ASTM D5749-17

(Specification)Standard Specification for Reinforced and Plain Gummed Tape for Sealing and Securing

Standard Specification for Reinforced and Plain Gummed Tape for Sealing and Securing

ABSTRACT

This specification covers reinforced (Type I) and plain (Type II) paper gummed adhesive tapes used for securing and banding paper products and sealing fiberboard boxes. Type I gummed tape may be strippable (Class 1) or nonstrippable (Class 2), while Type II paper-backed gummed tape, whether Grade A (light duty), B (medium duty), or C (heavy duty), is nonstrippable. The tapes shall be manufactured from kraft paper, but the use of recycled pulp in the paper is encouraged as well, and the adhesive used must not have an offensive odor and shall conform to the environmental considerations specified. Type I tapes shall consist of two strips of paper in roll form, while Type II tapes shall consist of one strip of paper in roll form. Upon manufacture, the tape shall be clean and free of folds, sharp creases, tears, cuts, and holes. The tapes shall be examined for visual defects, defects in roll construction, and defects in dimensions. Tests for adhesiveness, tensile strength, and elongation shall be performed as well, and shall conform to the physical properties specified.

SCOPE

1.1 This specification covers plain and reinforced paper gummed adhesive tapes suitable for securing and banding paper products and closing fiberboard boxes.

1.2 This specification is intended to replace Fed. Specs. CID A-A-1492, CID A-A-1671, and PPP-T-45 in part.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D5749 −17

Standard Specification for

Reinforced and Plain Gummed Tape for Sealing and

1

Securing

This standard is issued under the fixed designation D5749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1974/D1974MPractice for Methods of Closing, Sealing,

and Reinforcing Fiberboard Boxes

1.1 This specification covers plain and reinforced paper

D3951Practice for Commercial Packaging

gummed adhesive tapes suitable for securing and banding

2.2 TAPPI Standards:

paper products and closing fiberboard boxes.

3

T401Fiber Analysis of Paper and Paperboard

1.2 ThisspecificationisintendedtoreplaceFed.Specs.CID 3

T410Weight per Unit Area (Basis Weight or Substance)

A-A-1492, CID A-A-1671, and PPP-T-45 in part.

T414InternalTearingResistanceofPaper(Elmendorf-Type

3

1.3 The values stated in SI units are to be regarded as Method)

standard. The values given in parentheses are for information

UM 575Water Resistance of Adhesive Bond in Laminated

3

only. Paper and Paperboard

2.3 ANSI/ASQC Standards:

1.4 The following safety hazards caveat pertains only to the

ANSI/ASQCZ1.4Sampling Procedures and Tables for In-

test methods portion, Section 11, of this specification: This

4

spection by Attributes

standard does not purport to address all of the safety concerns,

ANSI/ASQCZ1.9 Sampling Procedures and Tables for

if any, associated with its use. It is the responsibility of the user

4

Inspection by Variables for Percent Defective

of this standard to establish appropriate safety and health

2.4 Federal Specifications:

practices and determine the applicability of regulatory limita-

tions prior to use. PPP-T-45Tape, Gummed, Paper, Reinforced and Plain, for

5

Sealing and Securing

1.5 This international standard was developed in accor-

5

dance with internationally recognized principles on standard- PPP-T-681Tape, Gummed, Packaging and Packing of

CID A-A-1492 Commercial Item Description Tape,

ization established in the Decision on Principles for the

5

Gummed, Paper, Plain

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical CID A-A-1671 Commercial Item Description Tape,

5

Gummed, (Paper, Reinforced, Laminated)

Barriers to Trade (TBT) Committee.

2.5 ISO Standard:

2. Referenced Documents ISO 9002Quality Systems Model for Quality Assurance in

4

2

Production and Installations

2.1 ASTM Standards:

D685Practice for Conditioning Paper and Paper Products

3. Terminology

for Testing

3.1 Definitions—General definitions for packaging and dis-

D828Test Method for Tensile Properties of Paper and

tribution environments are found in Terminology D996.

PaperboardUsingConstant-Rate-of-ElongationApparatus

D996Terminology of Packaging and Distribution Environ-

4. Classification

ments

4.1 Type I Reinforced, Laminated:

4.1.1 Class 1—Strippable.

4.1.2 Class 2—Nonstrippable.

1

This specification is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

Labels.

3

Current edition approved April 1, 2017. Published June 2017. Originally Available from Technological Association of the Pulp and Paper Industry

approved in 1995. Last previous edition approved in 2012 as D5749–01(2012). (TAPPI), 15 Technology Parkway South, Suite 115, Peachtree Corners, GA30092,

DOI: 10.1520/D5749-17. http://www.tappi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Government Publishing Office, 732 N. Capitol St., NW,

the ASTM website. Washington, DC 20401-0001, http://www.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5749−17

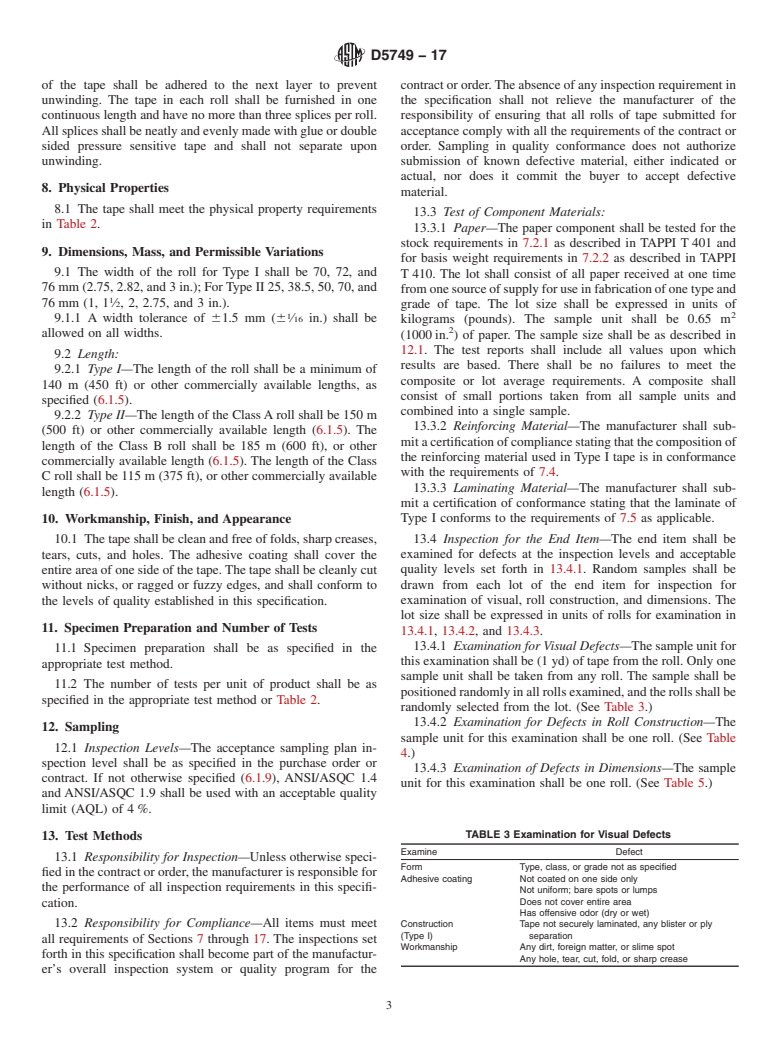

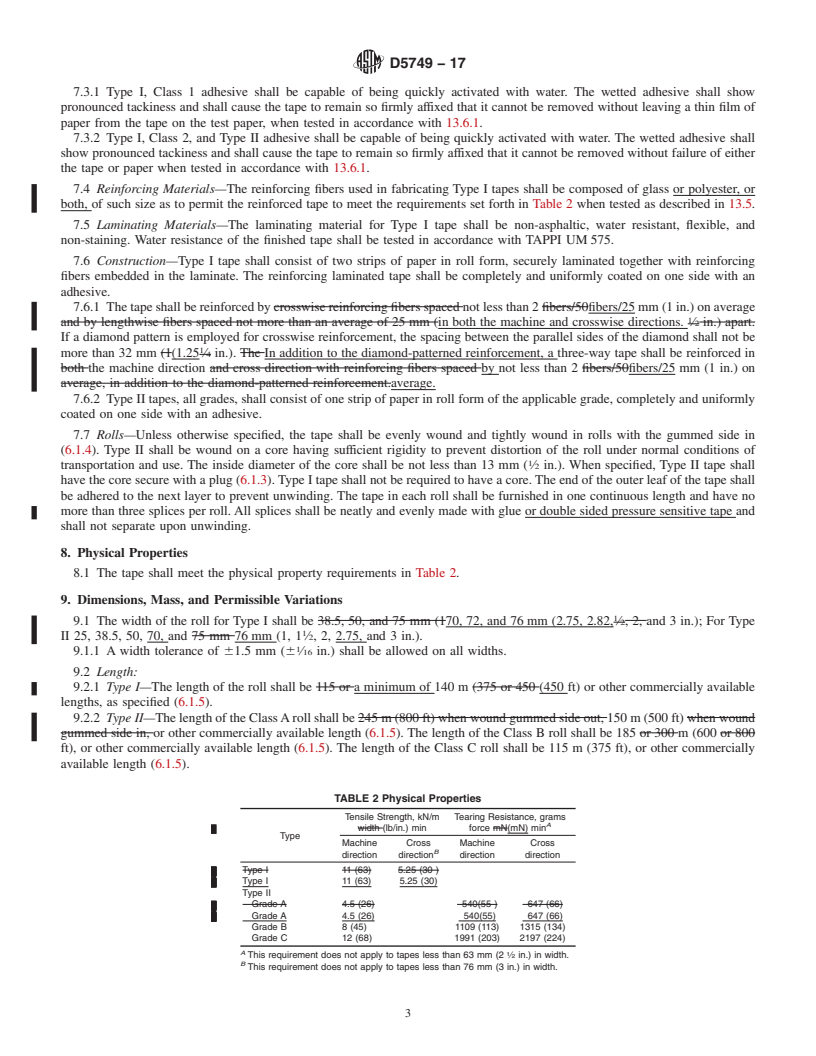

4.2 Type II Plain, Single Ply, Strippable: 7.3.1 Type I, Class 1 adhesive shall be capable of being

4.2.1 Grade A—Light duty, for lightweight packages. quickly activated with water. The wetted adhesive shall show

4.2.2 Grade B—Medium duty, for medium-sized packages. pronounced tackiness and shall cause the tape to remain so

4.2.3 G

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5749 − 01 (Reapproved 2012) D5749 − 17

Standard Specification for

Reinforced and Plain Gummed Tape for Sealing and

1

Securing

This standard is issued under the fixed designation D5749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers plain and reinforced paper gummed adhesive tapes suitable for securing and banding paper

products and closing fiberboard boxes.

1.2 This specification is intended to replace Fed. Specs. CID A-A-1492, CID A-A-1671, and PPP-T-45 in part.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D685 Practice for Conditioning Paper and Paper Products for Testing

D828 Test Method for Tensile Properties of Paper and Paperboard Using Constant-Rate-of-Elongation Apparatus

D996 Terminology of Packaging and Distribution Environments

D1974D1974/D1974M Practice for Methods of Closing, Sealing, and Reinforcing Fiberboard Boxes

D3951 Practice for Commercial Packaging

2.2 TAPPI Standards:

3

T 401 Fiber Analysis of Paper and Paperboard

3

T 410 Weight per Unit Area (Basis Weight or Substance)

3

T 414 Internal Tearing Resistance of Paper (Elmendorf-Type Method)

3

UM 575 Water Resistance of Adhesive Bond in Laminated Paper and Paperboard

2.3 ANSI/ASQC Standards:

4

ANSI/ASQC Z 1.4 Sampling Procedures and Tables for Inspection by Attributes

4

ANSI/ASQC Z 1.9 Sampling Procedures and Tables for Inspection by Variables for Percent Defective

2.4 Federal Specifications:

5

PPP-T-45 Tape, Gummed, Paper, Reinforced and Plain, for Sealing and Securing

5

PPP-T-681 Tape, Gummed, Packaging and Packing of

5

CID A-A-1492 Commercial Item Description Tape, Gummed, Paper, Plain

5

CID A-A-1671 Commercial Item Description Tape, Gummed, (Paper, Reinforced, Laminated)

1

This specification is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and Labels.

Current edition approved April 1, 2012April 1, 2017. Published May 2012June 2017. Originally approved in 1995. Last previous edition approved in 20062012 as

D5749 – 01(2006).(2012). DOI: 10.1520/D5749-01R12. 10.1520/D5749-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from TechnicalTechnological Association of the Pulp and Paper Industry (TAPPI), 15 Technology Parkway South, Norcross, Suite 115, Peachtree Corners, GA

30092, http://www.tappi.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Available from U.S. Government Printing Office Superintendent of Documents, Publishing Office, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401,

http://www.access.gpo.gov.20401-0001, http://www.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5749 − 17

2.5 ISO Standard:

4

ISO 9002 Quality Systems Model for Quality Assurance in Production and Installations

3. Terminology

3.1 Definitions—General definitions for packaging and distribution environments are found in Terminology D996.

4. Classification

4.1 Type I Reinforced, Laminated:

4.1.1 Class 1—Strippable.

4

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5749 − 17

Standard Specification for

Reinforced and Plain Gummed Tape for Sealing and

1

Securing

This standard is issued under the fixed designation D5749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1974/D1974M Practice for Methods of Closing, Sealing,

and Reinforcing Fiberboard Boxes

1.1 This specification covers plain and reinforced paper

D3951 Practice for Commercial Packaging

gummed adhesive tapes suitable for securing and banding

2.2 TAPPI Standards:

paper products and closing fiberboard boxes.

3

T 401 Fiber Analysis of Paper and Paperboard

1.2 This specification is intended to replace Fed. Specs. CID

3

T 410 Weight per Unit Area (Basis Weight or Substance)

A-A-1492, CID A-A-1671, and PPP-T-45 in part.

T 414 Internal Tearing Resistance of Paper (Elmendorf-Type

3

1.3 The values stated in SI units are to be regarded as

Method)

standard. The values given in parentheses are for information UM 575 Water Resistance of Adhesive Bond in Laminated

3

only.

Paper and Paperboard

2.3 ANSI/ASQC Standards:

1.4 The following safety hazards caveat pertains only to the

ANSI/ASQC Z 1.4 Sampling Procedures and Tables for In-

test methods portion, Section 11, of this specification: This

4

spection by Attributes

standard does not purport to address all of the safety concerns,

ANSI/ASQC Z 1.9 Sampling Procedures and Tables for

if any, associated with its use. It is the responsibility of the user

4

Inspection by Variables for Percent Defective

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita- 2.4 Federal Specifications:

PPP-T-45 Tape, Gummed, Paper, Reinforced and Plain, for

tions prior to use.

5

1.5 This international standard was developed in accor- Sealing and Securing

5

PPP-T-681 Tape, Gummed, Packaging and Packing of

dance with internationally recognized principles on standard-

CID A-A-1492 Commercial Item Description Tape,

ization established in the Decision on Principles for the

5

Development of International Standards, Guides and Recom- Gummed, Paper, Plain

CID A-A-1671 Commercial Item Description Tape,

mendations issued by the World Trade Organization Technical

5

Barriers to Trade (TBT) Committee. Gummed, (Paper, Reinforced, Laminated)

2.5 ISO Standard:

2. Referenced Documents

ISO 9002 Quality Systems Model for Quality Assurance in

4

2

Production and Installations

2.1 ASTM Standards:

D685 Practice for Conditioning Paper and Paper Products

3. Terminology

for Testing

3.1 Definitions—General definitions for packaging and dis-

D828 Test Method for Tensile Properties of Paper and

tribution environments are found in Terminology D996.

Paperboard Using Constant-Rate-of-Elongation Apparatus

D996 Terminology of Packaging and Distribution Environ-

4. Classification

ments

4.1 Type I Reinforced, Laminated:

4.1.1 Class 1—Strippable.

1 4.1.2 Class 2—Nonstrippable.

This specification is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

Labels.

3

Current edition approved April 1, 2017. Published June 2017. Originally Available from Technological Association of the Pulp and Paper Industry

approved in 1995. Last previous edition approved in 2012 as D5749 – 01(2012). (TAPPI), 15 Technology Parkway South, Suite 115, Peachtree Corners, GA 30092,

DOI: 10.1520/D5749-17. http://www.tappi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Government Publishing Office, 732 N. Capitol St., NW,

the ASTM website. Washington, DC 20401-0001, http://www.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5749 − 17

4.2 Type II Plain, Single Ply, Strippable: 7.3.1 Type I, Class 1 adhesive shall be capable of being

4.2.1 Grade A—Light duty, for lightweight packages. quickly activated with water. The wetted adhesive shall show

4.2.2 Grade B—Medium duty, for medium-sized packages. pronounced tackiness and shall cause the tape to remain so

4.2.3 Grade C—Heavy duty, for heavy-duty packages. firmly affixed that it cannot be removed without leavin

...

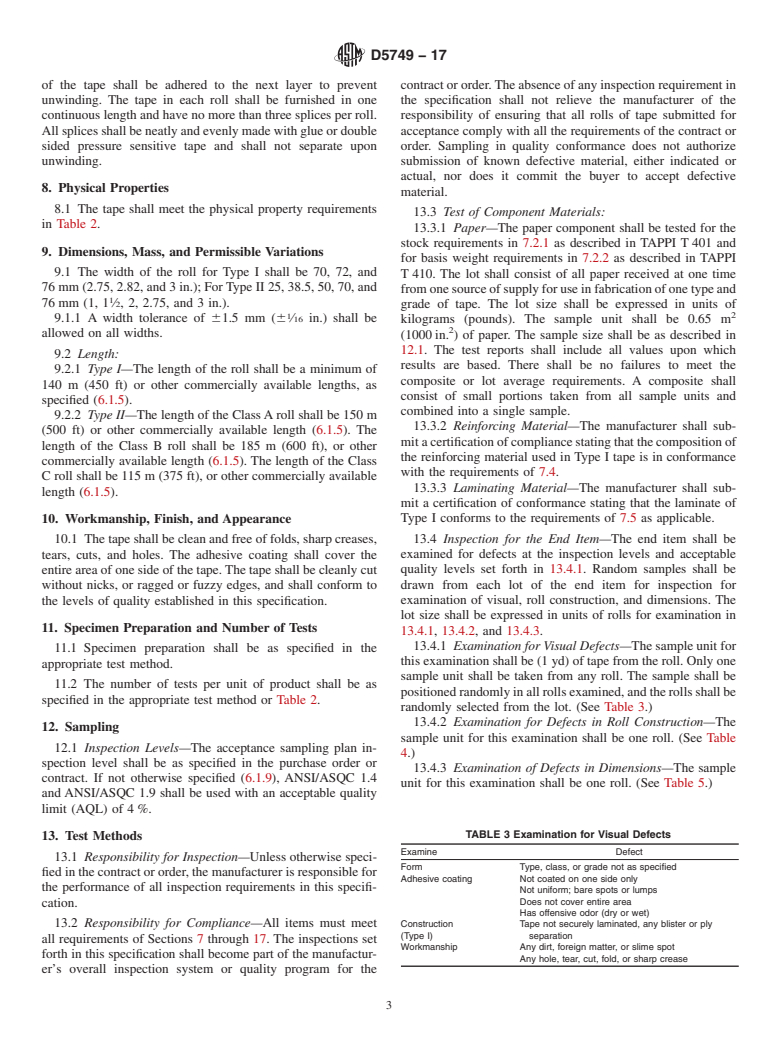

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.