ASTM D6925-03

(Test Method)Standard Test Method for Preparation and Determination of the Relative Density of Hot Mix Asphalt (HMA) Specimens by Means of the Superpave Gyratory Compactor

Standard Test Method for Preparation and Determination of the Relative Density of Hot Mix Asphalt (HMA) Specimens by Means of the Superpave Gyratory Compactor

SCOPE

1.1 This standard concerns the compaction of cylindrical specimens of hot mix asphalt (HMA) using the Superpave Gyratory Compactor (SGC). This standard also refers to the determination of the relative density of the compacted specimens at any point in the compaction process. Compacted specimens are suitable for volumetric and physical property testing.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6925–03

Standard Test Method for

Preparation and Determination of the Relative Density of

Hot Mix Asphalt (HMA) Specimens by Means of the

Superpave Gyratory Compactor

This standard is issued under the fixed designation D 6925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Gyratory Compactors (SGCs)

AASHTO T312 Preparing and Determining the Density of

1.1 This standard concerns the compaction of cylindrical

Hot-Mix Asphalt (HMA) Specimens by means of the

specimens of hot mix asphalt (HMA) using the Superpave

Superpave Gyratory Compactor

Gyratory Compactor (SGC). This standard also refers to the

2.3 Other References:

determination of the relative density of the compacted speci-

ANSI B46.1 American National Standards Institute

mens at any point in the compaction process. Compacted

PP ## Standard Practice for Evaluation of Superpave

specimens are suitable for volumetric and physical property

Gyratory Compactor (SGC) Internal Angle of Gyration

testing.

Asphalt Institute MS-2 Mix Design Methods for Asphalt

1.2 The values stated in SI units are to be regarded as the

Concrete

standard.

Ruggedness Evaluation of AASHTO TP4 The Superpave

1.3 This standard does not purport to address all of the

GyratoryCompactor,McGennis,R;Kennedy,TW;Ander-

safety concerns, if any, associated with its use. It is the

son, VL; Perdomo, D, Journal of the Association of

responsibility of the user of this standard to establish appro-

Asphalt Paving Technologists Vol: 66

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Significance and Use

2. Referenced Documents 3.1 This standard is used to prepare specimens for deter-

mining the volumetric and physical properties of HMA speci-

2.1 ASTM Standards:

mens.

D 1188 Test Method for Bulk Specific Gravity and Density

3.2 This test method is useful for monitoring the density of

of Compacted Bituminous Mixtures Using Coated

test specimens during the compaction process. This method is

Samples

suited for the laboratory design and field control of HMA.

D 2041 Test Method for Theoretical Maximum Specific

Gravity and Density of Bituminous Paving Mixtures

4. Apparatus

D 2726 Test Method for Bulk Specific Gravity and Density

4.1 Superpave Gyratory Compactor—An electromechani-

of Compacted Bituminous Mixtures Using Saturated

cal, electro hydraulic, or electro pneumatic compactor com-

Surface-Dry Specimens

prised of the following system components: (1) reaction frame,

D 4402 Test Method forViscosity Determination ofAsphalt

and drive motor, (2) loading system, loading ram, and pressure

at Elevated Temperatures Using a Rotational Viscometer

indicator, (3) height measurement and recording system, and

D 4753 Specification for Evaluating, Selecting, and Speci-

(4) mold and base plate.

fying Balances and Scales for Use in Testing Soil, Rock,

4.1.1 The reaction frame shall provide a non-compliant

and Related Construction Materials

structure against which the vertical loading ram can push when

2.2 AASHTO Standards:

compacting specimens. Reaction bearings shall be capable of

PP35 Provisional Practice for Evaluation of Superpave

creating, and firmly maintaining during the compaction pro-

cess, an external angle of gyration of 21.8 6 0.4 mrad (1.25 6

0.02 degrees).

This test method is under the jurisdiction of ASTM Committee D04 on Road

NOTE 1—Research has shown external angle (measurement between

and Paving Materials and is the direct responsibility of Subcommittee D04.20 on

the external mold wall and the frame of the compactor) to be different

Mechanical Tests of Bituminous Mixtures.

Current edition approved Sept. 10, 2003. Published November 2003.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of State Highway and Transportation

the ASTM website. Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

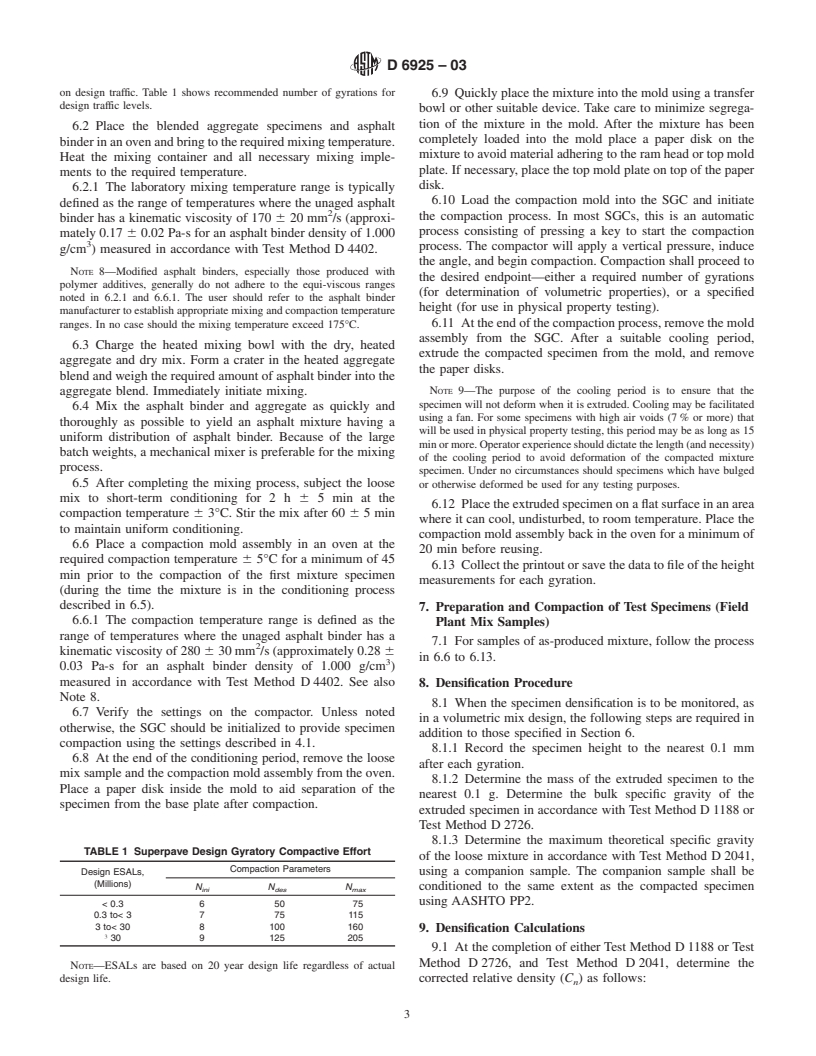

D6925–03

from the internal angle (measurement between internal mold wall and top

aggregates, asphalt binders, and equipment. This oven shall

and bottom plate). The difference between these measurements varies for

have a range to a minimum of 204°C, thermostatically con-

different types of compactors. Some discrepancies in relative density have

trolled to 6 3°C.

been resolved by use of the internal angle adjustment. Agencies may

4.7 Miscellaneous—Miscellaneous equipment may include:

choose the internal angle as the basis for calibration. If internal angle is

flat bottom metal pans for heating aggregates; scoops for

chosen for calibration the recommendation of the Superpave expert task

batching aggregates; containers for heating asphalt binders;

groupistouseaninternalangleof20.2 60.4mrad(1.16 60.02degrees).

(See AASHTO PP ## for the procedure to determine the internal angle). mixing spoons; trowels; spatulas; welders gloves for handling

hot equipment; 150 mm paper disks; lubricants for moving

4.1.2 The rotating base and drive motor shall be capable of

parts; laboratory timers; and mechanical mixers.

gyrating the specimen at a rate of 30.0 6 0.5 revolutions per

minute. The compactor shall be designed to permit the speci-

5. Standardization

men mold to gyrate freely on its tilted axis during compaction.

5.1 Items requiring periodic verification of calibration in-

4.1.3 The loading system, ram, and pressure indicator shall

clude the vertical pressure, angle of gyration, frequency of

be capable of providing and measuring a constant vertical

gyration, height measurement system, and oven temperature.

pressure of 600 6 60 kPa during the first five gyrations, and

Verificationofthemoldandplatendimensionsandsmoothness

600 6 18 kPa during the remainder of the compaction process.

of finish is also required. Verification of calibration, system

NOTE 2—The report on the ruggedness evaluation of AASHTO TP4,

standardization, and quality checks shall be performed by the

“Standard Method for Preparing and Determining the Density of Hot Mix

manufacturer, other agencies providing standardization ser-

Asphalt Specimens by Means of the SHRP Gyratory Compactor,”

vices, or in-house personnel.

(McGennis, et.al 1997) indicated that the pressure tolerance of 618 kPa

5.2 It is recommended that the user verify the calibration of

resulted in significantly different values of bulk specific gravity of the

the following items following the manufacturer’s recommen-

compacted specimens (G ) in some cases. However, since the pressure is

mb

directly set at 600 kPa, the tolerance of 618 kPa should apply only to the dations: angle, pressure, height, and rotational speed.

ability of the SGC to maintain vertical pressure during compaction. To

NOTE 3—If no manufacturer recommendations are available, the fol-

minimize potential errors caused by pressure, operators should take care

lowing schedule should be sufficient to assure the user that the SGC is

during calibration verification to assure that the specified pressure has

operating using the proper parameters:

been attained.

Angle of gyration monthly

4.1.4 The axis of the loading ram shall be perpendicular to

Vertical Pressure monthly

Height Measurement System monthly

the platen of the compactor.

Frequency of Gyration quarterly

4.1.5 The height measurement and recording system shall

Mold and platen dimensions annually

be capable of continuously measuring and recording the height

Calibration shall be performed if the gyratory compactor is transported

of the specimen during the compaction process to the nearest

to a new location.

0.1 mm. The height shall be recorded once per gyration.

NOTE 4—Unknown SGC equipment shall be evaluated using proce-

4.1.6 The system shall record test information, such as

dures described in AASHTO PP35 to assess its ability to produce

specimen heights per gyration. This may be accomplished compacted specimens at various compaction levels which are equivalent

to two models of SGC (Pine and Troxler), which have been used by most

through data acquisition or printing.

of the state DOT’s in the past, and are known to have met the

4.2 Specimen Molds—Specimen molds shall have steel

specifications.

walls that are at least 7.5 mm thick and are hardened to

Rockwell C48 or better. Molds shall have an inside diameter of

6. Preparation and Compaction of Test Specimens

149.90 mm to 150.00 mm and be at least 250 mm high. The

(Laboratory Design)

inside finish of the molds shall be smooth (rms of 1.60 mm or

6.1 Preparation of Aggregates—Weigh and combine the

smoother when measured in accordance with ANSI B46.1).

appropriateaggregatefractionstothedesiredspecimenweight.

4.3 Mold Plates and Ram Heads—All mold plates and ram

The specimen weight will vary based on the ultimate disposi-

heads shall be fabricated from steel with a minimum Rockwell

tion of the test specimens. If a target air void level is desired,

hardness of C48. The mold plates and ram heads shall be flat.

specimen weights will be adjusted to create a given density in

Mold plates and ram heads (if in contact with the HMA

a known volume. If the specimens are to be used for determi-

specimen) shall have an outside diameter of 149.50 mm to

nation of volumetric properties, the weights will be adjusted to

149.75 mm.

result in a compacted specimen having dimensions of 150 mm

4.4 Thermometers—Armored, glass, or dial type thermom-

in diameter and 115 6 5 mm in height at the required number

eters with metal stems for determining the temperature of

of gyrations.

aggregates, asphalt binders, and asphalt mixtures between

NOTE 5—It may be necessary to produce a trial specimen to achieve

10°C and 232°C, with a minimum sensitivity of 3°C.

this height requirement. Generally, 4500 to 4700 g of aggregate are

4.5 Balance—The balance shall have a minimum capacity

required to achieve this height for aggregates with combined bulk specific

of 10 000 g with a sensitivity of 0.1 g. The balance shall

gravities of 2.55 to 2.70 respectively.

conform to Specification D 4753 as a Class GP2 balance.

NOTE 6—Details of aggregate preparation may be found in any suitable

4.6 Ovens—Two ovens are recommended. One oven shall

mix design manual, such as the Asphalt Institute’s MS-2, Mix Design

be a forced draft oven capable of maintai

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.