EN 15152:2019

(Main)Railway applications - Windscreens for trains

Railway applications - Windscreens for trains

This document specifies the functional requirements for rail vehicle windscreens, including type testing, routine testing and inspection methods for high speed rail, heavy rail, light rail and metro applications.

This document is also applicable for tram vehicles.

For on-track machines (OTMs) when in transport mode (self-propelled or hauled) the requirements of this standard are applicable. OTMs in working configuration are outside the scope of this document.

Determination of the size, shape, orientation and position of windscreens is outside the scope of this document. These data form part of the windscreen technical specification.

This document applies to windscreens made of laminated glass, which is the most commonly used material but also to other materials, subject to the performance requirements being satisfied.

This document does not specify requirements for the interfaces between the windscreen and the vehicle. Accordingly this document does not address issues relating to: installation, structural integrity and crashworthiness.

Bahnanwendungen - Frontscheiben für Schienenfahrzeuge

Dieses Dokument legt die funktionellen Anforderungen für Frontscheiben in Schienenfahrzeugen fest, einschließlich Typprüfung, Serienprüfung und Untersuchungsverfahren für Hochgeschwindigkeits-, Voll-bahn-, Light Rail- und Untergrundbahnanwendungen.

Dieses Dokument ist auch für Straßenbahnfahrzeuge anwendbar.

Für Gleisbaumaschinen (OTM, en: on-track machines) sind die Anforderungen dieser Norm anwendbar, wenn sie im Transportmodus sind (selbstangetrieben oder geschleppt). Gleisbaumaschinen im Arbeits-modus fallen nicht in den Anwendungsbereich dieses Dokuments.

Die Bestimmung von Größe, Form, Ausrichtung und Position von Frontscheiben fällt nicht in den Anwendungsbereich dieser Norm. Diese Angaben sind Teil der technischen Spezifikation der Frontscheiben.

Dieses Dokument gilt für Frontscheiben aus Verbundglas, dem am häufigsten verwendeten Material, aber auch für andere Materialien, mit denen die Anforderungen an die Frontscheibe erfüllt werden können.

Dieses Dokument legt keine Anforderungen für die Schnittstellen zwischen Frontscheibe und Fahrzeug fest. Folglich behandelt dieses Dokument nicht Themen der Installation, der Fahrzeugstruktureigenschaften und des Crashverhaltens.

Applications ferroviaires - Vitres frontales pour véhicules ferroviaires

Le présent document spécifie les exigences fonctionnelles relatives aux vitres frontales des véhicules ferroviaires, y compris les essais de type, les essais de série et les méthodes d'examen associées pour les trains à grande vitesse, les véhicules ferroviaires lourds, les véhicules ferroviaires légers et les métros.

Le présent document est également applicable aux tramways.

Pour les engins de voie (OTM, On Track Machine) en mode transport (machines automotrices ou remorquées), les exigences de la présente norme sont applicables. Les engins de voie en configuration de travail ne relèvent pas du domaine d'application du présent document.

La détermination des dimensions, de la forme, de l'orientation et de la position des vitres frontales ne relève pas du domaine d'application de la présente norme. Ces données sont indiquées dans la spécification technique de la vitre frontale.

Le présent document s'applique aux vitres frontales composées de verre feuilleté (matériau le plus couramment utilisé), mais aussi à d'autres matériaux sous réserve qu'ils respectent les exigences de performances.

Le présent document ne spécifie pas les exigences relatives aux interfaces entre la vitre frontale et le véhicule. Par conséquent, le présent document ne traite pas des questions relatives à l’installation, l'intégrité structurelle et à l'aptitude à la collision.

Železniške naprave - Vetrobranska stekla za vlake

Ta evropski standard določa funkcionalne zahteve za vetrobranska stekla za vlake, vključno s tipskim preskušanjem, rutinskim preskušanjem in metodami nadzora.

Zahteve iz tega standarda se uporabljajo za tirne stroje (OTM), ko so v načinu transporta (samognani ali vlečeni). Področje uporabe tega standarda ne zajema tirnih strojev v delovni konfiguraciji.

Določanje velikosti, oblike, usmerjenosti in položaja vetrobranskega stekla ne spada na področje uporabe tega dokumenta. Ti podatki so del tehnične specifikacije za vetrobranska stekla.

Ta dokument se uporablja za vetrobranska stekla iz lepljenega stekla, ki je najpogosteje uporabljen material, in tudi drugih materialov, ki morajo izpolnjevati zahteve glede zmogljivosti.

Ta dokument ne določa zahtev za vmesnike med vetrobranskim steklom in vozilom. Skladno s tem ta dokument ne obravnava vprašanj v zvezi s strukturno celovitostjo in zagotavljanjem pasivne varnosti pri trčenju.

General Information

- Status

- Withdrawn

- Publication Date

- 13-Aug-2019

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/WG 49 - Glazing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Dec-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 15-Aug-2012

- Effective Date

- 01-Nov-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO/CIE 11664-2:2022 - Colorimetry - Part 2: CIE standard illuminants (ISO/CIE 11664-2:2022) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 15152:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Windscreens for trains". This standard covers: This document specifies the functional requirements for rail vehicle windscreens, including type testing, routine testing and inspection methods for high speed rail, heavy rail, light rail and metro applications. This document is also applicable for tram vehicles. For on-track machines (OTMs) when in transport mode (self-propelled or hauled) the requirements of this standard are applicable. OTMs in working configuration are outside the scope of this document. Determination of the size, shape, orientation and position of windscreens is outside the scope of this document. These data form part of the windscreen technical specification. This document applies to windscreens made of laminated glass, which is the most commonly used material but also to other materials, subject to the performance requirements being satisfied. This document does not specify requirements for the interfaces between the windscreen and the vehicle. Accordingly this document does not address issues relating to: installation, structural integrity and crashworthiness.

This document specifies the functional requirements for rail vehicle windscreens, including type testing, routine testing and inspection methods for high speed rail, heavy rail, light rail and metro applications. This document is also applicable for tram vehicles. For on-track machines (OTMs) when in transport mode (self-propelled or hauled) the requirements of this standard are applicable. OTMs in working configuration are outside the scope of this document. Determination of the size, shape, orientation and position of windscreens is outside the scope of this document. These data form part of the windscreen technical specification. This document applies to windscreens made of laminated glass, which is the most commonly used material but also to other materials, subject to the performance requirements being satisfied. This document does not specify requirements for the interfaces between the windscreen and the vehicle. Accordingly this document does not address issues relating to: installation, structural integrity and crashworthiness.

EN 15152:2019 is classified under the following ICS (International Classification for Standards) categories: 45.060.10 - Tractive stock. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15152:2019 has the following relationships with other standards: It is inter standard links to EN 15152:2007, EN 15152:2019+A1:2023, ISO 48:2010, EN 50155:2021, ISO 3537:2015, EN 50155:1995, EN 755-2:2016, EN 2155-9:1989, EN 1063:1999, EN ISO/CIE 11664-2:2022, EN ISO/CIE 11664-1:2019, EN 45545-2:2020+A1:2023, EN 1896:2001, EN ISO/CIE 11664-3:2019, EN ISO 4892-3:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15152:2019 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15152:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2019

Nadomešča:

SIST EN 15152:2007

Železniške naprave - Vetrobranska stekla za vlake

Railway applications - Windscreens for trains

Bahnanwendungen - Frontscheiben für Schienenfahrzeuge

Applications ferroviaires - Vitres frontales pour trains

Ta slovenski standard je istoveten z: EN 15152:2019

ICS:

45.060.10 Vlečna vozila Tractive stock

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15152

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2019

EUROPÄISCHE NORM

ICS 45.060.10 Supersedes EN 15152:2007

English Version

Railway applications - Windscreens for trains

Applications ferroviaires - Vitres frontales pour Bahnanwendungen - Frontscheiben für

véhicules ferroviaires Schienenfahrzeuge

This European Standard was approved by CEN on 17 June 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15152:2019 E

worldwide for CEN national Members.

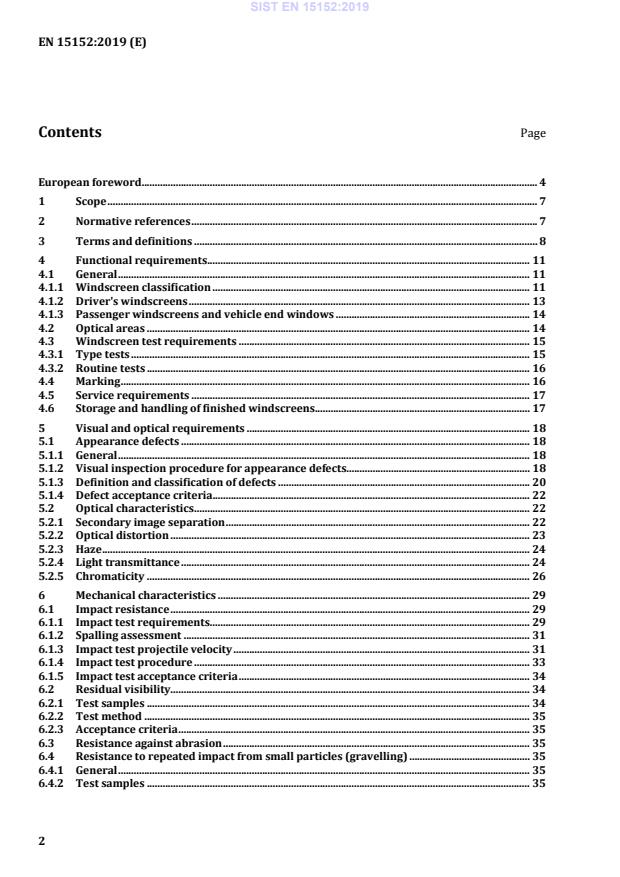

Contents Page

European foreword . 4

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Functional requirements. 11

4.1 General . 11

4.1.1 Windscreen classification . 11

4.1.2 Driver's windscreens . 13

4.1.3 Passenger windscreens and vehicle end windows . 14

4.2 Optical areas . 14

4.3 Windscreen test requirements . 15

4.3.1 Type tests . 15

4.3.2 Routine tests . 16

4.4 Marking . 16

4.5 Service requirements . 17

4.6 Storage and handling of finished windscreens. 17

5 Visual and optical requirements . 18

5.1 Appearance defects . 18

5.1.1 General . 18

5.1.2 Visual inspection procedure for appearance defects. 18

5.1.3 Definition and classification of defects . 20

5.1.4 Defect acceptance criteria . 22

5.2 Optical characteristics . 22

5.2.1 Secondary image separation . 22

5.2.2 Optical distortion . 23

5.2.3 Haze . 24

5.2.4 Light transmittance . 24

5.2.5 Chromaticity . 26

6 Mechanical characteristics . 29

6.1 Impact resistance . 29

6.1.1 Impact test requirements. 29

6.1.2 Spalling assessment . 31

6.1.3 Impact test projectile velocity . 31

6.1.4 Impact test procedure . 33

6.1.5 Impact test acceptance criteria . 34

6.2 Residual visibility. 34

6.2.1 Test samples . 34

6.2.2 Test method . 35

6.2.3 Acceptance criteria . 35

6.3 Resistance against abrasion . 35

6.4 Resistance to repeated impact from small particles (gravelling) . 35

6.4.1 General . 35

6.4.2 Test samples . 35

6.4.3 Test method . 36

6.5 Bullet resistance . 36

7 Performance in service . 37

7.1 Heating system . 37

7.1.1 General . 37

7.1.2 Heating uniformity . 37

7.1.3 Coating based heating systems . 38

7.1.4 Wire based heating systems . 38

7.1.5 Resistance measurement . 38

7.1.6 Voltage withstand test . 38

7.2 Resistance against ageing . 38

7.2.1 General . 38

7.2.2 Accelerated weathering test . 39

7.2.3 Thermal cycling . 39

7.2.4 Humidity test . 40

7.2.5 Windscreen heating test . 41

Annex A (normative) Determination of windscreen angles . 42

A.1 Determination of windscreen plan view angle . 42

A.2 Determination of the rake angle . 45

Annex B (normative) Transmittance calculation for inclined windscreen . 46

Annex C (normative) Windscreen test sample mounting . 49

Annex D (normative) Impact test projectile . 51

Annex E (normative) Gravelling test projectile . 53

Annex F (informative) Test samples . 54

F.1 Test sample properties . 54

F.2 Test sample for optical tests . 54

F.3 .Test sample for mechanical tests . 54

F.4 Test sample for ageing tests . 54

Annex G (normative) Summary of testing requirements . 55

Annex H (informative) Alternative method for testing resistance to Ultra Violet radiation . 56

H.1 General . 56

H.2 Test method . 56

H.3 Interpretation of results . 56

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2008/57/EC aimed to be covered . 57

Bibliography . 58

European foreword

This document (EN 15152:2019) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2020, and conflicting national standards

shall be withdrawn at the latest by February 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15152:2007.

In comparison with the previous edition, the following technical modifications have been made:

Clause/subclause/table/figure Change

Whole document and scope Introduction of urban rail requirements, requirements for

high speed trains and for certain types of OTMs

2 Normative references The normative references have been updated

3 Terms and definitions Creation of new definitions for different types of windscreen

and glazing (e.g lateral windscreens, passenger windscreens,

etc)

3 Terms and definitions New definitions for hotspots, heavy rail and light rail

4.1.1 Windscreen classifications New sub clause for the classification of windscreens into

different types: driver's windscreens, lateral windscreen,

passenger windscreen

4.2 Optical areas New definitions of different optical areas based on the types

of windscreens

4.3 Windscreen test requirements All the test requirements as well as test prescriptions have

been moved to the corresponding sub clauses

4.4 Marking Former 4.3.3 has been moved and modified

4.5 Service requirements New sub clause for in service requirements for windscreens

4.6 Storage and handling New sub clause for storage and handling requirements for

windscreens

5 Visual and optical requirements New clause created for visual and optical requirements in

order to separate them from functional requirements

5.1.2 Visual inspection procedure for appearance New sub clause with precise instructions for the inspection of

defects windscreens

5.1.3 Definition and classification of defects New criteria for defining defects and their tolerances

5.1.4 Defect acceptance criteria The notion of negligible, minor and major defects has been

replaced by the number of acceptable defects on a given

surface of the windscreen

5.2 Optical characteristics New sub clause assembling all the optical requirements as

well as the related measurement methods. Different

requirements for urban rail have been introduced

Clause/subclause/table/figure Change

6 Mechanical characteristics New clause assembling all the mechanical requirements for

windscreens. The clause has been editorially rearranged with

regards to the previous version

6.1.1 Impact test requirements Separate new requirements for the testing of high speed

trains. Temperature ranges for the test have been introduced.

The notion of testing at different angles (e.g 90° or at

installation angle) has been introduced

6.1.4 Impact test procedure The test procedure is now described in detail. Notably The

notion of testing at different angles (e.g 90° or at installation

angle) has been introduced

6.2 Residual visibility New requirement and associated test

6.4 Resistance to repeated impact from small Editorial rearrangement of the sub clause and introduction of

particles (gravelling) more precise test methods

6.5 Bullet resistance New requirement and associated test

7 Performance in service New clause assembling several requirements for heating

systems, for the resistance against ageing, the accelerated

weathering test, thermal cycling, etc. All the sub clauses have

been editorial reworked and more precise test methods have

been introduced

Annex A – Determination of windscreen angles New annex introduced to help the user determine the type of

the windscreen (e.g driver's windscreen, lateral windscreen,

etc)

Annex B – Transmittance calculation for inclined New annex explaining the calculation method for light

windscreens transmittance of windscreens at installation angle

Annex C – Windscreen test sample mounting New annex giving precise instructions for the installation of

test samples. The set up applies to impact and gravelling

tests

Annex D – Impact test projectile New, more precise criteria for the impact test projectile,

based on actual examples

Annex E – Gravelling test projectile New annex for the precise description of the gravelling test

projectile

Annex F – Test samples New annex with precise requirements for test samples used

in different tests throughout the document

Annex G – Summary of testing requirements Editorial rearrangement of the annex in order to take into

account all the changes made to the document

Annex ZA – Relationship between this European New Annex ZA

Standard and the Essential Requirements of EU

Directive 2008/57/EC aimed to be covered

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2008/57/EC.

For relationship with EU Directive 2008/57/EC, see informative Annex ZA, which is an integral part of

this document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies the functional requirements for rail vehicle windscreens, including type

testing, routine testing and inspection methods for high speed rail, heavy rail, light rail and metro

applications.

This document is also applicable for tram vehicles.

For on-track machines (OTMs) when in transport mode (self-propelled or hauled) the requirements of

this standard are applicable. OTMs in working configuration are outside the scope of this document.

Determination of the size, shape, orientation and position of windscreens is outside the scope of this

document. These data form part of the windscreen technical specification.

This document applies to windscreens made of laminated glass, which is the most commonly used

material but also to other materials, subject to the performance requirements being satisfied.

This document does not specify requirements for the interfaces between the windscreen and the

vehicle. Accordingly this document does not address issues relating to: installation, structural integrity

and crashworthiness.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 755-2:2016, Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 2:

Mechanical properties

EN 1063:1999, Glass in building - Security glazing - Testing and classification of resistance against bullet

attack

EN 2155-9, Aerospace series - Test method for transparent materials for aircraft glazing - Part 9 :

Determination of haze

EN 45545-2, Railway applications — Fire protection on railway vehicles – Part 2: Requirements for fire

behaviour of materials and components

EN 50155, Railway applications — Rolling stock — Electronic equipment

EN ISO 4892-3, Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps

(ISO 4892-3)

EN ISO 11664-1 (CIE S 014-1), Colorimetry — Part 1: CIE standard colorimetric observers (ISO 11664-1)

EN ISO 11664-2 (CIE, S 014-2), Colorimetry — Part 2: CIE standard illuminants (ISO 11664-2)

EN ISO 11664-3 (CIE, S 014-3), Colorimetry — Part 3: CIE tristimulus values (ISO 11664-3)

ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD

and 100 IRHD)

ISO 3537, Road vehicles — Safety glazing materials — Mechanical tests

ISO 3538:1997, Road vehicles — Safety glazing materials — Test methods for optical properties

ISO 6362-2:2014, Wrought aluminium and aluminium alloys — Extruded rods/bars, tubes and profiles —

Part 2: Mechanical properties

CIE 15:2004, Colorimetry, 3rd Edition

CIE 38:1977, Radiometric and photometric characteristics of materials and their measurement

CIE S 004, Colours of Light Signals

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

Note 1 to entry: Figure 1 shows examples of the different types of windscreen, bodyside windows and external

glazing.

3.1

glazing

glass or equivalent transparent material

3.2

windscreen

glazing in front of a driver or passengers through which the track ahead can be observed

3.2.1

driver's windscreen

windscreen used by a driver in service to observe the track and signals

3.2.2

side windscreen

additional glazing positioned at the side of a windscreen that is predominately positioned transversely

to the running direction

3.2.3

passenger windscreen

windscreen primarily for passenger use in the leading ends of rail vehicles

Can be obtained from: International Commission of Illumination, CIE Central Bureau, Kegelgasse 27, A-1030

Wien.

a) light rail b) heavy rail

Key

1 driver's windscreen (3.2.1)

2 side windscreen (3.2.2)

3 bodyside window

4 external glazing (for example covers for lights, information displays)

Figure 1 — Windscreen, window and glazing definitions

3.3

primary vision area

area of the windscreen through which track and signals are visible from the driving position

Note 1 to entry: Defined as “vision area A” by EN 16186-1.

3.4

secondary vision area

area of the windscreen outside the primary vision area, through which the driver can also look from the

driving position

Note 1 to entry: Defined as “vision area B” by EN 16186-1.

3.5

peripheral area

area of the windscreen outside the secondary vision area

Note 1 to entry: The peripheral area includes any screen-printed areas.

3.6

secondary image separation

angular separation between the primary and the brightest secondary images (due to internal reflection)

of a distant light source or object when viewed through glazing

3.7

ultra-violet radiation

UV

electromagnetic radiation of a wavelength shorter than that of visible light

Note 1 to entry: For the purposes of this document, wavelength is between 200 nm and 380 nm.

3.8

spall

small glass particles which detach from the face of a window pane when it is subjected to impact on the

opposite side

Note 1 to entry: Spalling in this document describes the detachment of spall from the inside face of a

windscreen or window, when the outer face is subjected to impact.

3.9

hot-spot

highly localised area where the temperature deviates significantly from the area surrounding it

3.10

heavy rail

general purpose rail transport system for passengers and freight, for local, regional, long distance or

international traffic, accessible to all types of rail vehicles, subject to operational requirements

Note 1 to entry: Heavy rail passenger vehicles are generally structural categories P-I or P-II (in accordance with

EN 12663-1) and crashworthiness category C-I (in accordance with EN 15227).

Note 2 to entry: Does not include metro, light rail or tramway systems

3.11

light rail

urban and/or suburban rail transport system (excluding metros), typically only for passengers

Note 1 to entry: Light rail vehicles are generally structural categories P-III, P-IV or P-V (in accordance with

EN 12663-1) and crashworthiness categories C-III or C-IV (in accordance with EN 15227).

Note 2 to entry: Light rail systems typically have their own right of way or share it with road traffic and usually

do not exchange vehicles with long-distance passenger or freight traffic.

3.12

metro

high-capacity public transport system generally found in urban areas, operated on a dedicated railway

infrastructure

Note 1 to entry: Metro vehicles are generally structural categories P-III or P-IV (in accordance with

EN 12663-1) and crashworthiness category C-II (in accordance with EN 15227).

Note 2 to entry: Metro systems typically have their own right of way with no level crossings and no interface

with road traffic and usually do not exchange vehicles with long-distance passenger or freight traffic.

3.13

tramway

rail system exclusively or predominately for passengers, which typically operates in areas accessible to

the public and road traffic and where the speed of the vehicles is limited to enable the driver to stop

within the distance they can see to be clear ahead

Note 1 to entry: Tramway vehicles are generally structural categories P-IV or P-V (in accordance with

EN 12663-1) and crashworthiness category C-IV (in accordance with EN 15227).

3.14

technical specification

document describing specific parameters and/or product requirements as an addition to the

requirements of this standard

3.15

inspector

person with evidence of training, professional knowledge, skill and experience to enable the required

inspection(s) to be performed

3.16

seat reference point

SRP

reference point at the back pan of a new seat design with a horizontal distance of 135 mm and vertical

distance of 98 mm from the H point according to ISO 20176:2011

Note 1 to entry: See Figure 2 of EN 16186-1:2014+A1:2018.

[SOURCE, EN 16186-1:2014+A1:2018, 3.1.6, modified]

4 Functional requirements

4.1 General

4.1.1 Windscreen classification

Windscreens are positioned to allow observation of the track and signals ahead of a vehicle. Additional

side windscreens or windows may be provided to the side of the windscreen or windscreens (see

Figure 2).

Key

1 windscreen

2 side windscreen

3 side windscreen (cab window forward of seat reference point, see 4.1.2)

4 bodyside window

5 driver's seat (or passenger seats, for example in automatic vehicles)

6 seat reference point (SRP)

Θi, Θn plan view angles (for curved windscreens, values vary with position)

X direction of travel

Figure 2 — Windscreens and side windscreens

The classification of rail vehicle glazing (windscreens, side windscreens or bodyside windows) affects

the characteristics required and primarily depends on the orientation relative to the track. For the

determination of a windscreen’s orientation, only the parts of the glazing which if removed would

create an aperture in the structure of the vehicle and expose the occupants of a vehicle to the outside

shall be considered. Glazing that covers lights, information displays or extends over the structure for

aesthetic purposes is therefore excluded.

Except when the requirements for driver’s cabs apply (see 4.1.2), where the projected forward facing

area determined according to Annex A is less than or equal to 0,065 m , the glazing shall be considered

to be a bodyside window and therefore outside the scope of this document.

For windscreens that can be considered to be forward facing (including those which are not required or

intended for direct observation of the track and signals) the maximum and minimum plan view angles,

Θ (See Figure 2), shall be determined according to Annex A.

For driver's windscreens, with a central driving position, the plan view angle, Θ may be assumed to

be = 0°.

The maximum and minimum rake angles Φ shall be determined according to Annex A.

For curved windscreens the method set out in Annex A should be followed for the determination of plan

view and rake angles.

The maximum and minimum installation angles Ψ shall be determined from the maximum and

minimum plan view angles Θ and the maximum and minimum rake angles Φ using the relation

cos(Ψ) = cos(Θ).cos(Φ).

The maximum and minimum windscreen plan view angles, rake angles and installation angles shall

form part of the specification for manufacture and testing.

Where samples are used to determine optical properties, the maximum installation angle shall be used

(see for example 5.2).

Where samples are used to determine mechanical properties such as impact resistance, the minimum

installation angle shall be used (see for example 6.1).

4.1.2 Driver's windscreens

All windows in driver’s cabs that are fully or partially in front of the driver’s seat reference point (SRP),

measured in the longitudinal direction shall be considered as windscreens or side windscreens (see

Figure 2).

Where two, or more, windscreens are fitted (for example two on either side of a cab end gangway) and

only one of which is required to be a driver’s windscreen, the requirements for driver’s windscreens

shall apply to both (or all) windscreens (see Figure 3).

For driver’s windscreens, the plan view angle shall be determined using the points defining the primary

vision area (see 4.2, see Zone A in Figure 4).

Key

1 leading vehicle (alternate cab types shown)

2 intermediate and/or end vehicles

3 driver's windscreen(s)

4 passenger windscreen

5 vehicle end windows

6 driver's cab partition wall

X direction of travel

Figure 3 — Windscreens and body end windows

4.1.3 Passenger windscreens and vehicle end windows

Windscreens or side windscreens that are only provided for observation by passengers shall be

referred to as passenger windscreens (see Figure 3).

NOTE Examples of passenger windscreens could be the leading end windows in fully automatic rail vehicles

or leading end windows in vehicles where the cab only uses part of the width allowing passenger access to the

remainder.

The following may be considered to be equivalent to bodyside windows and therefore outside the scope

of this document:

— forward facing vehicle end windows, located at an intermediate end of a vehicle, if they are shielded

by an adjacent vehicle from the risk of a direct longitudinal impact (see Figure 3);

— forward facing vehicle end windows, for example in body end doors, where people are not present

during operation;

— vehicle end windows that only face to the rear in normal service (see Figure 3).

4.2 Optical areas

A windscreen can be divided into a maximum of three optical areas as shown in Figure 4.

A primary vision area shall be defined for driver’s windscreens. The boundary between secondary and

peripheral areas shall form part of the windscreen technical specification.

For other types of windscreen and glazing in the scope of this document a primary vision area may not

be required and the boundaries between optical areas shall form part of the windscreen technical

specification.

Key

A primary vision area

B secondary vision area

C peripheral area

O assumed eye position

1 driver's sightlines

W, X, Y, Z sightline intersection points

Figure 4 — Windscreen optical areas

The four points W, X, Y and Z, shown on Figure 4, represent the intersections between the windscreen

and the driver’s sightlines. These points are joined by lines as shown in Figure 4 to define the primary

vision area.

The definition of the driver’s sightlines (for the observation of track and signals) is outside of the scope

of this document. Data to define these points shall form part of the windscreen technical specification.

NOTE For heavy rail applications, driver's sightlines are defined in EN 16186-1.

The peripheral area can be deliberately obscured (in whole or in part) e.g. by silk-screen printing for

any of the following reasons:

— elimination of distracting items from the field of vision;

— for windscreens that are bonded into position, to protect the bonded area from the effect of

ultraviolet (UV) radiation;

— aesthetic purposes.

If obscuration is used to protect bonded areas from UV degradation, the obscuration should not permit

more than 0,1 % of incident UV light to reach the bonded area.

4.3 Windscreen test requirements

4.3.1 Type tests

The windscreen design shall be validated by satisfactory completion of the assessments and tests for:

— appearance (see 5.1);

— secondary images (see 5.2.1);

— optical distortion (see 5.2.2);

— haze (see 5.2.3);

— transmittance (see 5.2.4);

— chromaticity (see 5.2.5);

— impact (including spalling) (see 6.1);

— residual visibility (6.2);

— abrasion resistance (see 6.3);

— gravelling (if required by the windscreen technical specification) (see 6.4);

— bullet resistance (if required by the windscreen technical specification) (see 6.5);

— heating (see 7.1);

— ageing (see 7.2).

For a passenger windscreens the following tests are optional:

— secondary images (see 5.2.1);

— haze (see 5.2.3);

— transmittance (see 5.2.4), a minimum transmittance of 40 % may be accepted;

— chromaticity (see 5.2.5).

If a windscreen is fitted with a heating device the following tests shall be repeated with the heating

device in use:

— secondary images (see 5.2.1);

— optical distortion test (see 5.2.2).

When type tests are repeated with the heating device in use:

— the heater shall be operated at its nominal voltage;

— thermal stabilization shall be reached before measurements are undertaken.

This requirement shall not apply to additional start-up heating provided for use on a stationary vehicle

to accelerate the removal of ice or snow.

Testing requirements are summarized in Annex G.

If a windscreen validated in accordance with this document is modified, where it can be shown, for a

given type test, that the required performance is not affected, a new type test may not be required.

4.3.2 Routine tests

Routine testing shall be undertaken during production on all windscreens for the following:

— appearance (see 5.1);

— optical distortion (see 5.2.2);

— heating (see 7.1).

Transmittance (see 5.2.4) and haze (see 5.2.3) shall be tested periodically at a frequency given in the

windscreen technical specification.

4.4 Marking

The windscreen shall be permanently marked. The marking shall be readable and visible from inside

the cab. The minimum height of characters shall be 4 mm.

The marking shall be outside of the primary vision area. If there are no conflicting requirements, it

should be in the upper right hand corner of the windscreen.

As a minimum, the following information shall be included in the marking:

— name or logo of windscreen supplier;

— date of manufacturing (month and the last two numerals of the year or a code by which this

information can be identified);

— unique identification number (part number and serial number);

— nominal voltage and type of current (AC or DC) of the heater (if applicable);

— total power of the heater (if applicable);

— the applicable version of this document, e.g. EN 15152:2019.

4.5 Service requirements

Windscreens shall be designed to withstand normal operational conditions, including induced static

and dynamic loadings and environmental conditions such as temperature and humidity, when installed

in a railway vehicle.

NOTE 1 Typically, reference is made to EN 50125-1 temperature classes T1, T2 or T3.

Requirements for use in a specific environment which are in addition to the requirements set out in this

document shall form part of the windscreen technical specification.

A heating system can be incorporated in a driver’s windscreen for de-icing and de-misting so that the

driver can maintain a clear external view in most weather and operating conditions. If such an integral

heating system is provided it shall satisfy the requirements set out in 7.1.

A heating device is required for driver’s windscreens in vehicles which conform to Directive

2008/57/EC.

If an anti-spall layer is used, it shall satisfy the fire safety requirements set out in EN 45545-2.

Driver’s windscreens, when impacted or cracked, shall have sufficient residual visibility to allow the

train to be moved, subject to operational rules. This requirement shall be deemed to be satisfied by

achieving the residual visibility requirements set out in 6.2.

NOTE 2 For heavy rail vehicles, requirements for cab layout that can affect windscreen design and installation

are set out in EN 16186-1.

NOTE 3 The mechanical strength of the windscreen installation is within the scope of the requirements that are

applicable for equipment attachments set out in EN 12663-1. In case a retaining bracket needs to be installed, a

calculation, to demonstrate the adequacy of the retaining bracket, might be required.

NOTE 4 The windscreen installation is within the scope of the requirements set out in EN 15227. These

requirements are for the prevention of intrusion by the windscreen and maintenance of survival space for the

driver in the event of a collision.

NOTE 5 The windscreen installation is in the scope of the fire safety requirements set out in EN 45545-2.

NOTE 6 For passenger windscreens, an anti-defenestration and containment test can be required by the

windscreen technical specification.

4.6 Storage and handling of finished windscreens

Windscreens should be stored in a well ventilated area, protected from the weather and out of direct

sunlight.

Flat windscreens should be stored on a solid base in a vertical orientation, inclined at a rake angle of

approximately 6 degrees. The windscreens should be continuously supported by brackets along each

edge. The supporting brackets should be covered with soft material to prevent damage.

Storage for curved windscreens should follow the same principles adapted for the specific geometry of

the product.

5 Visual and optical requirements

5.1 Appearance defects

5.1.1 General

Appearance defects (blemishes) are characteristics of one of the following elements of the windscreen

or the processes in its manufacture:

— glazing material(s);

— interlayer(s);

— assembly;

— handling;

— anti-spall layer, if fitted.

To ensure an acceptable quality of vision to the driver, windscreens shall be inspected according to the

procedure set out in 5.1.2. Any defects shall be classified according to 5.1.3 and the number and size of

such defects shall not exceed the limits listed in 5.1.4.

5.1.2 Visual inspection procedure for appearance defects

Windscreens shall be inspected in a darkened test chamber equipped with a vertical luminous screen.

The light from the luminous screen passing through the windscreen shall be used to determine by a

visual inspection if there are defects in the windscreen. If defects are found, their type and size shall be

recorded and the acceptability of the windscreen determined. The test arrangement is shown in

Figure 5.

Dimensions in metres

a) Top view b) View from the inspector's position

Key

A windscreen

B luminous screen

C inspector

Figure 5 — Device for checking the appearance, front view and top view

The luminous screen shall be NCS 7502-B grey or equivalent. The use of any other screen colour shall

be part of the windscreen technical specification.

The windscreen shall be assessed according to the following procedure:

— The windscreen shall be positioned vertically in front of the luminous screen at a distance of 3m.

For curved windscreens the distance shall be measured from the centre of the primary vision area.

The outside surface of the windscreen shall face the luminous screen.

— The glazing shall be clean, dry and free of deposits of material or fluid that could affect the

inspection.

— The residual lighting level in the test chamber, with the luminous screen power off, shall not be

greater than 60 lx measured at the inner face of the windscreen.

NOTE 60 lx is representative of the acceptable limit in the driver's cab.

— The luminous screen shall be lit to give it a uniform luminance of at least 500

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...