ASTM D7667-21

(Test Method)Standard Test Method for Determination of Corrosiveness to Silver by Automotive Spark-Ignition Engine Fuel-Thin Silver Strip Method

Standard Test Method for Determination of Corrosiveness to Silver by Automotive Spark-Ignition Engine Fuel-Thin Silver Strip Method

SIGNIFICANCE AND USE

5.1 Crude petroleum contains sulfur compounds, most of which are removed during refining. However, of the sulfur compounds remaining in the petroleum product or introduced into the fuel during storage and distribution, some can have a corroding action on various metals and this corrosivity is not necessarily related directly to the total sulfur content. The effect can vary according to the chemical types of sulfur compounds present. The silver strip corrosion test is designed to assess the relative degree of corrosivity of a petroleum product towards silver and silver alloys.

5.2 Under some circumstances, reactive sulfur compounds present in automotive spark-ignition engine fuels can tarnish or even corrode silver alloy fuel gauge in-tank sender units or silver-plated bearings (in 2-stroke cycle engines). To minimize or prevent the failure of silver alloy in-tank sender units by tarnish or corrosion, Specification D4814 requires that fuels shall pass a silver strip corrosion test.

SCOPE

1.1 This test method covers the determination of the corrosiveness to silver by automotive spark-ignition engine fuel (for example, gasoline), as defined by Specification D4814 or similar specifications in other jurisdictions, having a vapor pressure no greater than 124 kPa (18 psi) at 37.8 °C (100 °F) by one of two procedures.

1.1.1 Procedure A-Involves the use of a pressure vessel.

1.1.2 Procedure B-Involves the use of a vented test tube.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 WARNING-Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM D7667-21 is a standard published by ASTM International. Its full title is "Standard Test Method for Determination of Corrosiveness to Silver by Automotive Spark-Ignition Engine Fuel-Thin Silver Strip Method". This standard covers: SIGNIFICANCE AND USE 5.1 Crude petroleum contains sulfur compounds, most of which are removed during refining. However, of the sulfur compounds remaining in the petroleum product or introduced into the fuel during storage and distribution, some can have a corroding action on various metals and this corrosivity is not necessarily related directly to the total sulfur content. The effect can vary according to the chemical types of sulfur compounds present. The silver strip corrosion test is designed to assess the relative degree of corrosivity of a petroleum product towards silver and silver alloys. 5.2 Under some circumstances, reactive sulfur compounds present in automotive spark-ignition engine fuels can tarnish or even corrode silver alloy fuel gauge in-tank sender units or silver-plated bearings (in 2-stroke cycle engines). To minimize or prevent the failure of silver alloy in-tank sender units by tarnish or corrosion, Specification D4814 requires that fuels shall pass a silver strip corrosion test. SCOPE 1.1 This test method covers the determination of the corrosiveness to silver by automotive spark-ignition engine fuel (for example, gasoline), as defined by Specification D4814 or similar specifications in other jurisdictions, having a vapor pressure no greater than 124 kPa (18 psi) at 37.8 °C (100 °F) by one of two procedures. 1.1.1 Procedure A-Involves the use of a pressure vessel. 1.1.2 Procedure B-Involves the use of a vented test tube. 1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only. 1.3 WARNING-Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 Crude petroleum contains sulfur compounds, most of which are removed during refining. However, of the sulfur compounds remaining in the petroleum product or introduced into the fuel during storage and distribution, some can have a corroding action on various metals and this corrosivity is not necessarily related directly to the total sulfur content. The effect can vary according to the chemical types of sulfur compounds present. The silver strip corrosion test is designed to assess the relative degree of corrosivity of a petroleum product towards silver and silver alloys. 5.2 Under some circumstances, reactive sulfur compounds present in automotive spark-ignition engine fuels can tarnish or even corrode silver alloy fuel gauge in-tank sender units or silver-plated bearings (in 2-stroke cycle engines). To minimize or prevent the failure of silver alloy in-tank sender units by tarnish or corrosion, Specification D4814 requires that fuels shall pass a silver strip corrosion test. SCOPE 1.1 This test method covers the determination of the corrosiveness to silver by automotive spark-ignition engine fuel (for example, gasoline), as defined by Specification D4814 or similar specifications in other jurisdictions, having a vapor pressure no greater than 124 kPa (18 psi) at 37.8 °C (100 °F) by one of two procedures. 1.1.1 Procedure A-Involves the use of a pressure vessel. 1.1.2 Procedure B-Involves the use of a vented test tube. 1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only. 1.3 WARNING-Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D7667-21 is classified under the following ICS (International Classification for Standards) categories: 75.160.20 - Liquid fuels. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D7667-21 has the following relationships with other standards: It is inter standard links to ASTM D3241-24, ASTM D4814-24, ASTM D4814-23a, ASTM D3241-23a, ASTM D3241-23ae1, ASTM D4814-20, ASTM D4814-19a, ASTM D3241-19a, ASTM D4814-18c, ASTM D4814-18a, ASTM D4814-18, ASTM D3241-17, ASTM D4814-16ee1, ASTM D4814-16e, ASTM D4814-16d. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM D7667-21 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7667 − 21

Standard Test Method for

Determination of Corrosiveness to Silver by Automotive

Spark-Ignition Engine Fuel—Thin Silver Strip Method

This standard is issued under the fixed designation D7667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the corro-

D130 Test Method for Corrosiveness to Copper from Petro-

siveness to silver by automotive spark-ignition engine fuel (for

leum Products by Copper Strip Test

example, gasoline), as defined by Specification D4814 or

D3241 Test Method for Thermal Oxidation Stability of

similar specifications in other jurisdictions, having a vapor

Aviation Turbine Fuels

pressure no greater than 124 kPa (18 psi) at 37.8 °C (100 °F)

D4057 Practice for Manual Sampling of Petroleum and

by one of two procedures.

Petroleum Products

1.1.1 Procedure A—Involves the use of a pressure vessel.

D4177 Practice for Automatic Sampling of Petroleum and

1.1.2 Procedure B—Involves the use of a vented test tube.

Petroleum Products

D4814 Specification for Automotive Spark-Ignition Engine

1.2 The values stated in SI units are to be regarded as the

Fuel

standard. The values in parentheses are for information only.

E1 Specification for ASTM Liquid-in-Glass Thermometers

1.3 WARNING—Mercury has been designated by many

2.2 Energy Institute Standards:

regulatory agencies as a hazardous substance that can cause

IP 227 Determination of Corrosiveness to Silver ofAviation

serious medical issues. Mercury, or its vapor, has been dem-

Turbine Fuels - Silver Strip Method

onstrated to be hazardous to health and corrosive to materials.

2.3 ASTM Adjuncts:

Use caution when handling mercury and mercury-containing

Color standard for tube deposit rating (5 aluminum strips)

products. See the applicable product Safety Data Sheet (SDS)

for additional information. The potential exists that selling

3. Terminology

mercury or mercury-containing products, or both, is prohibited

3.1 Abbreviations:

by local or national law. Users must determine legality of sales

3.1.1 PTFE—polytetrafluoroethylene

in their location.

3.1.2 PV—pressure vessel

1.4 This standard does not purport to address all of the

3.1.3 PVP—pressure vessel procedure

safety concerns, if any, associated with its use. It is the

3.1.4 SSCD—silver strip centering device

responsibility of the user of this standard to establish appro-

3.1.5 TSMD—temperature sensing and monitoring device

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1.6 VTTP—vented test tube procedure

1.5 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.1 Apolished, thin silver strip is immersed in 30 mLof the

sample being tested, and heated at 50 °C (122 °F) for 2 h. At

Development of International Standards, Guides and Recom-

the end of the heating period, the silver strip is removed,

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee D02 on Standards volume information, refer to the standard’s Document Summary page on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of the ASTM website.

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial. Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

Current edition approved Nov. 1, 2021. Published December 2021. Originally U.K., http://www.energyinst.org.uk.

approved in 2010. Last previous edition approved in 2015 as D7667 – 10 (2015). Available from ASTM International Headquarters. Order Adjunct No.

DOI: 10.1520/D7667-21. ADJD3241. Original adjunct produced in 1986.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7667 − 21

washed, and the color and tarnish level assessed against the 6.3.1 Bath,shallbefittedwithsuitablesupportstoholdeach

Silver Strip Classifications in Table 1. test tube (see 6.2) in a vertical position to a depth of about

100 mm (4 in.) as measured from the bottom of the test tube to

5. Significance and Use the bath surface.

6.3.2 BathMedium,asaliquidbathmedium,bothwaterand

5.1 Crude petroleum contains sulfur compounds, most of

oil have been found to be satisfactory and controllable at the

which are removed during refining. However, of the sulfur

specified test temperature and duration required by the test

compounds remaining in the petroleum product or introduced

procedure.

into the fuel during storage and distribution, some can have a

6.3.3 Solid Block Bath, made of aluminum, shall meet the

corroding action on various metals and this corrosivity is not

test temperature control, test duration, and immersion condi-

necessarily related directly to the total sulfur content. The

tions required by the test procedure, and shall be verified, at

effect can vary according to the chemical types of sulfur

least annually, for temperature measurement (heat transfer) by

compounds present. The silver strip corrosion test is designed

running tests on tubes filled with 30 mL of product plus a thin

to assess the relative degree of corrosivity of a petroleum

silver strip of the given nominal dimensions, plus a tempera-

product towards silver and silver alloys.

ture sensor.

5.2 Under some circumstances, reactive sulfur compounds 6.3.3.1 Wells provided in the solid block bath to accommo-

presentinautomotivespark-ignitionenginefuelscantarnishor

date pressure vessels (see Fig. 1) shall be of the following

even corrode silver alloy fuel gauge in-tank sender units or

dimensions: ~54 mm (2 ⁄8 in.) diameter from top, up to a depth

silver-plated bearings (in 2-stroke cycle engines). To minimize

of ~70 mm (2 ⁄4 in.) continuing with an opening of ~38 mm

1 1

or prevent the failure of silver alloy in-tank sender units by

(1 ⁄2 in.) diameter up to a depth of ~140 mm (5 ⁄2 in.). An

5 1

tarnish or corrosion, Specification D4814 requires that fuels

opening of ~8 mm ( ⁄16 in.) diameter by ~210 mm (8 ⁄4 in.)

shall pass a silver strip corrosion test.

depthshallbeprovidedinthecenteroftheblockforimmersion

of a metal temperature sensor (connected to a suitable 50 °C 6

6. Apparatus 1 °C (122 °F 6 2 °F) temperature controller), or thermometer

(see 6.5).

6.1 Silver Strip Corrosion Pressure Vessel (Procedure A),

6.3.3.2 Wells provided in the solid block bath to accommo-

constructed from stainless steel according to dimensions given

date test tubes shall be of the following dimensions: ~20 mm

in Fig. 1, as described in Test Method D130. The vessel shall

1 1

(1 ⁄16 in.) diameter by ~140 mm (5 ⁄2 in.) deep.An opening of

becapableofwithstandingatestpressureof700 kPa(100 psi).

5 1

~8 mm ( ⁄16 in.) diameter by ~210 mm (8 ⁄4 in.) depth shall be

Alternative designs for the vessel’s cap and synthetic rubber

provided in the center of the block for immersion of a metal

gasketmaybeusedprovidedthattheinternaldimensionsofthe

temperature sensor (connected to a suitable 50 °C 6 1°C

vessel are the same as shown in Fig. 1, which allow a nominal

(122 °F 6 2 °F) temperature controller), or thermometer (see

25 mm by 150 mm (1 in. by 6 in.) test tube (see 6.2) and the

6.5).

SSCD (see 6.4) to be placed inside the pressure vessel.

6.3.3.3 Provide insulation made of ~25.4 mm (1.0 in.) thick

6.2 Test Tubes, of borosilicate glass of nominal 25 mm by

fiberglass with aluminum backing (or, similar insulation) to

150 mm (1 in. by 6 in.) dimensions, preferably graduated at

cover all the four sides of the solid block bath.

30 mL volume. The internal dimensions shall be checked as

5,6

6.4 Silver Strip Centering Device (SSCD), made of mate-

acceptable by use of a silver strip (see 7.4). When 30 mL of

rial which is gasoline-compatible at 50 °C (122 °F) for the

sample is added to the test tube with the silver strip in it, a

duration of the test, such asAcetal Resin, White Nylon 6/6, or

minimum of 5 mm of liquid shall be above the top surface of

the strip.

The sole source of supply of the apparatus known to the committee at this time

6.3 Test Bath, General, whether liquid or solid, the test bath

isK&C Manufacturing, 210 S. Main, Newkirk, OK 74647.

shall be able to maintain the test temperature to within 61°C

If you are aware of alternative suppliers, please provide this information to

(2 °F) of the required test temperature. It is recommended that

ASTM International Headquarters. Your comments will receive careful consider-

baths be placed inside a fume-hood. ation at a meeting of the responsible technical committee, which you may attend.

TABLE 1 Silver Strip Classifications

NOTE 1—Acknowledgement—This table has been reproduced from Standard IP 227.

Classification Designation Description

0 No Tarnish Identical to a freshly-polished strip but may have

some very slight loss of luster

1 Slight Tarnish Faint brown or white discoloration of strip (see 12.2)

2 Moderate Tarnish Peacock colors such as blue or mauve or medium/

dark straw or brown coloration (see 12.2)

3 Slight blackening Spots and patches of black or gray on surface or uni-

form thin film of black deposit

4 Blackening Uniform heavy blackening with or without scaling

D7667 − 21

that the lower edge of the assembled silver strip is about

22 mm ( ⁄8 in.) from the bottom of the test tube.

6.5 Temperature Sensing and Monitoring Device (TSMD),

capable of sensing and monitoring the desired test temperature

in the bath to within an accuracy of 61 °C (2 °F). The ASTM

12C (12F) (see Specification E1) or IP 64C (64F) total

immersion thermometer has been found suitable for use in the

test. If used, no more than 10 mm (0.4 in.) of the mercury shall

extend above the surface of the bath at the test temperature.

6.6 Timing Device, electronic or manual, capable of accu-

rately measuring the test duration within the allowable toler-

ance.

6.7 Forceps, with inert tips, stainless steel or polytetrafluo-

roethylene (PTFE) tips, have been found suitable for use in

handling the silver strips.

6.8 PolishingBoard,150 mmby100 mmby3 mm(6 in.by

4 in. by ⁄8 in.) solid plastic piece having a smooth surface, for

placement of silver strip during polishing.

6.9 Optional Equipment:

6.9.1 Refrigerator, for cooling samples below 5 °C (41 °F)

during storage.

6.10 ASTM Silver Strip Corrosion Standards, consist of

reproductions in color of typical test strips representing in-

creasing degrees of tarnish and corrosion, the reproductions

beingencasedforprotectioninplasticandmadeupintheform

of a plaque. See Table 1.

6.10.1 Keep the plastic-encased ASTM Silver Strip Corro-

sion Standards protected from light to avoid the possibility of

fading. Inspect for fading by comparing two different plaques,

one of which has been carefully protected from light (for

example, new plaque). Observe both sets in diffused daylight

(or equivalent) first from a point directly above and then from

an angle of 45°. If any evidence of fading is observed,

particularly at the left-hand end of the plaque, it is suggested

that the one that is the more faded with respect to the other be

discarded.

6.10.1.1 Alternatively, place a suitably sized opaque strip

(for example, 20 mm ( ⁄4 in.) black electrical tape) across the

top of the colored portion of the plaque when initially

Key:

1. Lifting eye

purchased. At intervals remove the opaque strip and observe.

2. Wide groove for pressure relief

When there is any evidence of fading of the exposed portion,

3. Knurled cap

the standards shall be replaced.

4. Twelve threads per inch NF thread or equivalent

5. Camber inside cap to protect “O” ring when closing pressure vessel

6.10.2 The plaques are full-color reproductions of typical

6. Synthetic rubber “O” ring without free sulfur

strips.Theyhavebeenprintedonaluminumsheetsbya4-color

7. Seamless tube

process and are encased in plastic for protection. Directions for

Material: stainless steel

Welded construction

their use are given on the reverse side of each plaque.

Maximum test gauge pressure: 700 kPa

6.10.3 If the surface of the plastic cover shows excessive

NOTE 1—Dimensions in millimetres.

scratching, it is suggested that the plaque be replaced.

NOTE 2—All dimensions without tolerance limits are nominal values.

FIG. 1 Pressure Vessel for Silver Strip Corrosion Test – Proce-

7. Reagents and Materials

dure A

7.1 Wash Solvent, 2,2,4-trimethylpentane (iso-octane) of

PTFE. See details in A1.1 (Assembly View) and A1.2 (Indi- minimum 99.75 % purity. (Warning—Extremely flammable,

vidualPartsView).LengthofSSCDinsidethetesttubeissuch see 8.1.)

----------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7667 − 10 (Reapproved 2015) D7667 − 21

Standard Test Method for

Determination of Corrosiveness to Silver by Automotive

Spark-Ignition Engine Fuel—Thin Silver Strip Method

This standard is issued under the fixed designation D7667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of the corrosiveness to silver by automotive spark-ignition engine fuel (for example,

gasoline), as defined by Specification D4814 or similar specifications in other jurisdictions, having a vapor pressure no greater than

124 kPa (18 psi) at 37.8 °C (100 °F) by one of two procedures.

1.1.1 Procedure A—Involves the use of a pressure vessel.

1.1.2 Procedure B—Involves the use of a vented test tube.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous materialsubstance that can cause

central nervous system, kidney and liver damage. serious medical issues. Mercury, or its vapor, may has been demonstrated to be

hazardous to health and corrosive to materials. Caution should be taken Use caution when handling mercury and mercury

containing mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware (SDS) for additional informa-

tion. The potential exists that selling mercury and/or mercury containing products into your state or country may be prohibited by

law.or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their

location.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Oct. 1, 2015Nov. 1, 2021. Published December 2015December 2021. Originally approved in 2010. Last previous edition approved in 20102015

ɛ2

as D7667 – 10 (2015). . DOI: 10.1520/D7667-10R15.10.1520/D7667-21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7667 − 21

D3241 Test Method for Thermal Oxidation Stability of Aviation Turbine Fuels

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4814 Specification for Automotive Spark-Ignition Engine Fuel

E1 Specification for ASTM Liquid-in-Glass Thermometers

2.2 Energy Institute Standards:

IP 227 Determination of Corrosiveness to Silver of Aviation Turbine Fuels - Silver Strip Method

2.3 ASTM Adjuncts:

Color standard for tube deposit rating (5 aluminum strips)

3. Terminology

3.1 Abbreviations:

PTFE = polytetrafluoroethylene

PV = pressure vessel

PVP = pressure vessel procedure

SSCD = silver strip centering device

TSMD = temperature sensing and monitoring device

VTTP = vented test tube procedure

3.1.1 PTFE—polytetrafluoroethylene

3.1.2 PV—pressure vessel

3.1.3 PVP—pressure vessel procedure

3.1.4 SSCD—silver strip centering device

3.1.5 TSMD—temperature sensing and monitoring device

3.1.6 VTTP—vented test tube procedure

4. Summary of Test Method

4.1 A polished, thin silver strip is immersed in 30 mL of the sample being tested, and heated at 50 °C (122 °F) for 2 h. At the end

of the heating period, the silver strip is removed, washed, and the color and tarnish level assessed against the Silver Strip

Classifications in Table 1.

TABLE 1 Silver Strip Classifications

NOTE 1—Acknowledgement—This table has been reproduced from Standard IP 227.

Classification Designation Description

0 No Tarnish Identical to a freshly-polished strip but may have

some very slight loss of luster

1 Slight Tarnish Faint brown or white discoloration of strip (see 12.2)

2 Moderate Tarnish Peacock colors such as blue or mauve or medium/

dark straw or brown coloration (see 12.2)

3 Slight blackening Spots and patches of black or gray on surface or uni-

form thin film of black deposit

4 Blackening Uniform heavy blackening with or without scaling

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

Available from ASTM International Headquarters. Order Adjunct No. ADJD3241. Original adjunct produced in 1986.

D7667 − 21

5. Significance and Use

5.1 Crude petroleum contains sulfur compounds, most of which are removed during refining. However, of the sulfur compounds

remaining in the petroleum product or introduced into the fuel during storage and distribution, some can have a corroding action

on various metals and this corrosivity is not necessarily related directly to the total sulfur content. The effect can vary according

to the chemical types of sulfur compounds present. The silver strip corrosion test is designed to assess the relative degree of

corrosivity of a petroleum product towards silver and silver alloys.

5.2 Under some circumstances, reactive sulfur compounds present in automotive spark-ignition engine fuels can tarnish or even

corrode silver alloy fuel gauge in-tank sender units or silver-plated bearings (in 2-stroke cycle engines). To minimize or prevent

the failure of silver alloy in-tank sender units by tarnish or corrosion, Specification D4814 requires that fuels shall pass a silver

strip corrosion test.

6. Apparatus

6.1 Silver Strip Corrosion Pressure Vessel (Procedure A), constructed from stainless steel according to dimensions given in Fig.

1, as described in Test Method D130. The vessel shall be capable of withstanding a test pressure of 700 kPa (100 psi). Alternative

designs for the vessel’s cap and synthetic rubber gasket may be used provided that the internal dimensions of the vessel are the

same as shown in Fig. 1, which allow a nominal 25 mm by 150 mm (1 in. by 6 in.) test tube (see 6.2) and the SSCD (see 6.4) to

be placed inside the pressure vessel.

6.2 Test Tubes, of borosilicate glass of nominal 25 mm by 150 mm (1 in. by 6 in.) dimensions, preferably graduated at 30 mL

,

volume. The internal dimensions shall be checked as acceptable by use of a silver strip (see 7.4). When 30 mL of sample is added

to the test tube with the silver strip in it, a minimum of 5 mm of liquid shall be above the top surface of the strip.

6.3 Test Bath, General, whether liquid or solid, the test bath shall be able to maintain the test temperature to within 61 °C (2 °F)

of the required test temperature. It is recommended that baths be placed inside a fume-hood.

6.3.1 Bath, shall be fitted with suitable supports to hold each test tube (see 6.2) in a vertical position to a depth of about 100 mm

(4 in.) as measured from the bottom of the test tube to the bath surface.

6.3.2 Bath Medium, as a liquid bath medium, both water and oil have been found to be satisfactory and controllable at the specified

test temperature and duration required by the test procedure.

6.3.3 Solid Block Bath, made of aluminum, shall meet the test temperature control, test duration, and immersion conditions

required by the test procedure, and shall be verified, at least annually, for temperature measurement (heat transfer) by running tests

on tubes filled with 30 mL of product plus a thin silver strip of the given nominal dimensions, plus a temperature sensor.

6.3.3.1 Wells provided in the solid block bath to accommodate pressure vessels (see Fig. 1) shall be of the following dimensions:

1 3 1

~54 mm (2 ⁄8 in.) diameter from top, up to a depth of ~70 mm (2 ⁄4 in.) continuing with an opening of ~38 mm (1 ⁄2 in.) diameter

1 5 1

up to a depth of ~140 mm (5 ⁄2 in.). An opening of ~8 mm ( ⁄16 in.) diameter by ~210 mm (8 ⁄4 in.) depth shall be provided in the

center of the block for immersion of a metal temperature sensor (connected to a suitable 50 °C 6 1°C1 °C (122 °F 6 2 °F)

temperature controller), or thermometer (see 6.5).

6.3.3.2 Wells provided in the solid block bath to accommodate test tubes shall be of the following dimensions: ~20 mm (1 ⁄16 in.)

1 5 1

diameter by ~140 mm (5 ⁄2 in.) deep. An opening of ~8 mm ( ⁄16 in.) diameter by ~210 mm (8 ⁄4 in.) depth shall be provided in the

center of the block for immersion of a metal temperature sensor (connected to a suitable 50 °C 6 1 °C (122 °F 6 2 °F) temperature

controller), or thermometer (see 6.5).

6.3.3.3 Provide insulation made of ~25.4 mm (1.0 in.) thick fiberglass with aluminum backing (or, similar insulation) to cover all

the four sides of the solid block bath.

5,6

6.4 Silver Strip Centering Device (SSCD), made of material which is gasoline-compatible at 50 °C (122 °F) for the duration of

The sole source of supply of the apparatus known to the committee at this time is Quark Enterprises, Inc., 320 Morton Ave., Rosenhayn, NJ 08352.K & C Manufacturing,

210 S. Main, Newkirk, OK 74647.

D7667 − 21

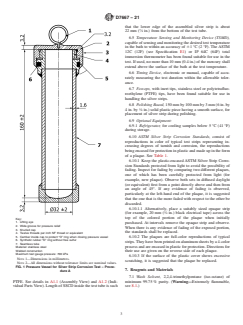

Key:

1. Lifting eye

2. Wide groove for pressure relief

3. Knurled cap

4. Twelve threads per inch NF thread or equivalent

5. Camber inside cap to protect “O” ring when closing pressure vessel

6. Synthetic rubber “O” ring without free sulfur

7. Seamless tube

Material: stainless steel

Welded construction

Maximum test gauge pressure: 700 kPa

NOTE 1—Dimensions in millimetres.

NOTE 2—All dimensions without tolerance limits are nominal values.

FIG. 1 Pressure Vessel for Silver Strip Corrosion Test – Procedure A

the test, such as Acetal Resin, White Nylon 6/6, or PTFE. See details in A1.1 (Assembly View) and A1.2 (Individual Parts View).

Length of SSCD inside the test tube is such that the lower edge of the assembled silver strip is about 22 mm ( ⁄8 in.) from the

bottom of the test tube.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend.

D7667 − 21

6.5 Temperature Sensing and Monitoring Device (TSMD), capable of sensing and monitoring the desired test temperature in the

bath to within an accuracy of 61 °C (2 °F). The ASTM 12C (12F) (see Specification E1) or IP 64C (64F) total immersion

thermometer has been found suitable for use in the test. If used, no more than 10 mm (0.4 in.) of the mercury shall extend above

the surface of the bath at the test temperature.

6.6 Timing Device, electronic or manual, capable of accurately measuring the test duration within the allowable tolerance.

6.7 Forceps, with inert tips, stainless steel or polytetrafluoroethylene (PTFE) tips, have been found suitable for use in handling

the silver strips.

6.8 Polishing Board, 150 mm by 100 mm by 3 mm (6 in. by 4 in. by ⁄8 in.) solid plastic piece having a smooth surface, for

placement of silver strip during polishing.

6.9 Optional Equipment:

6.9.1 Refrigerator, for cooling samples below 5 °C (41 °F) during storage.

6.10 ASTM Silver Strip Corrosion Standards, consist of reproductions in color of typical test strips representing increasing degrees

of tarnish and corrosion, the reproductions being encased for protection in plastic and made up in the form of a plaque. See Table

1.

6.10.1 Keep the plastic-encased ASTM Silver Strip Corrosion Standards protected from light to avoid the possibility of fading.

Inspect for fading by comparing two different plaques, one of which has been carefully protected from light (for example, new

plaque). Observe both sets in diffused daylight (or equivalent) first from a point directly above and then from an angle of 45°. If

any evidence of fading is observed, particularly at the left-hand end of the plaque, it is suggested that the one that is the more faded

with respect to the other be discarded.

6.10.1.1 Alternatively, place a suitably sized opaque strip (for example, 20 mm ( ⁄4 in.) black electrical tape) across the top of the

colored portion of the plaque when initially purchased. At intervals remove the opaque strip and observe. When there is any

evidence of fading of the exposed portion, the standards shall be replaced.

6.10.2 The plaques are full-color reproductions of typical strips. They have been printed on aluminum sheets by a 4-color process

and are encased in plastic for protection. Directions for their use are given on the reverse side of each plaque.

6.10.3 If the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...