ASTM A866-09

(Specification)Standard Specification for Medium Carbon Anti-Friction Bearing Steel

Standard Specification for Medium Carbon Anti-Friction Bearing Steel

ABSTRACT

This specification covers the standard specification for medium carbon bearing quality steel to be used in the manufacture of anti-friction bearings. The bearings shall conform to the required chemical composition for carbon, phosphorus, manganese, sulfur, silicon, chromium, molybdenum, vanadium, copper, oxygen and aluminum. Requirement for dimensional tolerances of hot-rolled or hot-rolled and annealed bars, in straight lengths or coils, and cold-finished bars and larger in diameter furnished shall conform to the specified size, shape and tolerances. The grain size of the material shall conform to the required size, otherwise it shall be normalized and retested. Decarburization and surface imperfection shall not exceed the limit in the specified values. Material may be ordered as hot rolled or thermally treated. No hardness limits shall apply for as-hot-rolled materials.

SCOPE

1.1 This specification covers medium carbon bearing quality steel to be used in the manufacture of anti-friction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A866 −09

StandardSpecification for

1

Medium Carbon Anti-Friction Bearing Steel

This standard is issued under the fixed designation A866; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 Quantity (weight or pieces),

3.1.2 Grade identification,

1.1 This specification covers medium carbon bearing qual-

3.1.3 ASTM designation and year of issue,

ity steel to be used in the manufacture of anti-friction bearings.

3.1.4 Dimensions, and

1.2 Supplementary requirements of an optional nature are

3.1.5 Supplementary requirements, if included.

provided and when desired shall be so stated in the order.

4. Materials and Manufacture

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4.1 Process:

conversions to SI units that are provided for information only

4.1.1 The steel shall be made by a process that is capable of

and are not considered standard.

providing a high quality product meeting the requirements of

this specification.

2. Referenced Documents

2

2.1 ASTM Standards: 5. Chemical Composition and Analysis

A29/A29M Specification for Steel Bars, Carbon and Alloy,

5.1 Typical examples of chemical composition are shown in

Hot-Wrought, General Requirements for

Table 1. Other compositions may be specified.

A751 Test Methods, Practices, and Terminology for Chemi-

5.2 An analysis of each heat of steel shall be made by the

cal Analysis of Steel Products

steel manufacturer in accordance withTest Methods, Practices,

E45 Test Methods for Determining the Inclusion Content of

and Terminology A751. The chemical composition thus deter-

Steel

mined shall conform to the requirements specified in Table 1

E112 Test Methods for Determining Average Grain Size

for the ordered grade or to other requirements agreed upon

E381 Method of Macroetch Testing Steel Bars, Billets,

between the manufacturer and the purchaser.

Blooms, and Forgings

E1019 Test Methods for Determination of Carbon, Sulfur, 5.3 Product analysis may be made by the purchaser in

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

accordance with Test Methods, Practices, and Terminology

Alloys by Various Combustion and Fusion Techniques A751. Permissible variations in product analysis shall be in

E1077 Test Methods for Estimating the Depth of Decarbur-

accordance with Specification A29/A29M.

ization of Steel Specimens

3

6. Sizes, Shapes, and Dimensional Tolerances

2.2 ISO Standard:

ISO 683 Part 17: Ball and Roller Bearing Steels

6.1 The physical size and shape of the material shall be

agreed upon between the manufacturer and the purchaser.

3. Ordering Information

6.2 Dimensional tolerances for hot-rolled or hot-rolled and

3.1 Orders for material under this specification should

annealed bars, in straight lengths or coils, and cold-finished

include the following information:

bars0.500in.(12.7mm)andlargerindiameterfurnishedunder

thisspecificationshallconformtotherequirementsspecifiedin

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

the latest edition of Specification A29/A29M.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.28 on Bearing Steels.

6.3 Dimensional tolerances for cold-finished coils for ball

Current edition approved Oct. 1, 2009. Published November 2009. Originally

and roller material shall be as shown in Table 2.

approved in 1987. Last previous edition approved in 2001 as A866 – 01. DOI:

10.1520/A0866-09.

6.4 Coil tolerances also apply to cold-finished straight

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

lengths under 0.500 in. in diameter.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 7. Quality Tests

3

Available from International Organization for Standardization (ISO), 1, ch. de

7.1 The supplier shall be held responsible for the quality of

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch. the material furnished and shall make the necessary tests to

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

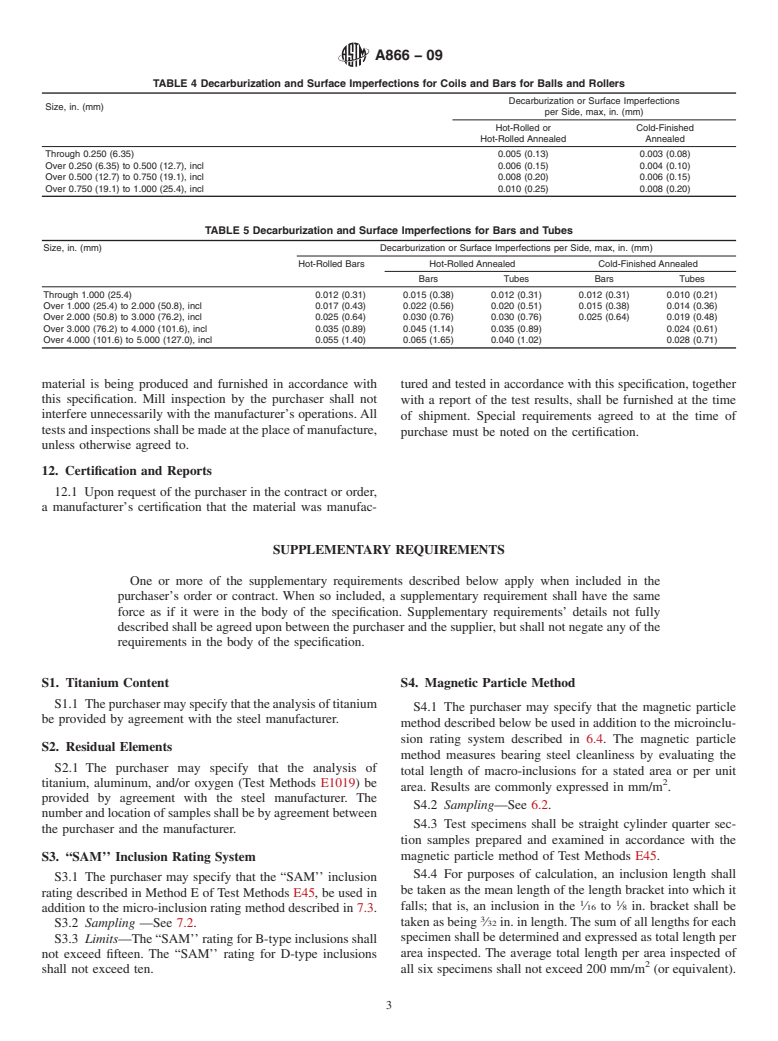

A866 − 09

A,B

TABLE 1 Chemical Composition

C D

Number Name C Mn P (max) S (max) Si Cr Mo V Cu (max) O (max) Al (max)

. . . 1030 0.28 to 0.34 0.60 to 0.90 0.025 0.025 0.15 to 0.35 . . . . . . . . . 0.30 0.0020 0.050

. . . 1040 0.3

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A866–01 Designation: A866 – 09

Standard Specification for

1

Medium Carbon Anti-Friction Bearing Steel

This standard is issued under the fixed designation A866; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers medium carbon bearing quality steel to be used in the manufacture of anti-friction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3The values stated in inch-pound units are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A29/A29M Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E45 Test Methods for Determining the Inclusion Content of Steel

E112 Test Methods for Determining Average Grain Size

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E1019 Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by

Various Combustion and Fusion Techniques

E1077 Test Methods for Estimating the Depth of Decarburization of Steel Specimens

3

2.2 ISO Standard:

ISO 683 Part 17: Ball and Roller Bearing Steels

3. Ordering Information

3.1 Orders for material under this specification should include the following information:

3.1.1 Quantity (weight or pieces),

3.1.2 Grade identification,

3.1.3 ASTM designation and year of issue,

3.1.4 Dimensions, and

3.1.5 Supplementary requirements, if included.

4. Materials and Manufacture

4.1 Process:

4.1.1 The steel shall be made by a process that is capable of providing a high quality product meeting the requirements of this

specification.

5. Chemical Composition and Analysis

5.1 Typical examples of chemical composition are shown in Table 1. Other compositions may be specified.

5.2 An analysis of each heat of steel shall be made by the steel manufacturer in accordance with Test Methods, Practices, and

Terminology A751. The chemical composition thus determined shall conform to the requirements specified in Table 1 for the

ordered grade or to other requirements agreed upon between the manufacturer and the purchaser.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.28 on Bearing Steels.

Current edition approved Dec. 10, 2001. Published February 2002. Originally published as A866–87. Last previous edition A866–94. DOI: 10.1520/A0866-01.

Current edition approved Oct. 1, 2009. Published November 2009. Originally approved in 1987. Last previous edition approved in 2001 as A866 – 01. DOI:

10.1520/A0866-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 01.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 01.03.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

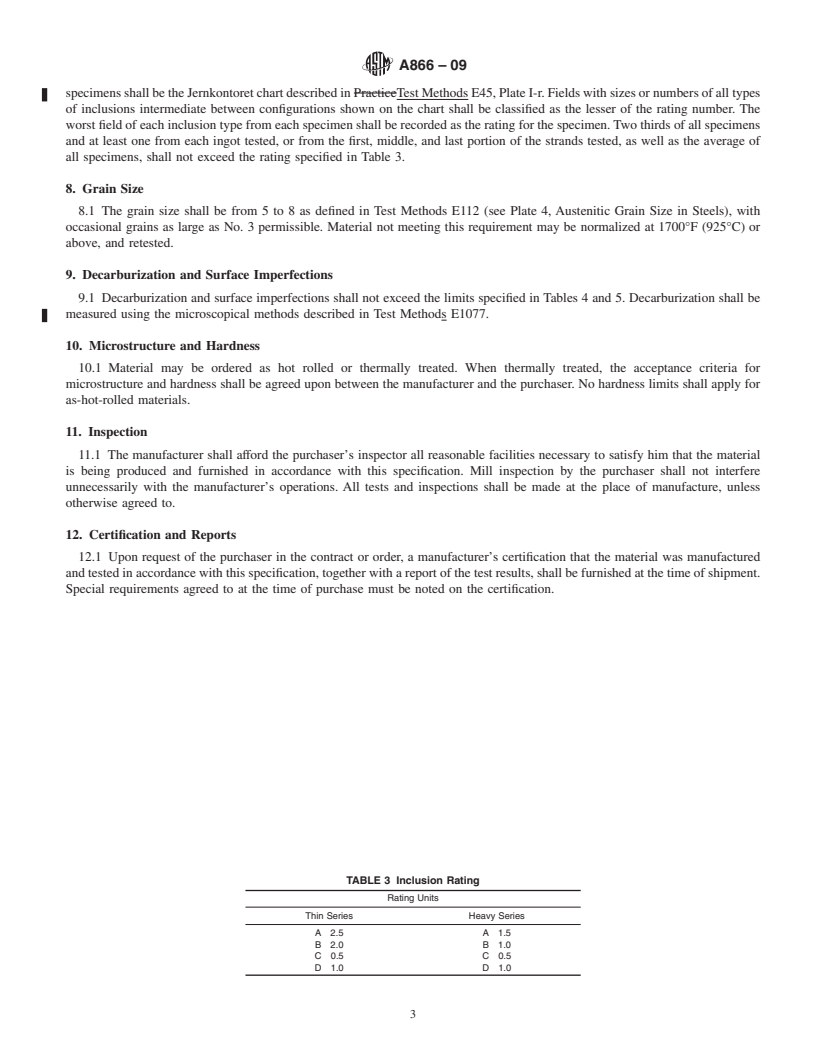

A866 – 09

A,B

TABLE 1 Chemical Composition

C D

Number Name C Mn P (max) S (max) Si Cr Mo V Cu (max) O (max) Al (max)

. . . 1030 0.28 to 0.34 0.60 to 0.90 0.025 0.025 0.15 to 0.35 . . . . . . . . . 0.30 0.0020 0.050

. . . 1040 0.37 to 0.44 0.60 to 0.90 0.025 0.025 0.15 to 0.35 . . . . . . . . . 0.30 0.0020 0.050

. . . 1050 0.48 to 0.55 0.60 to 0.90 0.025 0.025 0.15 to 0.35 . . . . . . . . . 0.30 0.0020 0.050

. . . 1541 0.36 to 0.44 1.35 to 1.65 0.025 0.025 0.15 to 0.35 . . . . . . . . . 0.30 0.0020 0.050

. . . 1552 0.47 to 0.55 1.20 to 1.50 0.025 0.025 0.15 to 0.35 . . . . . . . . . 0.30 0.0020 0.050

. . . 4130 0.28 to 0.33 0.40 t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.