ASTM A1-00

(Specification)Standard Specification for Carbon Steel Tee Rails

Standard Specification for Carbon Steel Tee Rails

SCOPE

1.1 This specification covers carbon steel tee rails of nominal weights of 60 lb/yd (29.8 kg/m) and over for use in railway track, including export and industrial applications.

1.2 Supplementary requirementsS1and S2 shall apply only when specified by the purchaser in the order.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1–00

Standard Specification for

Carbon Steel Tee Rails

ThisstandardisissuedunderthefixeddesignationA1;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.3 Quantity (tons or pieces as appropriate).

3.1.4 Full identification of section with dimensional draw-

1.1 This specification covers carbon steel tee rails of nomi-

ing, if required.

nalweightsof60lb/yd(29.8kg/m)andoverforuseinrailway

3.1.5 Arrangement of drilled bolt holes, if any, with dimen-

track, including export and industrial applications.

sional drawing, if required.

1.2 SupplementaryrequirementsS1andS2shallapplyonly

3.1.6 Quantity of right-hand and left-hand (Note 1) drilled

when specified by the purchaser in the order.

rails, drilled both-end rails, and undrilled (blank) rails desired.

1.3 The values stated in inch-pound units are to be regarded

3.1.7 Supplementary requirements that shall apply (see S1

as the standard. The values given in parentheses are for

and S2).

information only.

3.1.8 Dispositionofvariousclassificationsofrails(see8.3.6

2. Referenced Documents

and 8.3.7).

2.1 ASTM Standards:

NOTE 1—The right-hand or left-hand end of the rail is determined by

A29/A29M SpecificationforSteelBars,CarbonandAlloy,

facing the side of the rail on which the brand (raised characters) appears.

Hot-Wrought and Cold-Finished, General Requirements

4. Materials and Manufacture

for

A 700 Practices for Packaging, Marking, and Loading 4.1 Rail Types—Rails shall be furnished as-rolled (standard

Methods for Steel Products for Domestic Shipment and alloy), head hardened (on-line or off-line processes), or

E10 Test Method for Brinell Hardness of Metallic Materi- fullyheattreatedasagreeduponbetweenthepurchaserandthe

als manufacturer.

E127 Practice for Fabricating and Checking Aluminum 4.2 Melting Practice—Thesteelshallbemadebyanyofthe

Alloy Ultrasonic Standard Reference Blocks following processes: basic-oxygen or electric-furnace.

E428 Practice for Fabrication and Control of Steel Refer- 4.2.1 The steel shall be cast by a continuous process, in

ence Blocks Used in Ultrasonic Inspection hot-topped ingots, or by other methods agreed upon between

2.2 American Railway Engineering and Maintenance of the purchaser and the manufacturer.

Way Association (AREMA) Manual for Railway Engineering: 4.3 Discard—Sufficient discard shall be taken from the

,

Specifications for Steel Rails, Chapter 4, Part 2 bloom or ingot to ensure freedom from injurious segregation

and pipe.

3. Ordering Information

4.4 Hydrogen Elimination:

3.1 Orders for rails under this specification shall include the

4.4.1 Applicability:

following information: 4.4.1.1 Rails 60 through 70 lb/yd (29.8 through 34.8 kg/m)

3.1.1 ASTM designation and year of issue.

are not subject to treatment for hydrogen elimination.

3.1.2 Type of rail desired. 4.4.1.2 Rails over 70 through 84 lb/yd (over 34.8 through

41.7 kg/m) may be subjected to treatment for hydrogen

elimination at the option of the manufacturer.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

4.4.1.3 Rails over 84 lb/yd (41.7 kg/m) shall be processed

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

by methods that prevent the formation of shatter cracks as

A01.01 on Steel Rails and Accessories.

Current edition approved Sept. 10, 2000. Published November 2000. Originally agreed upon between the purchaser and the manufacturer.

published as A1–01. Last previous editionA1–92.

4.4.2 Rail heats shall be tested for hydrogen content using

Annual Book of ASTM Standards, Vol 01.05.

either a sampling/analytical method or a direct measurement

Annual Book of ASTM Standards, Vol 03.01.

methodoftheliquidsteel.Thetestingshallbeperformedeither

Annual Book of ASTM Standards, Vol 03.03.

AvailablefromAmericanRailwayEngineeringandMaintenanceofWayAssn.,

during the continuous casting process or during ingot teeming.

8201 Corporate Drive, Suite 1125, Landover, MD 20785.

Hydrogencontentshallberecordedandavailableforreviewor

Adapted from AREMA Specifications for Steel Rails (see 2.2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A1

TABLE 1 Chemical Requirements—Heat Analysis

reporting at the request of the purchaser. The producer shall

define the method used to determine hydrogen content, which Nominal Weight, lb/yd (kg/m)

of the following methods are used for hydrogen removal, and

60 to 84 85 to 114

Element

(29.8 to (42.2 to

present evidence of applicable procedures used to control the

(57.0)

41.7), 56.6),

final rail hydrogen: and over

incl incl

4.4.2.1 Vacuum degassing.

Carbon 0.55 to 0.68 0.70 to 0.80 0.74 to 0.84

4.4.2.2 Bloom control cooling. A

Manganese 0.60 to 0.90 0.70 to 1.00 0.80 to 1.10

Phosphorus, max 0.040 0.035 0.035

4.4.2.3 Rail control cooling.

Sulfur, max 0.050 0.040 0.040

4.4.3 Rail Control-Cooling Procedure (AREMA Specifica-

Silicon 0.10 to 0.50 0.10 to 0.50 0.10 to 0.50

tions for Steel Rails)—Rails shall be control-cooled in accor-

A

Theuppermanganeselimitmaybeextendedto1.25 %bythemanufacturerto

dance with the following procedure, except when produced

meet the Brinell hardness specification. When manganese exceeds 1.10 %, the

from vacuum degassed steel or control-cooled blooms, in residual alloy contents will be held to 0.25 % maximum nickel; 0.25 % maximum

chromium; 0.10 % maximum molybdenum; and 0.03 % maximum vanadium.

which case the rails may be air-cooled, and 4.4.3.1-4.4.3.5 are

not applicable.

TABLE 2 Product Analysis Allowance Beyond Limits of

4.4.3.1 All rails shall be cooled on the hot beds or runways

Specified Chemical Analysis

until full transformation is accomplished and then charged

Percent Under Percent Over

immediately into the containers. In no case should the rail be

Minimum Limit Maximum Limit

charged at a temperature below 725°F (385°C).

Carbon 0.04 0.04

4.4.3.2 Thetemperatureoftherailsbeforechargingshallbe

Manganese 0.06 0.06

determined with a reliable calibrated pyrometer at the top of

Phosphorus . . . 0.008

Sulfur . . . 0.008

the rail head at least 12 in. (305 mm) from the end.

A

Silicon 0.02 0.02

4.4.3.3 The cover shall be placed on the container immedi-

A

Continuously cast allowances shall be 0.05 % over maximum limit for silicon.

ately after completion of the charge and shall remain in place

for at least 10 h. After removal or raising of the lid of the

container, no rail shall be removed until the top layer of rails

chemicalanalysisrequirementsofTable1maybeapplied.The

has fallen to 300°F (149°C) or lower.

analysis, most representative of the heat (clear of the transition

4.4.3.4 The temperature between an outside rail and the

zone for continuous cast steel), shall be recorded as the official

adjacent rail in the bottom tier of the container at a point not

analysis, but the purchaser shall have access to all chemical

less than 12 in. (305 mm) nor more than 36 in. (915 mm) from

analysisdeterminations.Additionally,anymaterialmeetingthe

the rail end shall be recorded. This temperature shall be the

product analysis limits shown in Table 2 may be applied after

control for judging rate of cooling.

testing such material in accordance with Specification A29/

4.4.3.5 The container shall be so protected and insulated

A29M.

that the control temperature shall not drop below 300°F

5.2.2 Upon request by the purchaser, samples shall be

(149°C) in 7 h for rails 100 lb/yd (49.7 kg/m) in weight or

furnished to verify the analysis as determined in 5.2.1.

heavier, from the time that the bottom tier is placed in the

container, and in 5 h for rails of less than 100 lb/yd in weight.

6. Interior Condition

If this cooling requirement is not met, the rails shall be

6.1 Forbothingotsteelandcontinuouslycaststeel,between

considered control-cooled, provided that the temperature at a

macroetch testing shall be performed as agreed upon between

location not less than 12 in. (305 mm) from the end of a rail at

the purchaser and the manufacturer.

approximatelythecenterofthemiddletierdoesnotdropbelow

6.2 Macroetch Testing—Rail soundness shall be evaluated

300°F in less than 15 h.

by macroetching in a hot acid solution.

5. Chemical Composition

6.2.1 Sample Location and Frequency:

5.1 The chemical composition of the standard, head hard- 6.2.1.1 Ingot Steel—Atest piece representing the top end of

the top rail from one of the first three, middle three, and last

ened, and fully heat treated rail steel, determined as prescribed

in 5.2.1, shall be within the limits shown in Table 1. The three ingots of each heat shall be macroetched.

chemicalcompositionofalloyrailwillbesubjecttoagreement 6.2.1.2 Continuous Cast Steel—A test piece shall be mac-

between the purchaser and the manufacturer. roetched representing a rail from each strand from the begin-

5.1.1 When ladle tests are not available, finished material ning of each sequence and whenever a new ladle is begun,

representing the heat may be product tested. The product which is the point representative of the lowest level in the

analysis allowance beyond the limits of the specified ladle tundish (that is, the point of lowest ferrostatic pressure). One

analysis shall be within the limits for product analyses speci- additional sample from the end of each strand of the last heat

fied in Table 2. in the sequence shall also be tested. A new tundish is

5.2 Heat or Cast Analysis: considered to be the beginning of a new sequence.

5.2.1 Separate analysis shall be made from test samples 6.2.2 If any test specimen does not conform to the accept-

representing one of the first three and one of the last three able macroetch pictorial standards agreed upon between the

ingots or continuously cast blooms preferably taken during the purchaser and the manufacturer, further samples shall be taken

pouring of the heat. Determinations may be made chemically from the same strand or ingot. For continuously cast steel, two

or spectrographically. Any portion of the heat meeting the retestsshallbetakenonefromeachsideoftheoriginalsample

A1

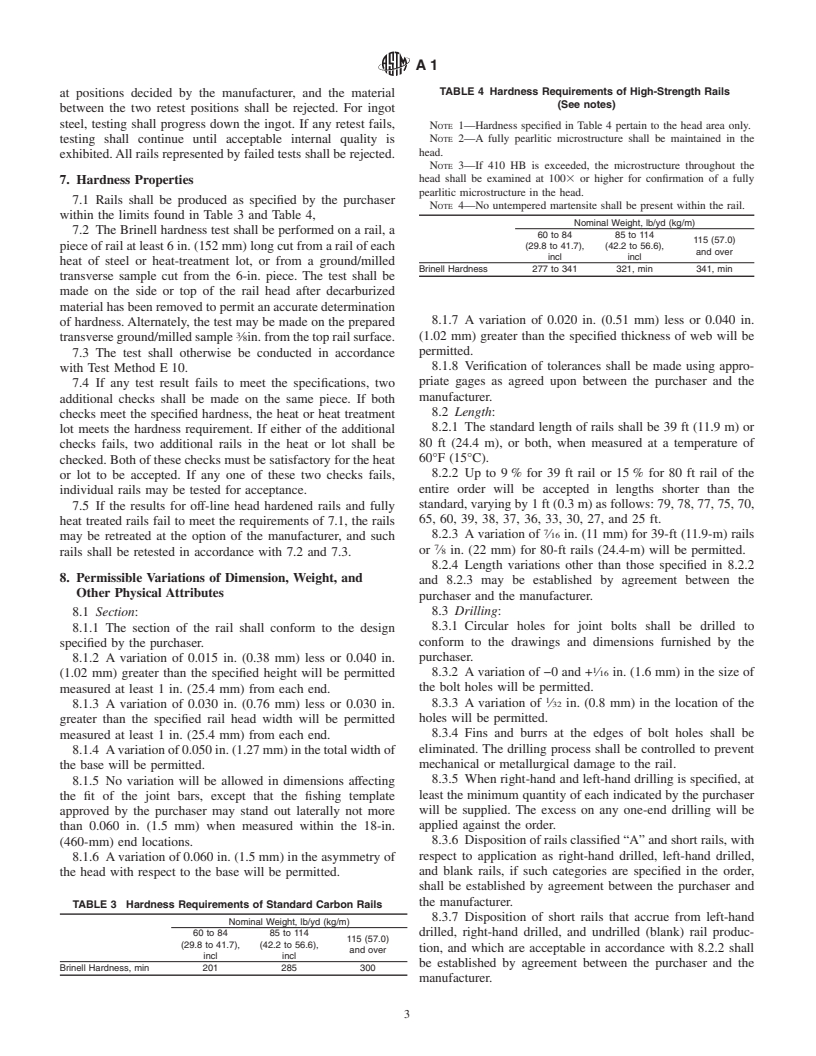

TABLE 4 Hardness Requirements of High-Strength Rails

at positions decided by the manufacturer, and the material

(See notes)

between the two retest positions shall be rejected. For ingot

steel, testing shall progress down the ingot. If any retest fails,

NOTE 1—Hardness specified in Table 4 pertain to the head area only.

NOTE 2—A fully pearlitic microstructure shall be maintained in the

testing shall continue until acceptable internal quality is

head.

exhibited.All rails represented by failed tests shall be rejected.

NOTE 3—If 410 HB is exceeded, the microstructure throughout the

head shall be examined at 1003 or higher for confirmation of a fully

7. Hardness Properties

pearlitic microstructure in the head.

7.1 Rails shall be produced as specified by the purchaser

NOTE 4—No untempered martensite shall be present within the rail.

within the limits found in Table 3 and Table 4,

Nominal Weight, lb/yd (kg/m)

7.2 The Brinell hardness test shall be performed on a rail, a

60 to 84 85 to 114

115 (57.0)

(29.8 to 41.7), (42.2 to 56.6),

pieceofrailatleast6in.(152mm)longcutfromarailofeach

and over

incl incl

heat of steel or heat-treatment lot, or from a ground/milled

Brinell Hardness 277 to 341 321, min 341, min

transverse sample cut from the 6-in. piece. The test shall be

made on the side or top of the rail head after decarburized

materialhasbeenremovedtopermitanaccuratedetermination

8.1.7 A variation of 0.020 in. (0.51 mm) less or 0.040 in.

of hardness.Alternately, the test may be made on the prepared

(1.02 mm) greater than the specified thickness of web will be

transverseground/milledsample ⁄8in.fromthetoprailsurface.

permitted.

7.3 The test shall otherwise be conducted in accordance

8.1.8 Verification of tolerances shall be made using appro-

with Test Method E10.

priate gages as agreed upon between the purchaser and the

7.4 If any test result fails to meet the specifications, two

manufacturer.

additional checks shall be made on the same piece. If both

8.2 Length:

checks meet the specified hardness, the heat or heat treatment

8.2.1 The standard length of rails shall be 39 ft (11.9 m) or

lot meets the hardness requirement. If either of the additional

80 ft (24.4 m), or both, when measured at a temperature of

checks fails, two additional rails in the heat or lot shall be

60°F (15°C).

checked. Both of these checks must be satisfactory for the heat

8.2.2 Up to 9% for 39 ft rail or 15% for 80 ft rail of the

or lot to be accepted. If any one of these two checks fails,

entire order will be accepted in lengths shorter than the

individual rails may be tested for acceptance.

standard, varying by 1 ft (0.3 m) as follows: 79, 78, 77, 75, 70,

7.5 If the results for off-line head hardened rails and fully

65, 60, 39, 38, 37, 36, 33, 30, 27, and 25 ft.

heat treated rails fail to meet the requirements of 7.1, the rails

8.2.3 Avariation of ⁄16 in. (11 mm) for 39-ft (11.9-m) rails

may be retreated at the option of the manufacturer, and such

or ⁄8 in. (22 mm) for 80-ft rails (24.4-m) will be permitted.

rails shall be retested in accordance with 7.2 and 7.3.

8.2.4 Length variations other than those specified in 8.2.2

8. Permissible Variations of Dimension, Weight, and

and 8.2.3 may be established by agreement between the

Other Physical Attributes

purchaser and the manufacturer.

8.3 Drilling:

8.1 Section:

8.3.1 Circular holes for joint bolts shall be drilled to

8.1.1 The section of the rail shall conform to the design

conform to the drawings and dimensions furnished by the

specified by the purchaser.

purchaser.

8.1.2 A variation of 0.015 in. (0.38 mm) less or 0.040 in.

8.3.2 Avariation of −0 and + ⁄16 in. (1.6 mm) in the size of

(1.02 mm) greater than the specified height will be permitted

the bolt holes will be permitted.

measured at least 1 in. (25.4 mm) from each end.

8.3.3 A variation of ⁄32 in. (0.8 mm) in the location of the

8.1.3 A variation of 0.030 in. (0.76 mm) less or 0.030 in.

holes will be permitted.

greater than the specified rail head width will be permitted

measured at least 1 in. (25.4 mm) from each end. 8.3.4 Fins and burrs at the edges of bolt holes shall be

eliminated. The drilling process shall be controlled to prevent

8.1.4 Avariationof0.050in.(1.27mm)inthetotalwidthof

mechanical or metallurgical damage to the rail.

the base will be permitted.

8.3.5 When right-hand and left-hand drilling is specified, at

8.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.