ASTM C869-91(1999)

(Specification)Standard Specification for Foaming Agents Used in Making Preformed Foam for Cellular Concrete

Standard Specification for Foaming Agents Used in Making Preformed Foam for Cellular Concrete

SCOPE

1.1 This specification covers foaming agents specifically formulated for making preformed foam for use in the production of cellular concrete.

1.2 The function of this specification is to provide the means for evaluating the performance of a specific foaming agent. This is accomplished by using the foaming agent in making a standard cellular concrete test batch (see Method C796) from which test specimens are cast. Then, significant properties of the concrete are determined by tests and compared with the requirements of Section 3.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 869 – 91 (Reapproved 1999)

Standard Specification for

Foaming Agents Used in Making Preformed Foam for

Cellular Concrete

This standard is issued under the fixed designation C 869; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

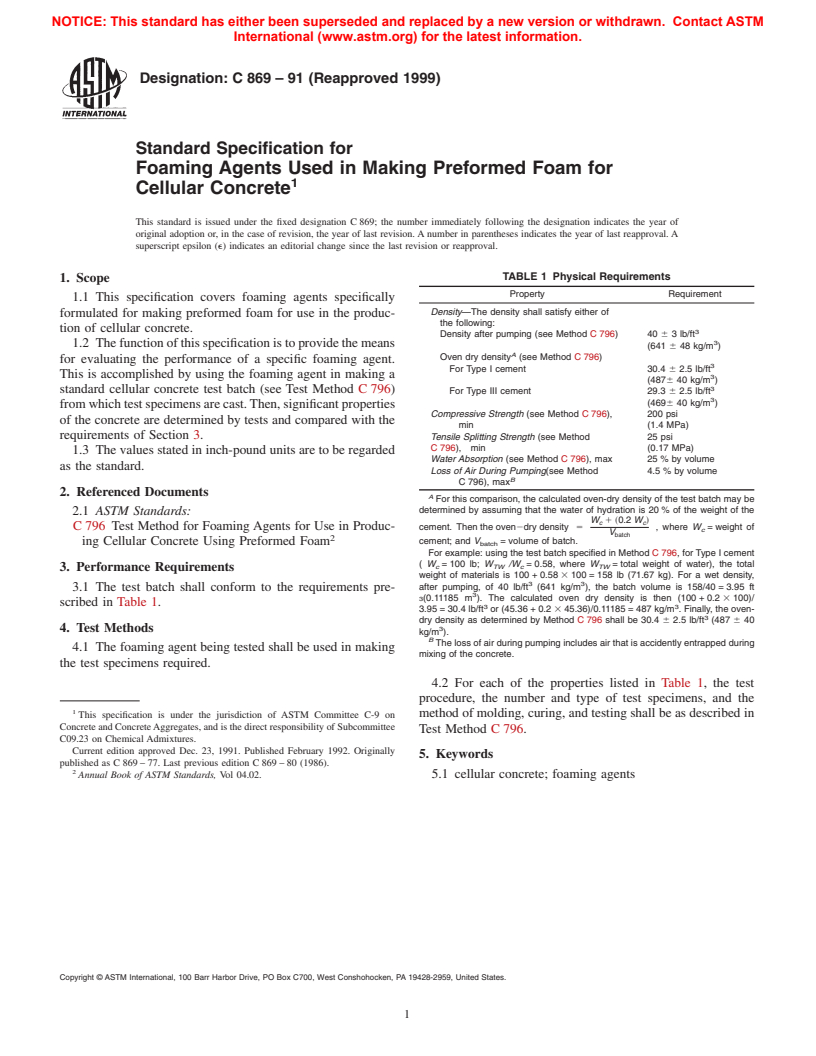

TABLE 1 Physical Requirements

1. Scope

Property Requirement

1.1 This specification covers foaming agents specifically

Density—The density shall satisfy either of

formulated for making preformed foam for use in the produc-

the following:

tion of cellular concrete.

Density after pumping (see Method C 796)40 6 3 lb/ft

1.2 The function of this specification is to provide the means

(641 6 48 kg/m )

A

Oven dry density (see Method C 796)

for evaluating the performance of a specific foaming agent.

For Type I cement 30.4 6 2.5 lb/ft

This is accomplished by using the foaming agent in making a

(4876 40 kg/m )

standard cellular concrete test batch (see Test Method C 796)

For Type III cement 29.3 6 2.5 lb/ft

(4696 40 kg/m )

from which test specimens are cast.Then, significant properties

Compressive Strength (see Method C 796), 200 psi

of the concrete are determined by tests and compared with the

min (1.4 MPa)

requirements of Section 3. Tensile Splitting Strength (see Method 25 psi

C 796), min (0.17 MPa)

1.3 The values stated in inch-pound units are to be regarded

Water Absorption (see Method C 796), max 25 % by volume

as the standard.

Loss of Air During Pumping(see Method 4.5 % by volume

B

C 796), max

2. Referenced Documents

A

For this comparison, the calculated oven-dry density of the test batch may be

determined by assuming that the water of hydration is 20 % of the weight of the

2.1 ASTM Standards:

W 1 ~0.2 W !

c c

C 796 Test Method for Foaming Agents for Use in Produc- cement. Then the oven2dry density 5 , where W = weight of

c

V

batch

cement; and V = volume of batch.

ing Cellular Concrete Using Preformed Foam batch

For example: using the test batch specified in Method C 796, for Type I cement

( W = 100 lb; W /W = 0.58, where W = total weight of water), the total

c TW c TW

3. Performance Requirements

weight of materials is 100 + 0.58 3 100 = 158 lb (71.67 kg). For a wet density,

3 3

after pumping, of 40 lb/ft (641 kg/m ), the batch volume is 158/40 = 3.95 ft

3.1 The test batch shall conform to the requirements pre-

3(0.11185 m ). The calculated oven dry density is then (

...

This May Also Interest You

SIGNIFICANCE AND USE

4.1 This practice provides standardized requirements for making, and curing test specimens in the field. This practice also provides requirements for transporting test specimens to the laboratory, and for curing test specimens in the laboratory. Depending on their purpose, test specimens are either standard-cured, or field-cured.

4.2 Uses of the test results of standard-cured test specimens include the following purposes:

4.2.1 Acceptance testing for specified concrete strength,

Note 2: Specification C94/C94M requires compressive-strength test specimens for acceptance to be standard-cured.

4.2.2 Checking adequacy of mixture proportions for concrete strength, and

4.2.3 Quality control.

4.3 Uses of test results of field-cured test specimens include:

4.3.1 Estimation of the in place concrete strength,

4.3.2 Comparison with test results of standard cured specimens or with test results from various in-place test methods,

4.3.3 Adequacy of curing and protection of concrete in the structure,

4.3.4 Form or shoring removal time requirements, or

4.3.5 Post-tensioning.

SCOPE

1.1 This practice covers procedures for making and curing cylinder and beam specimens from representative samples of fresh concrete for a construction project.

1.2 This practice is not intended for making specimens from concrete not having measurable slump or requiring other sizes or shapes of specimens.

1.3 This practice is not applicable to lightweight insulating concrete or controlled low strength material (CLSM).

Note 1: Test Method C495/C495M covers the preparation of specimens and the determination of the compressive strength of lightweight insulating concrete. Test Method D4832 covers procedures for the preparation, curing, transporting and testing of cylindrical test specimens of CLSM.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to exposed skin and tissue upon prolonged exposure.2)

1.6 The text of this standard references notes which provide explanatory material. These notes shall not be considered as requirements of the standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers ready-mixed concrete manufactured and delivered to a purchaser in freshly mixed and unhardened state as hereinafter specified. Requirements for quality of concrete shall be either as hereinafter specified or as specified by the purchase. In any case where the requirements of the purchaser differ from these in this specification, the purchaser's specification shall govern. In the absence of designated applicable materials specifications, materials specifications specified shall be used for cementitious materials, hydraulic cement, supplementary cementitious materials, cementitious concrete mixtures, aggregates, air-entraining admixtures, and chemical admixtures. Except as otherwise specifically permitted, cement, aggregate, and admixtures shall be measured by mass. Mixers will be stationary mixers or truck mixers. Agitators will be truck mixers or truck agitators. Test methods for compression, air content, slump, temperature shall be performed. For s strength test, at least two standard test specimens shall be made.

SCOPE

1.1 This specification covers ready-mixed concrete as defined in 3.2.2 (Note 1). Requirements for quality of ready-mixed concrete shall be either as stated in this specification or as ordered by the purchaser. When the purchaser’s requirements, as stated in the order, differ from those in this specification, the purchaser’s requirements shall govern. This specification does not cover the placement, consolidation, curing, or protection of the concrete after delivery to the purchaser.

Note 1: Concrete produced by volumetric batching and continuous mixing is covered in Specification C685/C685M. Fiber-reinforced concrete is covered in Specification C1116/C1116M.

1.2 As used throughout this specification the producer manufactures ready-mixed concrete and the purchaser buys ready-mixed concrete.

1.3 The values stated in either SI units, shown in brackets, or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged use.2)

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification16 pagesEnglish languagesale 15% off

- Technical specification16 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers three strength grades of finely ground granulated blast-furnace slag (Grades 80, 100, and 120) for use as a cementitious material in concrete and mortars. The slag shall contain no additions and shall conform to the sulfide sulfur and sulfate chemical composition requirement. Physical properties of the slag shall be in accordance with the requirements for fineness as determined by air permeability and air content, slag activity index, and compressive strength.

SCOPE

1.1 This specification covers slag cement for use as a cementitious material in concrete and mortar.

Note 1: The material described in this specification may be used to produce a blended cement meeting the requirements of Specification C595/C595M or as a separate ingredient in concrete or mortar mixtures. The material may also be useful in a variety of special grouts and mortars, and when used with an appropriate activator, as the principal cementitious material in some applications.

Note 2: Information on technical aspects of the use of the material described in this specification is contained in Appendix X1, Appendix X2, and Appendix X3. More detailed information on that subject is contained in ACI 233R.2

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables) shall not be considered as requirements of this standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification7 pagesEnglish languagesale 15% off

- Technical specification7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method covers the determination of the air content of freshly mixed concrete. It measures the air contained in the mortar fraction of the concrete, but is not affected by air that may be present inside porous aggregate particles.

4.1.1 Therefore, this is the appropriate test to determine the air content of concretes containing lightweight aggregates, air-cooled slag, and highly porous or vesicular natural aggregates.

4.2 This test method requires the addition of sufficient isopropyl alcohol, when the meter is initially being filled with water, so that after the first or subsequent rollings little or no foam collects in the neck of the top section of the meter. If more foam is present than that equivalent to 2 % air above the water level, the test is declared invalid and must be repeated using a larger quantity of alcohol. Addition of alcohol to dispel foam any time after the initial filling of the meter to the zero mark is not permitted.

4.3 The air content of hardened concrete may be either higher or lower than that determined by this test method. This depends upon the methods and amounts of consolidation effort applied to the concrete from which the hardened concrete specimen is taken; uniformity and stability of the air bubbles in the fresh and hardened concrete; accuracy of the microscopic examination, if used; time of comparison; environmental exposure; stage in the delivery, placement and consolidation processes at which the air content of the unhardened concrete is determined, that is, before or after the concrete goes through a pump; and other factors.

SCOPE

1.1 This test method covers determination of the air content of freshly mixed concrete containing any type of aggregate, whether it be dense, cellular, or lightweight.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The inch-pound units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

- Standard10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 This test method covers the determination of the air content of freshly mixed concrete. The test determines the air content of freshly mixed concrete exclusive of any air that may exist inside voids within aggregate particles. For this reason, it is applicable to concrete made with relatively dense aggregate particles and requires determination of the aggregate correction factor (see 6.1 and 9.1).

3.2 This test method and Test Method C138/C138M and C173/C173M provide pressure, gravimetric, and volumetric procedures, respectively, for determining the air content of freshly mixed concrete. The pressure procedure of this test method gives substantially the same air contents as the other two test methods for concretes made with dense aggregates.

3.3 The air content of hardened concrete may be either higher or lower than that determined by this test method. This depends upon the methods and amount of consolidation effort applied to the concrete from which the hardened concrete specimen is taken; uniformity and stability of the air bubbles in the fresh and hardened concrete; accuracy of the microscopic examination, if used; time of comparison; environmental exposure; stage in the delivery, placement and consolidation processes at which the air content of the unhardened concrete is determined, that is, before or after the concrete goes through a pump; and other factors.

SCOPE

1.1 This test method covers determination of the air content of freshly mixed concrete from observation of the change in volume of concrete with a change in pressure.

1.2 This test method is intended for use with concretes and mortars made with relatively dense aggregates for which the aggregate correction factor can be satisfactorily determined by the technique described in Section 6. It is not applicable to concretes made with lightweight aggregates, air-cooled blast-furnace slag, or aggregates of high porosity. In these cases, Test Method C173/C173M should be used. This test method is also not applicable to nonplastic concrete such as is commonly used in the manufacture of pipe and concrete masonry units.

1.3 The text of this test method references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

- Standard10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method measures the load-induced time-dependent compressive strain at selected ages for concrete under an arbitrary set of controlled environmental conditions.

4.2 This test method can be used to compare creep potentials of different concretes. A procedure is available, using the developed equation (or graphical plot), for calculating stress from strain data within massive non-reinforced concrete structures. For most specific design applications, the test conditions set forth herein must be modified to more closely simulate the anticipated curing, thermal, exposure, and loading age conditions for the prototype structure. Current theories and effects of material and environmental parameters are presented in ACI SP-135, Symposium on Creep and Shrinkage of Concrete: Effect of Materials and Environment.3

4.3 In the absence of a satisfactory hypothesis governing creep phenomena, a number of assumptions have been developed that have been generally substantiated by test and experience.

4.3.1 Creep is proportional to stress from 0 to 40 % of concrete compressive strength.

4.3.2 Creep has been conclusively shown to be directly proportional to paste content throughout the range of paste contents normally used in concrete. Thus, the creep characteristics of concrete mixtures containing aggregate of maximum size greater than 50 mm [2 in.] may be determined from the creep characteristics of the minus 50-mm [minus 2-in.] fraction obtained by wet-sieving. Multiply the value of the characteristic by the ratio of the cement paste content (proportion by volume) in the full concrete mixture to the paste content of the sieved sample.

4.4 The use of the logarithmic expression (Section 9) does not imply that the creep strain-time relationship is necessarily an exact logarithmic function; however, for the period of one year, the expression approximates normal creep behavior with sufficient accuracy to make possible the calculation of parameters that are useful...

SCOPE

1.1 This test method covers the determination of the creep of molded concrete cylinders subjected to sustained longitudinal compressive load. This test method is limited to concrete in which the maximum aggregate size does not exceed 50 mm [2 in.].

1.2 The text of this standard refers to notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method provides a procedure for making a preliminary estimate of the soundness of aggregates for use in concrete and other purposes. The values obtained may be compared with specifications, for example Specification C33/C33M, that are designed to indicate the suitability of aggregate proposed for use. Since the precision of this test method is poor (Section 13), it may not be suitable for outright rejection of aggregates without confirmation from other tests more closely related to the specific service intended.

4.2 Values for the permitted-loss percentage by this test method are usually different for fine and coarse aggregates, and attention is called to the fact that test results by use of the two salts differ considerably and care must be exercised in fixing proper limits in any specifications that include requirements for these tests. The test is usually more severe when magnesium sulfate is used; accordingly, limits for percent loss allowed when magnesium sulfate is used are normally higher than limits when sodium sulfate is used.

Note 2: Refer to the appropriate sections in Specification C33/C33M establishing conditions for acceptance of coarse and fine aggregates which fail to meet requirements based on this test.

SCOPE

1.1 This test method covers the testing of aggregates to estimate their soundness when subjected to weathering action in concrete or other applications. This is accomplished by repeated immersion in saturated solutions of sodium or magnesium sulfate followed by oven drying to partially or completely dehydrate the salt precipitated in permeable pore spaces. The internal expansive force, derived from the rehydration of the salt upon re-immersion, simulates the expansion of water on freezing. This test method furnishes information helpful in judging the soundness of aggregates when adequate information is not available from service records of the material exposed to actual weathering conditions.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 Some values have only SI units because the inch-pound equivalents are not used in practice.

1.4 If the results obtained from another standard are not reported in the same system of units as used by this test method, it is permitted to convert those results using the conversion factors found in the SI Quick Reference Guide.2

Note 1: Sieve size is identified by its standard designation in Specification E11. The alternate designation given in parentheses is for information only and does not represent a different standard sieve size.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 These test methods are used to develop data for comparison with the requirements of Specification C618 or Specification C1697. These test methods are based on standardized testing in the laboratory and are not intended to simulate job conditions.

4.1.1 Strength Activity Index—The test for strength activity index is used to determine whether coal ash or natural pozzolan results in an acceptable level of strength development when used in concrete. Since the test is performed with mortar, the results may not provide a direct correlation of how the coal ash or natural pozzolan will contribute to strength in concrete.

4.1.2 Chemical Tests—The chemical component determinations and the limits placed on each do not predict the performance of a coal ash or natural pozzolan in concrete, but collectively help describe composition and uniformity of the material.

SCOPE

1.1 These test methods cover procedures for sampling and testing coal ash and raw or calcined pozzolans for use in concrete.

1.2 The procedures appear in the following order:

Sections

Sampling

7

CHEMICAL ANALYSIS

Reagents and apparatus

10

Moisture content

11 and 12

Loss on ignition

13 and 14

Silicon dioxide, aluminum oxide, iron oxide,

calcium oxide, magnesium oxide, sulfur

trioxide, sodium oxide and potassium

oxide

15

Available alkali

16 and 17

Ammonia

18

PHYSICAL TESTS

Density

19

Fineness

20

Increase of drying shrinkage of mortar bars

21 – 23

Soundness

24

Air-entrainment of mortar

25 and 26

Strength activity index

27 – 30

Water requirement

31

Effectiveness of Coal Ash or Natural Pozzolan in

Controlling Alkali-Silica Reactions

32

Effectiveness of Coal Ash or Natural Pozzolan in

Contributing to Sulfate Resistance

34

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

Note 1: Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information only and does not represent a different standard sieve size.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables) shall not be considered as requirements of this standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard11 pagesEnglish languagesale 15% off

- Standard11 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 The testing and inspection of concrete and concrete aggregates are important elements in obtaining quality construction. A testing agency providing these services shall be selected with care.

4.2 A testing agency shall be deemed qualified to perform and report the results of its tests if the agency meets the requirements of this practice. The testing agency services shall be provided under the technical direction of a registered professional engineer.

4.3 This practice establishes essential characteristics pertaining to the organization, personnel, facilities, and quality systems of the testing agency. This practice may be supplemented by more specific criteria and requirements for particular projects.

SCOPE

1.1 This practice identifies and defines the duties, responsibilities, and minimum technical requirements of testing agency personnel and the minimum technical requirements for equipment utilized in testing concrete and concrete aggregates for use in construction.

1.2 This practice provides criteria for the evaluation of the capability of a testing agency to perform designated ASTM test methods on concrete and concrete aggregates. It can be used by an evaluation authority in the inspection or accreditation of a testing agency or by other parties to determine if the agency is qualified to conduct the specified tests.

Note 1: Specification E329 provides criteria for the evaluation of agencies that perform the inspection of concrete during placement.

1.3 This practice provides criteria for Inspection Bodies and Accreditation Bodies that provide services for evaluation of testing agencies in accordance with this practice.

1.4 The text of this standard references notes and footnotes, which provide explanatory material and shall not be considered as requirements of this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard9 pagesEnglish languagesale 15% off

- Standard9 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 For a given test apparatus, pullout strengths can be related to compressive strength test results. Such strength relationships are affected by the configuration of the embedded insert, bearing ring dimensions, depth of embedment, and the type of aggregate (lightweight or normal weight). Before use, the relationship must be established experimentally for each test system using a range of concrete mixtures or the specific concrete mixtures to be used in the project. Such relationships are more reliable if both pullout test specimens and compressive strength test specimens are of similar size, consolidated to similar density, and cured under similar conditions.

Note 1: Published reports (1-19)4 by different researchers present their experiences in the use of pullout test equipment. Refer to ACI PRC-228.1 (14) for guidance on establishing a strength relationship and interpreting test results.

5.2 If a strength relationship has been accepted by the specifier of tests, pullout tests are used to estimate the in-place strength of concrete to establish whether it has reached a specified level so that, for example:

(1) post-tensioning may proceed;

(2) forms and shores may be removed;

(3) structure may be placed into service; or

(4) winter protection and curing may be terminated.

In addition, post-installed pullout tests may be used to estimate the strength of concrete in existing construction.

5.3 In planning pullout tests and analyzing test results, consideration should be given to the normally expected decrease of concrete strength with increasing height within a given concrete placement in a structural element.

5.4 The measured pullout strength is indicative of the strength of concrete within the region represented by the conic frustum defined by the insert head and bearing ring. For typical surface installations, pullout strengths are indicative of the quality of the outer zone of concrete members and can be of benefit in evaluating the cover zo...

SCOPE

1.1 This test method covers determination of the pullout strength of hardened concrete by measuring the force required to pull an embedded metal insert and the attached concrete fragment from a concrete test specimen or structure. The insert is either cast into fresh concrete or installed in hardened concrete. This test method does not provide statistical procedures to estimate other strength properties.

1.2 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this test method.

1.3 The text of this test method refers to notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

- Standard10 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.