ASTM A262-02ae1

(Practice)Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

SCOPE

1.1 These practices cover the following five tests:

1.1.1 Practice A— Oxalic Acid Etch Test for Classification of Etch Structures of Austenitic Stainless Steels (Sections 3 to 7, inclusive),

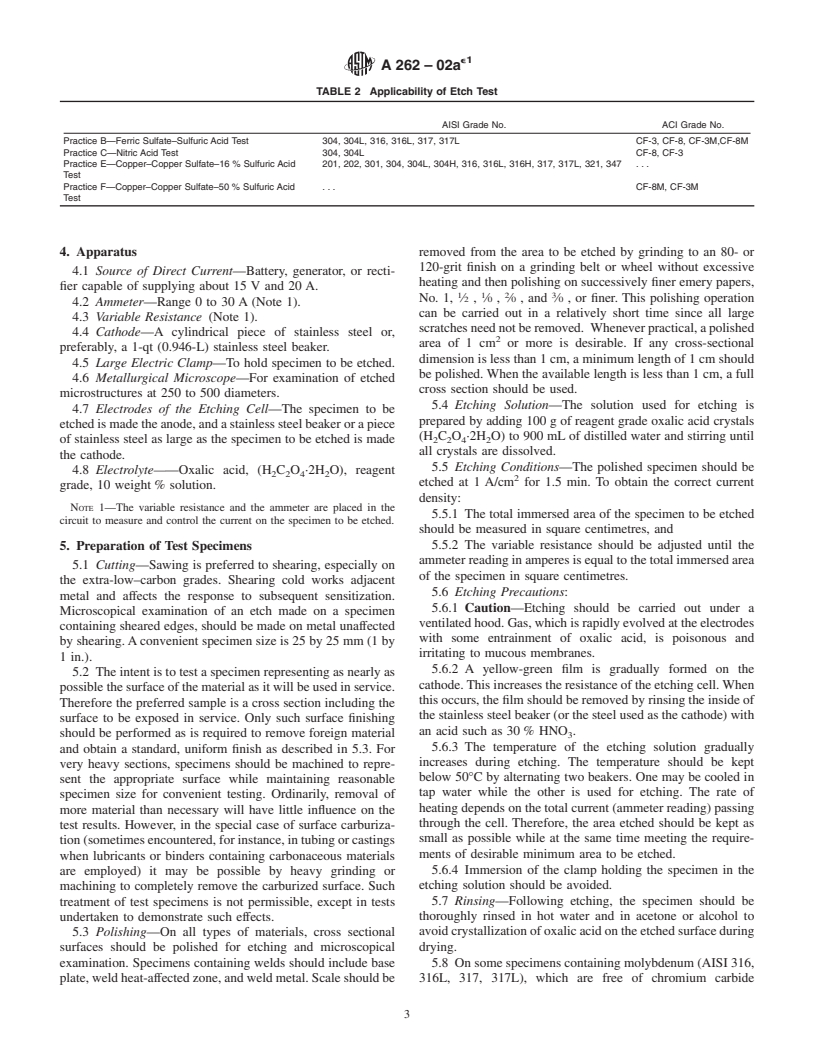

1.1.2 Practice B—Ferric Sulfate-Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections 8 to 14, inclusive),

1.1.3 Practice C—Nitric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections 15 to 21, inclusive),

1.1.4 Practice E—Copper-Copper Sulfate-Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (Sections 22 to 31, inclusive), and

1.1.5 Practice F—Copper-Copper Sulfate-50% Sulfuric Acid Test for Detecting Susceptibility to Intergranular Attack in Molybdenum-Bearing Cast Austenitic Stainless Steels (Sections 32 to 38, inclusive).

1.2 The following factors govern the application of these practices:

1.2.1 Susceptibility to intergranular attack associated with the precipitation of chromium carbides is readily detected in all six tests.

1.2.2 Sigma phase in wrought chromium-nickel-molybdenum steels, which may or may not be visible in the microstructure, can result in high corrosion rates only in nitric acid.

1.2.3 Sigma phase in titanium or columbium stabilized alloys and cast molybdenum bearing stainless alloys, which may or may not be visible in the microstructure, can result in high corrosion rates in both the nitric acid and ferric sulfate-sulfuric acid solutions.

1.3 The oxalic acid etch test is a rapid method of identifying, by simple etching, those specimens of certain stainless steel grades which are essentially free of susceptibility to intergranular attack associated with chromium carbide precipitates. These specimens will have low corrosion rates in certain corrosion tests and therefore can be eliminated (screened) from testing as "acceptable."

1.4 The ferric sulfate-sulfuric acid test, the copper-copper sulfate-50% sulfuric acid test, and the nitric acid test are based on weight loss determinations and, thus, provide a quantitative measure of the relative performance of specimens evaluated. In contrast, the copper-copper sulfate-16% sulfuric acid test is based on visual examination of bend specimens and, therefore, classifies the specimens only as acceptable or non-acceptable.

1.5 In most cases either the 24-h copper-copper sulfate-16% sulfuric acid test or the 120-h ferric sulfate-sulfuric acid test, combined with the oxalic acid etch test, will provide the required information in the shortest time. All stainless grades listed in the accompanying table may be evaluated in these combinations of screening and corrosion tests, except those specimens of molybdenum-bearing grades (for example 316, 316L, 317, and 317L), which represent steel intended for use in nitric acid environments.

1.6 The 240-h nitric acid test must be applied to stabilized and molybdenum-bearing grades intended for service in nitric acid and to all stainless steel grades which might be subject to end grain corrosion in nitric acid service.

1.7 Only those stainless steel grades are listed in Table 1 for which data on the application of the oxalic acid etch test and on their performance in various quantitative evaluation tests are available.

1.8 Extensive test results on various types of stainless steels evaluated by these practices have been published in Ref (1).

1.9 The values stated in SI units are to be regarded as standard. The inch-pound equivalents are in parentheses and may be approximate.

1.10 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Specific precautionary statements are given in 5.6, 11.1.1, ...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: A 262 – 02a

Standard Practices for

Detecting Susceptibility to Intergranular Attack in Austenitic

1

Stainless Steels

This standard is issued under the fixed designation A 262; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Table 1 was editorially corrected in August 2004.

1. Scope* steel grades that are essentially free of susceptibility to

intergranular attack associated with chromium carbide precipi-

1.1 These practices cover the following five tests:

tates. These specimens will have low corrosion rates in certain

1.1.1 Practice A—Oxalic Acid Etch Test for Classification

corrosion tests and therefore can be eliminated (screened) from

of Etch Structures of Austenitic Stainless Steels (Sections 3 to

testing as “acceptable.”

7, inclusive),

1.4 The ferric sulfate–sulfuric acid test, the copper–copper

1.1.2 Practice B—Ferric Sulfate–Sulfuric Acid Test for

sulfate–50 %sulfuricacidtest,andthenitricacidtestarebased

Detecting Susceptibility to Intergranular Attack in Austenitic

on weight loss determinations and, thus, provide a quantitative

Stainless Steels (Sections 8 to 14, inclusive),

measureoftherelativeperformanceofspecimensevaluated.In

1.1.3 Practice C—Nitric Acid Test for Detecting Suscepti-

contrast, the copper–copper sulfate–16 % sulfuric acid test is

bility to Intergranular Attack in Austenitic Stainless Steels

based on visual examination of bend specimens and, therefore,

(Sections 15 to 21, inclusive),

classifies the specimens only as acceptable or nonacceptable.

1.1.4 Practice E—Copper–Copper Sulfate–Sulfuric Acid

1.5 In most cases either the 24-h copper–copper sul-

Test for Detecting Susceptibility to Intergranular Attack in

fate–16 % sulfuric acid test or the 120-h ferric sulfate–sulfuric

Austenitic Stainless Steels (Sections 22 to 31, inclusive), and

acid test, combined with the oxalic acid etch test, will provide

1.1.5 Practice F—Copper–Copper Sulfate–50 % Sulfuric

the required information in the shortest time. All stainless

Acid Test for Detecting Susceptibility to Intergranular Attack

grades listed in the accompanying table may be evaluated in

in Molybdenum-Bearing CastAustenitic Stainless Steels (Sec-

these combinations of screening and corrosion tests, except

tions 32 to 38, inclusive).

those specimens of molybdenum-bearing grades (for example

1.2 The following factors govern the application of these

316, 316L, 317, and 317L), which represent steel intended for

practices:

use in nitric acid environments.

1.2.1 Susceptibility to intergranular attack associated with

1.6 The 240-h nitric acid test must be applied to stabilized

theprecipitationofchromiumcarbidesisreadilydetectedinall

and molybdenum-bearing grades intended for service in nitric

six tests.

acidandtoallstainlesssteelgradesthatmightbesubjecttoend

1.2.2 Sigma phase in wrought chromium-nickel-

grain corrosion in nitric acid service.

molybdenum steels, which may or may not be visible in the

1.7 Only those stainless steel grades are listed in Table 1 for

microstructure, can result in high corrosion rates only in nitric

whichdataontheapplicationoftheoxalicacidetchtestandon

acid.

their performance in various quantitative evaluation tests are

1.2.3 Sigma phase in titanium or columbium stabilized

available.

alloys and cast molybdenum-bearing stainless alloys, which

1.8 Extensive test results on various types of stainless steels

may or may not be visible in the microstructure, can result in

2

evaluated by these practices have been published in Ref (1).

high corrosion rates in both the nitric acid and ferric sulfate-

1.9 The values stated in SI units are to be regarded as

–sulfuric acid solutions.

standard. The inch-pound equivalents are in parentheses and

1.3 The oxalic acid etch test is a rapid method of identify-

may be approximate.

ing, by simple etching, those specimens of certain stainless

1.10 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

1

These practices are under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and are the direct responsibility of Subcommittee

A01.14 on Methods of Corrosion Testing.

2

Current edition approved Nov. 10, 2002. Published December 2002. Originally The boldface numbers in parentheses refer to the list of references found at the

approved in 1943. Last previous edition approved in 2002 as A 262 – 02. end of these practices.

*A Summary of Changes section appears at the end of this standard.

Copyright

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.