ASTM C485-83(1999)

(Test Method)Standard Test Method for Measuring Warpage of Ceramic Tile

Standard Test Method for Measuring Warpage of Ceramic Tile

SCOPE

1.1 This test method covers procedures for measuring diagonal and edge warpages of the following categories of ceramic tile:

1.1.1 Square Tile 2 by 2 in. (51 by 51 mm) or larger, that are nominally flat, of uniform overall thickness, and have a smooth face of one of the types: unglazed, bright glazed, matte glazed, or finely crystalline glazed.

1.1.2 Oblong Tile, no facial dimension smaller than 2 in. (51 mm), that are flat, of uniform overall thickness, and have a smooth face of one of the types: unglazed, bright glazed, matte glazed, or finely crystalline glazed.

1.1.3 Square and Oblong Tile, no facial dimension smaller than 2 in. (51 mm), that are flat, but have an irregular face such as embossed, sloped, bumpy, wavy, coarsely crystalline, or wire-cut textured.

1.1.4 Non-Rectilinear Tile, larger than 4 in. (26 cm ), that are flat and of uniform body thickness with smooth or irregular face, such as hexagonal, diamond, Spanish type, etc.

1.1.5 Trim Tile meeting one of the descriptions in 1.1.1 through 1.1.4 except that only a part of the tile surface is flat. (Surface trim tile should be treated as flat tile whenever possible.)

1.1.6 Square or Oblong Tile with facial area less than 4 in. (26 cm ) and at least two straight sides equal to or greater than 1.0 in. (25 mm) long. (Modular 1 by 1 in.-tile are not in the scope of this test method.)

1.2 This test method is not applicable to tile having embossed surfaces that are not flat, or that have a combination of variable body thickness and an irregular face.

1.3 The values stated in the inch-pound units are to be regarded as the standard. The SI (metric) units given in parentheses are for information only.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 485 – 83 (Reapproved 1999)

Standard Test Method for

Measuring Warpage of Ceramic Tile

This standard is issued under the fixed designation C 485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 242 Terminology of Ceramic Whitewares and Related

Products

1.1 This test method covers procedures for measuring di-

agonal and edge warpages of the following categories of

3. Terminology

ceramic tile:

3.1 Definitions:

1.1.1 Square Tile 2 by 2 in. (51 by 51 mm) or larger, that

3.1.1 tile—see Definitions C 242.

are nominally flat, of uniform overall thickness, and have a

3.1.2 warpage—curvature of a flat tile measured as devia-

smooth face of one of the types: unglazed, bright glazed, matte

tion of the tile surface from a true plane along the edges or the

glazed, or finely crystalline glazed.

diagonals. The deviation is measured at the mid-length of an

1.1.2 Oblong Tile, no facial dimension smaller than 2 in. (51

edge or diagonal, expressed as a percentage of the length of the

mm), that are flat, of uniform overall thickness, and have a

edge or diagonal, and called convex or concave with respect to

smooth face of one of the types: unglazed, bright glazed, matte

the face of the tile.

glazed, or finely crystalline glazed.

1.1.3 Square and Oblong Tile, no facial dimension smaller

4. Summary of Test Method

than 2 in. (51 mm), that are flat, but have an irregular face such

4.1 This test method consists of measuring the deviation

as embossed, sloped, bumpy, wavy, coarsely crystalline, or

from a straight line at the midpoint between reference points on

wire-cut textured.

2 2 the face or back of a tile. Measurements are made along the

1.1.4 Nonrectilinear Tile, larger than 4 in. (26 cm ), that

edges of a tile or along the diagonals, or both. The deviation is

are flat and of uniform body thickness with smooth or irregular

expressed as convex or concave warpage in relation to the tile

face, such as hexagonal, diamond, Spanish type, and so forth.

face, and its magnitude is calculated as a percentage of the

1.1.5 Trim Tile meeting one of the descriptions in 1.1.1-

length of the edge or diagonal.

1.1.4 except that only a part of the tile surface is flat. (Surface

trim tile should be treated as flat tile whenever possible.)

5. Significance and Use

1.1.6 Square or Oblong Tile with facial area less than 4

2 2 5.1 This test method provides a means for determining

in. (26 cm ) and at least two straight sides equal to or greater

whether or not a lot of ceramic tile meets the warpage

than 1.0 in. (25 mm) long. (Modular 1- by 1-in. tile are not in

requirements that may appear in specifications to assure

the scope of this test method.)

satisfactory tile installations. In accordance with this test

1.2 This test method is not applicable to tile having em-

method, warpage is calculated as a percentage of the length of

bossed surfaces that are not flat, or that have a combination of

the edge or diagonal being tested. It is realized that the

variable body thickness and an irregular face.

percentage values based on the overall edge length, or on the

1.3 The values stated in the inch-pound units are to be

overall diagonal length of a tile will be slightly lower than

regarded as the standard. The SI (metric) units given in

those based on the distance between reference points. How-

parentheses are for information only.

ever, the ratio of the overall lengths to the distance between

1.4 This standard does not purport to address all of the

reference points will be practically constant for any particular

safety concerns, if any, associated with its use. It is the

size of tile and, therefore, the percentage values will be

responsibility of the user of this standard to establish appro-

comparable and equally indicative of warpage.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Apparatus

6.1 General Apparatus—The size and arrangement of the

2. Referenced Documents

apparatus for measuring the warpages vary, depending on the

2.1 ASTM Standards:

size and shape of the tile to be measured. In general, the

apparatus consists of two stationary pins (reference pins)

This method is under the jurisdiction of ASTM Committee C-21 on Ceramic

spaced apart ⁄4 in. (19 mm) less than the length of the edge or

Whitewares and Related Productsand is the direct responsibility of Subcommittee

C21.06on Ceramic Tile.

Current edition approved Jan. 28, 1983. Published March 1983. Originally

published as C 485 – 61 T. Last previous edition C 485 – 83 (1993). Annual Book of ASTM Standards, Vol 15.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 485

6.2 Apparatus for Square Tile:

6.2.1 Metal Plate—A flat metal plate, 6 by 6 in. (152 by 152

1 7

mm) square and ⁄4 in. (6.4 mm) thick, with a ⁄16-in. (11-mm)

wide slot starting at the midpoint of one side and running at

right angles to that side for a distance of 2 ⁄8 in. (67 mm)

toward the center of the plate. The plate also has a ⁄16-in.

diameter hole in the exact center of the plate. One side of the

1 1

plate has two ⁄8-in. (3.2-mm) thick, ⁄2-in. (13-mm) wide, and

1-in. (25-mm) high projections, located not more than ⁄2 in.

from the corners, and a similar projection located on an

adjacent side and not more than ⁄2 in. from one of the corners

of the first side. These projections serve as permanent registry

stops for 6- by 6-in. tile during measurement.

6.2.1.1 In addition, the plate has a series of tapped holes for

insertion of removable reference pins and removable registry

stops. The centers of the holes for the reference pins are located

for each nominal size of tile near three of its corners, ⁄8 in. (9.5

mm) in from each side, when the tile is centered on the plate,

except that for 2- by 2-in. (51- by 51-mm) tile the distance in

from the edges is ⁄4 in. (6.4 mm). To receive the three registry

stops, the centers of two holes are located for each nominal size

1 1

of tile ⁄2in. (13 mm) from the corners of one side and ⁄8 in.

(3.2 mm) from the edge of the tile, while the center of a third

1 hole is located on an adjacent side, ⁄2 in. from one of the

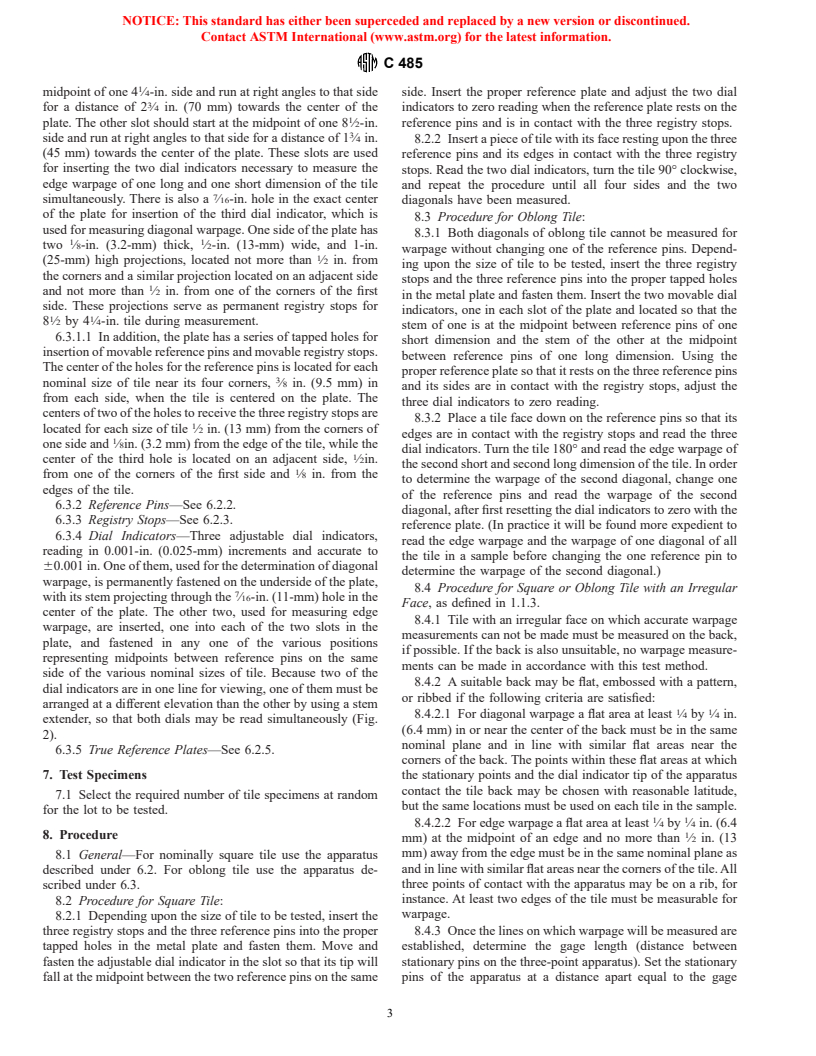

FIG. 1 Apparatus for Square Tile, Set Up for Measurement of 4 ⁄4-

1 1

by 4 ⁄4-in. (108- by 108-mm) Tile

corners of the first side and ⁄8 in. from the edge of the tile.

6.2.2 Reference Pins—Three movable reference pins ⁄8 in.

(16 mm) high and ⁄4 in. (6.4 mm) in diameter, with the free end

ground to a hemispherical tip and the other end threaded for a

distance of ⁄4 in. The reference pins are inserted in the metal

plate to support the tile during measurement.

6.2.3 Registry Stops—Three ⁄4-in. (6.4-mm) diameter and

1 ⁄4-in. (32-mm) high, movable, flat top registry stops with a

1 1

⁄16-in. (1.6-mm) wide and ⁄8-in. (3.2-mm) deep slot on one

end for the insertion of a screwdriver and threaded on the other

end for a distance of ⁄4 in. The registry stops are inserted in the

metal plate to fix the horizontal position of the tile during

measurement.

6.2.4 Dial Indicators—Two adjustable dial indicators, read-

ing in 0.001-in. (0.025-mm) increments and accurate to

60.001 in. One is inserted from the bottom through the ⁄16-in.

(11-mm) hole in the center of the plate, permanently fastened

to the underside of the metal plate, and used for measuring

diagonal warpage. The other is inserted into the slot in the plate

and fastened in any one of four positions which represent

midpoints between reference pins on one side of each of the

different nominal sizes of tile. This dial indicator is used for

determining edge warpage.

6.2.5 True Reference Plates—Four ⁄8-in. (9.5-mm) thick

FIG. 2 Apparatus as Shown in Fig. 1, Showing Arrangement of

plates of true plane surface, made of steel or polished glass, one

Stem Extender

each of the same dimensions as the four nominal sizes of tile

diagonal being tested, and a dial indicator tip midway between

which can be measured on this apparatus.

the stationary pins and in line with them. The pins and the dial

6.3 Apparatus for Oblong Tile:

indicator are mounted firmly on the same rigid metal bar. The

1 1

6.3.1 Metal Plate—A flat rectangular metal plate 8 ⁄2 by 4 ⁄4

pins may have a hemispherical tip, as described in 6.2.2, or

in. (216 by 108 mm) and ⁄4 in. (6.4 mm) thick, having two

they may be conical to a point. A more versatile apparatus for

⁄16-in. (11-mm) wide slots. One slot should start at the

standard sizes of tile consists of a metal plate having three

movable reference pins, three movable registry stops, and the

necessary number of dial indicators. See Fig. 1 and Fig. 2.

Three drawings showing construction details are available from ASTM

Headquarters. Order ADJC0485.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 485

midpoint of one 4 ⁄4-in. side and run at right angles to that side side. Insert the proper reference plate and adjust the two dial

for a distance of 2 ⁄4 in. (70 mm) towards the center of the indicators to zero reading when the reference plate rests on the

plate. The other slot should start at the midpoint of one 8 ⁄2-in. reference pins and is in contact with the three registry stops.

side and run at right angles to that side for a distance of 1 ⁄4 in.

8.2.2 Insert a piece of tile with its face resting upon the three

(45 mm) towards the center of the plate. These slots are used

reference pins and its edges in contact with the three registry

for inserting the two dial indicators necessary to measure the

stops. Read the two dial indicators, turn the tile 90° clockwise,

edge warpage of one long and one short dimension of the tile

and repeat the procedure until all four sides and the two

simultaneously. There is also a ⁄16-in. hole in the exact center

diagonals have been measured.

of the plate for insertion of the third dial indicator, which is

8.3 Procedure for Oblong Tile:

used for measuring diagonal warpage. One side of the plate has

8.3.1 Both diagonals of oblong tile cannot be measured for

1 1

two ⁄8-in. (3.2-mm) thick, ⁄2-in. (13-mm) wide, and 1-in.

warpage without changing one of the reference pins. Depend-

(25-mm) high projections, located not more than ⁄2 in. from

ing upon the size of tile to be tested, insert the three registry

the corners and a similar projection located on an adjacent side

stops and the three reference pins into the proper tapped holes

and not more than ⁄2 in. from one of the corners of the first

in the metal plate and fasten them. Insert the two movable dial

side. These projections serve as permanent registry stops for

indicators, one in each slot of the plate and located so that the

1 1

8 ⁄2 by 4 ⁄4-in. tile during measurement.

stem of one is at the midpoint between reference pins of one

6.3.1.1 In addition, the plate has a series of tapped holes for

short dimension and the stem of the other at the midpoint

insertion of movable reference pins and movable registry stops.

between reference pins of one long dimension. Using the

The center of the holes for the reference pins is located for each

proper reference plate so that it rests on the three reference pins

nominal size of tile near its four corners, ⁄8 in. (9.5 mm) in

and its sides are in contact with the registry stops, adjust the

from each side, when the tile is centered on the plate. The

three dial indicators to zero reading.

centers of two of the holes to receive the three registry stops are

8.3.2 Place a tile face down on the reference pins so that its

located for each size of tile ⁄2 in. (13 mm) from the corners of

edges are in contact with the registry stops and read the three

one side and ⁄8in. (3.2 mm) from the edge of the tile, while the

dial indicators. Turn the tile 180° and read the edge warpage of

center of the third hole is located on an adjacent side, ⁄2in.

the second short and second long dimension of the tile. In order

from one of the corners of the first side and ⁄8 in. from the

to determine the warpage of the second diagonal, change one

edges of the tile.

of the reference pins and read the warpage of the second

6.3.2 Reference Pins—See 6.2.2.

diagonal, after first resetting the dial indicators to zero with the

6.3.3 Registry Stops—See 6.2.3.

reference plate. (In practice it will be found more expedient to

6.3.4 Dial Indicators—Three adjustable dial indicators,

read the edge warpage and the warpage of one diagonal of all

reading in 0.001-in. (0.025-mm) increments and accurate to

the tile in a sample before changing the one reference pin to

60.001 in. One of them, used for the determination of diagonal

determine the warpage of the second diagonal.)

warpage, is permanently fastened on the underside of the plate,

8.4 Procedure for Square or Oblong Tile with an Irregular

with its stem projecting through the ⁄16-in. (11-mm) hole in the

Face, as defined in 1.1.3.

center of the plate. The other two, used for measuring edge

8.4.1 Tile with an irregular face on which accurate warpage

warpage, are inserted, one into each of the two slots in the

measurements can not be made must be measured on the back,

plate, and fastened in any one of the various positions

if possible. If the back is also unsuitable, no warpage measure-

representing midpoints between reference pins on the same

ments can be made in accordance with this test method.

side of the various nominal sizes of tile. Because two of the

8.4.2 A suitable back may be flat, embossed with a pattern,

dial indicators are in one line for viewing, one of them must be

or ribbed if the following criteria are satisfied:

arranged at a different elevation than the other by using a stem

1 1

8.4.2.1 For diagonal warpage a flat area at least ⁄4 by ⁄4 in.

extender, so that both dials may be read simultaneously (Fig.

(6.4 mm) in or near the center of the back must be in the same

2).

nominal plane and in line with similar flat areas near the

6.3.5 True Reference Plates—See 6.2.5.

corners of the back. The points within these flat areas at which

7. Test Specimens the stationary points and the dial indicator tip of the apparatus

contact the tile back may be chosen with reasonable latitude,

7.1 Select the required number of tile specimens at rand

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.