ASTM D5801-95(2006)

(Test Method)Standard Test Method for Toughness and Tenacity of Bituminous Materials

Standard Test Method for Toughness and Tenacity of Bituminous Materials

SCOPE

1.1 This test method describes the procedure for measuring the toughness and tenacity of bituminous materials. Typically, the test method has been used to characterize elastomer modified asphalts, although values for toughness and tenacity may be obtained for any type of polymer-modified or non-modified asphalt.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.2 The values given in SI units are to be regarded as the standard. The values given in inch-pound units in parentheses are for informational purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5801 – 95 (Reapproved 2006)

Standard Test Method for

Toughness and Tenacity of Bituminous Materials

This standard is issued under the fixed designation D 5801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Toughness is defined in this procedure as the total work

required to completely separate the tension head from the

1.1 This test method describes the procedure for measuring

sample under the specified test conditions. Tenacity is a

the toughness and tenacity of bituminous materials. Typically,

measure of the increasing force as the sample is stretched past

the test method has been used to characterize elastomer

the initial peak, and may indicate the type and amount of

modified asphalts, although values for toughness and tenacity

polymer used to modify the asphalt. It is defined as the work

may be obtained for any type of polymer-modified or non-

required to stretch the material after the initial resistance is

modified asphalt.

overcome.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 This test method is useful in confirming that an asphalt

priate safety and health practices and determine the applica-

cement has been modified with a material that provides a

bility of regulatory limitations prior to use.

significant elastomeric component. Elastomer modified as-

1.3 The values given in SI units are to be regarded as the

phalts can be characterized by their ability to be stretched to a

standard. The values given in inch-pound units in parentheses

large elongation while at the same time resisting further

are for informational purposes only.

stretching. Toughness and tenacity are two parameters for

1.4 This standard does not purport to address all of the

measuring this ability.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Apparatus

priate safety and health practices and determine the applica-

5.1 Sample Container—A metal, cylindrical, flat bottom

bility of regulatory limitations prior to use.

container with a nominal inside diameter of 55 mm (2 ⁄8 in.)

2. Referenced Documents andadepthof35mm(1 ⁄8in.)shallbeusedtoholdthesample.

2 Containers known as tin boxes or seamless ointment boxes

2.1 ASTM Standards:

with a 3-oz capacity meet these requirements.

D5 Test Method for Penetration of Bituminous Materials

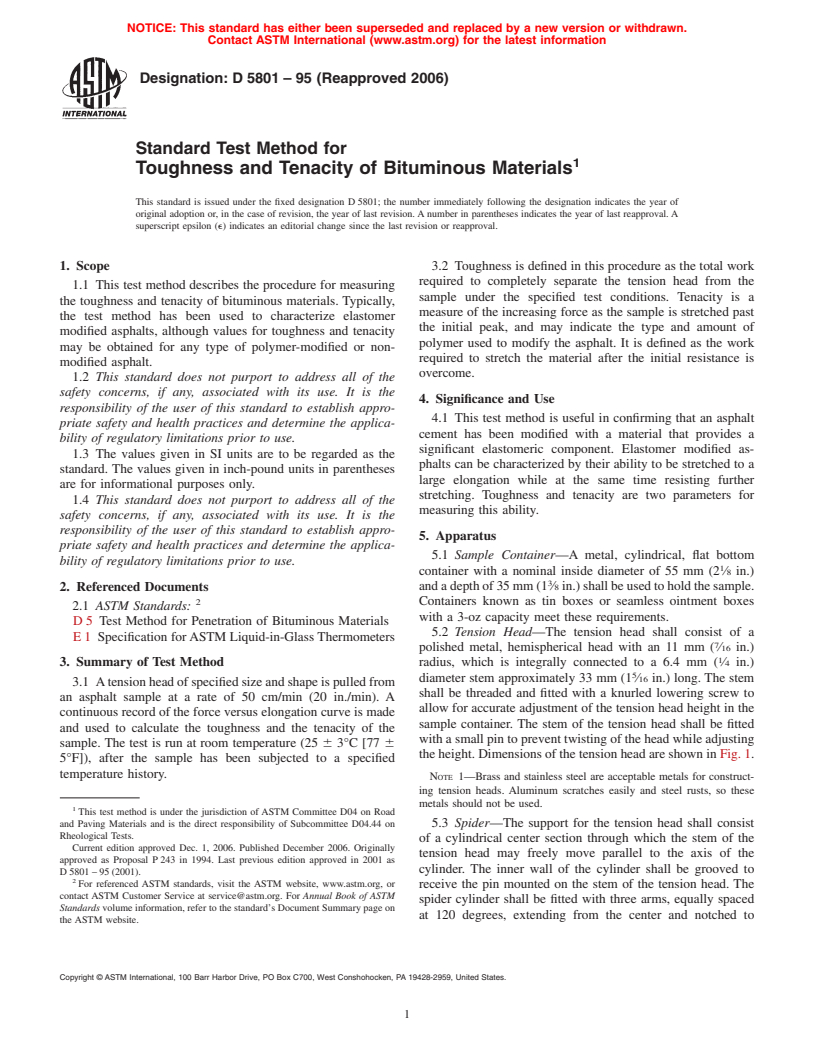

5.2 Tension Head—The tension head shall consist of a

E1 Specification forASTM Liquid-in-Glass Thermometers

polished metal, hemispherical head with an 11 mm ( ⁄16 in.)

3. Summary of Test Method radius, which is integrally connected to a 6.4 mm ( ⁄4 in.)

diameter stem approximately 33 mm (1 ⁄16 in.) long. The stem

3.1 Atensionheadofspecifiedsizeandshapeispulledfrom

shall be threaded and fitted with a knurled lowering screw to

an asphalt sample at a rate of 50 cm/min (20 in./min). A

allow for accurate adjustment of the tension head height in the

continuous record of the force versus elongation curve is made

sample container. The stem of the tension head shall be fitted

and used to calculate the toughness and the tenacity of the

with a small pin to prevent twisting of the head while adjusting

sample. The test is run at room temperature (25 6 3°C [77 6

the height. Dimensions of the tension head are shown in Fig. 1.

5°F]), after the sample has been subjected to a specified

temperature history.

NOTE 1—Brass and stainless steel are acceptable metals for construct-

ing tension heads. Aluminum scratches easily and steel rusts, so these

metals should not be used.

This test method is under the jurisdiction of ASTM Committee D04 on Road

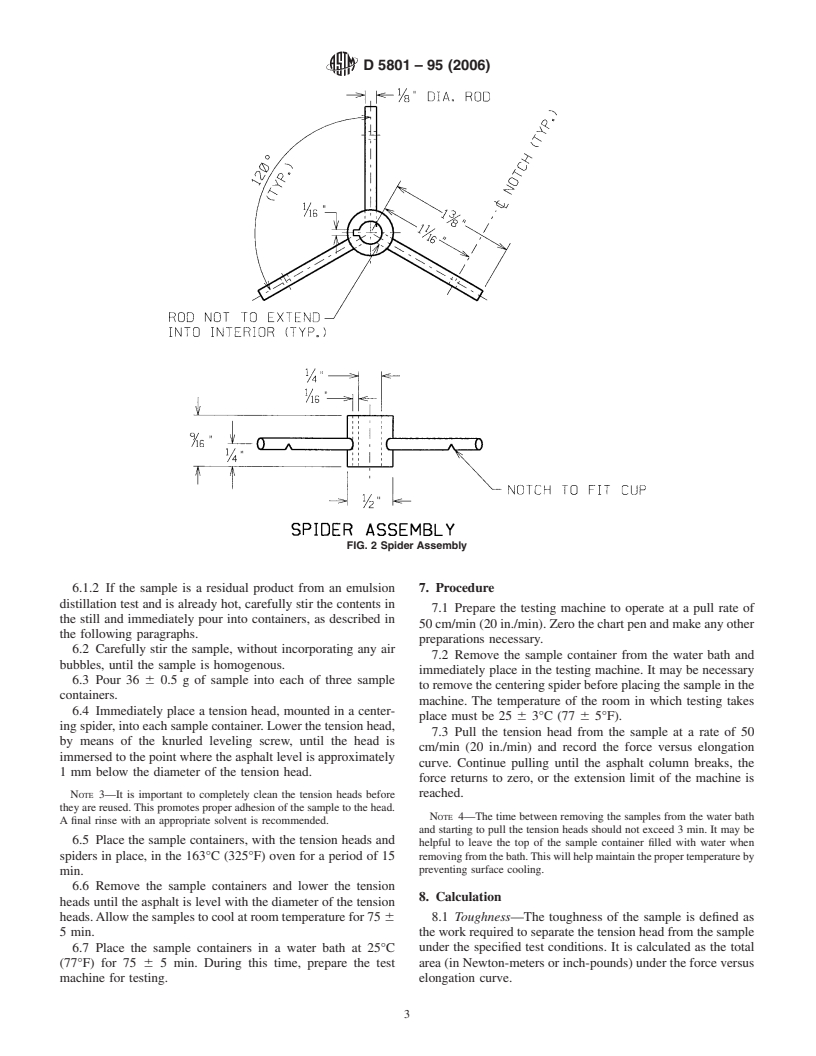

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on 5.3 Spider—The support for the tension head shall consist

Rheological Tests.

of a cylindrical center section through which the stem of the

Current edition approved Dec. 1, 2006. Published December 2006. Originally

tension head may freely move parallel to the axis of the

approved as Proposal P 243 in 1994. Last previous edition approved in 2001 as

cylinder. The inner wall of the cylinder shall be grooved to

D 5801 – 95 (2001).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or receive the pin mounted on the stem of the tension head. The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

spider cylinder shall be fitted with three arms, equally spaced

Standards volume information, refer to the standard’s Document Summary page on

at 120 degrees, extending from the center and notched to

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5801 – 95 (2006)

FIG. 1 Tension Head and Lowering Screw

receive the lip of the sample container, thereby centering the 5.6 Oven—A gravity convection oven capable of maintain-

spider and tension head in the sample container. Details of the ing a temperature of 163 6 5.5°C (325 6 10°F) shall be used

spider construction are shown in Fig. 2.

to heat the samples.

5.4 Testing Machine—Any tensile tester capable of pulling

5.7 Thermometer—A calibrated thermometer having a

the tension head at a uniform rate of 50 cm/min (20 in./min),

range as shown as follows and conforming to the requirements

and recording the force versus elongation curve, may be used.

prescribed in SpecificationE1.

The accuracy of the pull rate shall be 62 % or better. The

Temperature Range ASTM Thermometer Number

maximum load capacity shall be at least 45 kg (100 lb). If

−8 to 32°C 63C

polymer modified asphalts are to be tested after aging in the 18 to 89°F 63F

thin film oven or the rolling thin film oven, higher load

NOTE 2—In those cases where the samples are conditioned in the

capacities are needed.Amaximum load capacity of 90 kg (200

standard penetration bath, the thermometer as prescribed for Test Method

lb) is suggested.

D5 may be substituted in place of the above.

5.4.1 The tensile tester must be equipped to hold the sample

container firmly in place while the tension head is pulled away.

6. Sample Preparation

The details of this sample holder will vary with the type of

6.1 Bring the sample to a temperature where it is sufficiently

tester used. The tester must have a minimum effective pull

fluid to pour, as described in the following paragraphs.

length of 61 cm (24 in.) after installing the sample holder.

6.1.1 If the sample is at room temperature, place the sample

5.5 Water Bath—A bath capable of maintaining a tempera-

in a loosely covered container in an oven at 163°C (325°F)

ture of 25 6 0.1°C (77 6 0.18°F) is required. The bath shall

until th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.