CEN/TR 16443:2013

(Main)Backgrounds to the revision of EN 450-1:2005+A1:2007 - Fly ash for concrete

Backgrounds to the revision of EN 450-1:2005+A1:2007 - Fly ash for concrete

This Technical Report describes the backgrounds to the revision on EN 450-1:2005+A1:2007, Fly ash for concrete - Part 1: Definition, specifications and conformity criteria.

Hintergründe zur Überarbeitung der EN 450-1:2005+A1:2007 - Flugasche für Beton

Contexte de la révision de l'EN 450-1:2005+A1:2007 - Cendres volantes pour béton

Podlaga za revizijo EN 450-1:2005+A1:2007 - Elektrofiltrski pepel

To tehnično poročilo opisuje ozadje revizije standarda EN 450-1:2005+A1:2007, Elektrofiltrski pepel za beton – 1. del: Opredelitev, specifikacije in merila skladnosti.

General Information

- Status

- Published

- Publication Date

- 12-Mar-2013

- Technical Committee

- CEN/TC 104 - Concrete ( performance, production, placing and compliance criteria )

- Drafting Committee

- CEN/TC 104/WG 4 - EN 450 fly ash for concrete

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 13-Mar-2013

- Due Date

- 04-Nov-2013

- Completion Date

- 13-Mar-2013

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 450-1:2012 - Fly ash for concrete - Part 1: Definition, specifications and conformity criteria - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - CEN/TR 16443:2013 (Backgrounds to the revision of EN 450-1)

CEN/TR 16443:2013 is a Technical Report from CEN/TC 104 that documents the technical background and rationale used to revise EN 450-1:2005+A1:2007 (Fly ash for concrete - Part 1: Definition, specifications and conformity criteria). It summarises evidence, industry experience (including European Technical Approvals - ETAs) and test-data that informed the revised standard (EN 450-1:2012). The report explains why specific requirements were changed, deleted or retained and provides supporting analysis on co-combustion, test methods, conformity assessment and environmental aspects.

Key topics and requirements

- Definition of fly ash: Clarifies origin (pulverised coal combustion) and glassy pozzolanic nature; the requirement for reactive SiO2 was removed from the definition but retained for initial type testing.

- Co‑combustion materials: Examines permitted amounts and types of co‑combustion fuels and demonstrates that wider co‑combustion limits can be safely accepted based on ETA experience.

- Chemical criteria: Reviews key chemical parameters such as Loss on Ignition (LOI) (class limits and deletion of lower LOI limits for classes B and C), free calcium oxide (CaO), reactive silicon dioxide (SiO2), total phosphate (P2O5) (new total phosphate limit introduced), chlorides, alkalis and sulphur content.

- Physical and performance tests: Discusses fineness, particle density, water requirement, setting time, activity index (28/91 days) and soundness tests.

- Conformity and statistics: Evaluates conformity procedures and the statistical assessment by variables, with recommended modifications to sampling and acceptance criteria.

- Test methods and quality control: Background for test method selection (chemical analysis, wet/dry fineness), production quality assurance and conformity evaluation.

- Environmental and toxicological aspects: Considers leaching and regulated dangerous substances released by co‑combustion and measures to ensure safe use in concrete.

Practical applications - who uses this report

- Concrete, mortar and cement manufacturers assessing suitability of fly ash for concrete

- Producers and suppliers of fly ash implementing quality control and CE marking

- Test laboratories and conformity assessment bodies applying EN 450‑1 test methods

- Certification/approval bodies evaluating ETAs and non‑standard co‑combustion ashes

- Structural engineers and specifiers selecting supplementary cementitious materials

- Regulators and environmental agencies reviewing leaching and toxicology implications

Related standards

- EN 450‑1:2005+A1:2007 and EN 450‑1:2012 (revised standard)

- EN 450‑2:2005 (Conformity evaluation)

- EN 196‑2 (Cement chemical analysis), EN 197‑1 (Cement composition)

- EN 14588 (Solid biofuels terminology)

CEN/TR 16443:2013 is a practical resource explaining the technical basis for the EN 450‑1 revision, helping stakeholders apply updated requirements for safe, high‑performance use of fly ash in concrete.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

CEN/TR 16443:2013 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Backgrounds to the revision of EN 450-1:2005+A1:2007 - Fly ash for concrete". This standard covers: This Technical Report describes the backgrounds to the revision on EN 450-1:2005+A1:2007, Fly ash for concrete - Part 1: Definition, specifications and conformity criteria.

This Technical Report describes the backgrounds to the revision on EN 450-1:2005+A1:2007, Fly ash for concrete - Part 1: Definition, specifications and conformity criteria.

CEN/TR 16443:2013 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 16443:2013 has the following relationships with other standards: It is inter standard links to EN 450-2:2005, EN 14588:2010, EN 450-1:2012, EN 197-1:2000, EN 196-2:2025, EN 450-1:2005+A1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 16443:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2013

Podlaga za revizijo EN 450-1:2005+A1:2007 - Elektrofiltrski pepel

Backgrounds to the revision of EN 450-1:2005+A1:2007 - Fly ash for concrete

Hintergründe zur Überarbeitung der EN 450-1:2005+A1:2007 - Flugasche für Beton

Contexte de la révision de l'EN 450-1:2005+A1:2007 - Cendres volantes pour béton

Ta slovenski standard je istoveten z: CEN/TR 16443:2013

ICS:

91.100.30 Beton in betonski izdelki Concrete and concrete

products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CEN/TR 16443

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

March 2013

ICS 91.100.30

English Version

Backgrounds to the revision of EN 450-1:2005+A1:2007 - Fly

ash for concrete

Contexte de la révision de l'EN 450-1:2005+A1:2007 - Hintergründe zur Überarbeitung der EN 450-

Cendres volantes pour béton 1:2005+A1:2007 - Flugasche für Beton

This Technical Report was approved by CEN on 29 October 2012. It has been drawn up by the Technical Committee CEN/TC 104.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2013 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 16443:2013: E

worldwide for CEN national Members.

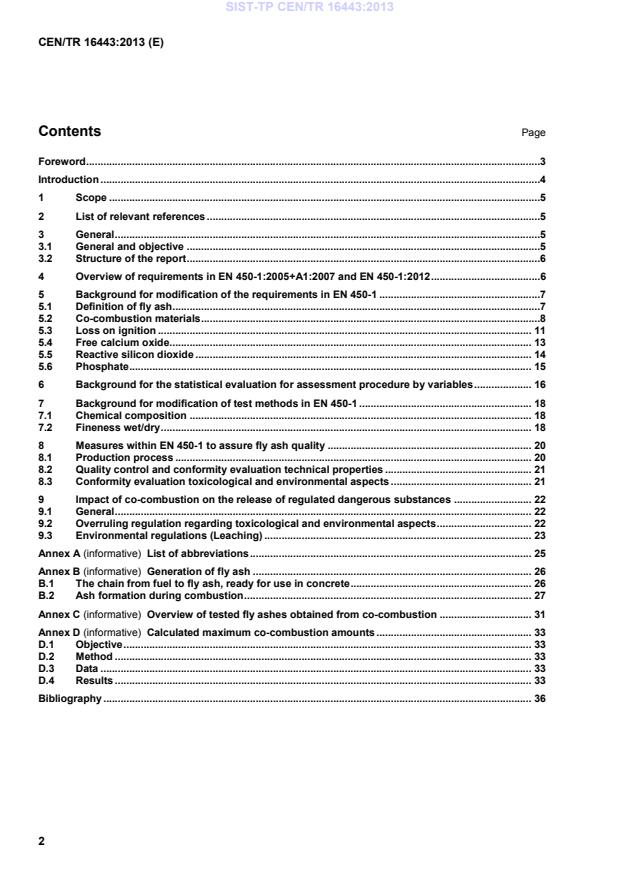

Contents Page

Foreword .3

Introduction .4

1 Scope .5

2 List of relevant references .5

3 General .5

3.1 General and objective .5

3.2 Structure of the report .6

4 Overview of requirements in EN 450-1:2005+A1:2007 and EN 450-1:2012 .6

5 Background for modification of the requirements in EN 450-1 .7

5.1 Definition of fly ash.7

5.2 Co-combustion materials .8

5.3 Loss on ignition . 11

5.4 Free calcium oxide. 13

5.5 Reactive silicon dioxide . 14

5.6 Phosphate . 15

6 Background for the statistical evaluation for assessment procedure by variables . 16

7 Background for modification of test methods in EN 450-1 . 18

7.1 Chemical composition . 18

7.2 Fineness wet/dry . 18

8 Measures within EN 450-1 to assure fly ash quality . 20

8.1 Production process . 20

8.2 Quality control and conformity evaluation technical properties . 21

8.3 Conformity evaluation toxicological and environmental aspects . 21

9 Impact of co-combustion on the release of regulated dangerous substances . 22

9.1 General . 22

9.2 Overruling regulation regarding toxicological and environmental aspects . 22

9.3 Environmental regulations (Leaching) . 23

Annex A (informative) List of abbreviations . 25

Annex B (informative) Generation of fly ash . 26

B.1 The chain from fuel to fly ash, ready for use in concrete . 26

B.2 Ash formation during combustion . 27

Annex C (informative) Overview of tested fly ashes obtained from co-combustion . 31

Annex D (informative) Calculated maximum co-combustion amounts . 33

D.1 Objective . 33

D.2 Method . 33

D.3 Data . 33

D.4 Results . 33

Bibliography . 36

Foreword

This document (CEN/TR 16443:2013) has been prepared by Technical Committee CEN/TC 104 “Concrete

and related products”, the secretariat of which is held by DIN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights.

Introduction

Following five years of experience using EN 450-1, it was clear that some clauses need improvement within

the standards. In the existing standards the maximum amount of fly ash from co-combustion was limited to

certain proportions. Experience gained with fly ashes conforming to a European Technical Approval (ETA),

where higher co-combustion amounts were permitted, showed that the requirements in the corresponding

Common Understanding of Assessment Procedure (CUAP) were sufficient guarantee for fly ashes to produce

excellent performance in concretes, mortars, grouts and cements. As agreed in CEN/TC 104, the experience

gained with ETA fly ashes should be incorporated in the revision of EN 450-1.

In this background report it is proved that wider ranging limits and types of co-combustion materials can be

safely applied in the revised EN 450-1. It is also shown that in practice some requirements in EN 450-1 have

been proven to be unrealistic. Improvements have been proposed for the definition of fly ash, the loss on

ignition, free calcium oxide, reactive silicon dioxide and the limits for phosphate.

The conformity procedures have also been evaluated, especially the assessment procedure for inspection by

1)

variables. Based on this evaluation work, modifications are needed for the LOI classes B and C.

The revised version of the standard incorporates the European Technical Approvals (ETA) and EU members

experience gained with fly ash in concrete. The requirements of the revised standard will result in fly ashes

which will perform similarly to those conforming to EN 450-1:2005.

1) LOI – Loss on ignition.

1 Scope

This Technical Report describes the backgrounds to the revision on EN 450-1:2005+A1:2007, Fly ash for

concrete Part 1: Definition, specifications and conformity criteria.

2 List of relevant references

The following references are covered by the present document:

EN 450-1:2005+A1:2007, Fly ash for concrete — Part 1: Definition, specifications and conformity criteria;

2)

), Fly ash for concrete — Part 1: Definition, specifications and

EN 450-1:2012 (revised EN 450-1

conformity criteria;

EN 450-2:2005, Fly ash for concrete — Part 2: Conformity evaluation;

EN 196-2, Methods of testing cement — Part 2: Chemical analysis of cement;

EN 197-1:2000, Cement — Part 1: Composition, specifications and conformity criteria for common

cements;

EN 14588:2010, Solid biofuels — Terminology, definitions and descriptions.

3 General

3.1 General and objective

Fly ash has been used for many decades in concrete as an addition for its positive influence on workability,

heat of hydration, strength development and durability. After the encouraging pilot projects some decades ago

with positive results, licenses for regular use and later on technical approvals were granted by the national

building authorities, certificates and standards. Today, regulations and standards exist for the use of fly ash in

mortar and concrete.

In 1995, the first EU standard was published, namely EN 450, Fly ash for concrete — Definitions,

requirements and quality control. This edition was followed up by a harmonised standard based on

Mandate M 128 in 2005 (EN 450-1:2005), together with a second standard (EN 450-2:2005), specific for

conformity evaluation.

The scope of EN 450-1:2005 states that fly ashes with percentages of co-combustion material higher than

those covered in EN 450-1:2005, Clause 4 or with other types of co-combustion material are outside the

scope of EN 450-1:2005.

In some countries, the use of fly ash with a higher percentage of co-combustion material was already common

practice and it was not accepted by these countries that these fly ashes, containing higher amounts of co-

combustion and other co-combustion materials, were excluded from CE marking.

It was agreed that European Technical Approvals (ETAs) could be granted for this product according to

Article 8.2 of the Construction Products Directive. The mandate M 128 was updated with the clarification that

fly ash produced with other types than those covered by EN 450-1 and fly ash produced with a percentage of

co-combustion material outside the limits defined in EN 450 (all parts), can be subject to ETAs, in order to

allow these products to be CE marked. The experience gained with the fly ashes conforming to these ETAs

has been used for the next revision of EN 450-1.

Due to the regular five-year revision, WG 4 of CEN TC 104 incorporated the knowledge gained with the fly

ashes conforming to these ETAs with EN 450-1. Other issues for the revision were identified as a lack of

clarity regarding the conformity evaluation and some of the other requirements.

2) In this present Technical Report a reference to the revised EN 450-1 always refers to EN 450-1:2012.

The objective of this report is to provide insight into the background to the modifications that have been taken

up in EN 450-1:2012 (revised EN 450-1) and of those requirements that have been deleted from

EN 450-1:2005+A1:2007

3.2 Structure of the report

Clause 4 provides an overview of the requirements of EN 450-1:2005+A1:2007 and EN 450-1:2012. In Clause

5 the background for the modifications of the requirements within EN 450-1 is described. Clause 6 gives the

background for the statistical evaluation for assessment procedure by variables, Clause 7, the background for

the required test methods, regarding chemical composition and the determination of fineness. In Clause 8, an

overview how fly ash quality is assured within the production process itself, the quality control system and the

conformity evaluation of toxicological and environmental aspects is given. Clause 9 deals with the impact of

co-combustion on the release of regulated dangerous substances.

More background information about the generation of fly ash can be found in Annex B.

4 Overview of requirements in EN 450-1:2005+A1:2007 and EN 450-1:2012

An overview of the requirements in the revised EN 450-1 is presented in Table 1. The requirements are

related to fresh and hardened concrete. The chemical requirements concern Loss On Ignition (LOI), chloride

(Cl), reactive and free Calcium Oxide or lime (CaO), reactive Silicon Dioxide (SiO ), the sum of SiO + Al O

2 2 2 3

+ Fe O , Magnesium Oxide (MgO) and soluble Phosphorus Pentoxide (P O ). The physical requirements

2 3 2 5

concern (or: are related to) fineness and the maximum deviation of particle density. The performance based

requirements are water requirement, initial setting, activity index and soundness.

In relation to the previous standard, the following changes have been adapted:

The definition of fly ash has been modified (EN 450-1:2012, 3.2).

The permitted amount and type of co-combustion materials have been changed (EN 450-1:2012, 4.1).

The requirement for the lower limit of LOI for category B and C fly ash has been deleted (EN 450-1:2012,

5.2.2).

The requirement for free lime (CaO) has been changed (EN 450-1:2012, 5.2.5).

The amount of total phosphate has been limited by a new requirement (EN 450-1:2012, 5.2.11).

Table 1 — Properties and requirements of fresh and hardened mortar and concrete

EN 450- EN 450-

Phase Property Unit

1:2005+A1:2007 1:2012

loss on ignition (LOI) class A ≤ 5,0 ≤ 5,0

class B % by mass 2,0 – 7,0 ≤ 7,0

class C 4,0 – 9,0 ≤ 9,0

workability

a e

water requirement % ≤ 95 n.m.

d

≤ 40 (cat. N)

e

fineness fraction > 45 µm % by mass n.m.

≤ 12 (cat. S)

e

soluble phosphate (P O )

mg/kg ≤ 100 n.m.

2 5

initial strength

total phosphate (P O )

% by mass — ≤ 5,0

2 5

development

b e

initial setting min. 2C n.m.

e

sum SiO + Al O + Fe O

% by mass ≥ 70 n.m.

2 2 3 2 3

e

reactive SiO

strength % by mass ≥ 25 n.m.

development

e

activity index 28 days ≥ 75 n.m.

%

e

91 days ≥ 85 n.m.

total content of alkalis

e

% by mass ≤ 5,0 n.m.

alkali silica reaction

(Na O equivalent)

(ASR)

e

reactive calcium oxide (CaO) % by mass ≤ 10,0 n.m.

e

sulphuric anhydride (SO )

% by mass ≤ 3,0 n.m.

c

f

free calcium oxide (CaO) % by mass ≤ 2,5

soundness/

e

soundness mm ≤ 10 n.m.

durability

e

magnesium oxide (MgO) % by mass ≤ 4,0 n.m.

-

e

chloride (Cl ) % by mass ≤ 0,10 n.m.

a

Only applicable for category S fly ash.

b

Initial setting of fly ash cement paste shall not be more than twice as long as the initial setting time of the test cement alone.

c If the content of free lime is greater than 1,0 % by mass, the fly ash shall be tested for conformity to the requirement for soundness.

d The fineness shall not vary by more than ±10 % from the declared value.

e n.m. = not modified.

f If the content of free lime is greater than 1,5 % by mass, the fly ash shall be tested for conformity to the requirement for soundness.

5 Background for modification of the requirements in EN 450-1

5.1 Definition of fly ash

5.1.1 Text of EN 450-1:2005+A1:2007

Fine powder of mainly spherical, glassy particles, derived from the burning of pulverised coal, with or without

co-combustion materials, which has pozzolanic properties and consists essentially of SiO and Al O . The

2 2 3

content of reactive SiO , as defined and described in EN 197-1 being at least 25% by mass.

5.1.2 Text of EN 450-1:2012 (revised EN 450-1)

Fine powder of mainly spherical, glassy particles, derived from the burning of pulverised coal, with or without

co-combustion materials, which has pozzolanic properties and consists essentially of SiO and Al O .

2 2 3

5.1.3 Background

The requirement of reactive SiO has been deleted in the definition of the revised EN 450-1, but still exists as

requirement for initial type testing (EN 450-1:2012, 5.2.7).

By definition fly ash has to be derived from the burning of pulverised coal and co-combustion materials. This is

only possible in dedicated boilers where combustion of finely ground fuel takes place in a cloud, with

combustion temperatures of 1 300 – 1 500 °C. This means that ashes from other boilers like grate-fired and

fluidised bed combustion boilers do not meet this definition. In other words, the definition guarantees that

combustion takes place at high temperature, which is high enough to facilitate glass formation in the fly ash.

The definition includes co-combustion, but, in EN 450-1:2012, 4.1, the amount and type of combustion

material are further restricted. Also, as noted in EN 450-1, municipal and industrial waste incineration ashes

do not conform to the definition of this clause. This implies that the fuel always contains coal. Coal contains

mineral matter that will form the glass phase during combustion. Also part of the secondary fuel also contains

mineral matter that contributes to glass formation. On a performance level, the requirement for the activity

index after 28 and 91 days provide enough assurance for a sufficient pozzolanic behaviour of the fly ash. The

presence of the glass phase is further assured by the requirement for the minimum total amount of

SiO + Al O + Fe O (as a main fraction of potential glass forming matter).

2 2 3 2 3

5.2 Co-combustion materials

5.2.1 Text of EN 450-1:2005+A1:2007

Fly ash from co-combustion as defined in 3.2 is obtained from pulverised coal fired simultaneously with co-

combustion materials as listed in Table 1 (Table 2 of this report). The minimum percentage, by dry mass, of

coal (K ) shall not be less than 80 % and the maximum proportion of fly ash derived from co-combustion

c

materials (M) shall not be greater than 10 % when calculated from Formula (1).

Table 2 (Table 1 of EN 450-1:2005+A1:2007) — Types of co-combustion materials

1 Vegetable material like wood chips, straw, olive shells and other vegetable fibres

2 Green wood and cultivated biomass

3 Animal meal

4 Municipal sewage sludge

5 Paper sludge

6 Petroleum coke

7 Virtually ash free liquid and gaseous fuels

5.2.2 Text of EN 450-1:2012 (revised EN 450)

Fly ash from co-combustion as defined in 3.2 is obtained from pulverised coal fired simultaneously with or

without co-combustion materials as listed in Table 1 (Table 3 of this report). The minimum percentage, by dry

mass, of coal (K ) shall be not less than 60 % or 50 % if the co-combustion material is only green wood. The

c

maximum proportion of ash derived from co-combustion materials (M) shall not be greater than 30 % by dry

mass when calculated from Formula (1).

Table 3 (Table 1 of the revised EN 450-1) — Types of co-combustion materials

Solid Bio Fuels conforming to EN 14588:2010 including animal husbandry residues as

defined in 4.3 and excluding waste wood as defined in 4.40, 4.107 and 4.136

2 Animal meal (meat and bone meal)

3 Municipal sewage sludge

4 Paper sludge

5 Petroleum coke

6 Virtually ash free liquid and gaseous fuels

NOTE Other types of co-combustion materials not included in Table 3 (Table 1 of the revised EN 450-1) may be

subject to an ETA.

5.2.3 Background

The classification of secondary fuels has been changed in the revised EN 450-1. The secondary fuels listed in

line 1 and 2 of table 3 have been merged as these are from the same origin and compiled in EN 14588. As

“green wood” is not defined in that report a definition was added in the revised EN 450-1 as:

"3.13

green wood

green wood is wood originating from trees, bushes and shrubs created when processing wood as cross-cut

ends, planings, saw dust and shavings used in the form of dust, chips and pellets".

The minimum proportion of coal has been decreased from 80 % by mass to 60 % by mass. Further, the

maximum proportion of ash derived from secondary fuels has been increased from 10 % to 30 % by mass.

Since 2005, ETAs have been used for testing the technical and environmental suitability of fly ash from co-

combustion for use as addition in concrete. Generated fly ashes from co-combustion exceeding the co-

combustion limits of EN 450-1:2005+A1:2007 were tested according to these ETAs. Before ETAs were

available, Dutch fly ashes from co-combustion were tested according to CUR recommendations (since 1999).

The tested fly ashes are presented in Annex C.

Co-combustion may increase the content of Ca, K, P and Mg in some cases. The other macro elements (Fe,

Al, Si, Na, and Ti) are mainly indirectly influenced by becoming impoverished due to the enrichment of other

macro elements. In most secondary fuels from vegetable and animal origin these macro-elements are present

in low concentrations (ash based), related to coal. The situation in fuels from industrial origin may be different

like the presence of Al, Si, Fe and Ti in demolition wood, Al, Si and P in sewage sludge and Al, Si and Ca in

paper sludge. The revised EN 450-1 contains an adequate set of requirements that covers these influences;

see Table 5. As can be derived from this table the influence of Ca, K, Mg and P is directly covered by at least

one requirement of the revised EN 450-1.

Table 4 — Requirements for fly ash for fresh and hardened concrete in relation to the effects of co-

combustion

Main influence co-combustion

Phase Requirement of EN 450-1

Ca K Mg P

LOI — — — —

workability water requirement — — — —

fineness fraction > 45 µm — V — —

soluble P O

VV

— — —

2 5

initial strength

total P O

— — — VV

2 5

development

initial setting — — — VV

sum SiO + Al O + Fe O

V V V V

2 2 3 2 3

strength

development

activity index — — — V

Na O equivalent

— VV — —

Alkali Silica

Reaction

VV

reactive CaO — — —

SO

— — — —

free CaO VV — — —

soundness/

Soundness V — — —

durability

total MgO — — VV —

-

Cl — — — —

Key

VV direct relation between the requirement and the influence of co-combustion

V in-direct relation between the requirement and the influence of co-combustion

— no relation

The test results showed that in nearly all cases, the chemical requirements of the ETA were met with one

exception, which in that case fly ash was rejected for use in concrete. This can be explained by the fact that

the co-combustion amount was adjusted to the chemical requirements or to operational conditions (fuel feed,

slagging, corrosion, etc.). An overview of limiting parameters for co-combustion materials is given in Table 5.

The results showed also that the XRD analyses of fly ash did not provide any extra information for quality

control purposes. In all cases no minerals were identified other than listed in the ETA. Therefore this criterion

was not included in the revised EN 450-1.

For a selection of these fly ashes, concrete specimens were produced to check if the proposed test

methodology is adequate. The performance of the concrete did not show significant influence of co-

combustion. The results are described in several reports and presentations (see CUR, 2003; Sarabèr, 2004;

Sarabèr and Van den Berg, 2005; Sarabèr and Van den Berg, 2006; CTSC, 2008). It was shown that the

performance of fly ash obtained from different co-combustion materials could be explained by the

mineralogical composition of the fly ash and that this could be related to the origin of the co-combustion

material. It was shown that depending on the origin of the fuel high co-combustion percentages are possible

up to 25 % by mass.

Table 5 — Limiting parameters for co-combustion materials (basis Table 1 of the revised EN 450-1)

Type Limited by

1 Solid Bio Fuels conforming to EN 14588:2010 including animal husbandry residues

as defined in 4.3 and excluding waste wood as defined in 4.40, 4.107 and 4.136.

green wood 1 Co-combustion fuel based

green wood 2 Co-combustion fuel based

green wood 3 Co-combustion fuel based

bark wood reactive CaO

Cacao shells Na O equivalent (K)

palm kernels total P O

2 5

2 Animal meal (meat and bone meal)

Meat and bone meal total P O

2 5

3 Municipal sewage sludge

Municipal sewage sludge total P O

2 5

4 Paper sludge

Paper sludge CaO

5 Petroleum coke

a

Petroleum coke —

6 Virtually ash free liquid and gaseous fuels

Industrial HC liquid Co-combustion fuel based

a

Prevented by National environmental regulations.

As already stated, the actual amount of co-combustion material is not only limited by the maximum

requirement for co-combustion, but also by the chemical requirements of EN 450-1. This means that in

practice, the actual amount of coal combustion (K ) will be higher than 60 % by mass and the maximum

c

proportion of ash derived from co-combustion materials (M) will be less than 30 % by mass. To illustrate this,

the maximum amount of co-combustion has been studied in relation to the chemical requirements (KEMA,

2008). The minimum proportion of coal combustion and the maximum proportion of ash derived from co-

combustion materials (M) adjusted to meet the requirements of EN 450-1 by calculating chemical ®

3)

compositions using the "KEMA TRACE MODEL " The study shows that co-combustion of most secondary

fuels will be limited by the chemical requirements or by the definition regarding the fuel based maximum co-

combustion. In Annex D all results are summarised.

5.3 Loss on ignition

5.3.1 Text of EN 450-1:2005+A1:2007

The loss on ignition shall be determined in accordance with the principles of the method described in

EN 196-2 but using an ignition time of 1 h, and shall fall within the limits of the categories specified below:

Category A: Not greater than 5,0 % by mass

Category B: Between 2,0 % and 7,0 % by mass

®

3) KEMA TRACE MODEL is the trade name of a product. This information is given for the convenience of the users of

this Technical Report and does not constitute an endorsement by CEN of the product named. Similar products may be

used if they can be shown to lead to equivalent results.

Category C: Between 4,0 % and 9,0 % by mass

5.3.2 Text of EN 450-1:2012 (revised EN 450-1)

The loss on ignition shall be determined in accordance with the principles of the method described in

EN 196-2 but using an ignition time of 1 h, and shall fall within the limits of the categories specified below:

Category A: Not greater than 5,0 % by mass

Category B: Not greater than 7,0 % by mass

Category C: Not greater than 9,0 % by mass.

5.3.3 Background

LOI of fly ash is an important quality parameter. LOI may influence several properties of concrete like

workability, interaction with organic admixtures, strength development, durability and visual aspects.

Key

1 LOI(mean) = UL – k · s

a

2 upper limit

3 single result limit

4 Prob.

5 LOI

a

PR

b

CR

Figure 1 — Producer and consumer risk in statistical evaluation

With the introduction of the revised EN 450-1:2005, three categories of LOI were introduced, each covering a

range of 5 % by mass but only category A with a lower limit of zero. The statistical assessment has to be

evaluated by variables. The system used is designed for normally distributed data sets and acceptability

constant together with producer and consumers risk. The system was established by D.B. Owen in 1962, but

for one sided evaluations only.

An example for producer and consumer risk in statistical evaluation is given in Figure 1. The consumer risk of

5 % is the right tail of the curve, the producer risk of 10 % is under the curve between UL and UL- k ·s. For

A

LOI category A no result can exceed the single result limit of 7 % LOI. The area under the normal curve at the

zero point is negligible for category A fly ash as its not possible to have an LOI value < 0 %. But for category B

or category C fly ash the lower limits of 2 or 4 % by mass cause compliance problems and reduce the possible

mean LOI between category A and B. By this category B fly ash can only be produced in a very small and

non-practical production window.

Based on the well proven systems of assessment by variables (see chapter 4) the lower limits need to be

deleted as the evaluation is valid for one-sided systems only.

As a result of these changes, in practical terms the quality in terms of LOI of the fly ash complying with

Category A, B or C will not change. This is demonstrated with the following examples using a typical SD of 1,0

and a typical k of 1,61 (for 60 – 69 results):

A

Cat A: Limit 5 %; mean value 3,0 %, follows: range is limited to 1,4 % to 4,6 %

Cat B: Limit 7 %; mean value 5,0 %, follows: range is limited to 3,4 % to 6,6 %

Cat C: Limit 9 %; mean value 7,0 %, follows: range is limited to 5,4 % to 8,6 %

The quality of fly ash in respect of consistency of LOI will not be negatively influenced with the deletion of the

lower limits, as the inherent statistical evaluation procedures required will still ensure a low standard deviation

for LOI will be achieved.

5.4 Free calcium oxide

5.4.1 Text of EN 450-1:2005+A1:2007

The content of free calcium oxide shall be determined by the method described in EN 451-1 and shall not be

greater than 2,5 % by mass. If the content of free calcium oxide is greater than 1,0 % by mass, then the fly

ash shall be tested for conformity to the requirements for soundness in 5.3.3.

5.4.2 Text of EN 450-1:2012 (revised EN 450-1)

The content of free calcium oxide shall be determined by the method described in EN 451-1. If the content of

free calcium oxide is greater than 1,5 % by mass, then the fly ash shall be tested for conformity to the

requirements for soundness in 5.3.3.

5.4.3 Background

The minimum free lime content above which soundness has to be tested has been increased from 1 % by

mass to 1,5 % by mass. Further, the maximum amount of free lime of 2,5 % by mass has been deleted.

Free lime present in fly ash and cement will convert into Portlandite sooner or later if it comes into contact with

water, according to the reaction:

CaO+ H O→ Ca(OH)

2 2

This conversion is accompanied by heat generation and by an increase in its solid volume. This process is

sufficiently powerful to generate large expansive forces, which may cause failure within the concrete. It has

been found that unsoundness of cement in the Le Chatelier test occurs appreciably when the free lime content

is in excess of 2 % by mass (Lea, 1970). A statistical analysis of data delivered from members of the CEN

working group was performed (ECOBA, 2008). Data not conforming to EN 450-1 are also included within this

dataset for demonstration purposes. See Figure 2. The results show that for up to 1,5 % by mass free CaO,

soundness expansion is minimal. Above this content the soundness values may increase, but still hardly any

fly ash exceeds the limit of 10 mm. Based on these data it is concluded that for only above 1,5 % by mass free

lime, soundness has to be proven. The soundness criteria together with the reactive CaO criteria provide

enough insurance that further limitation of the amount of free CaO is superfluous.

Key

CaO

soundness

free

X CaO [% by mass]

free

min 0,05 0,00

Y soundness [mm]

max 4,1 9,5

mean 1,28 1,86

s 0,49 1,10

n 734 734

Figure 2 — Relation between free lime and soundness (LeChatelier test)

(format modified acc. ISO 128 (all parts) and ISO 129 (all parts))

5.5 Reactive silicon dioxide

5.5.1 Text of EN 450-1:2005+A1:2007

The amount of reactive silicon shall be analysed in accordance with EN 197-1:2000 and shall not be less than

25 % by mass. Only fly ash from the combustion of pulverised coal shall be deemed to satisfy this

requirement.

5.5.2 Text of EN 450-1:2012 (revised EN 450-1)

In the initial type test for fly ash from co-combustion (4.2) the amount of reactive silicon shall be determined in

accordance with EN 196-2 and shall not be less than 25 % m/m. Fly ash obtained from combustion of

pulverised coal only shall be deemed to satisfy this requirement.

5.5.3 Background

Reactive SiO together with reactive Al O are the main components in the glass phase, and these form the

2 2 3

from the hydration reactions of the cement. So it

basics for the pozzolanic reaction, together with the Ca(OH)

is an essential compound in EN 450-1 fly ash. The requirement of reactive SiO is always met for coal fly ash.

NOTE ECOBA has produced a guidance document which details the test procedure for determining reactive SiO ,

which is available for download from the ECOBA web site (www.ecoba.org).

5.6 Phosphate

5.6.1 Text of EN 450-1:2005+A1:2007

The content of soluble phosphate (P O ) shall be determined in accordance with EN 196-2 and shall not be

2 5

greater than 100 mg/kg. Fly ash obtained from combustion of pulverised coal only shall be deemed to satisfy

this requirement.

5.6.2 Text of EN 450-1:2012 (revised EN 450-1)

The content of total phosphate (P O ) shall be determined in accordance with EN 196-2 and shall not be

2 5

greater than 5,0 % by mass. Fly ash obtained from combustion of pulverised coal only shall be deemed to

satisfy this requirement.

In the initial type test for fly ash from co-combustion (4.2) the content of soluble phosphate (P O ) shall be

2 5

determined in accordance with the method descried in Annex C and shall not be greater than 100 mg/kg.

5.6.3 Background

The requirement for phosphate has been extended with a requirement for total phosphate (maximum content

of 5 % by mass).

As already stated, phosphate is a compound that is normally present in fly ash from 100 % coal in low

concentrations; normally below 1 % by mass. Co-combustion of specific co-combustion materials, as are

listed in Table 1 will cause an increase of the phosphate content, e.g. animal meal, municipal sewage sludge

and solid bio fuels like cacao residues and wheat husks. The research data concerning the performance of

concrete with phosphate enriched fly ash is up to approximately 5 % by mass P O , originating from different

2 5

co-combustion materials. The assessment involved workability, strength development, freeze-thaw resistance

and chloride permeability. There were no specific effects identified caused by phosphate on concrete

performance. Therefore, it is concluded that fly ash may contain up to 5,0 % by mass P O .

2 5

In Figure 3, the relation between total and soluble phosphate is shown. It shows that up to 5% total P O no

2 5

fly ash exceeds the limit of 100 mg/kg soluble P O . As the analysis of soluble phosphate is a labour-intensive

2 5

procedure and needs specific training to obtain realistic figures the analysis of the total phosphate content by

means of X-ray fluorescence analysis is strongly recommended for autocontrol testing.

Key

total water soluble

X total P O in [% by mass]

2 5

min 0,1 0,2

Y soluble P O in [mg/kg]

max 0,6 2,7

2 5

mean 4,3 97

s 0,69 16,3

n 209 209

Figure 3 — Relation between the content of total phosphate and soluble phosphate

6 Background for the statistical evaluation for assessment procedure by variables

The Statistics Sub-group of TC 104/WG 4 carried out a comprehensive review of the compliance criteria of

EN 450-1:2005+A1:2007 and EN 450-2:2005. A detailed report is available separately from the

WG 4 secretariat.

The conformity criteria within EN 450-1:2005 were simply adapted from text within EN 197-1. There was little

information as to the basis for the compliance criteria within EN 197-1 and TC 51 members were asked to

provide the source information. It transpired the statistics adopted had been used for many years prior to the

development of EN 197-1. The system is based on the assumption there is no information about the mean

value or standard deviation of the data being analysed. At the time of drafting EN 450-1:2005 there was little

or no consideration as to the differences between cement and fly ash and the limiting criteria. The relatively

low standard deviation in comparison with the mean value for common cements, coupled with the relatively

wide limits for compliance makes it possible for cement production to easily comply, whereas fly ash will find it

much harder in some circumstances, particularly, as it transpired, in relation to Loss On Ignition (LOI).

One issue studied was whether the frequency distributions of data were in fact ‘normally’ distributed or better

represented by the more complex ‘gamma’ function. The EN 197-1 statistics are based on normal distributions

and would be invalid if non-normal or gamma functions were found. A detailed analysis of data on fineness,

LOI and to a lesser extent parameters tested by attributes on data provided by ash suppliers throughout the

EU were carried out. There was some evidence that LOI distributions were ‘non-normal’, but for all practical

purposes this could be ignored. However, compliance with the criteria for LOI subsequently proved to be a

significant issue due to the large statistical margins demanded by the compliance criteria.

There was evidence that some power stations were finding compliance with the LOI criteria difficult. This was

because their particular mean LOI coupled with the categories for LOI and the large margins, resulted in too

narrow a compliance band and in some circumstances proving completely impossible to comply. This was

especially true for new ash sources that had low numbers of results. As the mean LOI is a function of the

station, furnace, coals, etc., which ash producers are unable to change, this problem needed to be rectified.

After a more detailed analysis of these data it became clear the application of the EN 197-1 statistics were

never designed for such narrow bands within category B and C with LOI and two tail tests being impossible to

comply with. After a series of discussions, it was agreed the solution was to delete the lower limits for

categories B and C.

The quality of fly ash in respect of consistency of LOI will not be negatively influenced with the deletion of the

lower limits, as the inherent statistical evaluation procedures required will still ensure a low standard deviation

for LOI will be achieved (see 3.3).

One issue reviewed but not changed was the quoted producer and user risk values, P and C . These are

k R

somewhat misleading within EN 450-1:2005, as the actual failure rates for population distribution required are

considerably lower, in order to comply with EN 450-1, Tables 3 and 4. This is particularly true for testing by

attributes where low numbers of results are available, which results in compliance difficulties even in a system

fully statistically compliant. This is a result of the statistics adopted, which assume no knowledge of the data

mean and standard deviation, resulting in very high operating margins (k ).

A

There was little known about the original source of the statistics. It transpired that the tables within EN 197-1

and EN 450-1 were extracted from previous cement standards, which in themselves had been adapted from a

textbook by Owen (Owen, 1962). Further work by N. Bech within the statistics sub-group showed that k can

A

be evaluated using the following one sided approximation postulated by M. Natrella (Natrella, 1963).

z + z − ab

1−p

1−p

k = where

A

a

2 2

z z

1−γ 1−γ

a= 1− and b= z −

1−p

2(n− 1) n

The concept of producers and consumer risk in relation to fly ash is questionable and adoption of a single

compliance value of a 5 % failure rate (one tailed test) for all variables would simplify the statistics. However,

the sub-group in conjunction with Sector Group 2 agreed that to change the basis for compliance criteria away

from that within EN 197-1 was a step too far. However, it was agreed that values for the margins could be

calculated by computer using the Natrella approximation, allowing compliance monitoring spreadsheets to be

created and removing the rather stepped function seen in the table within EN 450, see Figure 4.

In conclusion the decisions taken have removed the main problems associated with statistical compliance for

LOI within EN 450-1. However, it is recommended that the basis of compliance both within EN 197-1 and

EN 450-1 should be reviewed again in any post 2010 revisions.

Key

1 EN 450-1:2005

2 calculation (Natrella)

X number of results in analysis

Y value k

a

Figure 4 — Comparison between EN 450 and Natrella approximation

7 Background for modification of test methods in EN 450-1

7.1 Chemical composition

7.1.1 Text of EN 450-1:2005+A1:2007 and Text of EN 450-1:2012 (revised EN 450-1), 5.2.8 and 5.2.10

“The content of silicon dioxide (SiO ), magnesium oxide (MgO), aluminium oxide (Al O ), and iron oxide

2 2 3

(Fe O ) shall be determined in accordance with EN 196-2, modified as indicated in [EN 450-1,] 5.2.1. (…)”

2 3

NOTE Text remained unchanged.

7.1.2 Background

The new standard EN 196-2 allows for using methods other than the classical chemical methods, namely X-

ray fluorescence analysis (XRF-EN196-2.2). By this, the use of XRF to determine the oxides need no longer

to be classified as alternative method with the proof of equivalent results but can be used directly as a

reference method.

7.2 Fineness wet/dry

7.2.1 Text of EN 450-1:2005+A1:2007,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...