EN 303-6:2019

(Main)Heating boilers - Part 6: Heating boilers with forced draught burners - Specific requirements for the domestic hot water operation and energy performance of water heaters and combination boilers with atomizing oil burners of nominal heat input not exceeding 70 kW

Heating boilers - Part 6: Heating boilers with forced draught burners - Specific requirements for the domestic hot water operation and energy performance of water heaters and combination boilers with atomizing oil burners of nominal heat input not exceeding 70 kW

This document is composed of two parts.

The first part supplements EN 303-1, EN 303-2, EN 303-4 and EN 304, hereafter called boiler standards. It specifies the supplementary requirements and tests for the construction, safety, rational use of energy, fitness for purpose, classification and marking related to the domestic hot water operation of oil-fired water heaters and combination boilers.

The domestic hot water is produced on either the instantaneous or storage principle. The domestic hot water production is integrated or coupled, the whole being marketed as a single unit.

The second part covers the energy performance of domestic hot water production of the appliances covered by the first part.

This second part sets out a method for assessing the energy performance of the appliances. It defines a number of daily tapping cycles for each domestic hot water use such as kitchen, shower, bath and a combination of these, together with corresponding test procedures, enabling the energy performances of combination boilers and water heaters to be compared and matched to the needs of the user.

The heat output of the appliances covered by this standard does not exceed 400 kW.

In the case of combination boilers, with or without storage tank, domestic hot water production is integrated or coupled, the whole being marketed as a single unit.

This standard only covers type testing.

Heizkessel - Teil 6: Heizkessel mit Gebläsebrennern - Spezielle Anforderungen an die trinkwasserseitige Funktion und energetische Bewertung von Wassererwärmern und von Kombi-Kesseln mit Ölzerstäubungsbrennern mit einer Nennwärmeleistung kleiner als oder gleich 70 kW

Dieses Dokument besteht aus zwei Teilen.

Der erste Teil vervollständigt die EN 303 1, EN 303 2, EN 303 4 und EN 304, nachfolgend Kesselnormen genannt. Er legt die zusätzlichen Anforderungen und Prüfungen für die Bauweise, die Sicherheit, die rationelle Energienutzung, die Gebrauchsgüte sowie die Einteilung und die Kennzeichnung bei der Betriebsart „Trinkwassererwärmung“ von ölbefeuerten Warmwasserbereitern und Kombi Kesseln fest.

Die Wassererwärmung erfolgt nach dem Durchlauf oder dem Speicherprinzip und ist integriert oder angebaut. Die Funktionen „Heizwassererwärmung“ und „Trinkwassererwärmung“ werden als Einheit vertrieben.

Der zweite Teil behandelt die Gesamtenergieeffizienz der Funktionen „Heizwassererwärmung“ und „Trinkwarmwassererwärmung“ der im ersten Teil behandelten Geräte.

Dieser zweite Teil legt ein Verfahren zur Bewertung der Gesamtenergieeffizienz der Geräte dar. Er definiert eine Anzahl an täglichen Zapfzyklen für jede Verwendungsart der Trinkwassererwärmung, wie beispiels¬weise Küche, Dusche, Bad, und eine Kombination dieser, zusammen mit den zugehörigen Prüfverfahren, wodurch die Gesamtenergieeffizienz der Kombi Kessel und Warmwasserbereiter verglichen und auf die Bedürfnisse des Anwenders abgestimmt werden kann.

Die Wärmeleistung der von dieser Norm behandelten Geräte darf 400 kW nicht überschreiten.

Im Falle von Kombi Kesseln mit oder ohne Speicher werden die Funktionen „Heizwassererwärmung“ und „Trinkwassererwärmung“ als Einheit vertrieben.

Die vorliegende Norm umfasst nur die Typprüfung.

Chaudières de chauffage - Partie 6 : Chaudières avec brûleurs à air soufflé - Exigences spécifiques à la fonction eau chaude sanitaire et à la performance énergétique des préparateurs d'eau chaude et des chaudières à deux services avec brûleurs fioul à pulvérisation dont le débit calorifique nominal est inférieur ou égal à 70 kW

Le présent document se compose de deux parties.

La première partie complète les normes EN 303 1, EN 303 2, EN 303 4 et EN 304, ci-après désignées normes chaudières. Elle définit les exigences et les essais complémentaires pour la construction, la sécurité, l'utilisation rationnelle de l'énergie, l'aptitude à la fonction, ainsi que la classification et le marquage concernant la fonction eau chaude sanitaire des chauffe-eau et des chaudières à deux services fonctionnant au fioul.

L'eau chaude sanitaire est produite selon la conception instantanée ou à accumulation. La production d'eau chaude sanitaire est intégrée ou accolée, l'ensemble étant commercialisé comme une seule unité.

La deuxième partie concerne les performances énergétiques de la production d'eau chaude sanitaire des appareils couverts par la première partie.

Elle établit également une méthode d'évaluation des performances énergétiques des appareils. Elle définit un nombre de cycles quotidiens de puisage pour chaque utilisation d'eau chaude sanitaire (par exemple, cuisine, douche et/ou bain), ainsi que les procédures d'essai correspondantes, afin de faciliter la comparaison des performances énergétiques des chaudières à deux services et des chauffe-eau, et d'adapter ces performances aux besoins de l'utilisateur.

La puissance utile des appareils couverts par la présente norme n'excède pas 400 kW.

Dans le cas des chaudières à deux services, avec ou sans ballon, la production d'eau chaude sanitaire est intégrée ou accolée, l'ensemble étant commercialisé comme une seule unité.

La présente norme couvre uniquement les essais de type.

Kotli za gretje - 6. del: Kotli z ventilatorskimi gorilniki - Posebne zahteve za delovanje in energijske lastnosti grelnikov sanitarne vode in kombiniranih kotlov z razprševalnimi oljnimi gorilniki z nazivno močjo do vključno 70 kW

Ta evropski standard je sestavljen iz dveh delov.

Prvi del dopolnjuje standarde EN 303 1, EN 303 2, EN 303 4 in EN 304, ki so v nadaljevanju imenovani standardi za kotle. Določa dopolnilne zahteve in preskuse za konstrukcijo, varnost, racionalno uporabo energije, primernost za namen, klasifikacijo ter označevanje v zvezi z delovanjem oljnih grelnikov sanitarne vode in kombiniranih kotlov.

Topla sanitarna voda se proizvaja po načelu pretočnosti ali po načelu shranjevanja. Proizvodnja tople sanitarne vode je integrirana ali združena, pri čemer se celota trži kot ena enota.

Drugi del zajema energijske lastnosti proizvodnje tople sanitarne vode z napravami, ki so zajete v prvem delu.

Ta drugi del določa metodo za ocenjevanje energetskih lastnosti naprav. Določa število dnevnih ciklov izpuščanja za vsako uporabo tople sanitarne vode, npr. za kuhinjo, prho, kad in njihove kombinacije, skupaj z ustreznimi preskusnimi postopki, da se omogoči primerjava energijskih lastnosti različnih kombiniranih kotlov in grelnikov vode ter njihova uskladitev s potrebami uporabnika.

Toplotna moč naprav, ki so zajete v tem standardu, ne presega 400 kW.

Pri kombiniranih kotlih, z rezervoarjem ali brez, je priprava tople sanitarne vode integrirana ali združena, pri čemer se celota trži kot ena enota.

Ta standard zajema le tipsko preskušanje.

General Information

- Status

- Published

- Publication Date

- 06-Aug-2019

- Withdrawal Date

- 28-Feb-2020

- Technical Committee

- CEN/TC 57 - Central heating boilers

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Mar-2025

- Completion Date

- 04-Mar-2025

Relations

- Effective Date

- 14-Aug-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 16-Dec-2020

Overview

EN 303-6:2019 (CEN) specifies requirements and test methods for the domestic hot water (DHW) operation and energy performance of oil‑fired water heaters and combination boilers with atomizing oil burners. The document is published by CEN (approved June 2019) and is composed of two parts:

- Part 1 supplements EN 303‑1, EN 303‑2, EN 303‑4 and EN 304, setting construction, safety, energy‑use and fitness for purpose requirements for DHW operation (instantaneous or storage; integrated or coupled units marketed as a single appliance).

- Part 2 defines a method for assessing energy performance of DHW production, including standard daily tapping cycles (kitchen, shower, bath and combinations) and related test procedures to enable product comparison.

The standard applies to appliances with atomizing oil burners (nominal heat input not exceeding 70 kW) and limits referenced in the text indicate applicability to heating outputs up to 400 kW. EN 303‑6:2019 covers type testing only and supersedes EN 303‑6:2000.

Key Topics

- Scope and definitions for combination boilers, instantaneous vs storage types, specific rate D, nominal DHW heat input Qnw, etc.

- Constructional requirements for domestic water circuits, materials, connections and soundness.

- Safety controls: thermostatic controls, pressure relief, temperature holding thermostats and related devices.

- Operational requirements addressing rational use of energy and fitness for purpose.

- Test methods for safety, energy efficiency, measurement of energy recovered by useful water, calculation of heating oil and electrical energy, standby/off mode consumption, and determination of wasted water.

- Energy performance assessment: standardized tapping cycles, measurement uncertainty, reference/test conditions and calculation procedures.

- Marking and instructions, plus informative annexes (test rig/measurement devices and links to EU eco‑design/ERP regulations).

Applications

EN 303‑6:2019 is used to:

- Guide manufacturers in designing and type‑testing oil‑fired water heaters and combination boilers for DHW performance and safety.

- Provide test laboratories with harmonized procedures to measure energy consumption, standby losses and DHW delivery characteristics.

- Support compliance with EU eco‑design / ERP requirements via annexed relationships to relevant regulations.

- Enable product comparison and selection by installers, specifiers and procurement teams by matching appliance energy performance to user needs (kitchen, shower, bath profiles).

Who Uses It

- Boiler and water‑heater manufacturers

- Independent test houses and certification bodies

- Design engineers and R&D teams

- Energy assessors, regulators and procurement professionals

- Installers and technical specifiers seeking energy‑efficient DHW solutions

Related Standards

- EN 303‑1, EN 303‑2, EN 303‑4, EN 304 (boiler family standards)

- EN 13203‑2 (assessment of energy consumption)

- Relevant EU eco‑design / ERP regulations (see informative annexes)

Keywords: EN 303‑6:2019, heating boilers, combination boilers, water heaters, atomizing oil burners, domestic hot water, energy performance, type testing, CEN, eco‑design.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 303-6:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Heating boilers - Part 6: Heating boilers with forced draught burners - Specific requirements for the domestic hot water operation and energy performance of water heaters and combination boilers with atomizing oil burners of nominal heat input not exceeding 70 kW". This standard covers: This document is composed of two parts. The first part supplements EN 303-1, EN 303-2, EN 303-4 and EN 304, hereafter called boiler standards. It specifies the supplementary requirements and tests for the construction, safety, rational use of energy, fitness for purpose, classification and marking related to the domestic hot water operation of oil-fired water heaters and combination boilers. The domestic hot water is produced on either the instantaneous or storage principle. The domestic hot water production is integrated or coupled, the whole being marketed as a single unit. The second part covers the energy performance of domestic hot water production of the appliances covered by the first part. This second part sets out a method for assessing the energy performance of the appliances. It defines a number of daily tapping cycles for each domestic hot water use such as kitchen, shower, bath and a combination of these, together with corresponding test procedures, enabling the energy performances of combination boilers and water heaters to be compared and matched to the needs of the user. The heat output of the appliances covered by this standard does not exceed 400 kW. In the case of combination boilers, with or without storage tank, domestic hot water production is integrated or coupled, the whole being marketed as a single unit. This standard only covers type testing.

This document is composed of two parts. The first part supplements EN 303-1, EN 303-2, EN 303-4 and EN 304, hereafter called boiler standards. It specifies the supplementary requirements and tests for the construction, safety, rational use of energy, fitness for purpose, classification and marking related to the domestic hot water operation of oil-fired water heaters and combination boilers. The domestic hot water is produced on either the instantaneous or storage principle. The domestic hot water production is integrated or coupled, the whole being marketed as a single unit. The second part covers the energy performance of domestic hot water production of the appliances covered by the first part. This second part sets out a method for assessing the energy performance of the appliances. It defines a number of daily tapping cycles for each domestic hot water use such as kitchen, shower, bath and a combination of these, together with corresponding test procedures, enabling the energy performances of combination boilers and water heaters to be compared and matched to the needs of the user. The heat output of the appliances covered by this standard does not exceed 400 kW. In the case of combination boilers, with or without storage tank, domestic hot water production is integrated or coupled, the whole being marketed as a single unit. This standard only covers type testing.

EN 303-6:2019 is classified under the following ICS (International Classification for Standards) categories: 91.140.10 - Central heating systems; 91.140.65 - Water heating equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 303-6:2019 has the following relationships with other standards: It is inter standard links to EN 303-6:2000, EN 1057:2006+A1:2010, EN 304:2017, prEN 15116, EN 13203-2:2022, EN 303-2:2017, EN 303-1:2017, EN 303-6:2019/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 303-6:2019 is associated with the following European legislation: EU Directives/Regulations: 811/2013, 812/2013, 813/2013, 814/2013; Standardization Mandates: M/495, M/534, M/535. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 303-6:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2019

Nadomešča:

SIST EN 303-6:2001

Kotli za gretje - 6. del: Kotli z ventilatorskimi gorilniki - Posebne zahteve za

delovanje in energijske lastnosti grelnikov sanitarne vode in kombiniranih kotlov z

razprševalnimi oljnimi gorilniki z nazivno močjo do vključno 70 kW

Heating boilers - Part 6: Heating boilers with forced draught burners - Specific

requirements for the domestic hot water operation and energy performance of water

heaters and combination boilers with atomizing oil burners of nominal heat input not

exceeding 70 kW

Heizkessel - Teil 6: Heizkessel mit Gebläsebrennern - Spezielle Anforderungen an die

trinkwasserseitige Funktion und energetische Bewertung von Wassererwärmern und von

Kombi-Kesseln mit Ölzerstäubungsbrennern mit einer Nennwärmeleistung kleiner als

oder gleich 70 kW

Chaudières de chauffage - Partie 6 : Chaudières avec brûleurs à air soufflé - Exigences

spécifiques à la fonction eau chaude sanitaire et à la performance énergétique des

préparateurs d'eau chaude et des chaudières à deux services avec brûleurs fioul à

pulvérisation dont le débit calorifique nominal est inférieur ou égal à 70 kW

Ta slovenski standard je istoveten z: EN 303-6:2019

ICS:

27.060.30 Grelniki vode in prenosniki Boilers and heat exchangers

toplote

91.140.65 Oprema za ogrevanje vode Water heating equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 303-6

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2019

EUROPÄISCHE NORM

ICS 91.140.10; 91.140.65 Supersedes EN 303-6:2000

English Version

Heating boilers - Part 6: Heating boilers with forced

draught burners - Specific requirements for the domestic

hot water operation and energy performance of water

heaters and combination boilers with atomizing oil

burners of nominal heat input not exceeding 70 kW

Chaudières de chauffage - Partie 6 : Chaudières avec Heizkessel - Teil 6: Heizkessel mit Gebläsebrennern -

brûleurs à air soufflé - Exigences spécifiques à la Spezielle Anforderungen an die trinkwasserseitige

fonction eau chaude sanitaire et à la performance Funktion und energetische Bewertung von

énergétique des préparateurs d'eau chaude et des Wassererwärmern und von Kombi-Kesseln mit

chaudières à deux services avec brûleurs fioul à Ölzerstäubungsbrennern mit einer

pulvérisation dont le débit calorifique nominal est Nennwärmeleistung kleiner als oder gleich 70 kW

inférieur ou égal à 70 kW

This European Standard was approved by CEN on 10 June 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 303-6:2019 E

worldwide for CEN national Members.

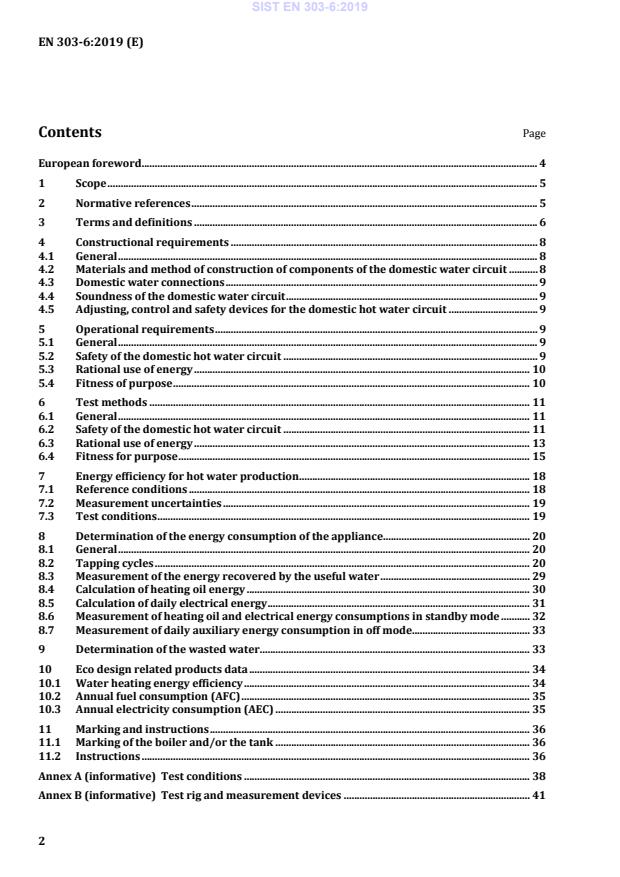

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Constructional requirements . 8

4.1 General . 8

4.2 Materials and method of construction of components of the domestic water circuit . 8

4.3 Domestic water connections . 9

4.4 Soundness of the domestic water circuit . 9

4.5 Adjusting, control and safety devices for the domestic hot water circuit . 9

5 Operational requirements . 9

5.1 General . 9

5.2 Safety of the domestic hot water circuit . 9

5.3 Rational use of energy . 10

5.4 Fitness of purpose . 10

6 Test methods . 11

6.1 General . 11

6.2 Safety of the domestic hot water circuit . 11

6.3 Rational use of energy . 13

6.4 Fitness for purpose . 15

7 Energy efficiency for hot water production . 18

7.1 Reference conditions . 18

7.2 Measurement uncertainties . 19

7.3 Test conditions . 19

8 Determination of the energy consumption of the appliance . 20

8.1 General . 20

8.2 Tapping cycles . 20

8.3 Measurement of the energy recovered by the useful water . 29

8.4 Calculation of heating oil energy . 30

8.5 Calculation of daily electrical energy . 31

8.6 Measurement of heating oil and electrical energy consumptions in standby mode . 32

8.7 Measurement of daily auxiliary energy consumption in off mode. 33

9 Determination of the wasted water . 33

10 Eco design related products data . 34

10.1 Water heating energy efficiency . 34

10.2 Annual fuel consumption (AFC) . 35

10.3 Annual electricity consumption (AEC) . 35

11 Marking and instructions . 36

11.1 Marking of the boiler and/or the tank . 36

11.2 Instructions . 36

Annex A (informative) Test conditions . 38

Annex B (informative) Test rig and measurement devices . 41

Annex ZA (informative) Relationship between this European Standard and the eco-design

requirements of Commission Regulation (EC) No 814/2013 aimed to be covered. 45

Annex ZB (informative) Relationship between this European Standard and the eco-design

requirements of Commission Regulation (EC)No 812/2013 aimed to be covered . 46

Annex ZC (informative) Relationship between this European Standard and the eco-design

requirements of Commission Regulation (EC) No 813/2013 aimed to be covered. 47

Annex ZD (informative) Relationship between this European Standard and the eco-design

requirements of Commission Regulation (EC) No 811/2013 aimed to be covered. 48

European foreword

This document (EN 303-6:2019) has been prepared by Technical Committee CEN/TC 57 “Central

heating boilers”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2020, and conflicting national standards

shall be withdrawn at the latest by February 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 303-6:2000.

EN 303-6 is revised to update it for:

— EN 13203-1 for the specific flow rate where a new method replaced the method used in EN 625

which was deleted (replaced partially by EN 15502-1 and EN 13203-1);

— ERP requirements for water heating appliances based on the work done by CEN/TC 109 WG4 in the

revision of EN 13203-2.

The following structure is intended for the European Standards for heating boilers:

— EN 303-1, Heating boilers — Part 1: Heating boilers with forced draught burners — Terminology,

general requirements, testing and marking

— EN 303-2, Heating boilers — Part 2: Heating boilers with forced draught burners — Special

requirements for boilers with atomizing oil burners

— EN 303-3, Heating boilers — Part 3: Gas fired central heating boilers — Assembly comprising a boiler

body and a forced draught burner

— EN 303-4, Heating boilers — Part 4: Heating boilers with forced draught burners — Special

requirements for boilers with forced draught oil burners with outputs up to 70 kW and a maximum

operating pressure of 3 bar — Terminology, special requirements, testing and marking

— EN 303-5, Heating boilers — Part 5: Special heating boilers for solid fuels, hand and automatically

stoked, nominal heat output of up to 300 kW — Terminology, requirements, testing and marking

— EN 304, Heating boilers — Test code for heating boilers for atomizing oil burners

Annexes A and B of this European Standard are informative.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annexes ZA, ZB, ZC and ZD, which are an integral

part of this document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document is composed of two parts.

The first part supplements EN 303-1, EN 303-2, EN 303-4 and EN 304, hereafter called boiler standards.

It specifies the supplementary requirements and tests for the construction, safety, rational use of

energy, fitness for purpose, classification and marking related to the domestic hot water operation of

oil-fired water heaters and combination boilers.

The domestic hot water is produced on either the instantaneous or storage principle. The domestic hot

water production is integrated or coupled, the whole being marketed as a single unit.

The second part covers the energy performance of domestic hot water production of the appliances

covered by the first part.

This second part sets out a method for assessing the energy performance of the appliances. It defines a

number of daily tapping cycles for each domestic hot water use such as kitchen, shower, bath and a

combination of these, together with corresponding test procedures, enabling the energy performances

of combination boilers and water heaters to be compared and matched to the needs of the user.

The heat output of the appliances covered by this standard does not exceed 400 kW.

In the case of combination boilers, with or without storage tank, domestic hot water production is

integrated or coupled, the whole being marketed as a single unit.

This standard only covers type testing.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 303-1:2017, Heating boilers — Part 1: Heating boilers with forced draught burners — Terminology,

general requirements, testing and marking

EN 303-2, Heating boiler —- Part 2: Heating boilers with forced draught burners — Special requirements

for boilers with atomizing oil burners

EN 304, Heating boilers — Test code for heating boilers for atomizing oil burners

EN 1057, Copper and copper alloys — Seamless, round copper tubes for water and gas in sanitary and

heating applications

EN 13203-2, Gas-fired domestic appliances producing hot water — Part 2: Assessment of energy

consumption

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions,

tolerances and designation

ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions,

tolerances and designation

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13203-2 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

combination boiler

boiler designed both for central heating and for the production of domestic hot water

Note 1 to entry: Depending on its type of domestic hot water production, the combination boiler is classed as

follows, in accordance with the manufacturer’s declaration.

3.1.1

instantaneous type

combination boiler which can continuously supply the specific domestic hot water rate “D” stated by the

manufacturer

3.1.2

storage type

combination boiler which can intermittently supply the specific domestic hot water rate “D” stated by

the manufacturer

3.2

“summer” operating mode

operating mode in which the boiler only provides heating of the domestic water

3.3

specific rate

D

domestic hot water rate declared by the manufacturer, corresponding to a mean temperature rise of

30 K, that the boiler can supply in two successive delivery periods (in l/min)

3.4

nominal domestic hot water heat input

Q

nw

value of the heat input in the domestic hot water mode indicated by the manufacturer (in kW)

3.5

maximum water service pressure

PMS

maximum pressure permitted in the domestic water circuit, as declared by the manufacturer (in bar)

3.6

tank

reservoir of domestic water

3.7

thermal store

heat reservoir sited mainly in heating water, as opposed to the domestic hot water storage in the tank

3.8

pressure relief valve

valve that opens automatically at a given pressure to discharge hot water

3.9

thermostatic control of the domestic hot water operation

means of control in which the fuel rate is subordinated to a thermostatic device controlling the

domestic hot water temperature, the set point of the device may be adjustable

3.10

temperature holding thermostat

device which maintains the water in the tank or the thermal store at a given temperature

3.11

low inertia thermometer

measuring instrument with a response time such that 90 % of the final temperature rise, in the range

15 °C to 100 °C, is obtained within 5 s when the sensor is plunged into still water

3.12

nominal domestic hot water input

Q

nw

value of the heat input for the production of domestic hot water stated in the instructions (in kW)

3.13

summer mode

conditions during which the appliance supplies energy only for the production of domestic hot water (is

also domestic hot water mode)

3.14

winter mode

conditions during which the combination boiler supplies energy for the production of domestic hot

water and space heating (the appliance produces domestic hot water and central heating hot water

simultaneously with a priority for domestic hot water production)

Note 1 to entry: A water heater operates always in summer mode, while a combination boiler operates in

summer and winter modes.

3.15

domestic water test temperature

temperature of the delivered water at which the tests are conducted

3.16

control cycle

time cycle for keeping components and/or the storage tank (if any) of the domestic hot water circuit at

predetermined temperature level

Note 1 to entry: It consists of an "ON" duration time during which the heating of the domestic hot water (by

liquid fuel and/or auxiliary energy) and an "OFF" duration time.

3.17

useful water

quantity of water delivered at the tap for which the temperature rise above the inlet water temperature

is in accordance with the requirement fixed for each individual delivery of the tapping cycles

3.18

wasted water

quantity of water delivered at the tap for which the temperature rise above the inlet water temperature

is not in accordance with the requirement fixed for each individual delivery of the tapping cycles

3.19

standby mode

operating state in which the appliance can provide domestic hot water at any time

Note 1 to entry: In the case of an appliance with a control cycle for keeping components and/or the storage tank

(if any) of the domestic hot water circuit at predetermined temperature level no tapping is made.

3.20

off mode

state of an appliance, selected by the user, in which domestic hot water cannot be provided

3.21

useful water flow rate

flow rate of water delivered at the tap for which the temperature rise above the inlet water temperature

is in accordance with the requirement fixed for each individual delivery of the tapping cycles

3.22

useful water temperature

water temperature, expressed in degrees Celsius, delivered at the tap

Note 1 to entry: Tap at the exit of the appliance.

3.23

appliance flow rate

flow rate delivered by the appliance before the mixing device, if applicable

3.24

appliance water temperature

water temperature, expressed in degrees Celsius, delivered by the appliance before the mixing device

4 Constructional requirements

4.1 General

It is checked that the assembly meets the constructional requirements by visual examination of the

boiler or the water heater and possibly the tank, and also by inspection of the technical file.

4.2 Materials and method of construction of components of the domestic water circuit

Materials shall be appropriate for their use, under intended application and at the maximum water

pressure stated by the manufacturer.

The requirements relating to thermal insulation and its use specified in the standards about boilers only

apply to parts of the domestic water circuit likely to come into contact with flames or sited close to the

combustion products outlet.

The materials of the parts containing domestic water shall not affect the quality of the domestic water

in respect of either health or taste.

The whole of the domestic hot water circuit shall be made up of corrosion resistant materials or shall be

protected against corrosion.

4.3 Domestic water connections

Threaded connections shall comply with ISO 228-1 or ISO 7-1.

If copper tubes are used for the connection, the end of the tube shall comply with EN 1057.

In accordance with the manufacturer’s instructions, the domestic water circuit shall be able to be

drained, without the discharge of water compromising electrical safety.

4.4 Soundness of the domestic water circuit

The domestic hot water circuit and the heating circuit shall be separate. If an actuator or a control has a

sliding shaft or a link with the diaphragm separating the heating water circuit and the domestic water

circuit there shall be an air vent between these circuits. The area of this aperture shall be at least

19 mm and it shall be possible to introduce a 3,5 mm pin gauge into it.

4.5 Adjusting, control and safety devices for the domestic hot water circuit

The domestic hot water circuit shall be fitted with control and safety devices necessary to comply with

the requirements “Temperature sensing control type TR and temperature sensing control type STB” of

EN 303-1:2017, 4.1.2.6.

The tank shall be fitted with a device for controlling the water temperature. This device shall allow a

temperature to be attained which is sufficient to prevent the build-up of bacteria (see 5.2.3.3).

When local installations require a temperature relief valve operating at 100 °C, any device controlling

the temperature of the domestic hot water shall act before this valve.

5 Operational requirements

5.1 General

If the nominal heat input in domestic hot water mode exceeds the nominal heat input in the central

heating mode, the combination boiler shall be tested according to the EN 303-2 at the nominal heat

input in the domestic hot water mode.

A combination boiler certified with an atomizing oil burner will also meet the requirements of this

standard if the same boiler is fixed with a forced draught burner for gaseous fuels.

5.2 Safety of the domestic hot water circuit

5.2.1 Instantaneous and storage types

5.2.1.1 Soundness of parts containing domestic water

Under the test conditions of 6.2.1.1, the parts containing domestic water shall withstand the test

pressure without permanent distortion or soundness defects, with respect to the outside or the heating

circuit.

5.2.1.2 Overheating of the domestic hot water by the heating circuit

Under the test conditions of 6.2.1.2, the domestic hot water temperature shall not exceed 95 °C.

5.2.1.3 Failure of the domestic hot water temperature control device

Under the test conditions of 6.2.1.3, in the domestic water mode and in the event of failure of the normal

control the requirements for safety limiter (see EN 303-1:2017, 4.1.2.6) concerning the limit thermostat

or the safety temperature limiter shall be met.

5.2.2 Instantaneous type

5.2.2.1 Maximum domestic hot water temperature

Under the test conditions of 6.2.2.1, the domestic hot water temperature shall not exceed 95 °C.

5.2.2.2 Overheating of the domestic hot water

Under the test conditions of 6.2.2.2, the domestic hot water temperature shall not exceed 95 °C.

5.2.3 Storage type

5.2.3.1 Maximum temperature of the domestic hot water

Under the test conditions of 6.2.3.1, the domestic hot water temperature shall not exceed 95 °C.

5.2.3.2 Overheating of the domestic hot water

Under the test conditions of 6.2.3.2 for boilers in which part of the tank is in contact with products of

combustion, the domestic hot water temperature shall not exceed 95 °C.

5.2.3.3 Temperature of the domestic hot water

Under the test conditions of 6.2.3.3, it shall be possible to adjust to or obtain a domestic hot water

temperature of at least 60 °C in the tank.

5.3 Rational use of energy

The considered useful efficiency is that measured in the central heating mode.

5.4 Fitness of purpose

5.4.1 Instantaneous and storage types — Specific water rate

Under the test conditions of 6.4.1, the measured value of the specific rate shall not be more than 5 %

below the value D stated by the manufacturer on the data plate.

5.4.2 Instantaneous type

5.4.2.1 Nominal domestic hot water heat input

Under the test conditions of 6.4.3.1, the nominal domestic hot water heat input shall be obtained or may

be adjusted to within ±5 %.

5.4.2.2 Water pressure to obtain the nominal heat input

Under the test conditions of 6.4.3.2, the heat input obtained shall be at least 95 % of the heat input

obtained in 6.4.3.1.

5.4.2.3 Obtaining the domestic hot water temperature

Under the conditions of 6.4.3.3, it shall be possible to achieve or adjust to a water rate that corresponds

to a temperature of between 50 °C and 80 °C for boilers with a thermostatic control or a temperature

rise at the boiler outlet of between 45 K and 65 K for boilers with proportioning control.

5.4.2.4 Heating-up time of the domestic hot water

Under the test conditions of 6.4.3.4, the heating-up time shall not exceed 2 min.

6 Test methods

6.1 General

6.1.1 Test conditions

Unless otherwise specified, the general test conditions of the standards about boilers are supplemented

as stated below:

— cold water: (10 ± 2) °C;

— hot water: 50 °C or as near as possible;

— central heating water (if necessary): see standards about boilers (flow 80 °C − return 60 °C).

For the tests:

— the domestic water pressure is the difference between the static inlet and outlet pressures of the

boiler measured as close as possible to the boiler;

— the inlet and outlet temperatures of the domestic water are measured in the centre of the flow and

as close as possible to the boiler.

In certain tests, a low inertia thermometer is used.

6.1.2 Adjustment of the domestic water pressure

The domestic water pressure shall be adjusted to the required value within a tolerance of ±4 %.

6.1.3 Operation of the boiler

Except where otherwise specified, the tests are carried out with the boiler operating in the domestic

water mode and the “summer” operating mode.

6.2 Safety of the domestic hot water circuit

6.2.1 Instantaneous and storage types

6.2.1.1 Soundness of the parts containing domestic water

The domestic water circuit is subjected to a pressure of 1,5 times the maximum pressure given on the

data plate for 10 min.

It is checked that the requirements of 5.2.1.1 are met.

6.2.1.2 Overheating of the domestic hot water by the central heating circuit

The central heating circuit thermostat is set at its maximum position.

The appliance operates continuously for one hour at the nominal heat input in the central heating mode,

without drawing domestic hot water. A draw off at the specific rate D is then carried out and the

requirement of 5.2.1.2 is checked.

6.2.1.3 Failure of the domestic hot water temperature control device

To check the requirements of 5.2.1.3, the draw off domestic water rate is progressively reduced after

having put out of action the adjusting control of the domestic water circuit, in accordance with the test

methods relating to the limit thermostat or the temperature limiter with the boiler operating at its

maximum heat input.

6.2.2 Instantaneous type

6.2.2.1 Maximum temperature of the domestic hot water

The boiler is operated at the nominal domestic hot water heat input with a domestic water supply

pressure of 2 bar.

Starting with this 2 bar supply pressure, the pressure is progressively reduced until the burner is

extinguished. The water outlet temperature is measured continuously with a low inertia thermometer.

The maximum temperature is measured and shall satisfy the requirements of 5.2.2.1.

6.2.2.2 Overheating of the domestic hot water

The boiler is operated at the nominal domestic hot water heat input, where appropriate. The water rate

and any water temperature control are adjusted to obtain the maximum water temperature at the

nominal domestic hot water heat input.

After the boiler has operated for 10 min, the hot water delivery tap is turned off quickly. After 10 s the

tap is turned on quickly and the highest temperature at the centre of the flow, as close as possible to the

boiler outlet, is measured by means of a low inertia thermometer. The boiler remains in operation until

it has again reached its steady-state condition. The same measurements are made during similar

operating cycles, but with the time that the draw off is stopped increased each time by 10 s, until the

maximum temperature is obtained.

It is checked that the requirement of 5.2.2.2 is met.

6.2.3 Storage type

6.2.3.1 Maximum temperature of the domestic hot water

The boiler is operated at the nominal domestic hot water heat input with the domestic water

thermostat at its maximum position. A draw off is carried out after a shut-down of the burner. The

maximum temperature measured shall meet the requirement of 5.2.3.1.

6.2.3.2 Overheating of the domestic hot water

The test starts after the tank or the thermal store has reached temperature and after the burner has

been shut down a second time by the controls. Water is drawn off several times at a rate corresponding

to 5 % of the water capacity of the tank, in litres per minute.

On each occasion, water is drawn until the burner ignites and at least 95 % of the nominal domestic hot

water heat input is obtained. The next draw off then takes place immediately after the burner shuts

down, and so on until the maximum temperature is obtained.

For modulating burners or multi-stage burners, the following draw off takes place when the fuel rate

has decreased at least to 50 % of the maximum domestic hot water heat input reached.

At the start of each draw off, the temperature of the delivered water is measured and it is checked that

the requirement of 5.2.3.2 is met.

6.2.3.3 Temperature of the domestic hot water

Where applicable, the adjuster is placed in the position stated by the manufacturer. After a controlled

shutdown of the boiler, a draw off is carried out for 10 min at a rate equivalent to 5 % of the water

capacity of the tank per minute or at the minimum rate stated by the manufacturer which allows burner

ignition if this is greater than 5 % of the capacity of the tank per minute. After 1 min, it is checked that

the requirements of 5.2.3.3 are met.

6.3 Rational use of energy

6.3.1 Useful efficiency

The test is carried out in the central heating mode in the relevant boiler standards.

6.3.2 Losses

6.3.2.1 General

Depending on the way in which hot water is produced, the requirement of 5.3 is checked under the test

conditions defined below.

6.3.2.2 Tank which can be disconnected from the boiler

6.3.2.2.1 General

The losses from the boiler/tank assembly are determined by adding up the losses from the boiler and

the tank.

The manufacturer states how the tank shall be separated from the boiler, and which pipework shall be

taken into account in the boiler losses and which will be counted with the tank.

6.3.2.2.2 Boiler

For the boiler, the losses (standby losses) are measured according to EN 304.

The heat exchanger for the tank is disconnected from the boiler.

Also, where the boiler and the tank are coupled within the same case, the losses from the boiler alone

are measured with the tank empty.

6.3.2.2.3 Tank

For the tank, the following mode of operation is used:

If the tank and the boiler are coupled within the same case, the losses from the tank alone are

determined with the boiler empty.

a) Preliminary conditions

The test is carried out with a rig equivalent to that described in Figure 1, in a room where the ambient

temperature is between 15 °C and 25 °C, with a permitted temperature variation of ±5 °C during the

test.

The installation includes an electrical resistance and a circulating pump (long circuit of Figure 1).

Before the test is carried out, the tank is placed in the position recommended by the manufacturer. For

a tank with two positions, vertical or horizontal, the test is done in the vertical position.

It is filled with water heated to a temperature of (65 ± 2) °C by circulation in a closed circuit, having the

tank and its exchanger in series. The tank domestic water temperatures are deemed to have reached

uniformity at the moment t that circulation stops, if the following conditions are met:

— the difference between the domestic water outlet temperature (T ) and the domestic water inlet

s

temperature (T ) remains less than 1 K continuously for the 15 min before moment t ;

e 1

— the inlet temperature (T ) has not changed by more than 1 K during this period.

e

It is assumed that the mean water temperature (T ) of the tank at moment t is equal to the arithmetic

o 1

mean of the inlet and outlet temperatures at that moment:

T ⋅ T

es

T = (1)

o

The preliminary conditions are met if this temperature T is equal to (65 ± 2) °C.

o

b) Cooling of the tank and determination of the corrected final mean temperature (Tfc)

At moment t , valves 2 and 3 of Figure 1 are shut off, and all the water connections are disconnected

and sealed at valves 2 and 3.

The parts of the pipework external to the tank shall be carefully insulated so that the heat losses

attributable to them are negligible compared to the losses from the tank.

The tank is left to cool for a measured time of ±20 min (moment t ). The ambient temperature is

measured at least every hour and the arithmetic mean (T ) calculated.

amb

The final mean water temperature (T ) of the tank at moment t is determined by the following method:

f 2

— the connections of the short circuit of Figure 1 are remade and the circulating pump is put into

operation;

— the mean water temperature of the tank at moment t is that obtained after stabilization when the

temperature difference between the inlet and outlet is less than 1 K. The re-circulation time is taken

into account in the cooling time;

— the corrected final mean water temperature (T ) of the tank is calculated by taking account of the

fc

water mass and water temperature of the test rig short circuit. This connecting circuit will be

designed such that the correction to the final temperature is less than 0,5 K for a tank of capacity

exceeding 50 l and 1 K for a tank of capacity less than 50 l.

The corrected final mean water temperature (T ) of the tank is calculated as follows:

fc

VT ⋅ + m ⋅= T V +m ⋅ T (2)

( ) ( )

( )

fc b a b f

when

V+−m T m T

( ) ( )

b f ba

(3)

T =

fc

V

where

T is the corrected final mean water temperature, in degrees Celsius (°C);

fc

T is the mean water temperature of the tank measured at the final moment t , in degrees Celsius (°C);

f 2

T is the ambient temperature at moment t , in degrees Celsius (°C) (assuming that at the end of 24 h the

a 2

short circuit is at ambient temperature);

V is the water capacity of the tank (including the water in any integral heat exchanger), in litres (l). This

value is declared by the manufacturer and checked from the drawings; it is also the mass

m is the mass of water in the connecting short circuit of the test rig, in kilograms (kg).

b

The density of water is taken to be 1 000 kg/m .

c) Calculation of the losses of the tank

The value of the losses of the tank is given by the following relationship:

−3

4 186× 10

( ) T − T

( )

V

o amb

q ×× ln × 45 (4)

a45

3 600

tt−−T T

( ) ( )

2 1 fc amb

or

T − T

( )

V o amb

−3

(5)

q= 52,33××10 × ln

( )

a45

tt−−T T

( ) ( )

2 1 fc amb

where

q are the losses of the tank for a temperature rise of 45 K, in kilowatts (kW);

a45

t − t is the period of cooling, in hours (h);

2 1

T is the mean water temperature of the tank at moment t , in degrees Celsius (°C);

o 1

T is the corrected mean water temperature of the tank at moment t , in degrees Celsius (°C);

fc 2

T is the mean ambient temperature during cooling, in degrees Celsius (°C);

amb

V is the water capacity of the tank (including the water in any integral heat exchanger), in litres (l).

This value is declared by the manufacturer and checked from the drawings.

6.3.2.3 Tank or thermal store which is integral with and cannot be separated from the boiler

The losses for the boiler tank or the boiler thermal store assembly are determined as stated for the

boiler alone in EN 304, or for a difference between the temperature declared by the manufacturer in

6.4.1 and the ambient temperature if this difference is greater than 45 K.

For this test, the tank and its exchanger (if appropriate) are connected in series with the boiler.

6.4 Fitness for purpose

6.4.1 Instantaneous and storage types — Specific water rate

The boiler is operated at the nominal domestic hot water heat input with an inlet water pressure of

2 bar.

The domestic hot water temperature is adjusted, where possible, to obtain an average temperature rise

as close as possible to 30 K which permits the nominal domestic hot water heat input to be obtained.

Before the test, the boiler is in the “summer” operating mode, at thermal equilibrium, without any draw

off.

For storage type boilers, the setting of the domestic hot water thermostat is adjusted to 65 °C or the

value stated by the manufacturer for boilers with integral, non-disconnectable tanks. If by design, the

65 °C temperature cannot be achieved, the test is carried out at the closest possible temperature to

65 °C. The first draw off is carried out no earlier than the second controlled shut down of the burner

and lasts 10 min. The temperature and the water rate are recorded.

The test follows the sequence:

— water delivery of 10 min duration;

— 20 min period of no water delivery;

— further water delivery of 10 min duration.

=

Measurements of temperature and flow rate shall be made and recorded, at intervals not exceeding 2 s.

A plot of temperature against time is made to obtain the mean water temperature rise during each

delivery.

For each delivery the following shall be calculated by the formula:

m

i 10

( )

∆T

D ⋅ (6)

i

10 30

where

D is the calculated rate for each delivery; D and D are determined respectively during the first and

i 1 2

second deliveries, in litre per minute (l/min);

m is the quantity of water collected during the first or second delivery with a minimum temperature

i(10)

rise of 30 K, in litre (l);

ΔT is the mean temperature rise of the collected water, in Kelvins (K), during the first and second

deliveries.

If the difference between D and D does not exceed numerically 10 % of their average value then

1 2

D + D

1 2

D= (7)

where D is the determined specific rate.

If the difference between D and D exceeds numerically 10 % of their average value, then D is the

1 2

lower value.

The kitchen specific rate shall be calculated by the formula:

D D⋅ (8)

c

NOTE When the water temperature is adjustable, additional measurement of the specific rate with a delivery

temperature can be specified by the appliance documentation.

6.4.2 Tapping capability

6.4.2.1 Requirements

The appliance shall be capable of delivering water at the rate stated in the appliance documentation

with a temperature rise not less than 30 K, for the standard time of 10 min and continuously. Additional

flow rate times of 5 min and 20 min can be used in accordance to the appliance documentation.

The tapping capability corresponding to these time periods shall be available to the consumer.

The measured tapping capability shall not be more than 5 % below the value stated by the appliance

documentation.

=

=

6.4.2.2 Test method

The appliance shall be adjusted to deliver water at the flow rate and temperature stated by the

appliance documentation for this test.

The pressure loss across the appliance shall not exceed 2 bar.

Before starting the tapping test, the appliance shall be in the initial state conditions and in the initial

adjustment conditions defined in 7.3.4 and 7.3.5. The flow rate and temperature of the delivery are

recorded at intervals not exceeding 2 s. The domestic water mean temperature is calculated.

Tapping capability shall be measured during the standardized times 10 minutes and continuously (with

the additional options of 5 min and/or 20 min).

For the test with a non-continuous delivery, the test shall be run for the standardized time(s) with a

tolerance of ±30 s. During the test, the temperature rise shall not fall below 30 K.

The tapping capability shall be calculated by the formula:

∆T

t

a

RR ⋅⋅ (9)

s

30 t

t

where

t is the time recorded during the test;

t is the standardized time;

t

ΔT is the mean water temperature increase (3.17);

a

R is the water rate stated by the appliance documentation;

R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...