ASTM D2384-83(2014)

(Test Method)Standard Test Methods for Traces of Volatile Chlorides in Butane-Butene Mixtures

Standard Test Methods for Traces of Volatile Chlorides in Butane-Butene Mixtures

SIGNIFICANCE AND USE

4.1 These test methods are used to determine trace amounts of volatile chlorides in butane-butene mixtures. Such information is valuable in cases where chloride is deleterious in the use of this product; also, chloride contributes to corrosion problems in processing units in instances where further processing of this material is involved.

SCOPE

1.1 These test methods cover the determination of the total volatile organic chlorides in concentrations from 10 to 100 ppm in butane-butene mixtures. The amperometric finish is not directly applicable in the presence of other substances that combine with silver ion or oxidize chloride ion in dilute acid solution. Bromides, sulfides, ammonia, tobacco smoke, and more than 25 μg of hydrogen peroxide in the test solution interfere in the spectrophotometric procedure.

1.2 Dissolved sodium chloride is not quantitatively determined using these test methods.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Sections 5, 8, 11, 14, 19, and Annex A1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2384 − 83 (Reapproved 2014)

Standard Test Methods for

Traces of Volatile Chlorides in Butane-Butene Mixtures

This standard is issued under the fixed designation D2384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 1—Lamp combustion is readily applicable to multiple testing.

1. Scope

Although an oxy-hydrogen burner does not lend itself to multiple testing,

1.1 These test methods cover the determination of the total

itaffordsmuchmorerapidanalysisforasinglesamplethandoesthelamp

volatile organic chlorides in concentrations from 10 to combustion.

100ppm in butane-butene mixtures. The amperometric finish

3.1.1 Lamp Combustion—The sample is burned in an atmo-

is not directly applicable in the presence of other substances

sphere of carbon dioxide and oxygen or in purified air; the

that combine with silver ion or oxidize chloride ion in dilute

halogen-containingcombustionproductsareabsorbedindilute

acid solution. Bromides, sulfides, ammonia, tobacco smoke,

sodium carbonate solution.

and more than 25 µg of hydrogen peroxide in the test solution

3.1.2 Oxy-Hydrogen Combustion—The sample is burned in

interfere in the spectrophotometric procedure.

anoxy-hydrogenatomizerburner,andthecombustionproducts

1.2 Dissolved sodium chloride is not quantitatively deter-

are absorbed in a dilute solution of sodium carbonate.

mined using these test methods.

3.2 Finishes—Either the amperometric titration or spectro-

1.3 The values stated in SI units are to be regarded as

photometric finish may be used for the chloride ion determi-

standard. No other units of measurement are included in this

nation.

standard.

3.2.1 Amperometric Titration—The chloride ion in aqueous

solution is titrated amperometrically with standard silver ni-

1.4 This standard does not purport to address all of the

trate solution, using a saturated calomel electrode as reference

safety concerns, if any, associated with its use. It is the

electrode. The diffusion currents are plotted against the corre-

responsibility of the user of this standard to establish appro-

sponding volumes of silver nitrate solution used; the end point

priate safety and health practices and determine the applica-

is taken as the intersection of the two straight-line portions of

bility of regulatory limitations prior to use. Specific warning

the curve.

statements are given in Sections 5, 8, 11, 14, 19, and Annex

A1.

3.2.2 Spectrophotometric Finish—Chloride ion in the ab-

sorber solution is determined by reaction with mercuric thio-

2. Referenced Documents

cyanate to release thiocyanate, which forms a reddish orange

+++

2.1 ASTM Standards:

complex with Fe . The intensity of the color is measured at

D329Specification for Acetone

460 nm with a spectrophotometer or filter photometer.

D1266TestMethodforSulfurinPetroleumProducts(Lamp

Method)

4. Significance and Use

3. Summary of Test Methods 4.1 These test methods are used to determine trace amounts

of volatile chlorides in butane-butene mixtures. Such informa-

3.1 Combination Test Methods—Either the lamp or oxy-

tionisvaluableincaseswherechlorideisdeleteriousintheuse

hydrogen test method may be used for combustion.

of this product; also, chloride contributes to corrosion prob-

lems in processing units in instances where further processing

These test methods are under the jurisdiction of ASTM Committee D02 on

of this material is involved.

Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility

of Subcommittee D02.D0.04 on C4 Hydrocarbons.

CurrenteditionapprovedMay1,2014.PublishedJuly2014.Originallyapproved

5. Purity of Reagents

in 1965. Last previous edition approved in 2009 as D2384–83(2009). DOI:

10.1520/D2384-83R14.

5.1 Purity of Reagents—Reagent grade chemicals shall be

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

used in all tests. Unless otherwise indicated, it is intended that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

all reagents shall conform to the specifications of the Commit-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tee onAnalytical Reagents of theAmerican Chemical Society,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2384 − 83 (2014)

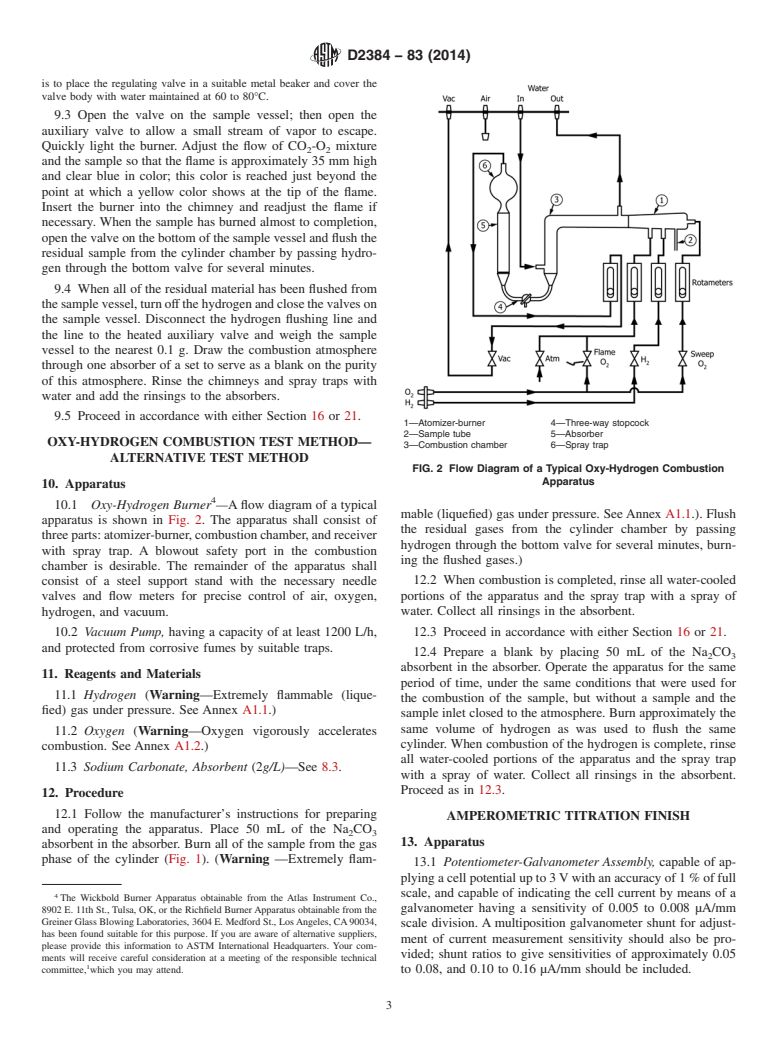

FIG. 1 Diagrammatic Sketch of Butane-Butene Heat Exchange System

where such specifications are available. Other grades may be LAMP COMBUSTION TEST METHOD

used, provided it is first ascertained that the reagent is of

7. Apparatus

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

7.1 ASTM Lamp Assembly—Use the apparatus specified in

Test Method D1266, including the liquefied petroleum gas

5.2 References to water shall be understood to mean

burner assembly.

chloride-free distilled or deionized water.

5.3 (Warning—In view of the common occurrence of

8. Reagents

chloride in reagents and laboratory air, special care must be

8.1 Use the necessary reagents and materials specified in

taken during preparation and storage of reagents to avoid

Test Method D1266, in addition to the absorber solution as

contamination. They should be isolated from other reagents

described in 8.3.

andusedsolelyforthesemethods.Ablankdeterminationmust

be performed each time a reagent is changed to ensure that it

8.2 Hydrogen (Warning—Extremely flammable (liquefied)

is not contaminated with chloride.

gas under pressure. See Annex A1.1.)

It is also imperative that all glassware used in this determi-

8.3 Sodium Carbonate Absorbent (2 g/L)— Dissolve 2.0 g

nation be cleaned thoroughly and rinsed four times with

of anhydrous sodium carbonate (Na CO ) in water and dilute

2 3

chloride-freedistilledordeionizedwater.Utmostcautionmust

to a litre with water.

be taken during the analysis to prevent contamination from

chlorides.)

9. Procedure

9.1 Prepare the combustion apparatus as described in Sec-

6. Sampling

tion 7 of Test Method D1266, Preparation ofApparatus, using

6.1 Steam and dry a 10 to 25-mL corrosion-resistant metal

35 mL of Na CO solution to charge the absorber.

2 3

samplecylinderhavinga450-psi(3100kPa)workingpressure

9.2 Weigh the vessel containing the sample to the nearest

and equipped with a needle valve outlet at each end.

0.1 g. Support the sample vessel in an upright position so that

6.2 Pressure the prepared cylinder with dry hydrogen to

the sample is burned from the gaseous phase. Connect the

20psig (137.5kPa gage) to afford a gas cushion preventing

sample vessel to the auxiliary corrosion-resistant regulating

rupture due to liquid expansion on increase of temperature.

valve by means of corrosion-resistant metal tubing (Fig. 1)

6.3 Obtain a liquid sample from the purged sample line,

(Note 2). Connect the bottom valve of the sample vessel to the

filling the upright cylinder through the bottom needle valve, regulated hydrogen supply. By means of short lengths of

keepingthetopvalveclosed.Donotpurgethesamplecylinder.

chloride-free rubber tubing, connect the auxiliary valve outlet

to the side inlet of the gas burner and the lower inlet of the gas

burner (Test Method D1266,AnnexA3,Apparatus Detail, Fig.

Reagent Chemicals, American Chemical Society Specifications, American 5) to the burner manifold.

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

NOTE 2—For steady burning, it may be necessary to surround the

listed by the American Chemical Society, see Annual Standards for Laboratory

auxiliary valve with a heat-exchanger system. A convenient means is

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, winding insulated heating wire, having a resistance of 40 to 60Ω, around

MD. theauxiliaryvalveandconnectingittoasuitablerheostat.Anothermeans

D2384 − 83 (2014)

is to place the regulating valve in a suitable metal beaker and cover the

valve body with water maintained at 60 to 80°C.

9.3 Open the valve on the sample vessel; then open the

auxiliary valve to allow a small stream of vapor to escape.

Quickly light the burner. Adjust the flow of CO -O mixture

2 2

and the sample so that the flame is approximately 35 mm high

and clear blue in color; this color is reached just beyond the

point at which a yellow color shows at the tip of the flame.

Insert the burner into the chimney and readjust the flame if

necessary. When the sample has burned almost to completion,

openthevalveonthebottomofthesamplevesselandflushthe

residual sample from the cylinder chamber by passing hydro-

gen through the bottom valve for several minutes.

9.4 When all of the residual material has been flushed from

thesamplevessel,turnoffthehydrogenandclosethevalveson

the sample vessel. Disconnect the hydrogen flushing line and

the line to the heated auxiliary valve and weigh the sample

vessel to the nearest 0.1 g. Draw the combustion atmosphere

through one absorber of a set to serve as a blank on the purity

of this atmosphere. Rinse the chimneys and spray traps with

water and add the rinsings to the absorbers.

9.5 Proceed in accordance with either Section 16 or 21.

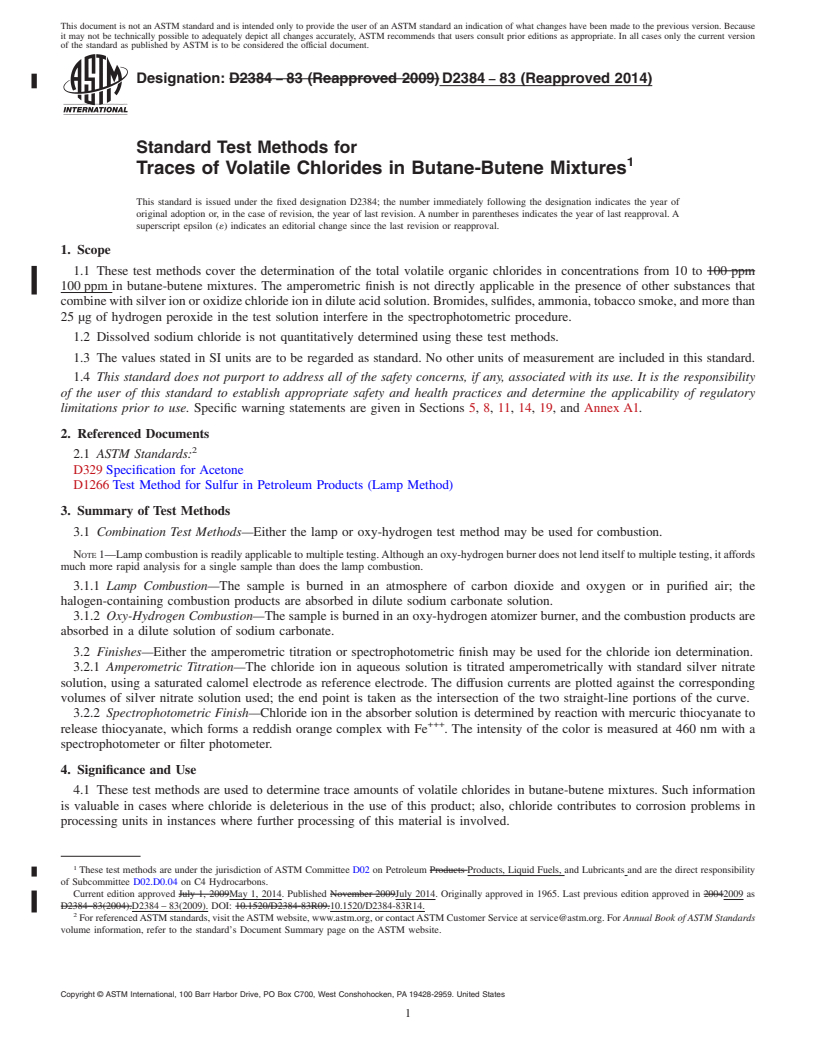

1—Atomizer-burner 4—Three-way stopcock

2—Sample tube 5—Absorber

OXY-HYDROGEN COMBUSTION TEST METHOD—

3—Combustion chamber 6—Spray trap

ALTERNATIVE TEST METHOD

FIG. 2 Flow Diagram of a Typical Oxy-Hydrogen Combustion

Apparatus

10. Apparatus

10.1 Oxy-Hydrogen Burner —Aflow diagram of a typical

mable (liquefied) gas under pressure. SeeAnnex A1.1.). Flush

apparatus is shown in Fig. 2. The apparatus shall consist of

the residual gases from the cylinder chamber by passing

threeparts:atomizer-burner,combustionchamber,andreceiver

hydrogen through the bottom valve for several minutes, burn-

with spray trap. A blowout safety port in the combustion

ing the flushed gases.)

chamber is desirable. The remainder of the apparatus shall

12.2 When combustion is completed, rinse all water-cooled

consist of a steel support stand with the necessary needle

valves and flow meters for precise control of air, oxygen, portions of the apparatus and the spray trap with a spray of

water. Collect all rinsings in the absorbent.

hydrogen, and vacuum.

10.2 Vacuum Pump, having a capacity of at least 1200 L/h, 12.3 Proceed in accordance with either Section 16 or 21.

and protected from corrosive fumes by suitable traps.

12.4 Prepare a blank by placing 50 mL of the Na CO

2 3

absorbent in the absorber. Operate the apparatus for the same

11. Reagents and Materials

period of time, under the same conditions that were used for

11.1 Hydrogen (Warning—Extremely flammable (lique-

the combustion of the sample, but without a sample and the

fied) gas under pressure. See Annex A1.1.)

sample inlet closed to the atmosphere. Burn approximately the

same volume of hydrogen as was used to flush the same

11.2 Oxygen (Warning—Oxygen vigorously accelerates

cylinder. When combustion of the hydrogen is complete, rinse

combustion. See Annex A1.2.)

all water-cooled portions of the apparatus and the spray trap

11.3 Sodium Carbonate, Absorbent (2g/L)—See 8.3.

with a spray of water. Collect all rinsings in the absorbent.

Proceed as in 12.3.

12. Procedure

12.1 Follow the manufacturer’s instructions for preparing

AMPEROMETRIC TITRATION FINISH

and operating the apparatus. Place 50 mL of the Na CO

2 3

13. Apparatus

absorbent in the absorber. Burn all of the sample from the gas

phase of the cylinder (Fig. 1). (Warning —Extremely flam-

13.1 Potentiometer-Galvanometer Assembly, capable of ap-

plyingacellpotentialupto3Vwithanaccuracyof1%offull

4 scale, and capable of indicating the cell current by means of a

The Wickbold Burner Apparatus obtainable from the Atlas Instrument Co.,

galvanometer having a sensitivity of 0.005 to 0.008 µA/mm

8902 E. 11th St., Tulsa, OK, or the Richfield BurnerApparatus obtainable from the

GreinerGlassBlowingLaboratories,3604E.MedfordSt.,LosAngeles,CA90034,

scale division. A multiposition galvanometer shunt for adjust-

has been found suitable for this purpose. If you are aware of alternative suppliers,

ment of current measurement sensitivity should also be pro-

please provide this information to ASTM International Headquarters. Your com-

vided; shunt ratios to give sensitivities of approximately 0.05

ments will receive careful consideration at a meeting of the responsible technical

committee, which you may attend. to 0.08, and 0.10 to 0.16 µA/mm should be included.

D2384 − 83 (2014)

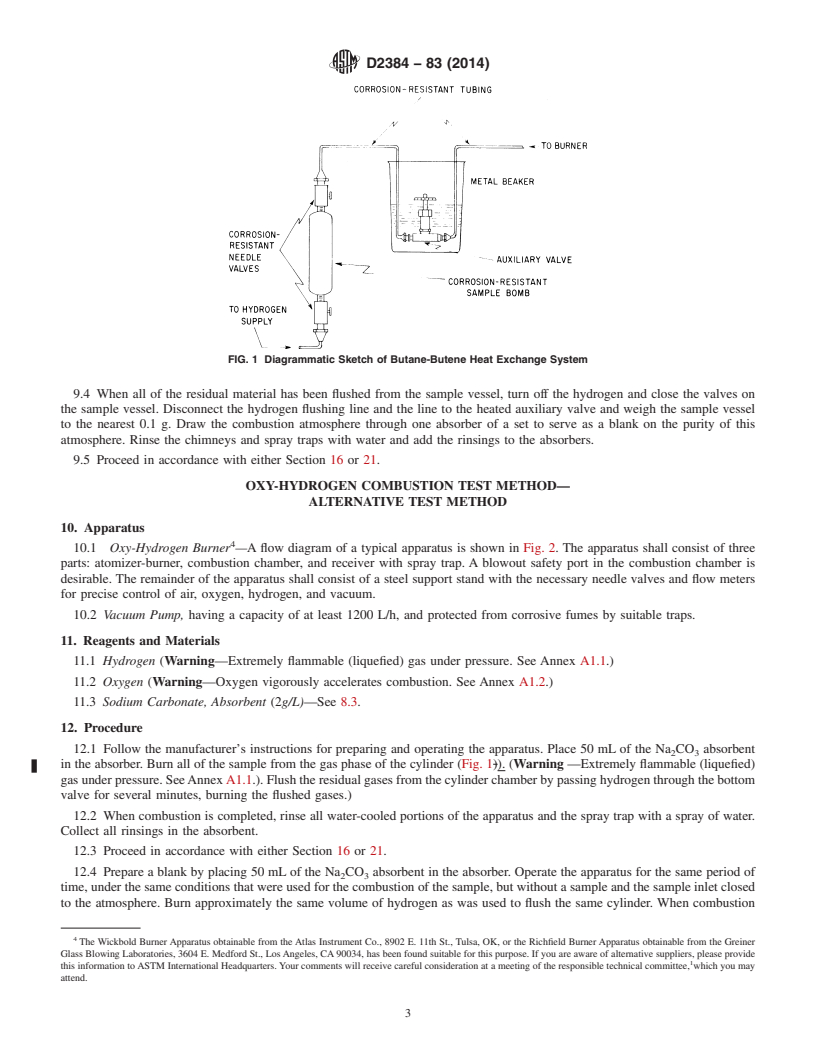

FIG. 3 Schematic Assembly of the Amperometric Titration Cell

13.2 Titration Assembly—An apparatus similar to that 14.2 Agar Solution—Dissolve2gof agar-agar powder in

shown in Fig. 3, consisting of a rotating (600 rpm) platinum 100 mL of hot water (80 to 100°C) containing 20 g of

electrode, a saturated calomel reference electrode with salt potassium nitrate (KNO ).

bridge, a means of blanketing the solution with nitrogen, and a

14.3 Bromthymol Blue Indicator Solution—Dissolve 0.10 g

holder for a 10-mL buret.

of the solid indicator in 100 mL of hot water, cool, and add 1

13.3 Calomel Electrode, constructed as shown in Fig. 3.

mLof chloroform as a preservative. Discard the solution when

it is 1 week old.

13.4 Platinum Electrode, rotating-hook type. A suitable

electrode may be constructed as follows: Seal a platinum wire

NOTE 3—Remove possible objectionable amounts of chloride by

0.03to0.05in.(0.76to1.3mm)indiameterand0.75to1.0in.

passing the solution through an ion-exchange resin in the hydroxyl form.

(19.1to25.4mm)longintotheendofa6-mmoutsidediameter

Neutralizetheresultingalkalinesolutiontothebromthymolblueendpoint

by titration with HNO (3+97).

soft glass tube that has been shaped into a stirrer blade. Bend 3

−

theextendingplatinumwireupwardsatitsmidpointtoforman

14.4 Chloride, Standard Solution (10 µg Cl /mL)—Dilute a

angleof90°.Placeafewdropsofmercuryintheglasstubeand

suitable volume of 1+10 assayed hydrochloric acid to obtain

−

make electrical contact between the mercury and the connec-

a solution containing 10 µg Cl /mL.

tion on the amperometric titrator with a piece of copper wire

14.5 Gelatin Solution (10 g/L)—Dissolve1gof gelatin in

(insulate the exposed wire to prevent shorting).

100 mL of hot water and add 1 mL of chloroform as a

13.5 Buret—A 10-mL semi-micro buret, with the tip con-

preservative. Discard the solution when it is 1 week old.

structedsoastobeabletodipbelowthesurfaceofthesolution

14.6 Hydrogen Peroxid

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2384 − 83 (Reapproved 2009) D2384 − 83 (Reapproved 2014)

Standard Test Methods for

Traces of Volatile Chlorides in Butane-Butene Mixtures

This standard is issued under the fixed designation D2384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the determination of the total volatile organic chlorides in concentrations from 10 to 100 ppm

100 ppm in butane-butene mixtures. The amperometric finish is not directly applicable in the presence of other substances that

combine with silver ion or oxidize chloride ion in dilute acid solution. Bromides, sulfides, ammonia, tobacco smoke, and more than

25 μg of hydrogen peroxide in the test solution interfere in the spectrophotometric procedure.

1.2 Dissolved sodium chloride is not quantitatively determined using these test methods.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements are given in Sections 5, 8, 11, 14, 19, and Annex A1.

2. Referenced Documents

2.1 ASTM Standards:

D329 Specification for Acetone

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

3. Summary of Test Methods

3.1 Combination Test Methods—Either the lamp or oxy-hydrogen test method may be used for combustion.

NOTE 1—Lamp combustion is readily applicable to multiple testing. Although an oxy-hydrogen burner does not lend itself to multiple testing, it affords

much more rapid analysis for a single sample than does the lamp combustion.

3.1.1 Lamp Combustion—The sample is burned in an atmosphere of carbon dioxide and oxygen or in purified air; the

halogen-containing combustion products are absorbed in dilute sodium carbonate solution.

3.1.2 Oxy-Hydrogen Combustion—The sample is burned in an oxy-hydrogen atomizer burner, and the combustion products are

absorbed in a dilute solution of sodium carbonate.

3.2 Finishes—Either the amperometric titration or spectrophotometric finish may be used for the chloride ion determination.

3.2.1 Amperometric Titration—The chloride ion in aqueous solution is titrated amperometrically with standard silver nitrate

solution, using a saturated calomel electrode as reference electrode. The diffusion currents are plotted against the corresponding

volumes of silver nitrate solution used; the end point is taken as the intersection of the two straight-line portions of the curve.

3.2.2 Spectrophotometric Finish—Chloride ion in the absorber solution is determined by reaction with mercuric thiocyanate to

+++

release thiocyanate, which forms a reddish orange complex with Fe . The intensity of the color is measured at 460 nm with a

spectrophotometer or filter photometer.

4. Significance and Use

4.1 These test methods are used to determine trace amounts of volatile chlorides in butane-butene mixtures. Such information

is valuable in cases where chloride is deleterious in the use of this product; also, chloride contributes to corrosion problems in

processing units in instances where further processing of this material is involved.

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and are the direct responsibility

of Subcommittee D02.D0.04 on C4 Hydrocarbons.

Current edition approved July 1, 2009May 1, 2014. Published November 2009July 2014. Originally approved in 1965. Last previous edition approved in 20042009 as

D2384–83(2004).D2384 – 83(2009). DOI: 10.1520/D2384-83R09.10.1520/D2384-83R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2384 − 83 (2014)

5. Purity of Reagents

5.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

5.2 References to water shall be understood to mean chloride-free distilled or deionized water.

5.3 (Warning—In view of the common occurrence of chloride in reagents and laboratory air, special care must be taken during

preparation and storage of reagents to avoid contamination. They should be isolated from other reagents and used solely for these

methods. A blank determination must be performed each time a reagent is changed to ensure that it is not contaminated with

chloride.

It is also imperative that all glassware used in this determination be cleaned thoroughly and rinsed four times with chloride -free

distilled or deionized water. Utmost caution must be taken during the analysis to prevent contamination from chlorides.)

6. Sampling

6.1 Steam and dry a 10 to 25-mL corrosion-resistant metal sample cylinder having a 450-psi (3100 kPa) working pressure and

equipped with a needle valve outlet at each end.

6.2 Pressure the prepared cylinder with dry hydrogen to 20 psig (137.5 kPa 20 psig (137.5 kPa gage) to afford a gas cushion

preventing rupture due to liquid expansion on increase of temperature.

6.3 Obtain a liquid sample from the purged sample line, filling the upright cylinder through the bottom needle valve, keeping

the top valve closed. Do not purge the sample cylinder.

LAMP COMBUSTION TEST METHOD

7. Apparatus

7.1 ASTM Lamp Assembly—Use the apparatus specified in Test Method D1266, including the liquefied petroleum gas burner

assembly.

8. Reagents

8.1 Use the necessary reagents and materials specified in Test Method D1266, in addition to the absorber solution as described

in 8.3.

8.2 Hydrogen (Warning—Extremely flammable (liquefied) gas under pressure. See Annex A1.1.)

8.3 Sodium Carbonate Absorbent (2 g/L)— Dissolve 2.0 g of anhydrous sodium carbonate (Na CO ) in water and dilute to a

2 3

litre with water.

9. Procedure

9.1 Prepare the combustion apparatus as described in Section 7 of Test Method D1266, Preparation of Apparatus, using 35 mL

of Na CO solution to charge the absorber.

2 3

9.2 Weigh the vessel containing the sample to the nearest 0.1 g. Support the sample vessel in an upright position so that the

sample is burned from the gaseous phase. Connect the sample vessel to the auxiliary corrosion-resistant regulating valve by means

of corrosion-resistant metal tubing (Fig. 1) (Note 2). Connect the bottom valve of the sample vessel to the regulated hydrogen

supply. By means of short lengths of chloride-free rubber tubing, connect the auxiliary valve outlet to the side inlet of the gas

burner and the lower inlet of the gas burner (Test Method D1266, Annex A3, Apparatus Detail, Fig. 5) to the burner manifold.

NOTE 2—For steady burning, it may be necessary to surround the auxiliary valve with a heat-exchanger system. A convenient means is winding

insulated heating wire, having a resistance of 40 to 60 Ω, around the auxiliary valve and connecting it to a suitable rheostat. Another means is to place

the regulating valve in a suitable metal beaker and cover the valve body with water maintained at 60 to 80°C.

9.3 Open the valve on the sample vessel; then open the auxiliary valve to allow a small stream of vapor to escape. Quickly light

the burner. Adjust the flow of CO -O mixture and the sample so that the flame is approximately 35 mm high and clear blue in

2 2

color; this color is reached just beyond the point at which a yellow color shows at the tip of the flame. Insert the burner into the

chimney and readjust the flame if necessary. When the sample has burned almost to completion, open the valve on the bottom of

the sample vessel and flush the residual sample from the cylinder chamber by passing hydrogen through the bottom valve for

several minutes.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D2384 − 83 (2014)

FIG. 1 Diagrammatic Sketch of Butane-Butene Heat Exchange System

9.4 When all of the residual material has been flushed from the sample vessel, turn off the hydrogen and close the valves on

the sample vessel. Disconnect the hydrogen flushing line and the line to the heated auxiliary valve and weigh the sample vessel

to the nearest 0.1 g. Draw the combustion atmosphere through one absorber of a set to serve as a blank on the purity of this

atmosphere. Rinse the chimneys and spray traps with water and add the rinsings to the absorbers.

9.5 Proceed in accordance with either Section 16 or 21.

OXY-HYDROGEN COMBUSTION TEST METHOD—

ALTERNATIVE TEST METHOD

10. Apparatus

10.1 Oxy-Hydrogen Burner —A flow diagram of a typical apparatus is shown in Fig. 2. The apparatus shall consist of three

parts: atomizer-burner, combustion chamber, and receiver with spray trap. A blowout safety port in the combustion chamber is

desirable. The remainder of the apparatus shall consist of a steel support stand with the necessary needle valves and flow meters

for precise control of air, oxygen, hydrogen, and vacuum.

10.2 Vacuum Pump, having a capacity of at least 1200 L/h, and protected from corrosive fumes by suitable traps.

11. Reagents and Materials

11.1 Hydrogen (Warning—Extremely flammable (liquefied) gas under pressure. See Annex A1.1.)

11.2 Oxygen (Warning—Oxygen vigorously accelerates combustion. See Annex A1.2.)

11.3 Sodium Carbonate, Absorbent (2g/L)—See 8.3.

12. Procedure

12.1 Follow the manufacturer’s instructions for preparing and operating the apparatus. Place 50 mL of the Na CO absorbent

2 3

in the absorber. Burn all of the sample from the gas phase of the cylinder (Fig. 1)). (Warning —Extremely flammable (liquefied)

gas under pressure. See Annex A1.1.). Flush the residual gases from the cylinder chamber by passing hydrogen through the bottom

valve for several minutes, burning the flushed gases.)

12.2 When combustion is completed, rinse all water-cooled portions of the apparatus and the spray trap with a spray of water.

Collect all rinsings in the absorbent.

12.3 Proceed in accordance with either Section 16 or 21.

12.4 Prepare a blank by placing 50 mL of the Na CO absorbent in the absorber. Operate the apparatus for the same period of

2 3

time, under the same conditions that were used for the combustion of the sample, but without a sample and the sample inlet closed

to the atmosphere. Burn approximately the same volume of hydrogen as was used to flush the same cylinder. When combustion

The Wickbold Burner Apparatus obtainable from the Atlas Instrument Co., 8902 E. 11th St., Tulsa, OK, or the Richfield Burner Apparatus obtainable from the Greiner

Glass Blowing Laboratories, 3604 E. Medford St., Los Angeles, CA 90034, has been found suitable for this purpose. If you are aware of alternative suppliers, please provide

this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may

attend.

D2384 − 83 (2014)

1—Atomizer-burner 4—Three-way stopcock

2—Sample tube 5—Absorber

3—Combustion chamber 6—Spray trap

FIG. 2 Flow Diagram of a Typical Oxy-Hydrogen Combustion Apparatus

of the hydrogen is complete, rinse all water-cooled portions of the apparatus and the spray trap with a spray of water. Collect all

rinsings in the absorbent. Proceed as in 12.3.

AMPEROMETRIC TITRATION FINISH

13. Apparatus

13.1 Potentiometer-Galvanometer Assembly, capable of applying a cell potential up to 3 V with an accuracy of 1 % of full scale,

and capable of indicating the cell current by means of a galvanometer having a sensitivity of 0.005 to 0.008 μA/mm scale division.

A multiposition galvanometer shunt for adjustment of current measurement sensitivity should also be provided; shunt ratios to give

sensitivities of approximately 0.05 to 0.08, and 0.10 to 0.16 μA/mm should be included.

13.2 Titration Assembly—An apparatus similar to that shown in Fig. 3, consisting of a rotating (600 rpm) platinum electrode,

a saturated calomel reference electrode with salt bridge, a means of blanketing the solution with nitrogen, and a holder for a 10-mL

buret.

13.3 Calomel Electrode, constructed as shown in Fig. 3.

13.4 Platinum Electrode, rotating-hook type. A suitable electrode may be constructed as follows: Seal a platinum wire 0.03 to

0.05 in. (0.76 to 1.3 mm) in diameter and 0.75 to 1.0 in. (19.1 to 25.4 mm) long into the end of a 6-mm outside diameter soft glass

tube that has been shaped into a stirrer blade. Bend the extending platinum wire upwards at its midpoint to form an angle of 90°.

Place a few drops of mercury in the glass tube and make electrical contact between the mercury and the connection on the

amperometric titrator with a piece of copper wire (insulate the exposed wire to prevent shorting).

13.5 Buret—A 10-mL semi-micro buret, with the tip constructed so as to be able to dip below the surface of the solution being

titrated.

14. Reagents

14.1 Acetone (99.5 %) (Warning—Extremely flammable. Vapor may cause fire. See Annex A1.3.)—Refined acetone

conforming to Specifications D329.

14.2 Agar Solution—Dissolve 2 g of agar-agar powder in 100 mL of hot water (80 to 100°C) containing 20 g of potassium

nitrate (KNO ).

14.3 Bromthymol Blue Indicator Solution—Dissolve 0.10 g of the solid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.