EN 17192:2026

(Main)Ventilation for buildings - Ductwork - Non-metallic ductwork - Requirements and test methods

Ventilation for buildings - Ductwork - Non-metallic ductwork - Requirements and test methods

This document specifies the requirements and test methods for rigid or semi-rigid non-metallic ductwork which are used for ventilation and air conditioning in buildings and excludes flexible ducts and ductwork made from insulation duct board

The specified test methods are under laboratory conditions and exclude on-site tests.

Lüftung von Gebäuden - Nichtmetallische Kanäle - Anforderungen und Prüfmethoden

Dieses Dokument legt die Anforderungen und Prüfverfahren für starre oder halbstarre nichtmetallische Leitungen fest, die für die Lüftung und Klimatisierung in Gebäuden verwendet werden. Flexible Luftleitungen und Luftleitungen die aus Isolierungs-Luftleitungsverkleidung hergestellt sind, sind ausgeschlossen.

Die festgelegten Prüfverfahren finden unter Laborbedingungen statt. Vorort-Prüfungen sind ausgeschlossen.

Ventilation des bâtiments - Réseau de conduits - Réseau de conduits non métalliques - Exigences et méthodes d'essai

Le présent document spécifie les exigences et les méthodes d’essai pour les réseaux de conduits non métalliques rigides ou semi-rigides qui sont utilisés pour la ventilation et le conditionnement d’air dans les bâtiments et exclus les conduits flexibles et les réseaux de conduits réalisés en panneaux isolants de conduits.

Les méthodes d'essai spécifiées sont celles utilisées en conditions de laboratoire et excluent les essais sur site.

Prezračevanje stavb - Kanali - Nekovinski kanali - Zahteve in preskusne metode

General Information

- Status

- Not Published

- Publication Date

- 24-Feb-2026

- Technical Committee

- CEN/TC 156 - Ventilation for buildings

- Drafting Committee

- CEN/TC 156/WG 3 - Ductwork

- Current Stage

- 6055 - CEN Ratification completed (DOR) - Publishing

- Start Date

- 12-Jan-2026

- Due Date

- 16-Mar-2025

- Completion Date

- 12-Jan-2026

Relations

- Effective Date

- 16-Nov-2022

Overview

FprEN 17192: Ventilation for Buildings - Non-metallic Ductwork is a comprehensive European standard developed by CEN Technical Committee 156. This standard specifies the essential requirements and laboratory test methods for rigid or semi-rigid non-metallic ductwork used in ventilation and air conditioning systems for buildings. It excludes flexible ducts, non-metallic spiral ducts, and insulation duct board ductwork, covered by other standards.

The document supports quality assurance and compliance with applicable EU directives, focusing on performance parameters critical to building ventilation systems such as air tightness, pressure drop, service temperature, fire reaction, external pressure resistance, and microbial resilience.

Key Topics

Scope and Application

- Defines test methods and performance characteristics under laboratory conditions for non-metallic ductwork.

- Applicable for ducts with circular, rectangular, or other cross sections used in HVAC installations.

- Excludes any on-site tests, flexible ducts (textile or spiral), and insulation duct board ducts.

Performance Requirements

- Air Tightness: Classification into air tightness classes (ATC1 to ATC7) based on leakage limits measured at specified pressure ranges.

- Pressure Drop: Declaration of pressure drop values for each duct and component to ensure efficient airflow management.

- Service Temperature: Specifies operating temperature range with minimum and maximum service temperatures designated by STL and STH.

- Reaction to Fire: Fire performance testing per EN 13501-1, updated with single-flame source fire classification (Classes D and E).

- Resistance to External Pressure: Mechanical resistance to withstand environmental and operational pressures.

- Microbial Resistance: Testing against microbial growth and biocidal efficacy according to EN ISO 846 or ISO 22196.

Construction and Materials

- Specifies duct dimensions, tolerances, and minimum bending radii for semi-rigid ducts.

- Defines mechanical connection categories from no seal/fastening to specially designed seals and fixations.

- Manufacturers must provide clear documentation including installation, operation, and maintenance guides.

Test Methods

- Air tightness testing under controlled laboratory conditions using standardized pressure ranges.

- Pressure drop measurements ensuring minimal airflow resistance.

- Fire reaction tests using updated flame source standards.

- Mechanical pressure resistance and microbial resistance evaluated with standardized procedures to ensure durability and hygiene.

Applications

FprEN 17192 is essential for manufacturers, installers, and inspectors of non-metallic ventilation ductwork in residential, commercial, and institutional buildings. Applying this standard ensures:

- Enhanced Indoor Air Quality: By controlling air leakage and pressure drops, ductwork conforming to this standard maintains HVAC system efficiency and reduces pollution ingress.

- Fire Safety Compliance: Aligns duct material reaction to fire with EU safety regulations for improved occupant safety.

- Durability: Ensures ducts withstand external loads, mechanical stresses, and microbial effects, extending longevity and reducing maintenance.

- System Optimization: Allows engineers to specify ducts with known performance metrics for reliable and effective air distribution.

- Regulatory Alignment: Complies with EU directives and supports national regulations concerning ventilation systems.

This standard serves as a guideline for the design, testing, and approval of non-metallic ductwork components ensuring system robustness and performance in modern ventilation engineering.

Related Standards

- EN 13180: Flexible ducts standards for ventilation applications.

- EN 13403: Requirements for ductwork made from insulation duct board.

- EN 16798-3: Air tightness requirements for ventilation systems in non-residential buildings.

- EN 1507 & EN 12237: Sheet metal ductwork strength and leakage requirements.

- EN 13501-1: Fire classification of construction products, including ducts.

- EN ISO 846 & ISO 22196: Microbial resistance testing methods for plastics and surfaces.

- EN ISO 11925-2: Reaction to fire - Single flame source test.

Using FprEN 17192 alongside these ensures comprehensive coverage for ductwork design, testing, and certification, facilitating safer and more efficient ventilation solutions in building construction.

Keywords: non-metallic ductwork, ventilation duct standards, air tightness classes, pressure drop, fire reaction test, microbial resistance, HVAC duct requirements, building ventilation safety, CEN standards, laboratory test methods

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 17192:2026 is a draft published by the European Committee for Standardization (CEN). Its full title is "Ventilation for buildings - Ductwork - Non-metallic ductwork - Requirements and test methods". This standard covers: This document specifies the requirements and test methods for rigid or semi-rigid non-metallic ductwork which are used for ventilation and air conditioning in buildings and excludes flexible ducts and ductwork made from insulation duct board The specified test methods are under laboratory conditions and exclude on-site tests.

This document specifies the requirements and test methods for rigid or semi-rigid non-metallic ductwork which are used for ventilation and air conditioning in buildings and excludes flexible ducts and ductwork made from insulation duct board The specified test methods are under laboratory conditions and exclude on-site tests.

EN 17192:2026 is classified under the following ICS (International Classification for Standards) categories: 91.140.30 - Ventilation and air-conditioning systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17192:2026 has the following relationships with other standards: It is inter standard links to EN 17192:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17192:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 17192:2024

01-oktober-2024

Prezračevanje stavb - Kanali - Nekovinski kanali - Zahteve in preskusne metode

Ventilation for buildings - Ductwork - Non-metallic ductwork - Requirements and test

methods

Lüftung von Gebäuden - Nichtmetallische Kanäle - Anforderungen und Prüfmethoden

Ventilation des bâtiments - Réseau de conduits - Réseau de conduits non métalliques -

Exigences et méthodes d'essai

Ta slovenski standard je istoveten z: prEN 17192

ICS:

91.140.30 Prezračevalni in klimatski Ventilation and air-

sistemi conditioning systems

oSIST prEN 17192:2024 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 17192:2024

oSIST prEN 17192:2024

DRAFT

EUROPEAN STANDARD

prEN 17192

NORME EUROPÉENNE

EUROPÄISCHE NORM

August 2024

ICS Will supersede EN 17192:2018

English Version

Ventilation for buildings - Ductwork - Non-metallic

ductwork - Requirements and test methods

Ventilation des bâtiments - Réseau de conduits - Lüftung von Gebäuden - Nichtmetallische Kanäle -

Réseau de conduits non métalliques - Exigences et Anforderungen und Prüfmethoden

méthodes d'essai

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 156.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 17192:2024 E

worldwide for CEN national Members.

oSIST prEN 17192:2024

prEN 17192:2024(E)

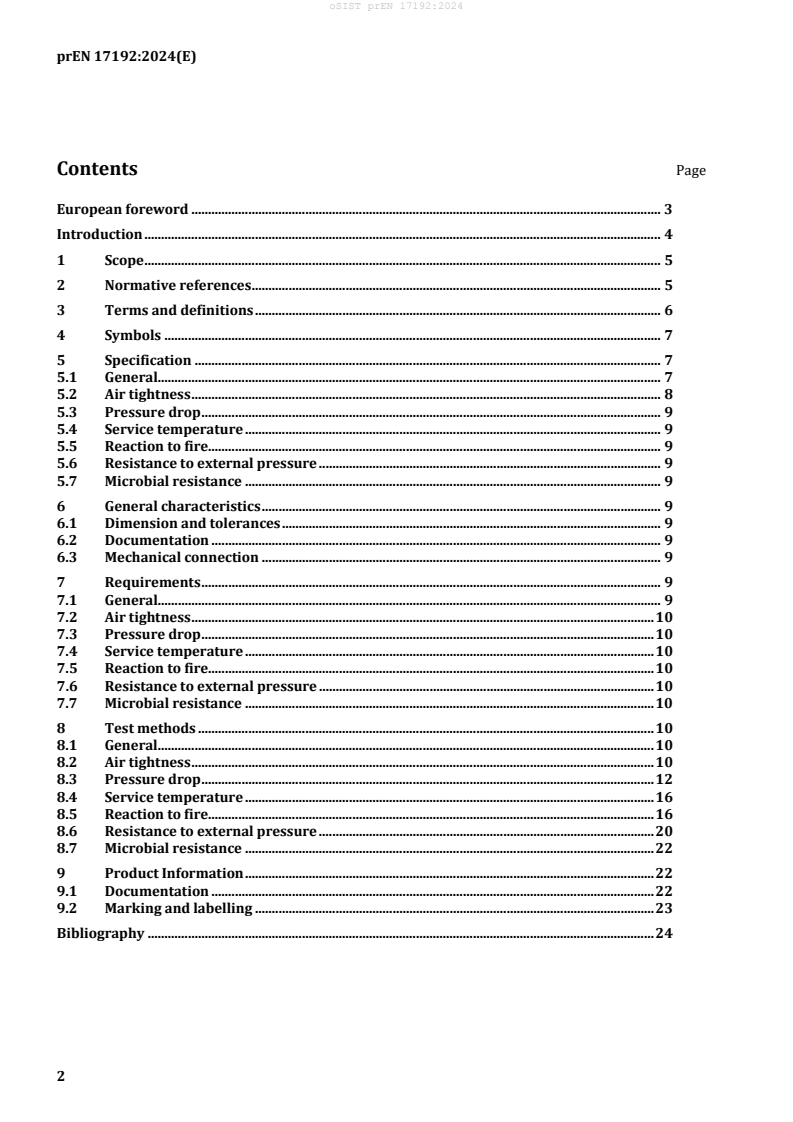

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols . 7

5 Specification . 7

5.1 General. 7

5.2 Air tightness . 8

5.3 Pressure drop . 9

5.4 Service temperature . 9

5.5 Reaction to fire. 9

5.6 Resistance to external pressure . 9

5.7 Microbial resistance . 9

6 General characteristics . 9

6.1 Dimension and tolerances . 9

6.2 Documentation . 9

6.3 Mechanical connection . 9

7 Requirements . 9

7.1 General. 9

7.2 Air tightness . 10

7.3 Pressure drop . 10

7.4 Service temperature . 10

7.5 Reaction to fire. 10

7.6 Resistance to external pressure . 10

7.7 Microbial resistance . 10

8 Test methods . 10

8.1 General. 10

8.2 Air tightness . 10

8.3 Pressure drop . 12

8.4 Service temperature . 16

8.5 Reaction to fire. 16

8.6 Resistance to external pressure . 20

8.7 Microbial resistance . 22

9 Product Information . 22

9.1 Documentation . 22

9.2 Marking and labelling . 23

Bibliography . 24

oSIST prEN 17192:2024

prEN 17219:2024 (E)

European foreword

This document (prEN 17192:2024) has been prepared by Technical Committee CEN/TC 156 “Ventilation

of buildings”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 17192:2019.

EN 17192:202Y includes the following significant technical changes with respect to EN 17192:2019:

— Reaction to fire tests have been updated with classifications D and E, the tests are in accordance with

the single-flame source test, according standard EN ISO 11925-2

— The thermal resistance test have been taken away because the test was based on flat material and is

difficult to perform on material taken from a duct. The result from Thermal resistance test is relevant

to non metallic ducts and can be added at a later stage if there is a adapted method available.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association,and supports essential requirements of

EU Directive(s) / Regulation(s).

oSIST prEN 17192:2024

prEN 17192:2024(E)

Introduction

This document handles technical requirements and test methods for Non metallic ducts and have been

developed after the Metallic duct, the Flexible duct and the ductwork made from insulation duct board

standards. All features in the other standards have been considered, used, ignored or adapted.

oSIST prEN 17192:2024

prEN 17219:2024 (E)

1 Scope

This document defines the test methods and performance characteristics for rigid or semi-rigid non-

metallic ductwork which are used for ventilation and air conditioning of buildings.

This document does not include flexible ducts such as those made of textiles, non-metallic spiral

ductwork or others, which are handled in EN 13180 or ductwork made from insulation duct board, which

is handled in EN 13403. Requirements for the air tightness of the ventilation system for non-residential

buildings are given in EN 16798-3. For residential buildings, it is essential to apply national rules.

This document specifies methods to test rigid or semi-rigid non-metallic ductwork under laboratory

conditions. On-site tests are excluded. The test methods and performance characteristics are valid for

ventilation ducts with circular, rectangular or other cross sections.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1507, Ventilation for buildings - Sheet metal air ducts with rectangular section - Requirements for

strength and leakage

EN 12237, Ventilation for buildings - Ductwork - Strength and leakage of circular sheet metal ducts

EN 12792, Ventilation for buildings - Symbols, terminology and graphical symbols

EN 13501-1, Fire classification of construction products and building elements - Part 1: Classification using

data from reaction to fire tests

EN 13823, Reaction to fire tests for building products — Building products excluding floorings exposed to

the thermal attack by a single burning item

EN ISO 846, Plastics - Evaluation of the action of microorganisms (ISO 846)

EN ISO 1182, Reaction to fire tests for products - Non-combustibility test (ISO 1182)

EN ISO 1716, Reaction to fire tests for products - Determination of the gross heat of combustion (calorific

value) (ISO 1716)

ISO 22196, Measurement of antibacterial activity on plastics and other non-porous surfaces

EN ISO 11925-2, Reaction to fire tests - Ignitability of products subjected to direct impingement of flame -

Part 2: Single-flame source test (ISO 11925-2)

oSIST prEN 17192:2024

prEN 17192:2024(E)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12792 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

ductwork

system or network of ducts and their components for the transport of air

3.2

rigid duct

duct which cannot be manually longitudinally compressed or decompressed and cannot be flexed in any

direction without permanently damaging the cross sectional area

3.3

semi rigid duct

duct which cannot be manually longitudinally compressed or decompressed but can be flexed in at least

one direction without permanently damaging the cross sectional area

3.4

bending radius

centreline radius after bending a duct

3.5

sealed connection length

length of the perimeter where a duct or component is connected with another duct or component

3.6

internal surface area

internal surface area is the sum of each internal perimeter multiplied by the length of that section of the

ductwork

Note 1 to entry: The length of semi-rigid ductwork is the centreline, the length of rigid ductwork is defined in

accordance with EN 14239.

3.7

maximum Service Temperature

STH

highest temperature at which the ducts and fittings, when installed, continue to function within specified

limits of performance

3.8

minimum Service Temperature

STL

lowest temperature at which the ducts and fittings, when installed, continue to function within specified

limits of performance

3.9

pressure drop

difference between total pressure upstream and downstream of component or duct

oSIST prEN 17192:2024

prEN 17219:2024 (E)

3.10

purpose-designed seal

sealing solution engineered and supplied by the manufacturer

3.11

purpose – designed fixation

connection solution of the ductwork engineered and supplied by the manufacturer

3.12

manufacturer

any natural or legal person who manufactures a construction product or who has such a product designed

or manufactured and markets that product under his name or trademark

4 Symbols

Nomenclature shown in Table 1 is used throughout this document.

Table 1 — Symbols

Symbol Quantity Units

A 2

p Product surface area m

d

h Hydraulic diameter m

L

sc Sealed connection length m

A 2

s Internal surface area m

f 3 -1 -2

c Air leakage factor m · s · m

f 3 -1 -2

max Limits leakage rate m · s · m

p

a Atmospheric pressure Pa

p

s Static gauge pressure Pa

p

test Test pressure Pa

q 3 -1

vl measured Measured air leakage volume rate m · s

q 3 -1

vl Leakage volume rate of air flow m · s

t Air temperature °C

5 Specification

5.1 General

The following ductwork parameters shall be specified:

— Air tightness;

— Pressure drop;

— Service temperature;

oSIST prEN 17192:2024

prEN 17192:2024(E)

— Reaction to fire;

— Resistance to external pressure;

— Microbial resistance.

5.2 Air tightness

The air tightness classes and the limits for the leakage rate are defined in Table 2.

Table 2 — Air tightness classes

Air tightness class Air leakage limit (f )

max

Old New 3 -1 -2

m · s · m

(EN 12599:2012 and (EN 16798-3:2017)

EN 13779:2008)

ATC 7 Not classified

ATC 6 0,65 −3

0,0675 × p x 10

t

A ATC 5 0,65

−3

0,027 × p x 10

t

B ATC 4 0,65

−3

0,009 × p x 10

t

C ATC 3 0,65 −3

0,003 × p x 10

t

D ATC 2 0,65

−3

0,001 × p x 10

t

ATC 1 0,65

−3

0,00033 × p x 10

t

0,65 −3

NOTE If no leakage is measured the default value for calculation will be 0,0675 × p x 10 .

t

The operating pressure range of the ductwork is defined by negative and positive pressures.

The air tightness class shall be declared together with the operating pressure range. The declared air

tightness class shall be valid for the specified operating pressure range.

The operating pressure range shall be declared in increments of 10 Pa together with the air tightness

class.

EXAMPLE

Example declaration:

Operating pressure range Air tightness class declared

−60 to +260 Pa ATC 4

−40 to +110 Pa ATC 3

−20 to +50 Pa ATC 2

Example explanation:

At an operating pressure of 125 Pa air tightness class ATC 4 can be declared.

At an operating pressure of 90 Pa air tightness class ATC 3 can be declared.

At an operating pressure of 40 Pa air tightness class ATC 2 can be declared.

oSIST prEN 17192:2024

prEN 17219:2024 (E)

5.3 Pressure drop

The pressure drop shall be declared for every duct and component of the ductwork.

5.4 Service temperature

The temperature class defines the range of the operating temperature for the use of the ventilation

ductwork. The designation for the lowest service temperature is STL and for the highest service

temperature STH.

The designation is followed by the operating temperature.

EXAMPLE STL-20 to STH +100

The operating temperature range for the use of the ventilation ductwork is −20 °C to +100 °C.

5.5 Reaction to fire

The reaction to fire shall be classified in accordance with EN 13501-1.

5.6 Resistance to external pressure

The resistance to pressure value is the maximum allowed force determined in accordance with 8.6. The

value shall be rounded down to the nearest ten.

5.7 Microbial resistance

The microbial resistance shall be determined in accordance with EN ISO 846 or ISO 22196. If ISO 22196

is used, then the biocidal effect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...