EN 1287:2017/prA1

(Amendment)Sanitary tapware - Low pressure thermostatic mixing valves - General technical specification

Sanitary tapware - Low pressure thermostatic mixing valves - General technical specification

This European Standard specifies general construction, performance and material requirements for PN 10 thermostatic mixing valves (TMV) and includes test methods for the verification of mixed water temperature performance at the point of use below 45 °C. This does not exclude the selection of higher temperatures where available. When these devices are used to provide anti-scald protection for children, elderly and disabled persons the mixed water temperature needs to be set at a suitable bathing temperature (body temperature - 38 °C) as children are at risk to scalding at lower temperatures than adults. This does not obviate the need for supervision of young children during bathing.

It applies to valves intended for use on sanitary appliances in kitchens, washrooms (incl. all rooms with sanitary tapware, e.g. toilet and cloakrooms) and bathrooms operating under the conditions specified in Table 1.

This standard allows TMVs to supply a single outlet or a small number of outlets in a "domestic" application (e.g. one valve, controlling a shower, bath, basin and/or, bidet), excluding valves specifically designed for supplying a large number of outlets (i.e. for institutional use).

The tests described are type tests (laboratory tests) and not quality control tests carried out during manufacture.

Table 1 - Conditions of use

Sanitärarmaturen - Thermostatische Mischer für die Anwendung im Niederdruckbereich - Allgemeine technische Spezifikation

Robinetterie sanitaire - Mitigeurs thermostatiques basse pression - Spécifications techniques générales

No scope available

Sanitarne armature - Termostatski mešalni ventili (PN 10) - Splošna tehnična specifikacija

General Information

- Status

- Not Published

- Publication Date

- 31-Jul-2022

- Withdrawal Date

- 31-Jan-2023

- Technical Committee

- CEN/TC 164 - Water supply

- Drafting Committee

- CEN/TC 164/WG 8 - Sanitary tapware

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 30-Sep-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 26-Jun-2019

Overview

EN 1287:2017/prA1 is a European Standard developed by the European Committee for Standardization (CEN) under Technical Committee CEN/TC 164, focusing on water supply. This standard establishes the general technical specifications for low-pressure thermostatic mixing valves (TMVs) with a nominal pressure rating of PN 10. It specifies essential requirements regarding the construction, performance, and materials used in TMVs designed for sanitary tapware installation, along with detailed test methods to verify the performance, especially concerning the mixed water temperature control.

The standard addresses TMVs intended for domestic applications-such as taps for showers, baths, basins, and bidets-operating in kitchens, washrooms, and bathrooms under defined pressure conditions. It excludes valves suited for large-scale or institutional use. Importantly, it prioritizes safety by defining temperature thresholds to minimize scald risk, particularly for vulnerable groups like children, the elderly, and disabled persons, recommending setting mixed water temperature around 38 °C, which aligns with a safe bathing temperature.

Key Topics

General Construction Requirements

EN 1287 defines material and design standards to ensure durability, resistance to corrosion, and compatibility with sanitary appliances.Performance Specifications

Includes precise control of mixed water temperature, ensuring stability and safety by limiting temperature deviations during operation and fluctuations in supply conditions.Testing Protocols

The standard prescribes laboratory (type) tests for verifying that TMVs maintain mixed water temperatures below 45 °C under varying conditions:- Water pressure changes

- Flow rate variations

- Supply temperature and pressure fluctuations

Safety Considerations for Vulnerable Users

Special attention is given to temperature control to prevent scalding risks, with guidelines for setting temperatures suitable for children's bathing.Scope of Application

Applicable to valves operating at PN 10 pressure rating in domestic settings with a single or small number of outlets to control hot water safely.

Applications

EN 1287:2017/prA1 serves as the benchmark for manufacturers, installers, and testing laboratories involved in the design, production, and quality assurance of TMVs for sanitary tapware. Practical applications include:

Residential Water Systems

Ensuring thermostatic mixing valves in home bathrooms, kitchens, and washrooms provide safe and stable water temperatures.Safety Installations in Care Facilities

Supporting safer water temperature controls in environments hosting children, elderly, or disabled residents to reduce scald injury risk.Sanitary Tapware Product Development

Guiding manufacturers on material conformity, performance criteria, and comprehensive testing, boosting product reliability and consumer safety.Regulatory Compliance and Certification

Assisting national standard bodies and certification agencies in assessing compliance for market approval in Europe.

Related Standards

- EN 1111 – Thermostatic mixing valves for hot water supplies. Covers different pressure classes and configurations.

- EN 15092 – Sanitary tapware mechanical performance and durability requirements.

- EN 806 series – Specifications for installation and maintenance of water supply systems.

- ISO 7241 – Connections for hydraulic fluid power, relevant for valve fittings and tapware.

Compliance with EN 1287:2017/prA1 aligns products with the latest European safety and performance mandates for thermostatic mixing valves, enhancing consumer protection and product quality in the sanitary industry. Manufacturers and installers leveraging this standard effectively mitigate scalding hazards and deliver reliable thermostatic control in low-pressure domestic applications.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1287:2017/prA1 is a draft published by the European Committee for Standardization (CEN). Its full title is "Sanitary tapware - Low pressure thermostatic mixing valves - General technical specification". This standard covers: This European Standard specifies general construction, performance and material requirements for PN 10 thermostatic mixing valves (TMV) and includes test methods for the verification of mixed water temperature performance at the point of use below 45 °C. This does not exclude the selection of higher temperatures where available. When these devices are used to provide anti-scald protection for children, elderly and disabled persons the mixed water temperature needs to be set at a suitable bathing temperature (body temperature - 38 °C) as children are at risk to scalding at lower temperatures than adults. This does not obviate the need for supervision of young children during bathing. It applies to valves intended for use on sanitary appliances in kitchens, washrooms (incl. all rooms with sanitary tapware, e.g. toilet and cloakrooms) and bathrooms operating under the conditions specified in Table 1. This standard allows TMVs to supply a single outlet or a small number of outlets in a "domestic" application (e.g. one valve, controlling a shower, bath, basin and/or, bidet), excluding valves specifically designed for supplying a large number of outlets (i.e. for institutional use). The tests described are type tests (laboratory tests) and not quality control tests carried out during manufacture. Table 1 - Conditions of use

This European Standard specifies general construction, performance and material requirements for PN 10 thermostatic mixing valves (TMV) and includes test methods for the verification of mixed water temperature performance at the point of use below 45 °C. This does not exclude the selection of higher temperatures where available. When these devices are used to provide anti-scald protection for children, elderly and disabled persons the mixed water temperature needs to be set at a suitable bathing temperature (body temperature - 38 °C) as children are at risk to scalding at lower temperatures than adults. This does not obviate the need for supervision of young children during bathing. It applies to valves intended for use on sanitary appliances in kitchens, washrooms (incl. all rooms with sanitary tapware, e.g. toilet and cloakrooms) and bathrooms operating under the conditions specified in Table 1. This standard allows TMVs to supply a single outlet or a small number of outlets in a "domestic" application (e.g. one valve, controlling a shower, bath, basin and/or, bidet), excluding valves specifically designed for supplying a large number of outlets (i.e. for institutional use). The tests described are type tests (laboratory tests) and not quality control tests carried out during manufacture. Table 1 - Conditions of use

EN 1287:2017/prA1 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1287:2017/prA1 has the following relationships with other standards: It is inter standard links to EN 1287:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1287:2017/prA1 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2021

Sanitarne armature - Termostatski mešalni ventili (PN 10) - Splošna tehnična

specifikacija

Sanitary tapware - Thermostatic mixing valves (PN 10) - General technical specification

Sanitärarmaturen - Thermostatische Mischer für die Anwendung im Niederdruckbereich -

Allgemeine technische Spezifikation

Robinetterie sanitaire - Mitigeurs thermostatiques (PN 10) - Spécifications techniques

générales

Ta slovenski standard je istoveten z: EN 1287:2017/prA1

ICS:

91.140.70 Sanitarne naprave Sanitary installations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

EN 1287:2017

NORME EUROPÉENNE

EUROPÄISCHE NORM

prA1

April 2021

ICS 91.140.70

English Version

Sanitary tapware - Thermostatic mixing valves (PN 10) -

General technical specification

Robinetterie sanitaire - Mitigeurs thermostatiques (PN Sanitärarmaturen - Thermostatische Mischer für die

10) - Spécifications techniques générales Anwendung im Niederdruckbereich - Allgemeine

technische Spezifikation

This draft amendment is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 164.

This draft amendment A1, if approved, will modify the European Standard EN 1287:2017. If this draft becomes an amendment,

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for inclusion of

this amendment into the relevant national standard without any alteration.

This draft amendment was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1287:2017/prA1:2021 E

worldwide for CEN national Members.

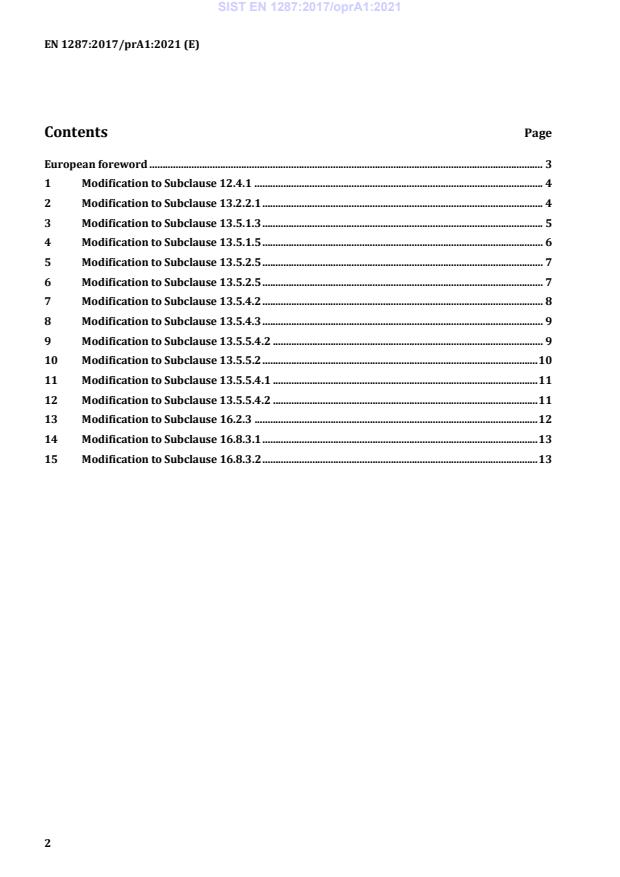

Contents Page

European foreword . 3

1 Modification to Subclause 12.4.1 . 4

2 Modification to Subclause 13.2.2.1 . 4

3 Modification to Subclause 13.5.1.3 . 5

4 Modification to Subclause 13.5.1.5 . 6

5 Modification to Subclause 13.5.2.5 . 7

6 Modification to Subclause 13.5.2.5 . 7

7 Modification to Subclause 13.5.4.2 . 8

8 Modification to Subclause 13.5.4.3 . 9

9 Modification to Subclause 13.5.5.4.2 . 9

10 Modification to Subclause 13.5.5.2 . 10

11 Modification to Subclause 13.5.5.4.1 . 11

12 Modification to Subclause 13.5.5.4.2 . 11

13 Modification to Subclause 16.2.3 . 12

14 Modification to Subclause 16.8.3.1 . 13

15 Modification to Subclause 16.8.3.2 . 13

European foreword

This document (EN 1287:2017/prA1:2021) has been prepared by Technical Committee CEN/TC 164

“Water supply”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

1 Modification to Subclause 12.4.1

Replace entire subclause: "

a) Connect the tap to the test circuit;

b) with the outlet orifice(s) artificially closed, and generally turned downwards open the obturator(s);

c) apply to the inlet of the tap a water pressure of (0,4 ± 0,02) MPa [(4,0 ± 0,2) bar] and maintain it for

(60 ± 5) s and adjust its temperature control over the full range;

d) within (5 ± 1) s reduce the pressure to (0,02 ± 0,002) MPa [(0,2 ± 0,02) bar] and maintain it for

(60 ± 5) s. "

with: "

a) Connect the tap to the test circuit;

b) with the outlet orifice(s) artificially closed, and generally turned downwards open the obturator(s);

c) apply to the inlet of the TMV a water pressure of (0,4 ± 0,02) MPa [(4,0 ± 0,2) bar] and maintain it

for (60 ± 5) s and adjust its temperature control over the full range;

d) within (5 ± 1) s reduce the pressure to (0,02 ± 0,002) MPa [(0,2 ± 0,02) bar] and maintain it for

(60 ± 5) s. ".

2 Modification to Subclause 13.2.2.1

Replace entire subclause:

" The measurement is made at the maximum available flow rate going from cold to hot and then from

hot to cold. For the measurement a TMV as supplied or the outlet pipework, as defined in A.3 is used.

Single sequential valves shall be adjusted to be able to attain a maximum 44 °C. Starting at full cold (off)

slowly adjust to 44 °C and then return to 34 °C.

Other device control systems (e.g. push-buttons, touch screens etc.) shall be tested by a method that

ensures the correlation between outlet temperature and flow rate can be suitably recorded.

The procedure is subject to agreement between manufacturer and test laboratory. "

with:

" The measurement is made at the maximum available flow rate going from cold to hot and then from

hot to cold. For the measurement a TMV as supplied, or, for valves without integral atmospheric

discharge, with the outlet pipework, as defined in A.3, is used.

Single sequential valves shall be adjusted to be able to attain a maximum 44 °C. Starting at full cold (off)

slowly adjust to 44 °C and then return to 34 °C.

Other device control systems (e.g. push-buttons, touch screens etc.) shall be tested by a method that

ensures the correlation between outlet temperature and flow rate can be suitably recorded.

The procedure is subject to agreement between manufacturer and test laboratory. ".

3 Modification to Subclause 13.5.1.3

Replace entire subclause: "

a) Starting from full hot determine the reference points in the following sequence: (38 ± 0,5) °C,

(36-1) °C, (40-1) °C;

b) apply and maintain the initial settings shown in Table 8 and allow water to flow until the outlet

temperature has stabilized;

c) start recording the mixed water temperature versus time;

d) within 1 s adjust the temperature control device to read ϑ = (36-1) °C;

mix

e) allow the outlet temperature to stabilize;

f) restore the settings in b);

g) within 1 s adjust the temperature control device to read ϑ = (40-1) °C;

mix

h) upon temperature stabilization stop recording mixed water temperature versus time. "

with: "

a) Apply and maintain the initial inlet settings shown in Table 8 and allow to flow for a period of

maximum 30 s;

b) starting from full hot, determine the position of the temperature control for the set temperatures in

the following sequence:

T1 : (38-1) °C;

T2 : (36-1) °C, and record the corresponding mixed water temperature measured (ϑ );

T3 : (40-1) °C, and record the corresponding mixed water temperature measured (ϑ );

c) set the temperature control into the position T1 and allow the mixed water temperature to stabilise

for a period of maximum 30 s;

d) start recording the mixed water temperature (ϑ ) versus time;

mix

e) within 1 s set the temperature control to the position T2;

f) allow the mixed water temperature (ϑ ) to stabilise for a period of maximum 30 s;

mix

g) set the temperature control into the position T1 and allow the mixed water temperature (ϑ ) to

mix

stabilize for period of maximum 30 s;

h) within 1 s set the temperature control to the position T3;

i) allow the mixed water temperature (ϑ ) to stabilise for a period of maximum 30 s, stop

mix

recording the mixed water temperature versus time. ".

4 Modification to Subclause 13.5.1.5

Replace entire subclause:

" The mixed water temperature ϑ shall not differ from the set temperatures ϑ for a duration (t -

mix 0 2

t ) longer than 1 s with an amplitude of more than ϑ = 3 K.

1 x

t = 5 s after disturbing the respective equilibrium the mixed water temperature shall not differ by

more than 2 K from the set temperatures nor oscillate in excess of 1 K .

PP

NOTE If this is done with single sequential control valves (Type 1) the flow rate will also change i.e. not

maintaining Table 8 conditions. "

with:

" Apply and maintain the initial settings shown in Table 8 and allow the mixed water temperature

(ϑ ) to The mixed water temperature (ϑ ) shall not differ more than 3 K from the respective set

mix mix

temperatures (ϑ , ϑ or ϑ ) for a duration (t – t respectively t – t ) longer than 1 s.

0 2 3 2 1 7 6

Maximum 5 s (t , respectively t ) after disturbing the respective equilibrium the mixed water

3 8

temperature shall not differ by more than 2 K from the set temperatures (ϑ or ϑ ) nor oscillate in

2 3

excess of 1 ϑKPP.

NOTE See also informative graph included in Figure 1. If this is done with single sequential control valves

(Type 1) the flow rate will also change i.e. not maintaining Table 8 conditions. ".

Add also Figure 1: "

Figure 1 — Temperature control operation ".

Update the figure numbering and the related cross references throughout the document.

5 Modification to Subclause 13.5.2.5

Replace entire subclause: "

a) Apply and maintain the initial settings shown in Table 8 and allow water to flow until the outlet

temperature has stabilized;

b) Start recording outlet temperature versus time.

c) Within (5-6) s adjust the flow control of the valve under test to deliver 50 % of the flow rate

according to a), in case the tested valve has no flow control the outlet pipework A.3 or A.4 shall be

used instead.

d) Upon temper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...