EN 1254-6:2012

(Main)Copper and copper alloys - Plumbing fittings - Part 6: Fittings with push-fit ends

Copper and copper alloys - Plumbing fittings - Part 6: Fittings with push-fit ends

This European Standard specifies materials and test requirements for fittings of copper and copper alloys.

This part of EN 1254 specifies push-fit end connections with or without plating or coating in the size range 6 mm to 54 mm for the purpose of joining tubes of copper, plated copper, multilayer pipes and plastics pipes, intended for use in hot or cold or combined hot and cold water systems, heating and cooling.

Permissible operating temperatures and maximum operating pressures are also established.

Fittings may comprise a combination of end types, specified in this standard, EN 1254, or other standards.

The standard establishes a designation system for the fittings.

This European Standard is applicable to push-fit fittings for joining one or more of the following tubes or pipes:

-Copper tubes to EN 1057;

-PE-X pipes to EN ISO 15875-2;

-PB pipes to EN ISO 15876-2;

-PP pipes to EN ISO 15874-2.

-Multilayer pipes to EN ISO 21003-2.

Fittings may be suitable for joining other tubes and pipes provided the push-fit joint with the specified tube or pipe meets the requirements of this standard.

Kupfer und Kupferlegierungen - Fittings - Teil 6: Einsteckfittings

Diese Europäische Norm legt Werkstoffe und Prüfanforderungen für Fittings aus Kupfer und Kupfer¬legie-rungen fest.

Dieser Teil von EN 1254 legt Einsteckfittingverbindungen mit oder ohne galvanischem oder nichtgalvanischem Über¬zug in einem Diese Europäische Norm legt Werkstoffe und Prüfanforderungen für Fittings aus Kupfer und Kupferlegie-rungen fest.

Dieser Teil von EN 1254 legt Einsteckfittingverbindungen mit oder ohne galvanischem oder nichtgalvanischem Überzug in einem Nenndurchmesserbereich von 6 mm bis 54 mm fest, die für das Verbinden von Kupferrohren, Kupferrohren mit galva¬nischem Überzug, Mehrschichtverbundrohren und Kunststoffrohren für die Verwen¬dung in Warm- und Kaltwassersystemen nach EN 806 vorgesehen sind, welche für eine Lebensdauer von bis zu fünfzig Jahren hergestellt sind, sowie für Heizungs- und Kühlungssysteme.

Zulässige Betriebstemperaturen und höchst zulässige Betriebsdrücke sind ebenfalls festgelegt.

Fittings können mit einer Kombination von Anschlusstypen versehen sein, die entweder in dieser Euro-päischen Norm EN 1254 oder in anderen Normen festgelegt sind, sofern diese für das durchgeleitete Medium geeignet sind.

Die Europäische Norm legt ein Bezeichnungssystem für die Fittings fest.

Diese Europäische Norm gilt für Einsteckfittings für das Verbinden eines oder mehrerer der folgenden Rohre:

Kupferrohre nach EN 1057;

PE-X-Rohre nach EN ISO 15875-2;

PB-Rohre nach EN ISO 15876-2;

PP-Rohre nach EN ISO 15874-2;

PE-RT Rohre nach EN ISO 22391-2;

Mehrschichtverbundrohre nach EN ISO 21003-2.

Fittings können für das Verbinden anderer Rohre geeignet sein, sofern die Einsteckverbindung mit dem festgelegten Rohr den Anforderungen dieser Norm entspricht.

Betriebstemperaturen und drücke

Verbindungen mit Kupferrohren

Betriebstemperaturen und höchst zulässige Betriebsdrücke für zusammengefügte Verbindungen dürfen die in Tabelle 1 festgelegten Werte nicht überschreiten.

Cuivre et alliages de cuivre - Raccords - Partie 6: Raccords instantanés

La présente Norme européenne spécifie les matériaux et les prescriptions d'essai concernant les raccords en cuivre et alliages de cuivre.

La présente partie de l'EN 1254 spécifie les raccordements instantanés, avec ou sans placage ou revêtement, dans la gamme de dimensions de 6 mm à 54 mm, destinés au raccordement de tubes de cuivre, de cuivre plaqué, de tubes multicouches et de tuyaux en plastique destinés à être utilisés dans des installations d'eau chaude et d’eau froide conformes à l’EN 806, conçues pour une durée de vie en service supérieure à 50 ans, ainsi que dans des installations de chauffage et de refroidissement.

Les températures d'utilisation tolérées et les pressions d'utilisation maximales sont également définies.

Les raccords peuvent comprendre une combinaison de plusieurs types d’extrémité, spécifiés dans la présente Norme européenne, EN 1254, ou dans d'autres normes, à condition qu’ils soient adaptés pour le fluide / le gaz devant être transportés.

La présente norme prescrit un système de désignation pour les raccords.

La présente Norme européenne est applicable aux raccords instantanés permettant de raccorder un ou plusieurs tubes ou tuyaux des types suivants :

tubes en cuivre selon l'EN 1057 ;

tuyaux PE-X selon l'EN ISO 15875-2 ;

tuyaux PB selon l'EN ISO 15876-2 ;

tuyaux PP selon l'EN ISO 15874-2 ;

tuyaux PE-RT selon l’EN ISO 22391-2 ;

tubes multicouches selon l'EN ISO 21003-2.

Les raccords peuvent être adaptés pour raccorder d'autres tubes et tuyaux à condition que l'emboîture instantanée avec le tube ou tuyau spécifié satisfasse aux prescriptions de la présente norme.

Températures et pressions d'utilisation

Pour raccordements avec des tubes de cuivre

Il est essentiel que les températures et les pressions maximales d'utilisation pour les raccordements assemblés ne doivent pas dépasser les valeurs indiquées dans le Tableau 1.

Baker in bakrove zlitine - Fitingi - 6. del: Fitingi s "push-fit" zaključki

Ta evropski standard določa materiale in preskusne zahteve za fitinge iz bakra in bakrovih zlitin. Ta del standarda EN 1254 določa zaključke »push-fit« z ali brez nanosa ali premaza v razponu od 6 mm do 54 mm za spajanje bakrenih, pobakrenih, večplastnih in plastičnih cevi, namenjene za uporabo tako v sistemih za vročo in hladno vodo v skladu s standardom EN 806, ki so zasnovani za življenjsko dobo do petdeset let, kot tudi v sistemih ogrevanja in hlajenja. Določena sta tudi dovoljena delovna temperatura in največji delovni tlak. Fitingi lahko sestavljajo kombinacijo zaključkov, določenih v tem evropskem standardu EN 1254 ali drugih standardih, če so ti primerni za prenašanje tekočin. Standard določa sistem označevanja za fitinge. Ta evropski standard se uporablja za fitinge »push-fit« za spajanje ene ali več naslednjih cevi: bakrene cevi po standardu EN 1057, cevi PE-X po standardu EN ISO 15875-2, cevi PB po standardu EN ISO 15876-2, cevi PP po standardu EN ISO 15874-2, cevi PE-RT po standardu EN ISO 22391-2, večplastne cevi po standardu EN ISO 21003-2. Fitingi so lahko primerni za spajanje drugih cevi, če spoj »push-fit« posamezne cevi ustreza zahtevam tega standarda.

General Information

- Status

- Withdrawn

- Publication Date

- 09-Oct-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 133 - Copper and copper alloys

- Drafting Committee

- CEN/TC 133/WG 8 - Fittings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-May-2021

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 02-Jun-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1254-6:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Copper and copper alloys - Plumbing fittings - Part 6: Fittings with push-fit ends". This standard covers: This European Standard specifies materials and test requirements for fittings of copper and copper alloys. This part of EN 1254 specifies push-fit end connections with or without plating or coating in the size range 6 mm to 54 mm for the purpose of joining tubes of copper, plated copper, multilayer pipes and plastics pipes, intended for use in hot or cold or combined hot and cold water systems, heating and cooling. Permissible operating temperatures and maximum operating pressures are also established. Fittings may comprise a combination of end types, specified in this standard, EN 1254, or other standards. The standard establishes a designation system for the fittings. This European Standard is applicable to push-fit fittings for joining one or more of the following tubes or pipes: -Copper tubes to EN 1057; -PE-X pipes to EN ISO 15875-2; -PB pipes to EN ISO 15876-2; -PP pipes to EN ISO 15874-2. -Multilayer pipes to EN ISO 21003-2. Fittings may be suitable for joining other tubes and pipes provided the push-fit joint with the specified tube or pipe meets the requirements of this standard.

This European Standard specifies materials and test requirements for fittings of copper and copper alloys. This part of EN 1254 specifies push-fit end connections with or without plating or coating in the size range 6 mm to 54 mm for the purpose of joining tubes of copper, plated copper, multilayer pipes and plastics pipes, intended for use in hot or cold or combined hot and cold water systems, heating and cooling. Permissible operating temperatures and maximum operating pressures are also established. Fittings may comprise a combination of end types, specified in this standard, EN 1254, or other standards. The standard establishes a designation system for the fittings. This European Standard is applicable to push-fit fittings for joining one or more of the following tubes or pipes: -Copper tubes to EN 1057; -PE-X pipes to EN ISO 15875-2; -PB pipes to EN ISO 15876-2; -PP pipes to EN ISO 15874-2. -Multilayer pipes to EN ISO 21003-2. Fittings may be suitable for joining other tubes and pipes provided the push-fit joint with the specified tube or pipe meets the requirements of this standard.

EN 1254-6:2012 is classified under the following ICS (International Classification for Standards) categories: 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1254-6:2012 has the following relationships with other standards: It is inter standard links to EN 1254-6:2021, ISO 815-1:2008, EN ISO 19892:2018, EN ISO 10140-1:2010/A1:2012, EN ISO 15876-2:2017, EN ISO 15876-5:2017, EN ISO 15874-5:2013, EN 1254-4:2021, EN ISO 6509:1995, EN ISO 15874-2:2013, EN 1057:2006+A1:2010, EN ISO 13056:2018, EN 12165:2024, EN ISO 21003-5:2008, EN ISO 21003-2:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1254-6:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1254-6:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kupfer und Kupferlegierungen - Fittings - Teil 6: EinsteckfittingsCuivre et alliages de cuivre - Raccords - Partie 6: Raccords instantanésCopper and copper alloys - Plumbing fittings - Part 6: Fittings with push-fit ends77.150.30Bakreni izdelkiCopper products23.040.40Kovinski fitingiMetal fittingsICS:Ta slovenski standard je istoveten z:EN 1254-6:2012SIST EN 1254-6:2014en,fr,de01-julij-2014SIST EN 1254-6:2014SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1254-6

October 2012 ICS 23.040.40 English Version

Copper and copper alloys - Plumbing fittings - Part 6: Fittings with push-fit ends

Cuivre et alliages de cuivre - Raccords - Partie 6: Raccords instantanés

Kupfer und Kupferlegierungen - Fittings - Teil 6: Einsteckfittings This European Standard was approved by CEN on 11 August 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1254-6:2012: ESIST EN 1254-6:2014

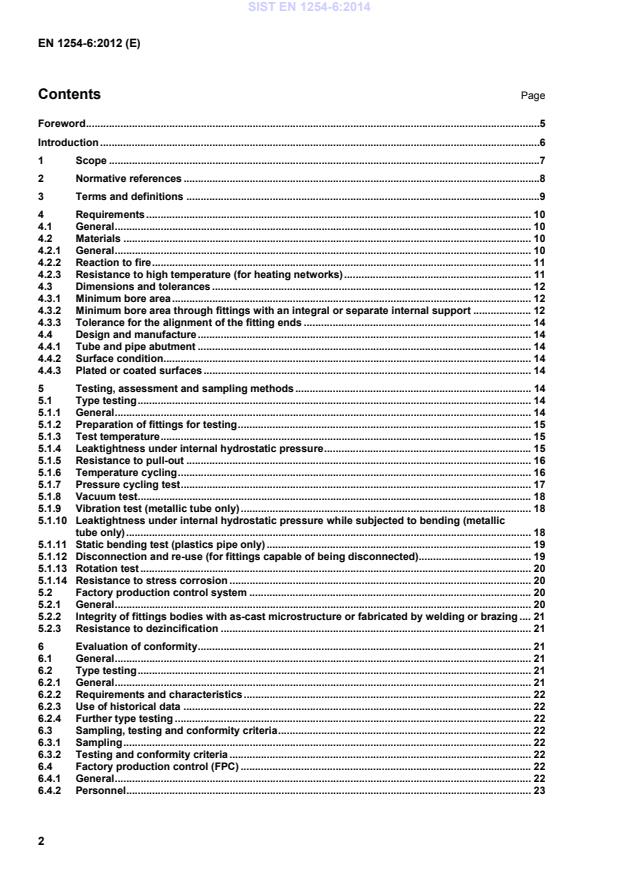

Method for testing leaktightness of joints

under internal hydrostatic pressure. 26A.1 Introduction . 26A.2 Principle. 26A.3 Apparatus . 26A.4 Test piece . 26A.5 Procedure . 27Annex B (normative)

Method for testing resistance to pull-out of joints with metallic tube . 28B.1 Introduction . 28B.2 Principle. 28B.3 Apparatus . 28B.4 Test assembly . 28B.5 Procedure . 28Annex C (normative)

Test method for resistance of joints with metallic tube to temperature cycling . 30C.1 Introduction . 30C.2 Principle. 30C.3 Apparatus . 30C.4 Test assembly . 30C.5 Procedure . 31Annex D (normative)

Method for testing the resistance of joints with metallic tube to pressure cycling . 32D.1 Introduction . 32D.2 Principle. 32D.3 Apparatus . 32D.4 Test pieces . 33D.5 Procedure . 33Annex E (normative)

Test method for leaktightness of joints with metallic tube under vacuum . 34E.1 Introduction . 34E.2 Principle. 34E.3 Apparatus . 34E.4 Test piece . 35E.5 Procedure . 35Annex F (normative)

Test method for the resistance of joints with metallic tube to vibration . 36F.1 Introduction . 36F.2 Principle. 36F.3 Apparatus . 36F.4 Test assembly . 36F.5 Procedure . 37SIST EN 1254-6:2014

Test method for leaktightness of joints with metallic tube under internal hydrostatic pressure while subjected to bending . 38G.1 Introduction . 38G.2 Principle . 38G.3 Apparatus . 38G.4 Test piece . 38G.5 Procedure . 39Annex H (normative)

Test method for disconnection and re-use . 40H.1 Introduction . 40H.2 Principle . 40H.3 Apparatus . 40H.4 Test assembly . 40H.5 Procedure . 40Annex I (normative)

Fitting rotation test . 41I.1 Introduction . 41I.2 Principle . 41I.3 Apparatus . 41I.4 Test assembly . 41I.5 Procedure . 42Annex J (normative)

Determination of resistance to stress corrosion . 43J.1 Introduction . 43J.2 Test piece . 43J.3 Procedure . 43J.4 Test report . 43Annex K (normative)

Pressure test for fittings bodies with as-cast microstructure or fabricated by welding or brazing . 44K.1 Introduction . 44K.2 Principle . 44K.3 Apparatus . 44K.4 Test piece . 44K.5 Procedure . 45Annex L (normative)

Determination of mean depth of dezincification . 46L.1 Introduction . 46L.2 Procedure . 46L.3 Expression of results . 46Bibliography . 48 SIST EN 1254-6:2014

Part 8: Fittings with press ends for use with plastics and multilayer pipes Part 7 will be the subject of future work. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

6 Intermediate pressure ratings are determined by linear interpolation. Certain designs of push-fit fittings are suitable for use at temperature/pressure ratings outside those given in this table. For such applications, the advice of the manufacturer should be sought. To allow for system malfunctions, it is essential that fittings be capable of temporary excursions up to a temperature of 110 °C at a pressure of 6 bar. SIST EN 1254-6:2014

1) Currently under revision. SIST EN 1254-6:2014

ISO 6957:1988, Copper alloys — Ammonia test for stress corrosion resistance ISO 9924-1, Rubber and rubber products — Determination of the composition of vulcanizates and uncured compounds by thermogravimetry — Part 1: Butadiene, ethylene-propylene copolymer and terpolymer, isobutene-isoprene, isoprene and styrene-butadiene rubbers 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 plumbing fitting device used in a tube system for the purpose of connecting the tubes either to each other or to a component part of the system 3.2 push-fit end end which incorporates a sealing element and a gripping device. The joint is made by pushing the tube into the fitting and a seal is achieved without the use of heat or tools Note 1 to entry: In some designs, this type of joint can be disconnected and re-connected or disconnected and the fitting

re-used elsewhere. 3.3 adaptor fitting fitting combining more than one type of end Note 1 to entry: For details of other ends, see the relevant parts of this European Standard or other standards. 3.4 nominal diameter nominal diameter of the fitting end expressed as the nominal outside diameter of the connecting tube SIST EN 1254-6:2014

Other components can be made from metallic or non-metallic materials, provided that they do not prevent the fitting meeting the functional requirements of this standard and do not cause degradation of the connected tube or pipes. Sealing elements shall conform to the requirements for elastomeric materials in EN 681-1 and Table 3 of this European Standard. Table 3 — Requirements and tests for non-metallic sealing elements Test procedures Tear strength for butyl rubbers in accordance with EN 681-1:1996, Table 3. Minimum tear strength: ≥ 20 N. Thermogravimetric analysis (TGA) for identity testing of elastomeric materials. The TGA is carried out in accordance with ISO 9924-1. Frequency of test — the TGA shall be carried out at the initial type testing stage to produce the master graph. Further analysis will be made to compare the production to the master graph at a frequency of once per year thereafter.

In order to demonstrate durability for long-term applications in water, elastomeric sealing elements shall be tested in accordance with the parameters shown in Table 4. Table 4 — Durability test for elastomeric sealing elements for fittings for water applications Test procedures Compression set test in water, in accordance with EN 681-1:1996, Annex B, and ISO 815-1. Test duration: 3 000 h Test temperature: 110 °C Test medium: Distilled water Compression set after 3 000 h: ≤ 30 % Compression set increase between 1 000 h and 3 000 h ≤ 5 % / 1 000 h Change in volume/Swelling (varying to EN 681-1 for IIR only). Test duration: 7 d Test temperature: 95 °C Test medium: Distilled water Change in volume ≤ 15 %

4.2.2 Reaction to fire Copper and copper alloys are products/materials that do not require to be tested for reaction to fire

(i.e. products/materials of class A.1 according to Commission Decision 96/603/EC, as amended 2000/605/EC). 4.2.3 Resistance to high temperature (for heating networks) The mechanical properties of products which consist of copper or copper alloys at temperatures encountered in heating networks are not reduced significantly; for example, it is not necessary to include the maximum admissible stress in pressure calculations from ambient up to 120 °C. SIST EN 1254-6:2014

Dimensions in millimetres Nominal diameterD Minimum bore diameter

4,0

6,0

7,0

9,0

10,0

14,7

11,0

11,0

12,0

13,0

14,0

16,0

18,0

18,0

21,0

27,4

23,0

23,0

26,0

29,0

29,0

35,0

40,5

36,0

36,0

40,0

53,6

47,0

47,0 4.3.2 Minimum bore area through fittings with an integral or separate internal support When an internal support is provided, either as an integral part of the fitting or loose, the minimum cross-sectional area of the bore through the support shall be in accordance with Table 6. SIST EN 1254-6:2014

mm for internal support with sealing element % for fitting and internal support without sealing element %

6 18 35

8 10 12 14 30 45

14,7 50 15 16 17 18 20 21 35 55 22 25

27,4 45 60 28 32 34 55 65 40

40,5 60 70 50

53,6 54

EXAMPLE For 16 mm nominal diameter push-fit end for plastics pipe with 2,0 mm wall thickness, area of bore = 113,1 mm2. Permissible area of bore through an internal support with sealing element (from table) = 30 % × 113,1 mm2 = 33,9 mm2. Therefore the minimum internal diameter of the internal support = 6,57 mm. Permissible area of bore through an internal support without sealing element (from table) = 50 % × 113,1 mm2 = 56,6 mm2. Therefore minimum internal diameter of the internal support = 8,49 mm. SIST EN 1254-6:2014

No Yes Disconnection and re use (if applicable) Yes Yes Fitting rotation Yes Yes Stress corrosion Yes Yes

5.1.2 Preparation of fittings for testing The fittings to be tested in accordance with 5.1.4 to 5.1.14 shall be assembled with the relevant tube or pipe, in accordance with the manufacturer’s instructions. 5.1.3 Test temperature Tests shall be conducted at a temperature of (23 ± 5) °C unless otherwise stated. 5.1.4 Leaktightness under internal hydrostatic pressure When tested in accordance with the parameters shown in Table 8 the fittings shall show no signs of leakage. Table 8 — Hydrostatic pressure test parameters Tube or pipe material Minimum free length of the tube or pipe in the testassembly Test pressure Test duration

Number of test pieces per size Test method

mm

min

Copper EN 1057 100 (24 ± 1) bar 15 1 Annex A PE-X

EN ISO 15875-2 1,5 PN of pipe 3 PB

EN ISO 15876-2 PP

EN ISO 15874-2 Multilayer

EN ISO 21003-2 SIST EN 1254-6:2014

EN ISO 15875-2 see EN ISO 15875-5 3 EN 712 followed by Annex A PB

EN ISO 15876-2 see EN SO 15876-5 PP

EN ISO 15874-2 see EN ISO 15874-5 Multilayer

EN ISO 21003-2 see EN ISO 21003-5

5.1.6 Temperature cycling When tested in accordance with the parameters shown in Table 10 the fittings under test shall show no signs of leakage.

°C °C bar m/s min

Copper EN 1057 93 ± 2 20 ± 5 10 ± 1 ≥ 0,5 (15 ± 1) hot

(15 ± 1) cold 5 000 Annex C PE-X EN ISO 15875-2 see EN ISO 15875-5 EN 12293 PB EN ISO 15876-2 see EN ISO 15876-5 PP EN ISO 15874-2 see EN ISO 15874-5 Multilayer

EN ISO 21003-2 see EN ISO 21003-5 5.1.7 Pressure cycling test When tested in accordance with the parameters shown in Table 11 the fittings under test shall show no signs of leakage. Table 11 — Pressure cycling test parameters Tube or pipe material Low pressure limitHigh pressure limitNumber of cycles Frequency of cycles Number of test pieces per size Test method Copper EN 1057 (1 ± 0,5) bar (25 ± 0,5) bar 10 000 (30 ± 5) per min 3 Annex D PE-X EN ISO 15875-2 see EN ISO 15875-5 EN 12295 PB EN ISO 15876-2 see EN ISO 15876-5 PP EN ISO 15874-2 see EN ISO 15874-5 Multilayer

EN ISO 21003-2 see EN ISO 21003-5 SIST EN 1254-6:2014

EN ISO 21003-2 see EN ISO 21003-5 5.1.9 Vibration test (metallic tube only) When tested in accordance with the parameters shown in Table 13 the fitting shall show no signs of leakage. Table 13 — Vibration test parameters Tube material Test pressure Deflection Number of cycles Frequencyof

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...