ASTM D5594-98(2012)

(Test Method)Standard Test Method for Determination of the Vinyl Acetate Content of Ethylene-Vinyl Acetate (EVA) Copolymers by Fourier Transform Infrared Spectroscopy (FT-IR)

Standard Test Method for Determination of the Vinyl Acetate Content of Ethylene-Vinyl Acetate (EVA) Copolymers by Fourier Transform Infrared Spectroscopy (FT-IR)

SIGNIFICANCE AND USE

Properties of EVA copolymers are affected by the amount of vinyl acetate incorporated in the copolymer: This test method provides a means to determine the vinyl acetate level in copolymer samples.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or a combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method covers infrared procedures for determining the vinyl acetate content of EVA copolymers using pressed films (Procedure A) or molded plaques (Procedure B) and internal corrections for sample thickness.

1.2 This test method is applicable to the analysis of EVA copolymers containing 0.5 to 55 % vinyl acetate except as specified in 1.3.

1.3 Talc interferes with the 1020 cm−1 vinyl acetate band. Resins containing 5 % vinyl acetate and talc are excluded from the scope of this test method.

1.4 The values stated in SI units are to be regarded as the standard. The values given in brackets are provided for information purposes only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

Note 1—This test method is not equivalent to ISO 8985.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5594 − 98 (Reapproved 2012)

Standard Test Method for

Determination of the Vinyl Acetate Content of Ethylene-Vinyl

Acetate (EVA) Copolymers by Fourier Transform Infrared

Spectroscopy (FT-IR)

This standard is issued under the fixed designation D5594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope (SI): The Modem Metric System

E691Practice for Conducting an Interlaboratory Study to

1.1 This test method covers infrared procedures for deter-

Determine the Precision of a Test Method

mining the vinyl acetate content of EVA copolymers using

2.2 ISO Standard:

pressed films (Procedure A) or molded plaques (Procedure B)

ISO 8985 Plastics—Ethylene/Vinyl Acetate Copolymer

and internal corrections for sample thickness.

3,4

Thermoplastics—Determination of VinylAcetate

1.2 This test method is applicable to the analysis of EVA

copolymers containing 0.5 to 55% vinyl acetate except as

3. Terminology

specified in 1.3.

3.1 Definitions:

−1

1.3 Talc interferes with the 1020 cm vinyl acetate band.

3.1.1 Units, symbols, and abbreviations used in this test

Resins containing <5% vinyl acetate and talc are excluded

method appear in Terminology E131 or IEEE/ASTM SI-10.

from the scope of this test method.

3.2 Abbreviations:

3.2.1 EVA—ethylene-vinyl acetate copolymer.

1.4 The values stated in SI units are to be regarded as the

standard. The values given in brackets are provided for

3.2.2 PTFE—tetrafluorethylene polymer.

information purposes only.

3.2.3 FT-IR—Fourier transform infrared.

1.5 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

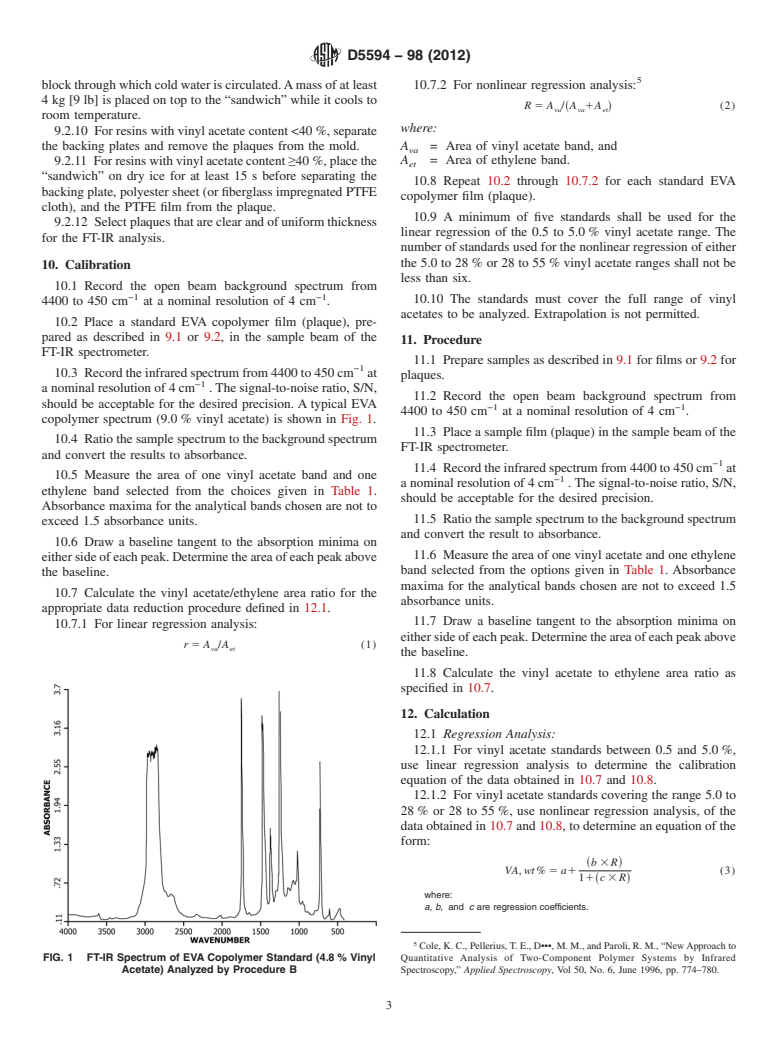

4.1 The vinyl acetate content is measured using infrared

−1

priate safety and health practices and determine the applica-

absorption band at 1020 cm (0.5 to 5%vinyl acetate) or 609

−1

bility of regulatory limitations prior to use. Specific precau-

cm (5 to 55% vinyl acetate).

tionary statements are given in Section 8.

4.2 Sample thickness is measured internally using an ethyl-

−1

NOTE 1—This test method is not equivalent to ISO 8985.

ene infrared absorption band at 720 cm (28 to 55% vinyl

−1 −1

acetate), 2020 cm (0.5 to 28% vinyl acetate), or 4250 cm

2. Referenced Documents

(5 to 28% vinyl acetate).

2.1 ASTM Standards:

4.3 Regression analysis is performed on vinyl acetate/

E131Terminology Relating to Molecular Spectroscopy

ethylene ratios versus known vinyl acetate contents for EVA

E168Practices for General Techniques of Infrared Quanti-

copolymer standards. The resulting equation is used to calcu-

tative Analysis

late the vinyl acetate content for subsequent EVA copolymer

E177Practice for Use of the Terms Precision and Bias in

samples.

ASTM Test Methods

IEEE/ASTM SI-10Use of the International System of Units

5. Significance and Use

5.1 Properties of EVA copolymers are affected by the

amount of vinyl acetate incorporated in the copolymer: This

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved April 1, 2012. Published June 2012. Originally

approved in 1994. Last previous edition approved in 2004 as D5594-98 (2004). Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/D5594-98R12. 4th Floor, New York, NY 10036, http://www.ansi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Nicolet20S×B,availablefromNicoletInstrumentCorp.,AnalyticalDivision,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 5225 Verona Rd., Madison, WI 53711-4495, and Perkin Elmer 1760, a registered

Standards volume information, refer to the standard’s Document Summary page on trademark of Perkin-Elmer Corp., 761 Main Ave., Norwalk, CT 06859-0156, or

the ASTM website. equivalents, have been found suitable for this purpose.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5594 − 98 (2012)

test method provides a means to determine the vinyl acetate 9. Specimen Preparation

level in copolymer samples.

9.1 Procedure A:

5.2 Before proceeding with this test method, reference

9.1.1 Control the hot-plate temperature at 250 610°C.

shouldbemadetothespecificationofthematerialbeingtested.

9.1.2 Place a microscope slide, containing a fraction of the

Any test specimen preparation, conditioning, dimensions, or

sample pellet, on the hot-plate.

testing parameters, or a combination thereof, covered in the

9.1.3 Cover the sample with another slide and press with a

materials specification shall take precedence over those men-

wooden pestle. Use film circular motions to press a uniform

tioned in this test method. If there are no material

film.

specifications, then the default conditions apply.

9.1.4 Remove the microscope slide from the hot-plate and

quenchthepressedpolymerfilmbydippingthetwoslidesinto

6. Apparatus

a beaker of cold water. Remove the film and blot dry with an

6.1 Fourier Transform Infrared (FT-IR) Spectrophotometer,

absorbent towel.

equipped with a detector, which gives a linear response over

9.1.5 Absorption maxima, measured on film produced by

the desired concentration range, is capable of 4-cm resolution

this procedure, shall not exceed 1.5 absorbance units for either

−1

(nominal), and is able to scan from 4400 to 450 cm .

of the analytical bands used.

NOTE2—ADTGSdetectorhasbeenfoundsuitableforthisapplication.

9.2 Procedure B:

6.2 Hot Plate, (Sample Preparation Procedure A only).

NOTE 3—Omit 9.2.1 to 9.2.11 for analysis of blown film.

6.3 Microscope Slides, (Sample Preparation Procedure A

9.2.1 Select a brass or paper mold with a thickness appro-

only).

priatetothevinylacetatecontentofthesample.Theabsorption

6.4 Laboratory Press, capable of at least 9000 kg [20000

maxima of the vinyl acetate and ethylene bands measured on

lb] 150°C [300°F], (Sample Preparation Procedure B only).

the plaque are not to exceed 1.5 absorbance units.

6.5 Backing Plates, steel or aluminum (Sample Preparation

NOTE 4—To meet the absorbance requirement specified in 9.2.1 it will

Procedure B only).

be necessary to vary the mold thickness as the vinyl acetate content

changes. The mold thickness required typically will be between 50 and

6.6 Brass Shim Stock (Roll), 50 to 150 µm [2 to 6 mil] thick

150 µm [2 to 6 mil].

and 150 mm [6 in.] wide (Sample Preparation Procedure B

9.2.2 Place a polyester sheet (or fiberglass impregnated

only).

PTFE cloth) followed by a brass or paper mold on a backing

6.7 Polyester Sheet, or fiberglass impregnated PTFE cloth

plate.Forresinswithvinylacetatecontent≥40%,aPTFEfilm

(Sample Preparation Procedure B only).

should be placed on top of the brass mold, or, if using a paper

6.8 PTFE Film (Sample Preparation Procedure B, resins

mold, under the paper.

containing ≥40% vinyl acetate only).

9.2.3 Place a quantity of sample, appropriate to the thick-

ness of the mold used, in the center of each opening in the

6.9 Templates, (mold) with 150×150 mm [6×6 in.] pieces

mold.Donotoverfillthemoldopenings.Ifflashingoccurs,the

of paper or brass shim stock (item 6.6) containing cavities of a

brass mold and backing plates can be cleaned with a nylon

size and shape appropriate for the sample holders used, and, if

scrubbing pad.

applicable, sheets of items 6.7 and 6.8 (Sample Preparation

Procedure B only). 9.2.4 Place another piece of polyester sheet (or fiberglass

impregnated PTFE cloth) and a backing plate on top of the

6.10 Cooling Block, steel or aluminum, at least 150×150

sample. For resins with vinyl acetate content ≥40%, a PTFE

mm [6×6 in.], approximately 25 mm [1 in.] thick, channeled

film should be placed over the sample before the polyester

for cooling water (Sample Preparation Procedure B only).

sheet (or fiberglass impregnated PTFE cloth).

9.2.5 Place the resulting “sandwich” in the press with the

7. Materials

platens heated at 150 to 175°C.

7.1 EVA copolymer standards containing nominal vinyl

9.2.6 Close the press until the top platen barely touches the

acetate concentrations of 0.5 to 55%, by weight.

top plate and leave for sufficient time to permit the sample to

7.2 Dry ice (Sample Preparation B Procedure A only).

soften and outgas.

NOTE 5—Acceptable plaques, free of gas bubbles, have been obtained

8. Hazards

when the sample is allowed to soften for 3 min.

8.1 Care should be taken to avoid burns when handling

9.2.7 Closethepresscompletelyandapplyatleast9000kg

microscope slides on the hot-plate (Sample Preparation Proce-

[20000 lb] force for approximately 1 min.

dureA),andglovesshouldbewornwhenplaquesareprepared

9.2.8 Cool the “sandwich” to room temperature, release the

using a heated press (Sample Preparation Procedure B).

pressure, and remove the “sandwich” from the press.

8.2 Care also should be taken to avoid breaking the micro-

9.2.9 In cases where the press does not have cooling

scope slides while removing the pressed polymer film.

capability or where sample throughput needs to be increased,

8.3 Care should be taken to avoid burns when handling dry thefollowingalternativeto9.2.8maybeused.The“sandwich”

ice. is removed from the press hot and placed on a metal cooling

D5594 − 98 (2012)

blockthroughwhichcoldwateriscirculated.Amassofatleast 10.7.2 For nonlinear regression analysis:

4 kg [9 lb] is placed on top to the “sandwich” while it cools to

R 5 A /~A 1A ! (2)

va va et

room temperature.

where:

9.2.10 Forre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.