EN 12390-3:2001

(Main)Testing hardened concrete - Part 3: Compressive strength of test specimens

Testing hardened concrete - Part 3: Compressive strength of test specimens

This standard specifies a method for the determination of the compressive strength of test specimens of hardened concrete.

Prüfung von Festbeton - Teil 3: Druckfestigkeit von Probekörpern

Die vorliegende Norm beschreibt ein Verfahren für die Bestimmung der Druckfestigkeit von Probekörpern aus Festbeton.

Essais pour béton durci - Partie 3: Résistance à la compression des éprouvettes

La présente norme spécifie une méthode de détermination de la résistance en compression d'éprouvettes de béton durci.

Preskušanje strjenega betona - 3. del: Tlačna trdnost preskušancev

General Information

- Status

- Withdrawn

- Publication Date

- 11-Dec-2001

- Withdrawal Date

- 17-Feb-2009

- Technical Committee

- CEN/TC 104 - Concrete ( performance, production, placing and compliance criteria )

- Drafting Committee

- CEN/TC 104/SC 1 - Revision of ENV 206

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Feb-2009

- Completion Date

- 18-Feb-2009

- Directive

- 89/106/EEC - Construction products

Relations

- Replaced By

EN 12390-3:2009 - Testing hardened concrete - Part 3: Compressive strength of test specimens - Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12390-3:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Testing hardened concrete - Part 3: Compressive strength of test specimens". This standard covers: This standard specifies a method for the determination of the compressive strength of test specimens of hardened concrete.

This standard specifies a method for the determination of the compressive strength of test specimens of hardened concrete.

EN 12390-3:2001 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12390-3:2001 has the following relationships with other standards: It is inter standard links to EN 12390-3:2009, EN 206-1:2000, EN 13286-41:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12390-3:2001 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/128. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12390-3:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.YPrüfung von Festbeton - Teil 3: Druckfestigkeit von ProbekörpernEssais pour béton durci - Partie 3: Résistance a la compression des éprouvettesTesting hardened concrete - Part 3: Compressive strength of test specimens91.100.30Beton in betonski izdelkiConcrete and concrete productsICS:Ta slovenski standard je istoveten z:EN 12390-3:2001SIST EN 12390-3:2002en01-maj-2002SIST EN 12390-3:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12390-3December 2001ICS 91.100.30English versionTesting hardened concrete - Part 3: Compressive strength oftest specimensEssais pour béton durci - Partie 3: Résistance à lacompression des éprouvettesPrüfung von Festbeton - Teil 3: Druckfestigkeit vonProbekörpernThis European Standard was approved by CEN on 2 September 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12390-3:2001 ESIST EN 12390-3:2002

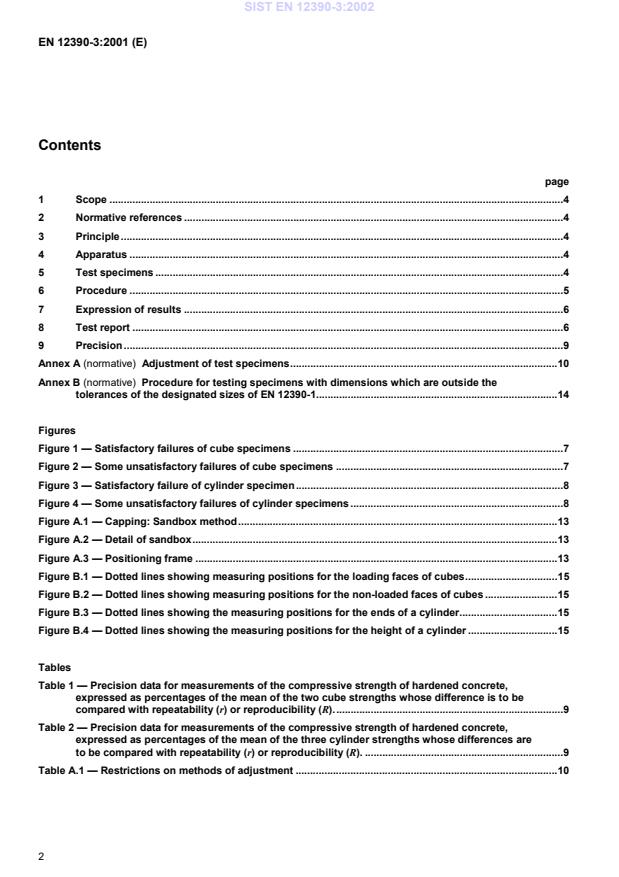

Adjustment of test specimens.10Annex B (normative)

Procedure for testing specimens with dimensions which are outside thetolerances of the designated sizes of EN 12390-1.14FiguresFigure 1 — Satisfactory failures of cube specimens.7Figure 2 — Some unsatisfactory failures of cube specimens.7Figure 3 — Satisfactory failure of cylinder specimen.8Figure 4 — Some unsatisfactory failures of cylinder specimens.8Figure A.1 — Capping: Sandbox method.13Figure A.2 — Detail of sandbox.13Figure A.3 — Positioning frame.13Figure B.1 — Dotted lines showing measuring positions for the loading faces of cubes.15Figure B.2 — Dotted lines showing measuring positions for the non-loaded faces of cubes.15Figure B.3 — Dotted lines showing the measuring positions for the ends of a cylinder.15Figure B.4 — Dotted lines showing the measuring positions for the height of a cylinder.15TablesTable 1 — Precision data for measurements of the compressive strength of hardened concrete,expressed as percentages of the mean of the two cube strengths whose difference is to becompared with repeatability (r) or reproducibility (R).9Table 2 — Precision data for measurements of the compressive strength of hardened concrete,expressed as percentages of the mean of the three cylinder strengths whose differences areto be compared with repeatability (r) or reproducibility (R).9Table A.1 — Restrictions on methods of adjustment.10SIST EN 12390-3:2002

Testing hardened concretePart 1:Shape, dimensions and other requirements for specimens and moulds (former prEN 12356:1996)Part 2:Making and curing specimens for strength tests (former prEN 12379:1996)Part 3:Compressive strength of test specimens (former prEN 12394:1996)Part 4:Compressive strength — Specification for testing machines (former prEN 12390:1996)Part 5:Flexural strength of test specimens (former prEN 12359:1996)Part 6:Tensile splitting strength of test specimens (former prEN 12362:1996)Part 7:Density of hardened concrete (former prEN 12363:1996)Part 8:Depth of penetration of water under pressure (former prEN 12364:1996)SIST EN 12390-3:2002

clean and remove any loose grit or other extraneous material from thesurfaces of the specimen that will be in contact with the platens.Do not use packing, other than auxiliary platens or

spacing blocks (see EN 12390-4) between the specimen and theplatens of the testing machine.Position the cube specimens that the load is applied perpendicularly to the direction of casting.Centre the specimen with respect to the lower platen to an accuracy of ± 1 % of the designated size of cubic, ordesignated diameter of cylindrical specimens.If auxiliary platens are used, align them with the top and bottom face of the specimen.With two-column testing machines, cubic specimens should be placed with the trowelled surface facing a column.6.2 LoadingSelect a constant rate of loading within the range 0,2 MPa/s (N/mm2

s) to 1,0 MPa/s (N/mm2

s). Apply the load tothe specimen without shock and increase continuously, at the selected constant rate ± 10 %, until no greater load canbe sustained.When using manually controlled testing machines, correct any tendency for the selected rate of loading to decrease,as specimen failure is approached by appropriate adjustment of the controls.Record the maximum load indicated.6.3 Assessment of type of failureExamples of the failure of specimen showing that the tests have proceeded satisfactorily are given in figure 1 forcubes and in figure 3 for cylinders.Examples for unsatisfactory failure of specimens are shown in figure 2 for cubes and in figure 4 for cylinders.If failure is unsatisfactory this shall be recorded with reference to the pattern letter according to figure 2 or 4 closest tothat observed.NOTEUnsatisfactory failures can be caused by: insufficient attention to testing procedures, especially positioning of the specimen; a fault with the testing machine.For cylindrical specimens, failure of the capping before the concrete is an unsatisfactory failure.SIST EN 12390-3:2002

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...