ASTM E1444-94A

(Practice)Standard Practice for Magnetic Particle Examination

Standard Practice for Magnetic Particle Examination

SCOPE

1.1 This practice establishes minimum requirements for magnetic particle examination used for the detection of surface or slightly subsurface discontinuities in ferromagnetic material. Guide E 709 can be used in conjunction with this practice as a tutorial.

Note 1--This Practice replaces MIL-STD-1949.

1.2 The magnetic particle examination method is used to detect cracks, laps, seams, inclusions, and other discontinuities on or near the surface of ferromagnetic materials. Magnetic particle examination may be applied to raw material, billets, finished and semifinished materials, welds, and in-service parts. Magnetic particle examination is not applicable to nonferromagnetic metals and alloys such as austenitic stainless steels. See for additional information.

1.3 All areas of this Practice may be open to agreement between the Cognizant Engineering Organization and the supplier, or specific direction from the Cognizant Engineering Organization.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1444 – 94a An American National Standard

Standard Practice for

Magnetic Particle Examination

This standard is issued under the fixed designation E 1444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

1. Scope SNT-TC-1A Recommended Practice and Supplement Mag-

netic Particle Inspection

1.1 This practice establishes minimum requirements for

2.4 Society of Automotive Engineers (SAE)-AMS Docu-

magnetic particle examination used for the detection of surface

ments:

or slightly subsurface discontinuities in ferromagnetic material.

AMS 2300 Premium Aircraft-Quality Steel Cleanliness

This practice is intended as a direct replacement of MIL-STD-

Magnetic Particle Inspection Procedure

1949. Guide E 709 can be used in conjunction with this

AMS 2301 Aircraft Quality Steel Cleanliness Magnetic Par-

practice as a tutorial.

ticle Inspection Procedure

1.2 The magnetic particle examination method is used to

AMS 2303 Aircraft Quality Steel Cleanliness Martensitic

detect cracks, laps, seams, inclusions, and other discontinuities

Corrosion Resistant Steels Magnetic Particle Inspection

on or near the surface of ferromagnetic materials. Magnetic

Procedure

particle examination may be applied to raw material, billets,

AMS 2641 Magnetic Particle Inspection Vehicle

finished and semifinished materials, welds, and in-service

AMS 3040 Magnetic Particles, Nonfluorescent, Dry

parts. Magnetic particle examination is not applicable to

Method

nonferromagnetic metals and alloys such as austenitic stainless

AMS 3041 Magnetic Particles, Nonfluorescent, Wet

steels.

Method, Oil Vehicle, Ready-To-Use

1.3 This standard does not purport to address all of the

AMS 3042 Magnetic Particles, Nonfluorescent, Wet

safety concerns, if any, associated with its use. It is the

Method, Dry Powder

responsibility of the user of this standard to establish appro-

AMS 3043 Magnetic Particles, Nonfluorescent, Wet

priate safety and health practices and determine the applica-

Method, Oil Vehicle, Aerosol Packaged

bility of regulatory limitations prior to use.

AMS 3044 Magnetic Particles, Fluorescent, Wet Method,

2. Referenced Documents Dry Powder

AMS 3045 Magnetic Particles, Fluorescent, Wet Method,

2.1 The following documents form a part of this standard

Oil Vehicle, Ready-To-Use

practice to the extent specified herein.

AMS 3046 Magnetic Particles, Fluorescent, Wet Method,

2.2 ASTM Standards:

Oil Vehicle, Aerosol Packaged

A 275/A 275M Test Method for Magnetic Particle Exami-

AMS 5355 Investment Castings

nation of Steel Forgings

2.5 Federal Standards:

A 456 Specification for Magnetic Particle Inspection of

FED-STD-313 Material Safety Data Sheets, Preparation

Large Crankshaft Forgings

and the Submission of

D 96 Test Methods for Water and Sediment in Crude Oil by

FED-STD-595 Colors

the Centrifuge Method (Field Procedure)

2.6 Military Standards:

E 543 Practice for Evaluating Agencies that Perform Non-

MIL-STD-1907 Inspection, Liquid Penetrant and Magnetic

destructive Testing

Particle Soundness Requirements for Materials, Parts, and

E 709 Guide for Magnetic Particle Examination

Weldments

E 1316 Terminology for Nondestructive Examinations

2.3 ASNT Document:

Available from American Society for Nondestructive Testing, 1711 Arlingate

Plaza, P.O. Box 28518, Columbus, OH 43228-0518.

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

Copies of standards, specifications, drawings, and publications required by

structive Testing and is the direct responsibility of Subcommittee E07.03 on Liquid

manufacturers in connection with specification acquisition should be obtained from

Penetrant and Magnetic Particle Methods.

Current edition approved Nov. 15, 1994. Published January 1995. Originally the contracting activity or as directed by the contracting officer.

published as E 1444 – 91. Last previous edition E 1444 – 94. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 01.05. Warrendale, PA 15096.

3 8

Annual Book of ASTM Standards, Vol 05.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 03.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1444

MIL-STD-410 Nondestructive Testing Personnel Qualifica- tions. Maximum detectability occurs when the discontinuity is

tion and Certification positioned perpendicular to the magnetic flux. In order to

MIL-STD-1949 Magnetic Particle Inspection, Method of detect discontinuities in all directions, at least two magnetic

MIL-STD-2175 Castings, Classification and Inspection of fields, perpendicular to one another in a plane parallel to the

MIL-STD-45662 Calibration Systems Requirements surface being inspected, shall be used, except when specifically

MIL-I-83387 Inspection Process, Magnetic Rubber exempted by the contracting agency.

DoD-F-87935 Fluid, Magnetic Particle Inspection, Suspen-

5. General Practice

sion (Metric)

2.7 OSHA Document:

5.1 Acceptance Requirements—The acceptance require-

29CFR 1910.1200 Hazard Communication

ments applicable to the part or group of parts shall be

2.8 DoD Contracts—Unless otherwise specified, the edi-

incorporated as part of the written procedure either specifically

tions of the documents that are DoD adopted are those listed in

or by reference to other applicable documents, such as MIL-

the issue of the DoDISS (Department of Defense Index of

STD-1907, containing the necessary information. Applicable

Specifications and Standards) cited in the solicitation.

drawings or other documents shall specify the acceptance size

and concentration of discontinuities for the component, with

2.9 Order of Precedence—In the event of conflict between

zoning of unique areas as required by design requirements.

the text of this practice and the referenced documents cited

These acceptance requirements shall be as approved on or as

herein, the text of this practice takes precedence.

specified by the contracting agency. Methods for establishing

acceptance requirements for large crankshaft forgings are

covered in Specification A 456. Methods for establishing

3. Terminology

requirements for steel forgings are covered in Test Method

3.1 Definitions—The definitions relating to magnetic par-

A 275/A 275M. Methods for classifying metal castings are

ticle examination, which appear in Terminology E 1316, shall

given in MIL-STD-2175 and AMS 5355. MIL-STD-1907 pro-

apply to the terms used in this practice.

vides a classification scheme for ferromagnetic forgings, cast-

3.2 Definitions of Terms Specific to This Standard:

ings, extrusions, and weldments.

3.2.1 alternating current (ac)—an electrical current that

5.1.1 Aircraft-Quality Steel Cleanliness—The examination

reverses its direction of flow at regular intervals.

of aircraft-quality steel for cleanliness using magnetic particle

3.2.2 ambient light—the visible light level measured at the

examination shall be as specified in AMS 2300, 2301, or 2303

specimen surface with the black light(s) on.

as appropriate to the type of steel being inspected. However,

3.2.3 contracting agency—a prime contractor, subcontrac-

inspection of parts fabricated from this material shall be in

tor, or government agency procuring magnetic particle inspec-

accordance with the requirements of this practice.

tion services.

5.2 Personnel Qualification—Personnel performing exami-

3.2.4 gauss (G)—the unit of flux density or induction in the

nations in accordance with this practice shall be qualified and

−4

cgs electromagnetic unit system (1 G 5 10 Tesla (T); in air,

certified in accordance with ASNT Personnel Qualification

1 G is equivalent to 1 oersted (Oe), which equals 79.58 A/m).

SNT-TC-1A or MIL-STD-410 for military purposes, or as

3.2.5 head shot—the production of circular magnetization

specified in the contract or purchase order.

by passing current directly through the part being inspected, or

5.3 Agency Qualification—The agency performing the test-

central conductor, while being held in contact with the head

ing or examination shall meet, as a minimum, the requirements

stocks in a horizontal wet machine.

of Practice E 543.

3.2.6 magnetic flux—a conceptualization of the magnetic

5.4 Written Procedure—Magnetic particle examination

field intensity based on the line pattern produced when iron

shall be performed in accordance with a written procedure

filings are sprinkled on paper laid over a permanent magnet.

applicable to the parts or group of parts under testing. The

The magnetic field lies in the direction of the flux lines and has

procedure shall be in accordance with the requirements and

an intensity proportional to the line density.

guidelines of this practice. The procedure shall be capable of

3.2.7 magnetization—the process by which the elementary

detecting the smallest rejectable discontinuities specified in the

magnetic domains of a material are predominantly aligned in

acceptance requirements. The written procedure may be gen-

one direction.

eral if it clearly applies to all of the specified parts being tested

3.2.8 retentivity—the ability of a material to retain magne-

and meets the requirements of this practice. All written

tism after the magnetizing force has been removed.

procedures shall be approved by an individual qualified and

certified at Level III for magnetic particle examination in

4. Significance and Use

accordance with 5.2. Procedures shall be submitted to the

4.1 Magnetic particle examination consists of magnetizing

contracting agency when requested.

the area to be inspected, applying suitably prepared magnetic

5.4.1 Elements of the Written Procedure—The written pro-

particles while the area is magnetized, and subsequently

cedure shall include at least the following elements, either

interpreting and evaluating any resulting particle accumula-

directly or by reference to the applicable documents:

5.4.1.1 Procedure identification number and the date it was

9 written;

Available from Superintendent of Documents, U.S. Government Printing

Office, Washington, D.C. 20402. 5.4.1.2 Identification of the parts to which the procedure

E 1444

applies; this shall include the material and alloy of which the fluorescent magnetic particle examinations shall be performed

parts are fabricated; in a darkened area with a maximum ambient visible light level

of 2 fc (20 lx) measured at the part surface.

5.4.1.3 Sequence of magnetic particle examination as re-

lated to manufacturing process operation, if applicable; 5.7.1.2 Special Visible Internal Light Source—When exami-

nations of internal surfaces must be performed using special

5.4.1.4 Identification of test parts used for system perfor-

visible light sources, the image produced must have sufficient

mance verification (see 7.1.2 and 7.1.3);

resolution to effectively evaluate the required discontinuities.

5.4.1.5 Areas of the part to be examined (include an

Light intensity shall be measured at the expected working

illustration–either sketch or photo);

distance of the equipment.

5.4.1.6 Part preparation required before testing;

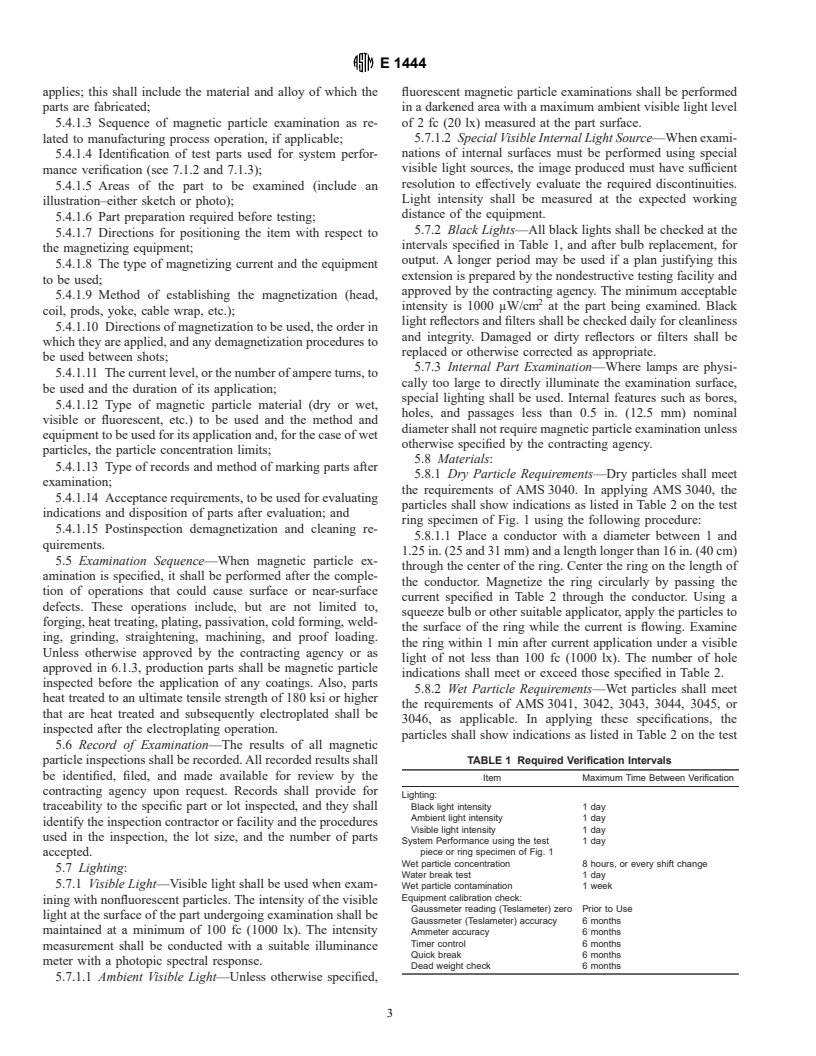

5.7.2 Black Lights—All black lights shall be checked at the

5.4.1.7 Directions for positioning the item with respect to

intervals specified in Table 1, and after bulb replacement, for

the magnetizing equipment;

output. A longer period may be used if a plan justifying this

5.4.1.8 The type of magnetizing current and the equipment

extension is prepared by the nondestructive testing facility and

to be used;

approved by the contracting agency. The minimum acceptable

5.4.1.9 Method of establishing the magnetization (head,

intensity is 1000 μW/cm at the part being examined. Black

coil, prods, yoke, cable wrap, etc.);

light reflectors and filters shall be checked daily for cleanliness

5.4.1.10 Directions of magnetization to be used, the order in

and integrity. Damaged or dirty reflectors or filters shall be

which they are applied, and any demagnetization procedures to

replaced or otherwise corrected as appropriate.

be used between shots;

5.7.3 Internal Part Examination—Where lamps are physi-

5.4.1.11 The current level, or the number of ampere turns, to

cally too large to directly illuminate the examination surface,

be used and the duration of its application;

special lighting shall be used. Internal features such as bores,

5.4.1.12 Type of magnetic particle material (dry or wet,

holes, and passages less than 0.5 in. (12.5 mm) nominal

visible or fluorescent, etc.) to be used and the method and

diameter shall not require magnetic particle examination unless

equipment to be used for its application and, for the case of wet

otherwise specified by the contracting agency.

particles, the particle concentration limits;

5.8 Materials:

5.4.1.13 Type of records and method of marking parts after

5.8.1 Dry Particle Requirements—Dry particles shall meet

examination;

the requirements of AMS 3040. In applying AMS 3040, the

5.4.1.14 Acceptance requirements, to be used for evaluating

particles shall show indications as listed in Table 2 on the test

indications and disposition of parts after evaluation; and

ring specimen of Fig. 1 using the following procedure:

5.4.1.15 Postinspection demagnetization and cleaning re-

5.8.1.1 Place a conductor with a diameter between 1 and

quirements.

1.25 in. (25 and 31 mm) and a length longer than 16 in. (40 cm)

5.5 Examination Sequence—When magnetic particle ex-

through the center of the ring. Center the ring on the length of

amination is specified, it shall be performed after the comple-

the conductor. Magnetize the ring circularly by passing the

tion of operations that could cause surface or near-surface

current specified in Table 2 through the conductor. Using a

defects. These operations include, but are not limited to,

squeeze bulb or other suitable applicator, apply the particles to

forging, heat treating, plating, passivation, cold forming, weld-

the surface of the ring while the current is flowing. Examine

ing, grinding, straightening, machining, and proof loading.

the ring within 1 min after current application under a visible

Unless otherwise approved by the contracting agency or as

light of not less than 100 fc (1000 lx). The number of hole

approved in 6.1.3, production parts shall be magnetic particle

indications shall meet or exceed those specifie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.