CEN/TR 17172:2018

(Main)Validation testing program on chloride penetration and carbonation standardized test methods

Validation testing program on chloride penetration and carbonation standardized test methods

The objective of the document consists in testing concrete mixes complying with EN 206 for particular aggressive environments with the test methods being standardized by TC 51/WG 12 on chloride penetration and carbonation in order to verify their robustness and coherence.

Validierungs-Prüfprogramm für genormte Prüfverfahren der Chlorideindringung und der Karbonatisierung

Programme d'essai de validation des méthodes d'essai normalisées relatives à la pénétration des chlorures et à la carbonatation

Le présent document a pour objectif de tester les formules conformes à l'EN 206 pour les environnements particulièrement agressifs avec les méthodes d'essai normalisées par le TC 51/GT 12 sur la pénétration des chlorures et la carbonatation afin de vérifier leur robustesse et leur cohérence.

Program validacije standardizirane preskusne metode za preskušanje penetracije kloridov in karbonatizacije

V tem dokumentu so navedeni podatki, pridobljeni s programom validacije (VTP) za preskušanje penetracije kloridov in karbonatizacije, ki ga vse od leta 2009 organizira delovna skupina WG 12, pri čemer je pripravo vzorcev, zbiranje rezultatov ter statistično analizo opravil inštitut za gradbeništvo Eduardo Torroja pod okriljem španske ustanove CSIC (IETcc–CSIC) in vodstvom prof. Carmen Andrade.

General Information

- Status

- Withdrawn

- Publication Date

- 18-Sep-2018

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 104 - Concrete ( performance, production, placing and compliance criteria )

- Drafting Committee

- CEN/TC 104/SC 1 - Revision of ENV 206

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Jun-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Nov-2020

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

CEN/TR 17172:2018 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Validation testing program on chloride penetration and carbonation standardized test methods". This standard covers: The objective of the document consists in testing concrete mixes complying with EN 206 for particular aggressive environments with the test methods being standardized by TC 51/WG 12 on chloride penetration and carbonation in order to verify their robustness and coherence.

The objective of the document consists in testing concrete mixes complying with EN 206 for particular aggressive environments with the test methods being standardized by TC 51/WG 12 on chloride penetration and carbonation in order to verify their robustness and coherence.

CEN/TR 17172:2018 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 17172:2018 has the following relationships with other standards: It is inter standard links to CEN/TR 17172:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 17172:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2018

Program validacije standardizirane preskusne metode za preskušanje penetracije

kloridov in karbonatizacije

Validation testing program on chloride penetration and carbonation standardized test

methods

Validierungs-Prüfprogramm für genormte Prüfverfahren der Chlorideindringung und der

Karbonatisierung

Programme d'essai de validation des méthodes d'essai normalisées relatives à la

pénétration des chlorures et à la carbonatation

Ta slovenski standard je istoveten z: CEN/TR 17172:2018

ICS:

91.100.30 Beton in betonski izdelki Concrete and concrete

products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TR 17172

TECHNICAL REPORT

RAPPORT TECHNIQUE

September 2018

TECHNISCHER BERICHT

ICS 91.100.30

English Version

Validation testing program on chloride penetration and

carbonation standardized test methods

Programme d'essai de validation des méthodes d'essai Validierungs-Prüfprogramm für genormte

normalisées relatives à la pénétration des chlorures et Prüfverfahren der Chlorideindringung und der

à la carbonatation Karbonatisierung

This Technical Report was approved by CEN on 1 January 2018. It has been drawn up by the Technical Committee CEN/TC 104.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2018 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 17172:2018 E

worldwide for CEN national Members.

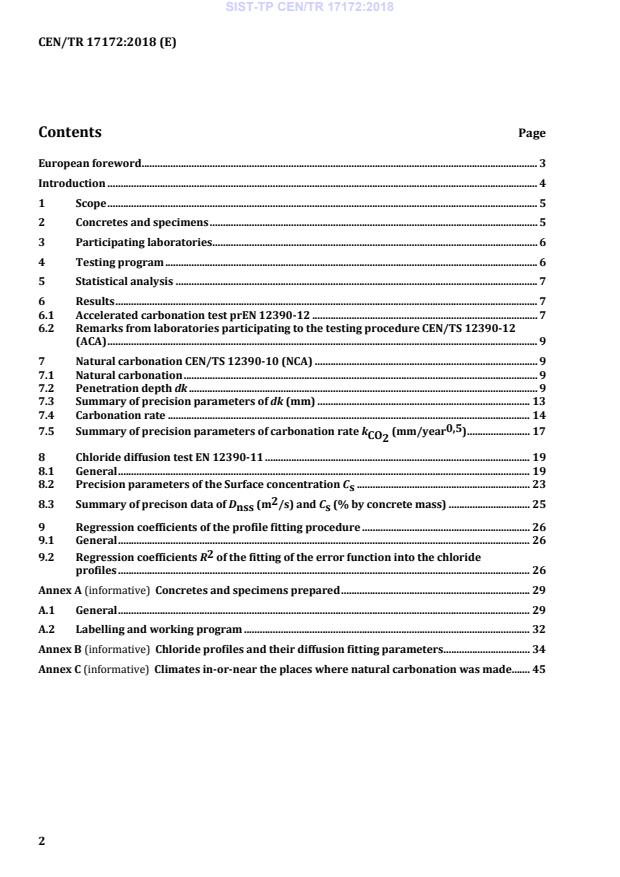

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Concretes and specimens . 5

3 Participating laboratories. 6

4 Testing program . 6

5 Statistical analysis . 7

6 Results . 7

6.1 Accelerated carbonation test prEN 12390-12 . 7

6.2 Remarks from laboratories participating to the testing procedure CEN/TS 12390-12

(ACA) . 9

7 Natural carbonation CEN/TS 12390-10 (NCA) . 9

7.1 Natural carbonation . 9

7.2 Penetration depth dk . 9

7.3 Summary of precision parameters of dk (mm) . 13

7.4 Carbonation rate . 14

0,5

7.5 Summary of precision parameters of carbonation rate k (mm/year ) . 17

CO

8 Chloride diffusion test EN 12390-11 . 19

8.1 General . 19

8.2 Precision parameters of the Surface concentration C . 23

s

8.3 Summary of precison data of D (m /s) and C (% by concrete mass) . 25

nss s

9 Regression coefficients of the profile fitting procedure . 26

9.1 General . 26

9.2 Regression coefficients R of the fitting of the error function into the chloride

profiles . 26

Annex A (informative) Concretes and specimens prepared . 29

A.1 General . 29

A.2 Labelling and working program . 32

Annex B (informative) Chloride profiles and their diffusion fitting parameters . 34

Annex C (informative) Climates in-or-near the places where natural carbonation was made. 45

European foreword

This document (CEN/TR 17172:2018) has been prepared by Technical Committee CEN/TC 104

“Concrete and related products”, the secretariat of which is held by DIN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document reports the data obtained in the Validation Testing Program (VTP) on chloride

penetration and carbonation organized by WG 12 starting from 2009 as from document

CEN/TC 51/WG 12 – Doc. N 229/2009, where the preparation of specimens the collection of results and

the statistical analysis were performed by the Institute of Construction Sciences “Eduardo Torroja” of

the CSIC of Spain, IETcc–CSIC, under the managing activities of Prof. Carmen Andrade.

Introduction

The procedure for the determination of chloride penetration is described in EN 12390-11:2015,

“Testing hardened concrete — Determination of the chloride resistance of concrete — Unidirectional

diffusion” and it has been published by CEN. The method is based on natural diffusion; a concentration

profile after 90 days of contact with the chloride solution is used to fit Fick’s law in order to calculate

the chloride surface concentration, C and the non-steady-state chloride diffusion coefficient, D . The

s nss

method specifies three different modes of contact of the salt solution with one face of the specimen,

immersion (DCL1), ponding (DCL2) and inversion (DCL3).

CEN/TC 51/WG 12 has also produced two methods addressed to the determination of the carbonation

resistance of the concrete, the first one refers to natural condition and has been published as

CEN/TS 12390-10, “Testing hardened concrete — Part 10: Determination of the relative carbonation

resistance of the concrete“, the second one, referring to accelerated condition, has been prepared by

1)

CEN/TC 51/WG 12/TG 5, but it has been disapproved by National Members at Formal Vote CEN TCA .

The upgrading to EN standard of the aforesaid documents should require as first step the evaluation of

robustness and precision data.

Having in mind these needs, CEN/TC 51/WG 12 organized a “Validation Testing Program (VTP) on

chloride penetration and carbonation” for the preliminary evaluation of the robustness and the

precision data of the test methods.

For the scope of the present work as robustness is intended the sensitivity of the test method to a

composition change of concrete that are expected to produce an appreciable change in related

performance.

1)

FprCEN/TS 12390-12:2010, Testing hardened concrete — Part 12: Determination of the potential carbonation

resistance of concrete: Accelerated carbonation method.

1 Scope

The objective of the document consists in testing concrete mixes complying with EN 206 for particular

aggressive environments with the test methods being standardized by TC 51/WG 12 on chloride

penetration and carbonation in order to verify their robustness and coherence.

2 Concretes and specimens

For the VTP four concrete mixes were designed considering the limiting values indicated in Table F1 of

EN 206 and the scope of assessing the robustness of the methods.

Three composition parameters (cement type, w/c ratio and cement content) were suitably chosen.

The following cement type and class were chosen: CEM II/A-LL 42.5 R and CEM II/B-V 32.5 R.

The w/c ratio was intentionally changed to substantially affect the concrete performances.

Two cement contents were used, the first one (300 kg/m ) for carbonation, the second one

(350 kg/m ) for chloride penetration.

Aggregate “round shaped” of siliceous nature and with a maximum diameter of 14 mm was used. In

Table 1 the composition of concrete mixes is shown.

The use of superplasticizer admixture was modulated, were necessary, to obtain a slump class S3

(100 mm – 150 mm). Table 1 gives the nominal proportions of the mixes used.

Table 1 — Proportions and cement types of the mixes prepared

CARBONATION CHLORIDE

MIX 1 MIX 2 MIX 3 MIX 4 MIX 5 MIX6 MIX7 MIX8

CEM II/A-LL CEM II/B-V

Cement type CEM II/A-LL 42.5R CEM II/B-V 32.5R

42.5R 32.5R

Cement amount

295 296 296 300 345 351 349 357

(kg/m )

144 173 144 175 137 173 138 176

Water (l/m )

w/c ratio 0,49 0,58 0,49 0,58 0,4 0,49 0,4 0,49

1 049 1 011 1 054 1 025 1 005 977 1 019 993

Gravel (kg/m )

857 827 861 838 816 793 827 806

Sand (kg/m )

Superplasticizer

0,60 0,20 0,50 0,15 0,79 0,23 0,57 0,10

(% cement weight)

2 260 2 265 2 294 2 285 2 273 2 313 2 330 2 330

Density (kg/dm )

Air content (%) 5,75 4,9 5,15 3,75 5,7 3,8 4,4 2,3

Slump (cm) 11 10 12 10 10 10 13,5 10

For each laboratory and test method 2 cubes (150 mm) were produced.

In Annex A a summary of the experimental details of the preparation of the specimens and their

submission is described. It is worth noting that the specimen preparation was centralized in one

laboratory (IETcc) in order to have a better homogeneity.

3 Participating laboratories

The Laboratories participating in the VTP were 14 of different European countries and are indicated in

Table 2 with the tests methods they performed.

Table 2 — List of laboratories participating in the exercise with the test types they perform

NATURAL ACCELERATED DIFFUSION CHLORIDE

CARBONATION CARBONATION PENETRATION

COUNTRY LABORATORY

NCA1 NCA2 ACA DCL1 DCL2 DCL3

France Lafarge X X

France LRPC X

Spain University of Alicante X X

Spain IETcc X X X X X X

Belgium CRIC X X

The

KEMA X X X

Netherlands

The

TNO X X X

Netherlands

The

SGS INTRON X X X X

Netherlands

United

Dundee University X X X X

Kingdom

Sweden CBI X X

Germany FIZ/VDZ X X X X

Italy Polytechnic Milan X X X X X

Poland ISCMOIB/OMMB X X

4 Testing program

The tests performed are summarized in Table 3.

Table 3 — Test methods and standards used in the program

Test methods Reference Methodology Label

At 4 % of CO

Accelerated carbonation a ACA

Natural exposure NCA1

b

Natural carbonation

CEN/TS 12390-10

c

NCA2

Climatic chamber

Immersion DCL1

Chloride diffusion EN 12390-11 Ponding DCL2

Inversion DCL3

a

The draft test method used for this research received a negative vote and the Work Item was withdrawn;

however it was published by BSI as BS1881-210. A new accelerated test is being prepared for

standardization with the main change being a carbon dioxide concentration of 3%. The robustness and

precision determined by the research is expected to be the same as for the test method under development.

b

The procedure described in CEN/TS 12390-10: 2007 differs from the method followed in the present report

in that the CEN/TS 12390-10 prescribes that test specimens shall be tested when they have reached the

50% of the compressive strength of the reference concrete; in the present report there was not reference

concrete as the purpose was not to determine the relative carbonation but the robustness of the testing

procedures.

c

At 350ppm of carbon dioxide. An EN to replace CEN/TS 12390-10 is under development and the most

significant change is to increase the carbon dioxide concentration in the chamber test to 400 ppm. This

change is unlikely to impact the robustness and precision determined by this research.

5 Statistical analysis

The statistical treatment has been made following ISO 5725-2, “Determination of the accuracy (trueness

and precision) of measurement methods and results — Part 2: Basic method for the determination of

repeatability and reproducibility of a standard measurement method”.

According to this standard, the parameters to be calculated are the mean value (m), the repeatability

standard deviation (s ), the reproducibility standard deviation (s ). In addition, the limiting values of

r R

the repeatability and reproducibility, r and R, have been also calculated.

The basic model is simple of type I applied to a single experiment. It has been applied in three steps:

1) A critical exam of all data in order to identify and to treat any anomalous value or irregularities

which could prevent the correct application of ISO 5725-2.

2) Once the outliers results are identified and discarded it is calculated the repeatability, r and r (%)

and reproducibility, R and R (%) of the remaining results (excluding the outliers).

3) Definitive calculation of the mean and precision values, including the relations between the mean

and the precision for each level (ISO 5725-2).

6 Results

6.1 Accelerated carbonation test prEN 12390-12

The individual results of carbonation depth are presented in Figure 1. The testing procedure ranks

concretes with CEM II/A-LL 42.5R as more resistant than concrete with CEM II/B-V 32.5R for the same

w/c ratios.

Also it can be noticed that the method is sensitive to changes in the w/c ratio for the concrete with the

same cement as it was evidenced an increasing of the carbonation depth with the increasing of

w/c ratio.

It is not possible to draft any conclusion on the effect of cement type because the strength class of

cement is different. Consequently different cement lead to different concrete strength and porosity and

they are subjected to the exposure with different degree of porosity evolution in concrete.

Lab 9 has been considered outlier due to its results were much smaller of the rest of laboratories,

having being identified later that its chamber did not control well the relative humidity which was

higher than that prescribed in the standard. Then the results of this LAB 9 in this test have not been

used in the calculations. Table 4 shows the results of the statistical analysis.

Figure 1 — Individual results averaged for each mix of accelerated carbonation depth

Table 4 — Summary of mean values of carbonation depth obtained for ACA method

Accelerated carbonation Mix 1 Mix 2 Mix 3 Mix 4

Average (mm) 8,38 15,17 16,79 23,85

s (mm)

Repeatability 0,76 0,56 0,60 0,90

r

Standard deviation

s (mm)

Reproducibility 0,86 0,87 1,41 2,30

R

CV (%)

Repeatability 9,12 3,69 3,56 3,76

r

Variation coef.

CV (%)

Reproducibility 10,27 5,75 8,37 9,66

R

Repeatability r (mm) 2,14 1,57 1,67 2,51

Limit values

Reproducibility R (mm) 2,41 2,44 3,93 6,45

Repeatability r (%) 25,53 10,33 9,96 10,53

Limit

values/average

Reproducibility R (%) 28,77 16,10 23,42 27,04

6.2 Remarks from laboratories participating to the testing procedure CEN/TS 12390-12

(ACA)

The main aspect that should be mentioned is that 2 of 8 laboratories did not consider the indication of

protecting 2 parallel faces of specimen (point 6.2) and then it can be recommended that the description

of the testing procedure regarding measurements points and the number of faces should be improved.

7 Natural carbonation CEN/TS 12390-10 (NCA)

7.1 Natural carbonation

Its main aim of this test was to check its comparative ability and the robustness of the two alternative

testing procedures. The “normalization” described in the chapter 6 of CEN/TS 12390-10 was not in the

scope of the VTP.

Two results were considered:

— dk (mm) the penetration depth;

0,5

— k (mm/year ) the rate of carbonation.

c

7.2 Penetration depth dk

The test was performed by 6 laboratories, although not all performed both tests (in controlled chamber

and outdoors), number of specimens and testing times. The durations on each test taken by each

laboratory were not exactly those of the standard, but the data collected at different ages by each lab

(see Table 5 and 6) were enough close between them to have relevance: all the tests were performed by

taking some data before or at 1 year and other, at around two years. Due to these different testing ages,

the direct comparison of the penetration depths using dk in mm is made with not all laboratories,

0,5

however all data were used in the case of the rate of carbonation in mm/tyear because each dk was

divided by the exact testing period.

For the sake of appraising the environmental conditions, in Annex III are given the average temperature

and relative humidity of the atmospheres where the participating laboratories are located. Their

relative differences are presented also in the sicrometric diagram.

Table 5 — Days of exposure by each laboratory in a controlled chamber or outdoor sheltered

from rain

TESTING TIMES

LABORATORIES

(days)

L2 365, 730

L5 375, 801

L7 365

L9 190, 730

L11 365, 730, 886

L13 365

Table 6 — Number of laboratory results averaged given in Figures 4 and 7

NUMBER OF LABORATORIES FOR EACH AVERAGED VALUE

Natural carbonation

NCA1 NCA2

Year 1 Year 2 Year 1 Year 2

Mix 1 5 4 4 2

Mix 2 5 5 4 3

Mix 3 5 4 4 2

Mix 4 5 5 4 3

For averaging the values, Table 6 shows the number of laboratories per mix considered giving valid

values. Figures 2 and 3 show the averaged "valid" results of the penetration depth per mix obtained by

each laboratory.

Figure 2 — Individual results of carbonation depth dk for each mix 1 to 4 in the order in natural

exposure (NCA1) at equal or around 1 year (dark grey bar) and at 2 years (light grey bar). (LAB 9

did not test at 365 days but at 190 days)

Figure 3 — Individual results of carbonation depth dk for each mix 1 to 4 in the order in

controlled chamber (NCA2) at equal or around 1 year (dark grey bar) and at 2 years (light grey

bar). (LAB 9 did not test at 365 days but at 190 days)

For comparative purposes between NCA1 and NCA 2 test procedures, the differences in the carbonation

depth dk obtained at around 1 year are given in Figure 4. It is remarkable to deduce that, in spite of the

very different climates in the countries of the different laboratories (see Annex III), the dk values in

natural outdoors sheltered from rain exposure are reasonable similar to those values obtained through

NCA2 (controlled chamber).

Figure 4 — Comparison of testing procedures NCA1 (natural outdoors sheltered from rain) and

NCA2 in the controlled chamber (LAB 9 did not test at 365 days but at 190 days). Individual

values per mix at equal or around 1 year (dark grey bar) and at 2 years (light grey bar)

The precision data of both test procedures (carbonation depth obtained in controlled chamber and

outdoors sheltered from rain) are given in Table 7 and 8 for the results at 1 year only because it was

considered that the number of laboratories making the tests at around two years was too few to allow

the calculation of precision at that age. Due to the same reason of the limited number of laboratories the

repeatability was made with all data by variance analysis and then it results the same for all mixes.

Table 7 — Summary of precision data of carbonation depth obtained for NCA1 method

at one year testing

dk Natural Carbonation NCA1 outdoors Mix 1 Mix 2 Mix 3 Mix 4

Average (mm) 1,57 4,04 3,04 5,99

s (mm)

Repeatability 0,34

r

Standard

deviation

s (mm)

Reproducibility 0,86

R

CV (%)

Repeatability 21,8 8,5 11,3 5,7

r

Variation

coef.

CV (%)

Reproducibility 61,2 23,7 31,5 16,0

R

r = 2,8 s (mm)

Repeatability 0,96

r

Limit values

R = 2,8 s (mm)

Reproducibility 2,42

R

r = 2,8 CV (%)

Repeatability 55,2 21,4 28,4 14,4

r

Limit values

R = 2,8 CV (%)

Reproducibility 154,5 59,9 79,6 40,4

R

Table 8 — Summary of mean values of carbonation depth obtained for NCA2 method

at one year testing

dk Natural Carbonation NCA2

Mix 1 Mix 3

Controlled chamber

Average (mm) 1,85 3,23

s (mm)

Repeatability 0,30

r

Standard

deviation

s (mm)

Reproducibility 0,40

R

CV (%)

Repeatability 16,3 9,3

r

Variation coef.

CV (%)

Reproducibility 21,8 12,5

R

r = 2,8 s (mm)

Repeatability 0,85

r

Limit values

R = 2,8 s (mm)

Reproducibility 1,13

R

r = 2,8 CV (%)

Repeatability 45,7 26,2

r

Limit values

R = 2,8 CV (%)

Reproducibility 61,0 34,9

R

7.3 Summary of precision parameters of dk (mm)

In Table 9 are summarized the precision data suggested for CEN/TS 12390-10, “Testing hardened

concrete — Part 10: Determination of the relative carbonation resistance of the concrete“, for

measurements of both test procedures (carbonation depth obtained in controlled chamber and

outdoors sheltered from rain) are given in Table 1. These data are expressed as standard deviation of

the mean of two determinations (two cube specimens). All the tests were performed by taking data at

1 year by 6 laboratories. Not all laboratories performed both tests on all samples.

Table 9 — Precision data of carbonation depth (CEN/TS 12390-10) for one year testing

Repeatability Reproducibility

Parameter Level s r = 2,8 s s R = 2,8 s

r r R R

(mm) (mm) (mm) (mm)

carbonation depth dk

0,5–7 (mm) 0,34 0,96 0,86 2,42

outdoors (NCA1)

carbonation depth in climatic

0,5–7 (mm) 0,30 0,85 0,40 1,13

chamber (NCA2)

Precision expressed in terms of coefficient of

CV (%) CV (%)

r (%) R (%)

r R

variation

NCA1 dk ± 12 33 30 84

NCA2 dk ± 13 36 17 48

Repeatability Reproducibility

Parameter Level s r = 2,8 s s R = 2,8 s

r r R R

(mm) (mm) (mm) (mm)

These are based on a precision exercise undertaken in 2014 using concrete samples made fulfilling EN 206

limiting values for concrete composition.

The carbonation depth results are obtained by 5 laboratories for NCA1 and by 4 laboratories for NCA2 using four

concrete samples (two for test).

The values apply to the two test methods (controlled chamber and outdoors) described in this standard for

1 year testing.

As the main objective of the exercise is to validate the test method, it can be confirmed that the standard

is clear enough, being however the number of readings per specimen face and the averaging which

would need improved description.

A final remark that can be made comparing natural carbonations and accelerated tests, are:

— The test in natural concentration conditions is sensitive to changes in w/c ratio for the same mix as

in the case of accelerated carbonation, but the relative ranking of concretes is different than in

ac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...