ASTM D2467-99

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 80

Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 80

SCOPE

1.1 This specification covers poly(vinyl chloride) (PVC) Schedule 80 pipe fittings. Included are requirements for materials, workmanship, dimensions, and burst pressure.

Note 1--CPVC plastic pipe fittings, which were formerly included in this standard, are now covered in Specification F439.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the piping materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 2--Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious saftey hazards should a system fail for any reason.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this specification.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section , of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2467 – 99 An American National Standard

Standard Specification for

Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule

This standard is issued under the fixed designation D 2467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope sure of Plastic Pipe, Tubing, and Fittings

D 1600 Terminology for Abbreviated Terms Relating to

1.1 This specification covers poly(vinyl chloride) (PVC)

Plastics

Schedule 80 pipe fittings. Included are requirements for mate-

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

rials, workmanship, dimensions, and burst pressure.

Compounds and Chlorinated Poly(Vinyl Chloride)

NOTE 1—CPVC plastic pipe fittings, which were formerly included in 2

(CPVC) Compounds

this standard, are now covered in Specification F 439.

D 1785 Specification for Poly(Vinyl Chloride) (PVC) Plas-

1.2 The products covered by this specification are intended

tic Pipe, Schedules 40, 80, and 120

for use with the distribution of pressurized liquids only, which

D 2122 Test Method for Determining Dimensions of Ther-

are chemically compatible with the piping materials. Due to

moplastic Pipe and Fittings

inherent hazards associated with testing components and sys-

D 2749 Symbols for Dimensions of Plastic Pipe Fittings

tems with compressed air or other compressed gases some

F 412 Terminology Relating to Plastic Piping Systems

manufacturers do not allow pneumatic testing of their products.

F 439 Specification for Socket-Type Chlorinated Poly (Vi-

Consult with specific product/component manufacturers for

nyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

their specific testing procedures prior to pneumatic testing.

F 1498 Specification for Taper Pipe Threads 60° for Ther-

moplastic Pipe and Fittings

NOTE 2—Pressurized (compressed) air or other compressed gases

2.2 Federal Standard:

contain large amounts of stored energy which present serious saftey

hazards should a system fail for any reason. Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 National Sanitation Foundation Standard:

1.3 The text of this specification references notes, footnotes,

Standard No. 14 for Plastic Piping Components and Related

and appendixes which provide explanatory material. These

Materials

notes and footnotes (excluding those in tables and figures) shall

Standard No. 61 for Drinking Water Systems

not be considered as requirements of this specification.

Components—Health Effects

1.4 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are provided

3. Terminology

for information only.

3.1 General—Definitions are in accordance with Terminol-

1.5 The following safety hazards caveat pertains only to the

ogy F 412 and abbreviations are in accordance with Teminol-

test method portion, Section 8, of this specification. This

ogy D 1600, unless otherwise indicated. The abbreviation for

standard does not purport to address all of the safety concerns,

poly(vinyl chloride) plastic is PVC.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

4. Classification

practices and determine the applicability of regulatory limita-

4.1 General—This specification covers Schedule 80 PVC

tions prior to use.

pipe fittings, socket-type, made from four PVC plastic com-

pounds and intended for use with Iron Pipe Size (IPS)

2. Referenced Documents

outside-diameter plastic pipe.

2.1 ASTM Standards:

4.1.1 Fittings covered by this specification are normally

D 618 Practice for Conditioning Plastics for Testing

molded. In-line fittings, such as couplings, unions, bushings,

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

1 3

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic Annual Book of ASTM Standards, Vol 08.04.

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Current edition approved May 10, 1999. Published July 1999. Originally Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

published as D 2467 – 65 T. Last previous edition D 2467 – 98a. Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor,

Annual Book of ASTM Standards, Vol 08.01. MI 48106.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2467

caps, nipples, etc., shall be molded or machined from extruded fittings shall be as uniform as commercially practicable in

stock. color, opacity, density, and other physical properties.

4.1.2 Fittings fabricated by back welding or butt fusion are

8. Test Methods

not included in this specification.

8.1 Conditioning—Condition the test specimens at 73.4 6

5. Materials and Manufacture

3.6°F (23 6 2°C) and 50 6 5 % relative humidity for not less

than 40 h prior to test in accordance with Procedure A of

5.1 This specification covers PVC pipe fittings made from

Practice D 618, for those tests where conditioning is required.

five PVC plastics as classified in Specification D 1784. These

8.2 Test Conditions—Conduct tests in the Standard Labora-

are PVC 12454-B, 12454-C, 13354-C, 11443-B, and 14333-D.

tory Atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 6 5%

5.2 Compound—The PVC plastic compound shall meet the

relative humidity, unless otherwise specified in the test meth-

requirements of PVC 12454-B, 12454-C, 11443-B, or

ods or in this specification.

14333-D, as described in Specification D 1784.

8.3 Sampling—A sufficient quantity of fittings as agreed

NOTE 3—Mechanical strength, heat resistance, flammability, and

upon between the seller and the purchaser shall be selected at

chemical resistance requirements are covered in Specification D 1784.

random from each lot or shipment and tested to determine that

5.3 Rework Material—The manufacturers shall use only

the basic design is in conformance with this specification.

their own clean rework fitting material and the fittings pro-

NOTE 4—For individual orders or specifications where supplemental

duced shall meet all the requirements of this specification.

tests are required, only those tests and numbers of tests specifically agreed

upon between purchaser and seller need be conducted.

6. Requirements

8.4 Threads—All taper pipe threads shall be gaged in

6.1 Dimensions and Tolerances:

accordance with Specification F 1498.

6.1.1 Fitting sockets inside diameters (waterways), mini-

8.5 Burst Pressure—Determine the minimum burst pressure

mum wall thicknesses, and dimensions shall be as shown in

in accordance with Test Method D 1599. The pressure shall be

Tables 1-4 when measured in accordance with Test Method

applied at a uniform rate such that the minimum allowable

D 2122.

burst pressure is attained in 60 to 70 s.

6.1.2 When multistep reducer bushings are cored out, the

inner socket shall be reinforced from the outer wall by a

NOTE 5—The time-to-failure may exceed 70 s.

minimum of three ribs extending from the top of the inner

9. Retest and Rejection

socket to the deepest extremity of the coring. The transition

from D to DJ (Table 3) shall be straight, tapered as shown, or 9.1 If the results of any test(s) do not meet the requirements

radiused. A positive taper in the same direction of the taper in

of this specification, the tests(s) shall be conducted again only

the socket on the outside diameter of the bushing is optional.

by agreement between the purchaser and seller. Under such

6.1.3 The maximum angular variation of any opening shall

agreement, minimum requirements shall not be lowered,

be not more than ⁄2° off the true centerline axis.

changed, or modified, nor shall specification limits be changed.

6.1.4 The minimum wall thickness of fittings shall be 125 %

If upon retest, failure occurs, the quantity of product repre-

of the minimum wall thickness of the corresponding size of

sented by the test(s) does not meet the requirements of this

Schedule 80 pipe for which they are designed to be used,

specification.

except that for the socket, the wall thickness shall be at least

10. Product Marking

equal to the minimum wall thickness of the corresponding size

of Schedule 80 pipe.

10.1 Quality of Marking—The markings shall be applied to

6.1.5 The minimum inside diameter of the fittings shall

the fittings in such a manner that they remain legible under

be not less than the minimum specified inside diameter of the

normal handling and installation practices.

corresponding size of Schedule 80 pipe.

10.2 Content of Marking—Fittings shall be marked with the

6.1.6 Minimum dimensions have zero negative tolerance.

following:

Tolerances on other dimensions are shown in Table 1 and Table

10.2.1 Material designation PVC I for PVC 12454-B, PVC

3.

12 for PVC 12454-C, PVC 13 for PVC 13354-C and 11443-B,

6.2 Threads—For all fittings having taper pipe threads,

and PVC II for PVC 14333-D,

threads shall conform to Specification F 1498 and be gaged in

10.2.2 The seal or mark of the laboratory making the

accordance with 8.4. evaluation for potable water contact,

6.3 Burst Pressure:

10.2.3 Size, and

6.4 . Fittings tested in accordance with 8.5 shall withstand 10.2.4 This designation, D 2467, with which the fitting

the minimum burst pressure shown in Table 5.

complies.

6.4.1 Pressures shown are minimum burst pressures and do

10.3 Where the size of the fitting does not allow complete

not imply rated working pressures. The burst pressure shall be

marking, omit identification marking in the following se-

used only as an indication of quality.

quence: size, material designation (D 2467), manufacturer’s

name, or trademark.

7. Workmanship, Finish, and Appearance

10.4 Marking or symbols shall be molded, hot-stamped, or

7.1 The fittings shall be homogeneous throughout and free applied to fittings by any other suitable method, such as

of cracks, holes, foreign inclusions, or other defects. The printing.

D 2467

A

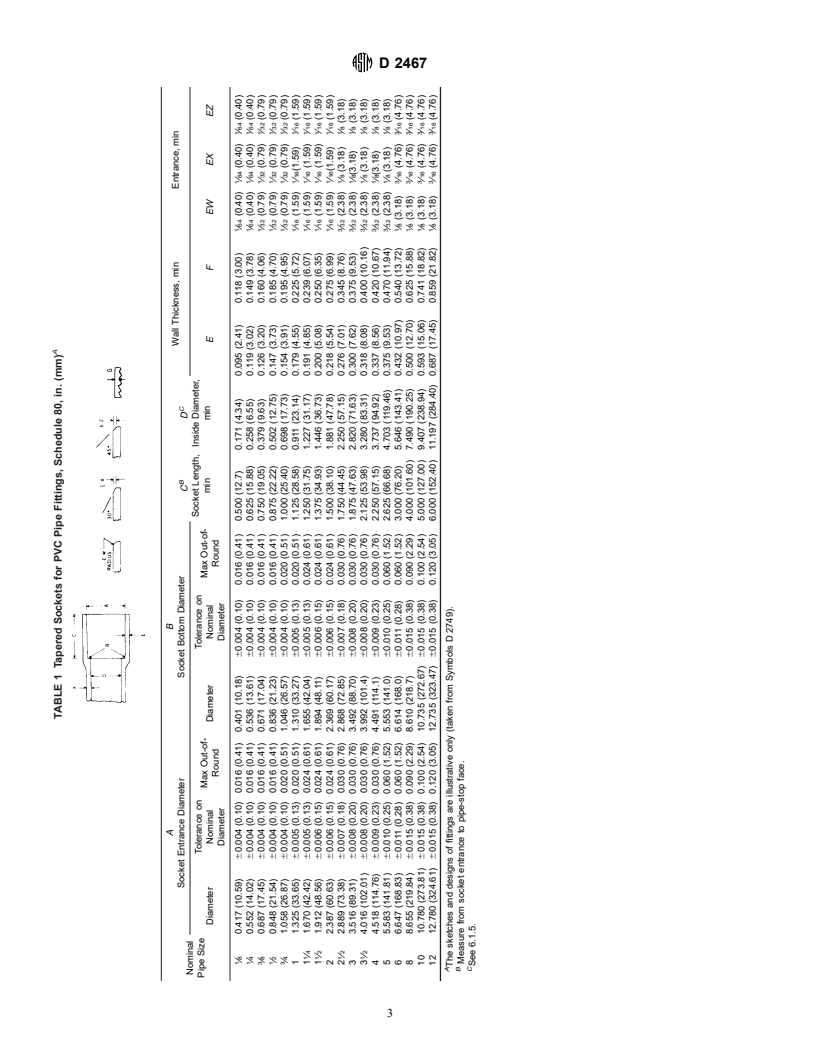

TABLE 1 Tapered Sockets for PVC Pipe Fittings, Schedule 80, in. (mm)

A B

Wall Thickness, min Entrance, min

B C

Socket Entrance Diameter Socket Bottom Diameter

C D

Nominal

Socket Length, Inside Diameter,

Tolerance on Tolerance on

Pipe Size

Max Out-of- Max Out-of-

min min

Diameter Nominal Diameter Nominal E F EW EX EZ

Round Round

Diameter Diameter

1 1 1 1

⁄8 0.417 (10.59) 60.004 (0.10) 0.016 (0.41) 0.401 (10.18) 60.004 (0.10) 0.016 (0.41) 0.500 (12.7) 0.171 (4.34) 0.095 (2.41) 0.118 (3.00) ⁄64 (0.40) ⁄64 (0.40) ⁄64 (0.40)

1 1 1 1

⁄4 0.552 (14.02) 60.004 (0.10) 0.016 (0.41) 0.536 (13.61) 60.004 (0.10) 0.016 (0.41) 0.625 (15.88) 0.258 (6.55) 0.119 (3.02) 0.149 (3.78) ⁄64 (0.40) ⁄64 (0.40) ⁄64 (0.40)

3 1 1 1

⁄8 0.687 (17.45) 60.004 (0.10) 0.016 (0.41) 0.671 (17.04) 60.004 (0.10) 0.016 (0.41) 0.750 (19.05) 0.379 (9.63) 0.126 (3.20) 0.160 (4.06) ⁄32 (0.79) ⁄32 (0.79) ⁄32 (0.79)

1 1 1 1

⁄2 0.848 (21.54) 60.004 (0.10) 0.016 (0.41) 0.836 (21.23) 60.004 (0.10) 0.016 (0.41) 0.875 (22.22) 0.502 (12.75) 0.147 (3.73) 0.185 (4.70) ⁄32 (0.79) ⁄32 (0.79) ⁄32 (0.79)

3 1 1 1

⁄4 1.058 (26.87) 60.004 (0.10) 0.020 (0.51) 1.046 (26.57) 60.004 (0.10) 0.020 (0.51) 1.000 (25.40) 0.698 (17.73) 0.154 (3.91) 0.195 (4.95) ⁄32 (0.79) ⁄32 (0.79) ⁄32 (0.79)

1 1 1

1 1.325 (33.65) 60.005 (0.13) 0.020 (0.51) 1.310 (33.27) 60.005 (0.13) 0.020 (0.51) 1.125 (28.58) 0.911 (23.14) 0.179 (4.55) 0.225 (5.72) ⁄16 (1.59) ⁄16(1.59) ⁄16 (1.59)

1 1 1 1

1 ⁄4 1.670 (42.42) 60.005 (0.13) 0.024 (0.61) 1.655 (42.04) 60.005 (0.13) 0.024 (0.61) 1.250 (31.75) 1.227 (31.17) 0.191 (4.85) 0.239 (6.07) ⁄16 (1.59) ⁄16 (1.59) ⁄16 (1.59)

1 1 1 1

1 ⁄2 1.912 (48.56) 60.006 (0.15) 0.024 (0.61) 1.894 (48.11) 60.006 (0.15) 0.024 (0.61) 1.375 (34.93) 1.446 (36.73) 0.200 (5.08) 0.250 (6.35) ⁄16 (1.59) ⁄16 (1.59) ⁄16 (1.59)

1 1 1

2 2.387 (60.63) 60.006 (0.15) 0.024 (0.61) 2.369 (60.17) 60.006 (0.15) 0.024 (0.61) 1.500 (38.10) 1.881 (47.78) 0.218 (5.54) 0.275 (6.99) ⁄16 (1.59) ⁄16(1.59) ⁄16 (1.59)

1 3 1 1

2 ⁄2 2.889 (73.38) 60.007 (0.18) 0.030 (0.76) 2.868 (72.85) 60.007 (0.18) 0.030 (0.76) 1.750 (44.45) 2.250 (57.15) 0.276 (7.01) 0.345 (8.76) ⁄32 (2.38) ⁄8 (3.18) ⁄8 (3.18)

3 1 1

3 3.516 (89.31) 60.008 (0.20) 0.030 (0.76) 3.492 (88.70) 60.008 (0.20) 0.030 (0.76) 1.875 (47.63) 2.820 (71.63) 0.300 (7.62) 0.375 (9.53) ⁄32 (2.38) ⁄8(3.18) ⁄8 (3.18)

1 3 1 1

3 ⁄2 4.016 (102.01) 60.008 (0.20) 0.030 (0.76) 3.992 (101.4) 60.008 (0.20) 0.030 (0.76) 2.125 (53.98) 3.280 (83.31) 0.318 (8.08) 0.400 (10.16) ⁄32 (2.38) ⁄8 (3.18) ⁄8 (3.18)

3 1 1

4 4.518 (114.76) 60.009 (0.23) 0.030 (0.76) 4.491 (114.1) 60.009 (0.23) 0.030 (0.76) 2.250 (57.15) 3.737 (94.92) 0.337 (8.56) 0.420 (10.67) ⁄32 (2.38) ⁄8(3.18) ⁄8 (3.18)

3 1 1

5 5.583 (141.81) 60.010 (0.25) 0.060 (1.52) 5.553 (141.0) 60.010 (0.25) 0.060 (1.52) 2.625 (66.68) 4.703 (119.46) 0.375 (9.53) 0.470 (11.94) ⁄32 (2.38) ⁄8 (3.18) ⁄8 (3.18)

1 3 3

6 6.647 (168.83) 60.011 (0.28) 0.060 (1.52) 6.614 (168.0) 60.011 (0.28) 0.060 (1.52) 3.000 (76.20) 5.646 (143.41) 0.432 (10.97) 0.540 (13.72) ⁄8 (3.18) ⁄16 (4.76) ⁄16 (4.76)

1 3 3

8 8.655 (219.84) 60.015 (0.38) 0.090 (2.29) 8.610 (218.7) 60.015 (0.38) 0.090 (2.29) 4.000 (101.60) 7.490 (190.25) 0.500 (12.70) 0.625 (15.88) ⁄8 (3.18) ⁄16 (4.76) ⁄16 (4.76)

1 3 3

10 10.780 (273.81) 60.015 (0.38) 0.100 (2.54) 10.735 (272.67) 60.015 (0.38) 0.100 (2.54) 5.000 (127.00) 9.407 (238.94) 0.593 (15.06) 0.741 (18.82) ⁄8 (3.18) ⁄16 (4.76) ⁄16 (4.76)

1 3 3

12 12.780 (324.61) 60.015 (0.38) 0.120 (3.05) 12.735 (323.47) 60.015 (0.38) 0.120 (3.05) 6.000 (152.40) 11.197 (284.40) 0.687 (17.45) 0.859 (21.82) ⁄8 (3.18) ⁄16 (4.76) ⁄16 (4.76)

A

The sketches and designs of fittings are illustrative only (taken from Symbols D 2749).

B

Measure from socket entrance to pipe-stop face.

C

See 6.1.5.

D 2467

A

TABLE 2 Dimensions of 90° Ells, Tees, Crosses, 45° Elbows and Couplings (Straight Sizes), in. (mm)

Center to Thread Length of Center to Thread Thread End to

Nominal Nominal Wall

B

End, 90° Thread, T, End, 45° Elbow, Inside Diameter Outside Diameter Thread End of

Pipe Thickness, F,

Elbows,Tees, min K, min of Fitting, D, min of Band, M, min Coupling, L, min

Size min

B

Crosses, H, min

! 0.688 (17.48) 0.38 (9.65) 0.625 (15.88) 0.215 (5.46) 0.118 0.645 (16.40) 0.813 (20.65)

¼ 0.812 (20.63) 0.50 (12.70) 0.688 (17.48) 0.302 (7.67) 0.149 0.840 (21.30) 1.063 (27.00)

" 0.938 (23.83) 0.50 (12.70) 0.750 (19.05) 0.423 (10.74) 0.160 1.000 (25.40) 1.063 (27.00)

½ 1.125 (28.58) 0.64 (16.26)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.