EN 14511-3:2007

(Main)Air conditioners, liquid chilling packages and heat pumps with electrically driven compressors for space heating and cooling - Part 3: Test methods

Air conditioners, liquid chilling packages and heat pumps with electrically driven compressors for space heating and cooling - Part 3: Test methods

This part of EN 14511 specifies the test methods for the rating and performance of air and water-cooled air conditioners, liquid chilling packages, air-to-air, water-to-air, air-to-water and water-to-water heat pumps with electrically driven compressors when used for space heating and cooling.

It also specifies the method of testing and reporting for heat recovery capacities, system reduced capacities and the capacity of individual indoor units of multisplit systems, where applicable.

This European Standard applies to factory made units that can be ducted.

This standard applies to factory made liquid chilling packages with integral condensers or for use with remote condensers.

This standard applies to factory-made units of either fixed capacity or variable capacity by any means.

Packaged units, single split and multisplit systems are covered by this standard. Single duct and double duct units are covered by the standard.

In the case of units consisting of several parts, the standard applies only to those designed and supplied as a complete package, except for liquid chilling packages with remote condenser.

This standard is primarily intended for water and brine chilling packages but can be used for other liquid subject to agreement.

This standard applies to air-to-air air conditioners which evaporate the condensate on the condenser side.

The units having their condenser cooled by air and by the evaporation of external additional water are not covered by this standard.

This standard does not apply to units using transcritical cycles, e.g. with CO2 as refrigerant.

Installations used for heating and/or cooling of industrial processes are not within the scope of this standard.

NOTE 1 Part load testing of units is dealt with in CEN/TS 14825.

NOTE 2 All the symbols given in this text should be used regardless of the language used.

Luftkonditionierer, Flüssigkeitskühlsätze und Wärmepumpen mit elektrisch angetriebenen Verdichtern für die Raumbeheizung und Kühlung - Teil 3: Prüfverfahren

Dieser Teil der EN 14511 legt die Prüfverfahren für die Einstufung und Leistung von luft- und wassergekühlten

Luftkonditionierern, Flüssigkeitskühlsätzen, Luft/Luft-, Wasser/Luft-, Luft/Wasser- und Wasser/Wasser-

Wärme-pumpen mit elektrisch angetriebenen Verdichtern für die Raumheizung und -kühlung fest.

Er legt ferner Verfahren fest zur Prüfung und Angabe von Wärmerückgewinnungsleistungen, systemreduzierten

Leistungen sowie der Leistung von Einzelgeräten von Multi-Split-Systemen für die Aufstellung im

Innenraum, soweit zutreffend.

Diese Europäische Norm gilt für fabrikmäßig zusammengebaute Geräte, die mit Luftkanalanschlüssen versehen

sein können.

Diese Norm gilt für fabrikmäßig zusammengebaute Flüssigkeitskühlsätze, die mit eingebauten Verflüssigern

oder mit getrennt angeordneten Verflüssigern betrieben werden.

Diese Norm gilt für fabrikmäßig zusammengebaute Geräte mit fest eingestellter oder durch beliebige Vorrichtungen

zu verändernder Leistung (variable Leistung).

Kompaktgeräte, Einzelgeräte in Split-Bauweise und Multi-Split-Systeme fallen unter den Anwendungsbereich

dieser Norm. Geräte mit Ein- und Zweikanalsystemen werden ebenfalls in dieser Norm behandelt.

Wenn die Geräte aus mehreren Teilen bestehen, gilt diese Norm mit der Ausnahme von Flüssigkeitskühlsätzen

mit getrennt angeordnetem Verflüssiger nur für die Teile, die als vollständige Baueinheit konstruiert

und geliefert werden.

Diese Norm gilt hauptsächlich für Wasser- und Solekühlsätze, kann jedoch bei Vereinbarung auf weitere

Flüssigkeitskühlsätze angewendet werden.

Diese Norm gilt für Luft/Luft-Luftkonditionierer, die das Kondensat auf der Verflüssigerseite verdampfen.

Geräte, deren Verflüssiger durch Belüftung und durch Verdampfung von zusätzlichem, von außen zugeführtem

Wasser abgekühlt wird, werden in dieser Norm nicht behandelt.

Diese Norm gilt nicht für Geräte, bei denen, z. B. mit CO2 als Kältemittel, der Kreisprozess transzyklisch betrieben

wird.

Anlagen für die Beheizun

Climatiseurs, groupes refroidisseurs de liquide et pompes à chaleur avec compresseur entraîné par moteur électrique pour le chauffage et la réfrigération des locaux - Partie 3 : Méthodes d'essai

La présente partie de lEN 14511 spécifie les méthodes dessai relatives à la détermination des caractéristiques

de performance des climatiseurs à condensation par air et à condensation par eau, des groupes refroidisseurs de

liquide et des pompes à chaleur air/air, eau/air, air/eau et eau/eau, avec compresseur entraîné par moteur

électrique, lorsquils sont utilisés pour le chauffage et la réfrigération des locaux.

Elle spécifie aussi la méthode dessai et de rapport pour les puissances calorifiques de récupération, les

puissances réduites de système et la puissance individuelle des unités intérieures des systèmes multi-split, le cas

échéant.

La présente Norme européenne sapplique aux appareils fabriqués en usine qui peuvent être raccordés.

La présente norme sapplique aux groupes refroidisseurs de liquide autonomes fabriqués en usine ou conçus

pour être utilisés avec des condenseurs fournis séparément.

La présente norme sapplique aux appareils fabriqués en usine de capacité fixe ou variable par tous moyens.

La présente norme couvre les systèmes monoblocs, à deux éléments séparés et multi-split. La présente norme

couvre les appareils à simple et à double raccordement.

Dans le cas dappareils à éléments séparés, la présente norme ne sapplique quaux appareils conçus et fournis

comme un ensemble, sauf pour ce qui concerne les groupes refroidisseurs de liquide avec condenseur séparé.

La présente norme est principalement destinée aux groupes refroidisseurs deau et deau glycolée mais peut être

utilisée, après accord, pour dautres liquides.

La présente norme sapplique aux climatiseurs air/air qui évaporent les condensats du côté condenseur.

La présente norme ne couvre pas les appareils ayant leur condenseur refroidi par air et par évaporation deau

dun circuit supplémentaire externe.

La présente norme ne couvre pas les appareils utilisant des cycles transcritiques, par exemple avec CO2

comme fluide frigorigène.

La présente norme ne sapplique

Klimatske naprave, enote za tekočinsko hlajenje in toplotne črpalke z električnimi kompresorji za segrevanje in hlajenje prostora - 3. del: Preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 27-Nov-2007

- Withdrawal Date

- 11-Oct-2011

- Technical Committee

- CEN/TC 113 - Heat pumps and air conditioning units

- Drafting Committee

- CEN/TC 113/WG 8 - Revision of existing standards

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Oct-2011

- Completion Date

- 12-Oct-2011

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 14511-3:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Air conditioners, liquid chilling packages and heat pumps with electrically driven compressors for space heating and cooling - Part 3: Test methods". This standard covers: This part of EN 14511 specifies the test methods for the rating and performance of air and water-cooled air conditioners, liquid chilling packages, air-to-air, water-to-air, air-to-water and water-to-water heat pumps with electrically driven compressors when used for space heating and cooling. It also specifies the method of testing and reporting for heat recovery capacities, system reduced capacities and the capacity of individual indoor units of multisplit systems, where applicable. This European Standard applies to factory made units that can be ducted. This standard applies to factory made liquid chilling packages with integral condensers or for use with remote condensers. This standard applies to factory-made units of either fixed capacity or variable capacity by any means. Packaged units, single split and multisplit systems are covered by this standard. Single duct and double duct units are covered by the standard. In the case of units consisting of several parts, the standard applies only to those designed and supplied as a complete package, except for liquid chilling packages with remote condenser. This standard is primarily intended for water and brine chilling packages but can be used for other liquid subject to agreement. This standard applies to air-to-air air conditioners which evaporate the condensate on the condenser side. The units having their condenser cooled by air and by the evaporation of external additional water are not covered by this standard. This standard does not apply to units using transcritical cycles, e.g. with CO2 as refrigerant. Installations used for heating and/or cooling of industrial processes are not within the scope of this standard. NOTE 1 Part load testing of units is dealt with in CEN/TS 14825. NOTE 2 All the symbols given in this text should be used regardless of the language used.

This part of EN 14511 specifies the test methods for the rating and performance of air and water-cooled air conditioners, liquid chilling packages, air-to-air, water-to-air, air-to-water and water-to-water heat pumps with electrically driven compressors when used for space heating and cooling. It also specifies the method of testing and reporting for heat recovery capacities, system reduced capacities and the capacity of individual indoor units of multisplit systems, where applicable. This European Standard applies to factory made units that can be ducted. This standard applies to factory made liquid chilling packages with integral condensers or for use with remote condensers. This standard applies to factory-made units of either fixed capacity or variable capacity by any means. Packaged units, single split and multisplit systems are covered by this standard. Single duct and double duct units are covered by the standard. In the case of units consisting of several parts, the standard applies only to those designed and supplied as a complete package, except for liquid chilling packages with remote condenser. This standard is primarily intended for water and brine chilling packages but can be used for other liquid subject to agreement. This standard applies to air-to-air air conditioners which evaporate the condensate on the condenser side. The units having their condenser cooled by air and by the evaporation of external additional water are not covered by this standard. This standard does not apply to units using transcritical cycles, e.g. with CO2 as refrigerant. Installations used for heating and/or cooling of industrial processes are not within the scope of this standard. NOTE 1 Part load testing of units is dealt with in CEN/TS 14825. NOTE 2 All the symbols given in this text should be used regardless of the language used.

EN 14511-3:2007 is classified under the following ICS (International Classification for Standards) categories: 23.120 - Ventilators. Fans. Air-conditioners. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14511-3:2007 has the following relationships with other standards: It is inter standard links to EN 14511-3:2004, EN 14511-3:2004/AC:2004, EN 14511-3:2011, CLC/TR 50600-99-1:2020, CLC/TS 50600-5-1:2023, CLC/TR 50600-99-1:2021, EN 12102:2008, EN 14511-3:2007/AC:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14511-3:2007 is associated with the following European legislation: EU Directives/Regulations: 2002/31/EC, 92/75/EEC; Standardization Mandates: M/274. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14511-3:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Luftkonditionierer, Flüssigkeitskühlsätze und Wärmepumpen mit elektrisch angetriebenen Verdichtern für die Raumbeheizung und Kühlung - Teil 3: PrüfverfahrenClimatiseurs, groupes refroidisseurs de liquide et pompes à chaleur avec compresseur entraîné par moteur électrique pour le chauffage et la réfrigération des locaux - Partie 3: Méthodes d'essaiAir conditioners, liquid chilling packages and heat pumps with electrically driven compressors for space heating and cooling - Part 3: Test methods91.140.30VLVWHPLVentilation and air-conditioning27.080Heat pumps23.120QDSUDYHVentilators. Fans. Air-conditionersICS:Ta slovenski standard je istoveten z:EN 14511-3:2007SIST EN 14511-3:2008en,fr,de01-maj-2008SIST EN 14511-3:2008SLOVENSKI

STANDARDSIST EN 14511-3:2004/AC:2005SIST EN 14511-3:20041DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14511-3November 2007ICS 23.120Supersedes EN 14511-3:2004

English VersionAir conditioners, liquid chilling packages and heat pumps withelectrically driven compressors for space heating and cooling -Part 3: Test methodsClimatiseurs, groupes refroidisseurs de liquide et pompes àchaleur avec compresseur entraîné par moteur électriquepour le chauffage et la réfrigération des locaux - Partie 3 :Méthodes d'essaiLuftkonditionierer, Flüssigkeitskühlsätze undWärmepumpen mit elektrisch angetriebenen Verdichternfür die Raumbeheizung und Kühlung - Teil 3: PrüfverfahrenThis European Standard was approved by CEN on 13 October 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14511-3:2007: ESIST EN 14511-3:2008

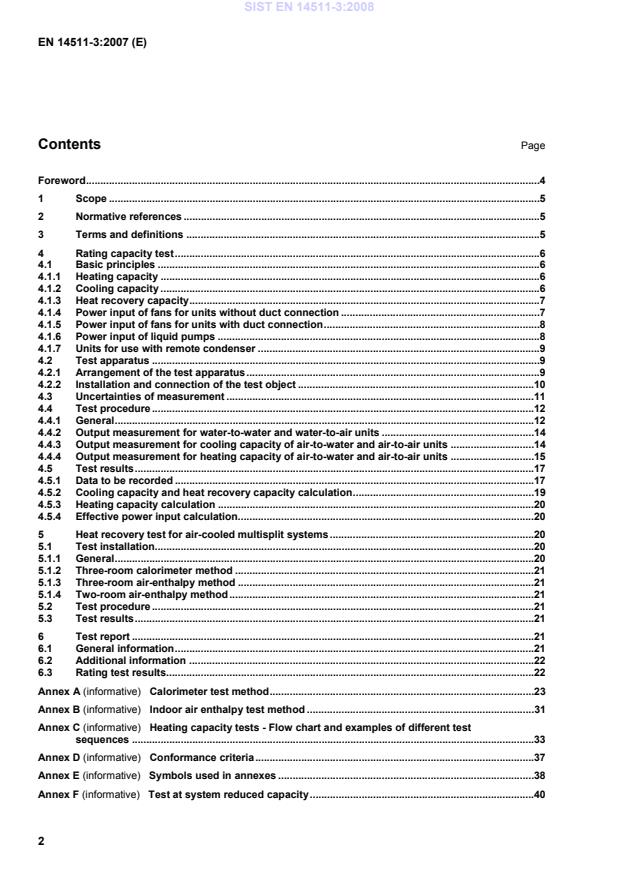

Calorimeter test method.23 Annex B (informative)

Indoor air enthalpy test method.31 Annex C (informative)

Heating capacity tests - Flow chart and examples of different test sequences.33 Annex D (informative)

Conformance criteria.37 Annex E (informative)

Symbols used in annexes.38 Annex F (informative)

Test at system reduced capacity.40 SIST EN 14511-3:2008

Individual unit tests.41 Bibliography.43

is the heat capacity, in Watts; q is the volume flow rate, in cubic metres per second; ρ is the density, in kilograms per cubic metre; cp is the specific heat at constant pressure, in joules per kilogram and kelvin; ∆t is the difference between inlet and outlet temperatures, in kelvin. For the heating capacity calculation in transient operation, refer to 4.5.3.2. The heating capacity shall be corrected for the heat from the fan or pump: − if the fan or pump at the indoor heat exchanger is an integral part of the unit, the same power (calculated in 4.1.5.1 or 4.1.6.1) which is excluded from the total power input shall be also subtracted from the heating capacity; − If the fan or pump at the indoor heat exchanger is not an integral part of the unit, the same power (calculated in 4.1.5.2 or 4.1.6.2) which is included in the effective power input shall be also added to the heating capacity. 4.1.2 Cooling capacity The cooling capacity of air conditioners and of air-to-air or water-to-air heat pumps shall be determined by measurements in a calorimeter room or by the air enthalpy method which are described in Annex A and Annex B respectively. The cooling capacity of air-to-water, water-to-water heat pumps and liquid chilling packages shall be determined in accordance with the direct method at the water or brine heat exchanger, by determination of the volume flow of the heat transfer medium, and the inlet and outlet temperatures, taking into consideration the specific heat capacity and density of the heat transfer medium. The cooling capacity shall be determined using the following formula: SIST EN 14511-3:2008

PC is the cooling capacity, in Watts; q is the volume flow rate, in cubic metres per second; ρ is the density, in kilograms per cubic metre; cp is the specific heat at constant pressure, in joules per kilogram and kelvin; ∆t is the difference between inlet and outlet temperatures, in kelvin. The cooling capacity shall be corrected for the heat from the fan or pump: a) If the fan or pump at the evaporator is an integral part of the unit, the same power (calculated in 4.1.5.1 or 4.1.6.1) which is excluded from the total power input is also added to the cooling capacity. b) If the fan or pump at the evaporator is not an integral part of the unit, the same power (calculated in 4.1.5.2 or 4.1.6.2) which is included in the effective power input is also subtracted from the cooling capacity. 4.1.3 Heat recovery capacity The heat recovery capacity of air-to-water and water-to-water heat pumps and liquid chilling packages shall be determined in accordance with the direct method at the water or brine heat exchanger, by determination of the volume flow of the heat transfer medium, and the inlet and outlet temperatures, taking into consideration the specific heat capacity and density of the heat transfer medium. The heat recovery capacity shall be determined using the following formula: tcqPpHR∆×××=ρ (3) where:

PHR is the heat recovery capacity, in Watts; q is the volume flow rate, in cubic metres per second; ρ is the density, in kilograms per cubic metre; cp is the specific heat at constant pressure, in joules per kilogram and kelvin; ∆t is the difference between inlet and outlet temperatures in kelvin. 4.1.4 Power input of fans for units without duct connection In the case of units which are not designed for duct connection, i.e. which do not permit any external pressure differences, and which are equipped with an integral fan, the power absorbed by the fan shall be included in the effective power absorbed by the unit. SIST EN 14511-3:2008

No accessory shall be connected to the discharge end of the duct.

For double duct units, the same requirements apply to both suction and discharge ducts, unless the appliance is designed to be installed directly on the wall. For multisplit systems, the test shall be performed with the system operating at a capacity ratio of 1, or as close as possible. When performing measures in heating mode, set the highest room temperature on the unit/system control device; when performing measures in cooling mode, set the lowest room temperature on the unit/system control device. For unit with open-type compressor the electric motor shall be supplied or specified by the manufacturer. The compressor shall be operated at the rotational speed specified by the manufacturer. For inverter type control units, if the manufacturer gives instructions for the setting of the frequency for each rating condition, this setting shall be done. NOTE To set up a multisplit system which incorporates an inverter-controlled compressor, skilled personnel with a knowledge of control software will be required. The manufacturer or his nominated agent should be in attendance when the system is being installed and prepared for tests. 4.2.2.2 Installation of unit consisting of several parts In the case of a unit consisting of several parts, the following installation conditions shall be complied with for the test. a) The refrigerant lines shall be installed in accordance with the manufacturer's instructions with a minimum length of 5 m and a greater length to a maximum of 7,5 m if the constraints of the test installation make

5 m not possible. b) The lines shall be installed so that the difference in elevation does not exceed 2,5 m. c) The thermal insulation of the lines shall be applied in accordance with the manufacturer's instructions. d) Unless constrained by the design, at least half of the connecting lines shall be exposed to the outside conditions, with the rest of the lines exposed to the inside conditions. 4.2.2.3 Indoor units of multisplit systems When testing a multisplit system, indoor units shall be either all non ducted or all ducted. If they are ducted, all indoor units shall be of the same model, i.e. having the same airflow rate and the same external static pressure. In case of equipment with non ducted indoor units tested using the air enthalpy method, the above requirement on ducted indoor units shall apply. SIST EN 14511-3:2008

- temperature inlet/outlet

- volume flow

- static pressure difference

°C

m3/s

Pa

± 0,1 K ± 1 % ± 5 Pa (∆p ≤ 100 Pa) ± 5 % (∆p > 100 Pa) Air

- dry bulb temperature

- wet bulb temperature

-

volume flow

- static pressure difference

°C

°C

m3/s

Pa

± 0,2 K ± 0,3 K ± 5 % ± 5 Pa (∆p ≤ 100 Pa) ± 5 % (∆p > 100 Pa) Refrigerant

- pressure at compressor outlet

- temperature

kPa

°C

± 1 % ± 0,5 K Concentration

- Heat transfer medium

%

± 2 % Electrical quantities

- electric power

- voltage

- current

- electrical energy

W

V

A

kWh

± 1 % ± 0,5 % ± 0,5 % ± 1 % Compressor rotational speed

min-1 ± 0,5 %

The heating or cooling capacities measured on the liquid side shall be determined within a maximum uncertainty of 5 % independent of the individual uncertainties of measurement including the uncertainties on the properties of fluids. SIST EN 14511-3:2008

ratings kW Minimum external static

pressure a

b Pa 0 < Q < 8 25 8 ≤ Q < 12 37 12 ≤ Q < 20 50 20 ≤ Q < 30 62 30 ≤ Q < 45 75 45 ≤ Q < 82 100 82 ≤ Q < 117 125 117 ≤ Q < 147 150 Q ≥ 147 175 a

For equipment tested without an air filter installed, the minimum external static pressure shall be increased by 10 Pa. b

If the manufacturer’s installation instructions state that the maximum allowable discharge duct length is less than 1 m, then the required minimum external static pressure shall be 10 Pa.

Table 3 — Pressure requirement for close control air conditioners Pressure Pa Capacity kW For down-flow dischargeinto double floor For up-flow discharge into duct all units < 30 50 - ≥ 30 75 - All - 50

Measured quantity Permissible deviation of the arithmetic mean values from set values Permissible deviations of individual measured values from set values Liquid

- inlet temperature

- outlet temperature

- volume flow

- static pressure difference

± 0,2 K ± 0,3 K ± 2 % --

± 0,5 K ± 0,6 K ± 5 % ± 10 % Air

- inlet temperature (dry bulb/wet

bulb)

- volume flow

- static pressure difference

± 0,3 K ± 5 % -

± 1 K ± 10 % ± 10 % Refrigerant

- liquid temperature

- saturated vapour/bubble point

temperature

± 1 K

± 0,5 K

± 2 K

± 1 K Voltage ± 4 % ± 4 % NOTE When testing single duct units the arithmetic mean value of the difference between the dry bulb temperature of the indoor compartment and of the air introduced from the outdoor compartment should have a maximum permissible deviation of 0,3 K. This requirement also applies to the wet bulb temperature difference.

4.4.2 Output measurement for water-to-water and water-to-air units 4.4.2.1 Steady state conditions This condition is considered obtained and maintained when all the measured quantities remain constant without having to alter the set values, for a minimum duration of 1 h, with respect to the tolerances given in Table 4. Periodic fluctuations of measured quantities caused by the operation of regulation and control devices are permissible, on condition the mean value of such fluctuations does not exceed the permissible deviations listed in Table 4. 4.4.2.2 Measurement of heating capacity, cooling capacity and heat recovery capacity For the output measurement it is necessary to record all the meaningful data continuously. In the case of recording instruments which operate on a cyclic basis, the sequence shall be adjusted such that a complete recording is effected at least once every 30 s. The output shall be measured in the steady state condition. The duration of measurement shall be not less than 35 min. 4.4.3 Output measurement for cooling capacity of air-to-water and air-to-air units 4.4.3.1 Steady state conditions This condition is considered obtained and maintained when all the measured quantities remain constant without having to alter the set values, for a minimum duration of 1 h, with respect to the tolerances given in SIST EN 14511-3:2008

EN 14511-2:2007. 4.4.4.3 Equilibrium period The equilibrium period immediately follows the preconditioning period or the defrost cycle and a recovery period of 10 min that ends a preconditioning period. A complete equilibrium period is one hour in duration. Except as specified in 4.4.4.7, the heat pump shall operate while meeting the test tolerances specified in Table 4. 4.4.4.4 Data collection period The data collection period immediately follows the equilibrium period. Data shall be sampled at equal intervals that span every 30 s or less, except during defrost cycles as specified below. During defrost cycles, plus the first 10 min following defrost termination, data used in evaluating the integrated heating capacity and the integrated power input of the heat pump shall be sampled more frequently, at equal intervals that span every 10 s or less. When using the indoor air enthalpy method, these more frequently SIST EN 14511-3:2008

35 min of data collection. 4.4.4.7 Test procedure for transient tests When, in accordance with 4.4.4.5, a heating capacity test is designated a transient test, the following adjustments shall apply. To constitute a valid transient heating capacity test, the test tolerances specified in Table 5 shall be achieved during both the equilibrium period and the data collection period. As noted in Table 5, the test tolerances are specified for two sub-intervals. Interval H consists of data collected during each heating interval, with the exception of the first 10 min after defrost termination. Interval D consists of data collected during each defrost cycle plus the first 10 min of the subsequent heating interval. SIST EN 14511-3:2008

a

Interval D

b Interval H

a Interval D

b Temperature of air entering indoor-side:

- dry-bulb

- wet-bulb

± 0,6 °K —

± 1,5 °K —

± 1,0 °K —

± 2,5 °K — Temperature of air entering outdoor-side:

- dry-bulb

- wet-bulb

± 0,6 °K ± 0,3 °K

± 1,5 °K ± 1,0 °K

± 1,0 °K ± 0,6 °K

± 5,0 °K — Inlet water temperature ± 0,2 °K — ± 0,5 °K — Outlet water temperature ± 0,5 °K — ± 1°K ± 2 a

Applies when the heat pump is in the heating mode, except for the first 10 min after termination of a defrost cycle. b

Applies during a defrost cycle and during the first 10 min after the termination of a defrost cycle when the heat pump is operating in the heating mode.

4.5 Test results 4.5.1 Data to be recorded The data to be recorded for the capacity tests are given in Table 6. The table identifies the general information required but is not intended to limit the data to be obtained. These data shall be the mean values taken over the data collection period, with the exception of time measurement. Table 6 — Data to be recorded Measured quantity of result Unit Calorimeter Air enthalpy method Water enthalpy method 1) Ambient conditions - air temperature, dry bulb - atmospheric pressure

°C kPa

X

X X

X 2) Electrical quantities

- voltage

- total current

- total power input, PT

- effective power input, PE

V A W W

X X X X

X X X X

X X X X 3) Thermodynamic quantities a) Indoor heat exchanger

- inlet temperature, dry bulb

- inlet temperature, wet bulb For duct connection

- outlet temperature, dry bulb

- outlet temperature, wet bulb

- external/internal static pressure difference

- volume flow rate, q Water or brine

- inlet temperature

- outlet temperature

- volume flow

- pressure difference

°C °C

°C °C Pa m3/s

°C °C m3/s kPa

X X

- - - --

X X X X

X X

X X X X

X X X X

- -

- - - -

X X X X b) Outdoor heat exchanger Air

- inlet temperature, dry bulb

- inlet temperature, wet bulb For duct connection

- outlet temperature, dry bulb

- outlet temperature, wet bulb

- external/internal static pressure difference

- volume flow rate, q Water or brine

- inlet temperature

- outlet temperature

- volume flow

- pressure difference

°C °C

°C °C Pa m3/s

°C °C m3/s kPa

X X

- - - --

X X X X

X X

X X X X

X X X X

X X

- - - -

X X X X c) Heat recovery heat exchanger

- inlet temperature

- outlet temperature

- volume flow

- pressure difference

°C °C m3/s kPa

- - - -

- - - -

X X X X d) Heat transfer medium (other than water)

- concentration

- density

- specific heat

% kg/m3 J/kg.K

X X X

X X X

X X X

- discharge pressure

- saturated vapour/bubble point temperature

- liquid temperature

bar abs. °C °C

- - -

- - -

X X X f) Compressor

- rotational speed of open type

- power input of motor

min-1 W

- -

- -

X X g) Calorimeter

- heat input to calorimeter

- heat extracted from calorimeter

- ambient temperature around the calorimeter

- temperature of the water entering the humidifier

- condensate temperature

- rate of condensate collection

W W °C °C °C kg/s

X X X X X X

- - - - - -

- - - - - - h) Defrost

- defrost period

- operating cycle with defrost

s min

X X

X X

- - 4) Data collection period min X

X

X 5) Capacities

- heating capacity (PH)

- total cooling capacity (PC)

- latent cooling capacity (PL)

- sensible cooling capacity (PS)

- heat recovery capacity

W W W W W

X X X X -

X X X X -

X X X X X 6) Ratios

- COP

- EER

- SHRb

W/W W/W W/W

X X X

X X X

X X - a Only for unit with remote condenser. b Only for air-to-air and water-to-air units.

4.5.2 Cooling capacity and heat recovery capacity calculation Average cooling and heat recovery capacities shall be determined from the set of cooling and heat recovery capacities recorded over the data collection period. SIST EN 14511-3:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...