions the operating conditions when the truck is used in substantially firm, smooth, level and prepared surfaces 3.11 service brake all build-in sequences or equipments (e.g. electrical, hydraulic or mechanical or in combination) used for deceleration of the truck in normal operating condition 4 !List significant of hazards" !This clause contains all significant hazards, hazardous situations and events, as far as they dealt with in this European Standard, identified by risk assessment as significant for this type of machinery and which requires action to eliminate or reduce the risk."

1.0.1 Principles of integrated explosion safety 5. Safety Requirements and/or Measures 1.0.2 Design considerations 5. Safety Requirements and/or Measures 1.0.3 Special checking and maintenance conditions 6.2 Temperature Measurement 7.1 Instruction Handbook 1.0.4 Surrounding area conditions 5.1.1

Hot surface

1.0.5 Marking 7.2

Minimum marking 1.0.6 Instructions 7.1 Instruction Handbook

7.2

Minimum marking 1.1 Selection of materials

1.1.1 Explosion avoidance 5.1.2

Mechanically generated sparks and clearances

5.1.7.3

Friction Clutches

5.1.8.2

Friction Brakes

5.1.9

Load handling device

5.2.2

Mechanically generated sparks

5.2.4

Ignition by Electrostatic discharges

5.2.8.2

Mechanical Clutches

5.2.9.2.4 Added Safety

5.2.10

Load handling device

5.3.2

Mechanically generated sparks and clearances

5.3.7.2

Friction Brakes

5.3.8

Load handling device

5.4.2

Mechanically generated sparks and clearances

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.1.2 Limits of operating conditions reaction between materials not applicable 1.1.3 Effects on predictable changes in materials characteristics 5.1.7.3

Friction Clutches 5.1.8.2

Friction Brakes

5.1.9

Load handling device

5.2.8.2

Mechanical Clutches

5.2.9.2.4 Added Safety

5.2.10

Load handling device

5.3.7.2

Friction Brakes

5.3.8

Load handling device

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems

1.2.1 Technological knowledge of explosion protection for safe operation throughout foreseeable lifetime 5.1.1

Hot surface 5.1.2

Mechanically generated sparks and clearances 5.1.3

Ignition by Electrostatic discharges 5.1.4

Reciprocating internal combustion engines

5.1.5

Electrical Installation

5.1.6

Pneumatic systems

5.1.7

Clutches

5.1.8

Brakes

5.1.9

Load handling device

5.1.10

Hydraulic system

5.2.1

Hot surface

5.2.2

Mechanically generated sparks

5.2.3

Clearances

5.2.4

Ignition by Electrostatic discharges

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.7

Pneumatic systems

5.2.8

Clutches

5.2.9

Brakes

5.2.10

Load handling device

5.2.11

Hydraulic system

5.3.1

Hot surface

5.3.2

Mechanically generated sparks and clearances

5.3.3

Reciprocating internal combustion engines

5.3.4

Electrical installation

5.3.5

Pneumatic systems

5.3.6

Clutches

5.3.7

Brakes

5.3.8

Load handling device

5.3.9

Hydraulic system

5.4.1

Hot surface

5.4.2

Mechanically generated sparks and clearances

5.4.3

Ignition by electrostatic discharges

5.4.4

Reciprocating internal combustion engines

5.4.5

Electrical installation

5.4.6

Pneumatic systems

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.2.2 Safe functioning of replacement components 5.1.1

Hot surface 5.1.2

Mechanically generated sparks and clearances

5.1.3

Ignition by Electrostatic discharges

5.1.4

Reciprocating internal combustion engines

5.1.5

Electrical Installation

5.1.6

Pneumatic systems

5.1.7

Clutches

5.1.8

Brakes

5.1.9

Load handling device

5.1.10

Hydraulic system

5.2.1

Hot surface

5.2.2

Mechanically generated sparks

5.2.3

Clearances

5.2.4

Ignition by Electrostatic discharges

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.7

Pneumatic systems

5.2.8

Clutches

5.2.9

Brakes

5.2.10

Load handling device

5.2.11

Hydraulic system

5.3.1

Hot surface

5.3.2

Mechanically generated sparks and clearances

5.3.3

Reciprocating internal combustion engines

5.3.4

Electrical installation

5.3.5

Pneumatic systems

5.3.6

Clutches

5.3.7

Brakes

5.3.8

Load handling device

5.3.9

Hydraulic system

5.4.1

Hot surface

5.4.2

Mechanically generated sparks and clearances

5.4.3

Ignition by electrostatic discharges

5.4.4

Reciprocating internal combustion engines

5.4.5

Electrical installation

5.4.6

Pneumatic systems

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.2.3 Enclosed structures and prevention of leaks not applicable 1.2.4 Dust deposits 5.3.1

Hot surface

5.4.1

Hot surface

7.1

Instruction Handbook 1.2.5 Additional means of protection for external stresses not covered by this standard 1.2.6 Safe opening 5.2.3

Clearances

5.2.5

Reciprocating internal combustion engines

5.2.6.2

Electrical equipment

5.2.8.3.3

Flameproof Enclosure (clutches)

5.2.9.2.3 Flameproof Enclosure(brakes)

5.3.4.2 Electrical equipment

5.3.6.3

Friction Clutches

5.3.7.3

Parking Brakes

5.4.4

Reciprocating internal combustion engines

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

7.1

Instruction Handbook 1.2.7 Protection against other hazards not applicable Note: requirement of standard trucks (EN 1726) a) injury not applicable b) Surface temperatures not applicable

Hot surface

5.1.4

Reciprocating internal combustion engines

5.1.5.1

Electrical Installation - General

5.1.5.2.2 Gas detection and restricted breathing enclosures

5.1.8.3

Parking Brakes

5.2.1

Hot surface

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.9.2.4 Added Safety

5.2.9.3

Parking Brakes

5.3.1

Hot surface

5.3.3

Reciprocating internal combustion engines

5.3.7.3

Parking Brakes

5.4.1

Hot surface

5.4.4

Reciprocating internal combustion engines

5.4.5

Electrical installation

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.2.9 Flameproof enclosure systems 5.2.5

Reciprocating internal combustion engines

5.2.6.2

Electrical equipment

5.2.7

Pneumatic systems

5.2.8.3.3

Flameproof Enclosure

5.2.9.2.3 Flameproof Enclosure

5.4.4

Reciprocating internal combustion engines

5.4.6

Pneumatic systems

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes) and hydraulic systems 1.3 Potential ignition sources

1.3.1 Hazards arising from different ignition sources 5.1.1

Hot surface 5.1.2

Mechanically generated sparks and clearances

5.1.4

Reciprocating internal combustion engines

5.2.1

Hot surface

5.2.2

Mechanically generated sparks

5.2.3

Clearances

5.2.5

Reciprocating internal combustion engines

5.3.1

Hot surface

5.3.2

Mechanically generated sparks and clearances

5.3.3

Reciprocating internal combustion engines

5.4.1

Hot surface

5.4.2

Mechanically generated sparks and clearances

5.4.4

Reciprocating internal combustion engines 1.3.2 Hazards arising from static electricity 5.1.3

Ignition by Electrostatic discharges 5.2.4

Ignition by Electrostatic discharges

5.4.3

Ignition by Electrostatic discharges 1.3.3 Hazards arising from stray electric and leakage currents not applicable

Mechanically generated sparks and clearances 5.1.7

Clutches

5.1.8

Brakes

5.2.2

Mechanically generated sparks

5.2.3

Clearances

5.2.8

Clutches

5.2.9

Brakes

5.3.2

Mechanically generated sparks and clearances

5.3.6

Clutches

5.3.7

Brakes

5.4.2

Mechanically generated sparks and clearances

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

1.3.5 Hazards arising from press-sure compensation operations not applicable 1.4 Hazards arising from external effects

1.4.1 Safe functioning not applicable 1.4.2 Mechanical and thermal stresses and withstanding attack by existing of foreseeable aggressive substances not applicable 1.5 Requirements in respect of safety-related devices

1.5.1 Independent function of safety devices of measurement and control. Fail safe principles for electric circuits. Safety-related switches independent of software and command 5.1.1

Hot surface 5.1.4

Reciprocating internal combustion engines 5.1.5.1

Electrical Installation - General 5.1.5.2.2 Gas detection and restricted breathing enclosures 5.1.9

Load handling device 5.2.1

Hot surface

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.8.3.1

Oil-protected Clutches

5.2.8.3.2

Pressurized Clutches

5.2.9.2.1

Oil-protected Brakes

5.2.9.2.2

Pressurized Brakes

5.2.9.2.4 Added Safety

5.2.9.3

Parking Brakes

5.3.1

Hot surface

5.3.3

Reciprocating internal combustion engines

5.3.7.3

Parking Brakes

5.4.1

Hot surface

5.4.4

Reciprocating internal combustion engines

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.5.2 Safety device failure 5.1.1

Hot surface

5.1.4

Reciprocating internal combustion engines

5.1.5.1

Electrical Installation - General

5.1.5.2.2 Gas detection and restricted breathing enclosures

5.1.9

Load handling device

5.2.1

Hot surface

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.8.3.1

Oil-protected Clutches

5.2.8.3.2

Pressurized Clutches

5.2.9.2.1

Oil-protected Brakes

5.2.9.2.2

Pressurized Brakes

5.2.9.2.4 Added Safety

5.2.9.3

Parking Brakes

5.3.1

Hot surface

5.3.3

Reciprocating internal combustion engines

5.3.7.3

Parking Brakes

5.4.1

Hot surface

5.4.4

Reciprocating internal combustion engines

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.5.3 Emergency stop controls 5.1.1

Hot surface

5.1.4

Reciprocating internal combustion engines

5.1.5.1

Electrical Installation - General

5.1.5.2.2 Gas detection and restricted breathing enclosures

5.1.8.3 Parking brakes

5.2.1

Hot surface

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.8.3.1 Oil-protected Clutches

5.2.8.3.2 Pressurized Clutches

5.2.9.2.1 Oil-protected Brakes

5.2.9.2.2 Pressurized Brakes

5.2.9.2.4 Added Safety

5.2.9.3

Parking Brakes

5.3.1

Hot surface

5.3.3

Reciprocating internal combustion engines

5.3.7.3

Parking Brakes

5.4.1

Hot surface

5.4.4

Reciprocating internal combustion engines

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.5.4 Control and display units 5.1.1

Hot surface

5.1.4

Reciprocating internal combustion engines

5.1.5.1

Electrical Installation - General

5.1.5.2.2 Gas detection and restricted breathing enclosures

5.1.8.3 Parking brakes

5.2.1

Hot surface

5.2.5

Reciprocating internal combustion engines

5.2.6

Electrical installation

5.2.8.3.1

Oil-protected Clutches

5.2.8.3.2

Pressurized Clutches

5.2.9.2.1

Oil-protected Brakes

5.2.9.2.2

Pressurized Brakes

5.2.9.2.4 Added Safety

5.2.9.3

Parking Brakes

5.3.1

Hot surface

5.3.3

Reciprocating internal combustion engines

5.3.7.3

Parking Brakes

5.4.1

Hot surface

5.4.4

Reciprocating internal combustion engines

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 1.5.5 Requirements in respect of devices with a measuring function for explosion protection not applicable 1.5.6 Checking accuracy of measuring devices 5.1.5.2.2 Gas detection and restricted breathing enclosures 1.5.7 Measuring device safety factor 5.1.5.2.2 Gas detection and restricted breathing enclosures

5.2.9.2.4 Added Safety 1.5.8 Risks arising from software 5.1.4

Reciprocating internal combustion engines

5.1.5.1

Electrical Installation - General

5.1.5.2.2 Gas detection and restricted breathing enclosures

5.2.5

Reciprocating internal combustion engines

5.2.6.1

Electrical installation - General

5.2.8.3.1

Oil-protected Clutches

5.2.9.2.1

Oil-protected Brakes

5.2.9.2.4 Added Safety

5.3.3

Reciprocating internal combustion engines

5.4.4

Reciprocating internal combustion engines

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

1.6 Integration of safety require-meanest relating to the system

1.6.1 Manual override not applicable 1.6.2 Emergency shutdown system not applicable 1.6.3 Hazards arising from power failure not covered by this standard Note: requirement of standard truck 1.6.4 Hazards arising from connections 5.1.5

Electrical Installation 5.2.6

Electrical Installation

5.3.4

Electrical Installation

5.4.5

Electrical Installation

equipment in category M 2 of equipment group 1 not covered by this standard (out of scope) 2.0.2.1 Sources of ignition not to become active in normal operation not covered by this standard (out of scope) 2.0.2.2 Opening of equipment only under non-active conditions not covered by this standard (out of scope) 2.0.2.3 Requirement for explosion hazards from dust category M 1 not covered by this standard (out of scope) 2.1 Requirements applicable to

equipment in category 1 of equipment group II not covered by this standard (out of scope) 2.1.1 Explosive atmospheres caused by gases, vapours or hazes not covered by this standard (out of scope) 2.1.1.1 Design and protection of equipment to prevent sources of ignition becoming active not covered by this standard (out of scope) 2.1.1.2 Stated max. surface tempera-tures not to be exceeded not covered by this standard (out of scope) 2.1.1.3 Opening of equipment only under non-active conditions not covered by this standard (out of scope) 2.1.2 Explosive atmospheres caused by air / dust mixtures not covered by this standard (out of scope) 2.1.2.1 Design and protection of equipment to prevent sources of ignition becoming active not covered by this standard (out of scope) 2.1.2.2 Designated points for entry and escape of dust not covered by this standard (out of scope) 2.1.2.3 Surface temperatures to be kept below ignition temperatures of suspended dust not covered by this standard (out of scope)

2.2.1 Explosive atmospheres caused by gases, vapours or mist

2.2.1.1 Design and construction of equipment to prevent ignition sources arising 5.2

Trucks for conformity category 2 G 5.2.1

Hot surface 5.2.2

Mechanically generated sparks

5.2.3

Clearances

5.2.4

Ignition by Electrostatic discharges

5.2.5

Reciprocating internal combustion engines to 2.2.1.1 5.2.6

Electrical installation

5.2.7

Pneumatic systems

5.2.8

Clutches

5.2.9

Brakes

5.2.10

Load handling device

5.2.11

Hydraulic system 2.2.1.2 Design and construction of equipment so that surface temperature is not exceeded 5.2.1

Hot surface 5.2.5

Reciprocating internal combustion engines 5.2.6.2

Electrical equipment

5.2.7

Pneumatic systems

5.2.8

Clutches

5.2.9

Brakes

5.2.11

Hydraulic system 2.2.1.3 Design of equipment for operating under non-active conditions / interlocking systems 5.2.3

Clearances 5.2.5

Reciprocating internal combustion engines 5.2.6.2

Electrical equipment

5.2.8.3.3

Flameproof Enclosure

5.2.9.2.3 Flameproof Enclosure

7.1

Instruction Handbook 2.2.2 Explosive atmospheres caused by air/dust mixtures

2.2.2.1 Design and construction of equipment to prevent ignition of air/ dust mixtures 5.4

Trucks for conformity category 2 D 5.4.1

Hot surface 5.4.2

Mechanically generated sparks and clearances

5.4.3

Ignition by electrostatic discharges

5.4.4

Reciprocating internal combustion engines

5.4.5

Electrical installation

5.4.6

Pneumatic systems

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems 2.2.2.2 Surface temperature must be kept well below the ignition temperature of the foreseeable air/dust mixture 5.4.1

Hot surface 5.4.4

Reciprocating internal combustion engines 5.4.5

Electrical installation 5.4.6

Pneumatic systems

5.4.7

Clutches

5.4.8

Friction brakes (Service brakes)

5.4.9 Parking brakes, load handling devices and hydraulic systems

Clutches 5.4.8

Friction brakes (Service brakes)

2.2.2.4 Opening of equipment is possible only under non-active conditions

5.4.4

Reciprocating internal combustion engines 5.4.7

Clutches 5.4.8

Friction brakes (Service brakes)

7.1

Instruction Handbook 2.3 Requirements applicable to equipment in category 3 of equipment group II

2.3.1 Explosive atmospheres caused by gases, vapours or mists

2.3.1.1 Design and construction of equipment to prevent foreseeable ignition during normal operation 5.1

Trucks for conformity category 3 G 5.1.1

Hot surface 5.1.2

Mechanically generated sparks and clearances 5.1.3

Ignition by Electrostatic discharges

5.1.4

Reciprocating internal combustion engines

5.1.5

Electrical Installation

5.1.6

Pneumatic systems

5.1.7

Clutches

5.1.8

Brakes

5.1.9

Load handling device

5.1.10

Hydraulic system 2.3.1.2 Surface temperatures not to exceed stated figures 5.1.1

Hot surface 5.1.4

Reciprocating internal combustion engines

5.1.5.2

Electrical Equipment

5.1.6

Pneumatic systems

5.1.7

Clutches

5.1.8

Brakes

5.1.10

Hydraulic system 2.3.2 Explosive atmospheres caused by air / dust mixtures

2.3.2.1 Design and construction of equipment to. prevent ignition of air/ dust mixtures during normal operation 5.3

Trucks for conformity category 3 D 5.3.1

Hot surface 5.3.2

Mechanically generated sparks and clearances 5.3.3

Reciprocating internal combustion engines

5.3.4

Electrical installation

5.3.5

Pneumatic systems

5.3.6

Clutches

5.3.7

Brakes

5.3.8

Load handling device

5.3.9

Hydraulic system 2.3.2.2 Surface temperature must be kept well below the ignition temperature of the foreseeable air/dust mixture 5.3.1

Hot surface 5.3.3

Reciprocating internal combustion engines 5.2.4.2 Electrical equipment 5.3.5

Pneumatic systems

5.3.6

Clutches

5.3.7

Brakes

5.3.9

Hydraulic system

Friction Clutches 5.3.7.2

Friction Brakes 3. Supplementary requirements in respect of protective systems not applicable 3.0 General requirements not applicable 3.0.1 Dimensions of protective systems safety level not applicable 3.0.2 Design of protective systems to prevent explosions due to chain reaction or flashover and incipient explosion not applicable 3.0.3 Protection systems operation in power failure situation not applicable 3.0.4 Failure of protective systems due to outside interference not applicable 3.1 Planning and design not applicable 3.1.1 Characteristics of materials not applicable 3.1.2 Withstanding shock wave effects of explosions not applicable 3.1.3 Accessories to withstand maximum pressure of explosions not applicable 3.1.4 Planning protective systems to take account of pressures on pipework etc. not applicable 3.1.5 Pressure relief systems not applicable 3.1.6 Explosion suppression systems not applicable 3.1.7 Explosion decoupling systems not applicable 3.1.8 Protective systems integrated into a circuit with an alarm not applicable

Reduction of this surface temperature by means of thermal insulation is not permitted. Trucks shall be arranged and marked according to clause 7 as a function of its maximum surface temperature and shall be either: classified in a temperature class given in Table 1; or defined by the actual maximum surface temperature. Table 1 — Classification of maximum surface temperatures

Temperature class Maximal surface temperature °C T1 450 T2 300 T3 200 T4 135 T5 100 T6 85

Equipment shall normally be designed for use in the ambient temperature range between –20 °C and +40 °C. In this case no additional marking is necessary. 5.1.2 Mechanically generated sparks and clearances In normal operation the clearances, taking into account design tolerances, between rotating parts and other parts shall be at least 1/100 of the maximum diameter of the moving part, except that the clearances need not exceed 5 mm and may be reduced to 1 mm if the opposing parts are manufactured so as to have dimensional accuracy and stability. In no case the clearances shall be less than 1 mm. 5.1.3 Ignition by electrostatic discharges To avoid the build-up of electrostatic charges the following precautions shall be taken: 5.1.3.1 Chassis All metal parts of the truck above 100 cm2 shall be bonded to the chassis of the truck in order to reach potential equalization. It is not necessary to connect parts to the frames by means of a separate conductor, if there parts are firmly secured and are in good metallic contact with the chassis. SIST EN 1755:2001+A2:2013

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...