ASTM E1132-99a

(Practice)Standard Practice for Health Requirements Relating to Occupational Exposure to Respirable Crystalline Silica

Standard Practice for Health Requirements Relating to Occupational Exposure to Respirable Crystalline Silica

SCOPE

1.1 This practice is designed to help protect the health of workers where there may be occupational exposure to quartz dust.

1.2 The various actions recommended in this practice apply where occupational exposures are at, or in excess of, the limits given in 5.1.

1.3 Nothing in this practice shall be interpreted as requiring any action that violates any statute or requirement of any federal, state, or other regulatory agency.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. It is the responsibility of the user to consult all material safety data sheets and labels pertaining to any hazardous materials used in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: E 1132 – 99a

Standard Practice for

Health Requirements Relating to Occupational Exposure to

Respirable Crystalline Silica

This standard is issued under the fixed designation E 1132; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Silicondioxide(silica,SiO )isencounteredinnatureandindustryinawidevarietyofforms.These

range from essentially anhydrous types with or without a very high degree of crystallinity, to highly

hydroxylated or hydrated types which are amorphous by x-ray diffraction examination. Crystalline

silica exists in a number of forms or polymorphs. The three major forms, quartz, cristobalite, and

tridymite, pertain to this practice. Quartz (or alpha quartz) is the more common form encountered as

airborne particulates. Two of the polymorphs, cristobalite and tridymite are formed at elevated

temperatures and are much less common in nature, but might be encountered in several occupations

where silicas are fired (calcined) at high temperatures. These silica materials have a broad range of

physical and chemical properties.

1. Scope 2. Referenced Documents

1.1 This practice covers a description of several actions that 2.1 ASTM Standards:

could be taken to reduce the probability of harmful occupa- E 1238 Specification for Transferring Clinical Observations

tional exposures to humans in environments containing respi- Between Independent Computer Systems

rable crystalline silica. E 1239 Guide or Description of Reservation/Registration-

1.2 Nothing in this practice shall be interpreted as requiring Admission, Discharge, Transfer (R-ADT) Systems for

any action that violates any statute or requirement of any Automated Patient Care Information Systems

federal, state, or other regulatory agency. E 1384 Guide for Content and Structure of the Computer-

1.3 This standard does not purport to address all of the Based Patient Record

safety concerns, if any, associated with its use. It is the E 1633 Specification for Coded Values Used in Computer-

responsibility of the user of this standard to establish appro- Based Patient Record

priate safety and health practices and determine the applica- E 1715 Practice for an Object-Oriented Model for Regis-

bility of regulatory limitations prior to use. It is the responsi- tration,Admitting, Discharge, and Transfer (RADT) Func-

bility of the user to consult all material safety data sheets and tions in Computer-Based Patient Record Systems

labels pertaining to any hazardous materials used in this 2.2 ANSI Standards:

standard. Z9.2 1979 Fundamentals Governing the Design and Opera-

tion of Local Exhaust Systems

Z88.2 1992American National Standard Practice for Respi-

ratory Protection

This practice is under the jurisdiction of ASTM Committee E34 on Occupa-

2.3 Code of Federal Regulations:

tional Health and Safety and is the direct responsibility of Subcommittee E34.16 on

29 CFR 1910.134, Respiratory Protection

Silicas.

Current edition approved Aug. 10, 1999. Published September 1999. Originally

Published as E 1132 - 99. Last Previous edition E 1132 - 99.

2 4

Smith, Deane K., Opal, cristobalite, and tridymite: Noncrystallinity versus For referenced ASTM standards, visit the ASTM website, www.astm.org, or

crystallinity, nomenclature of the silica minerals and bibliography, Powder Diffrac- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion, Vol 13, 1998, pp 1–18. Standards volume information, refer to the standard’s Document Summary page on

Miles, W.J., Crystalline silica analysis of Wyoming bentonite by X-ray the ASTM website.

diffraction after phosphoric acid digestion, Analytical Chemistry Acta, Vol 286, Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

1994, pp 97–105. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E 1132 – 99a

29 CFR 1910.1000, Air Contaminants Institute for Occupational Safety and Health (NIOSH), is 0.05

29 CFR 1910.1200, Hazard Communication mg/m as a time weighted average (TWA) for up to 10 h/day

42 CFR 84 Title 42, Part 84, Approval of Respiratory during a 40-h workweek.

Protective Devices, Tests for Permissibility, Fees

4.1.5 Other industries or companies may adapt different

30 CFR 56,Title 30, Subpart D, Air Quality, Radiation, and

exposure values to trigger protective actions and these values

Physical Agents (MSHA)

should be used as appropriate.

2.4 NIOSH Publications:

4.2 Exposure Assessment and Monitoring:

Manual of Analytical Methods, 4th Ed., DHHS (NIOSH),

4.2.1 Risk can be assessed qualitatively based on visible

Publication No. 94-113 August 1994.

dust in the air, proximity of airborne dust to workers, nature of

Method 7500 for Silica, Crystalline, Respirable (XRD)

the industrial process (example; wet work – low risk; dry work

Method 7601 for Silica, Crystalline Visible Absorption

– higher risk), and location of workers (example; control room

Spectrophotometry

or at a crusher). Note that the absence of visible dust is not a

Method 7602 for Silica, Crystalline (IR)

guarantee of lack of risk.

Method 7603 for Coal Mine Dust by IR

4.2.2 Workers with a high relative risk of dust exposure

2.5 Other Standards:

should be sampled first. Sampling should then progress toward

ACGIH, Threshold Limit Values for Chemical Substances

thoseindividualswithlowexposurerisk.Highrelativeriskcan

and Physical Agents; Biological Exposure Indices

be assigned to any area where the process involved may

HealthLevel 7 Interface Standard, Version 2.3

generate respirable crystalline silica particles and persons are

potentially exposed for most or all of a work shift.

3. Significance and Use

4.2.3 Initial sampling of representative workers’ exposures

3.1 These practices and criteria were developed for occupa-

shallbemadetocharacterizetheexposureanditsvariability,to

tional exposures. They are intended to (a) protect against

determine compliance with standards given in 4.1, and to

clinically significant lung or respiratory disease from exposure

establish a baseline exposure level in all areas where workers

to respirable crystalline silica, (b) be measurable by techniques

are or may be exposed to silica. Exposure sampling should be

that are valid, reproducible, and readily available, and (c)be

periodic and should occur frequently enough that a significant

attainable with existing technology and protective practices.

and deleterious change in the contaminant generation process

ortheexposurecontrolsisnotpermittedtogoundetected.This

4. General Requirements

isparticularlytrueforareasoroperationswhereconditionscan

4.1 Occupational Exposure Limits:

change dramatically within a short span of time.

4.1.1 Permissible Exposure Limit (PEL) – Occupational

4.2.4 Employers shall sample and maintain records of

Health and Safety Administration (OSHA) General Industry

occupational exposures of workers exposed to respirable crys-

(see 29 CFR 1910.1000)—Workers shall not be exposed to

talline silica.

respirable dust containing quartz exceeding 10/(% quartz + 2)

4.2.5 For workers engaged in dusty trades where overexpo-

mg/m as an 8-h time weighted average in any 8-h work shift

surestohighsilicaconcentrationsarecommonandworkersare

of a 40-h work week or, for total dust (respirable plus

placed inside of supplied air respirators or ventilated enclo-

non-respirable), 30/(% quartz + 2). The PEL for respirable

sures, such as in sandblasting, sampling should be conducted

cristobalite and tridymite is one-half the value for quartz.

inside of the control device to determine employee exposure.

4.1.2 PEL – Mine Safety and Health Administration

4.2.6 In areas where overexposures are persistent, an Expo-

(MSHA) (non-coal) (see 30 CFR 56.5001)—Workers shall not

sure Control Plan shall be established to implement engineer-

be exposed to respirable dust containing quartz exceeding the

ing, work practice, and administrative controls to reduce silica

PEL as determined for a time weighted 8-h workday and 40-h

exposures to below the PEL as soon as feasible.

workweek based on the following formula: PEL = 10/(%

3 4.2.7 Sampling information is summarized in Table 1.

quartz + 2) mg/m . The PEL for respirable cristobalite and

4.2.8 Because people have different work habits, sampling

tridymite is one-half the value for quartz.

should be rotated among employees with a goal of sampling

4.1.3 The Threshold Limit Value (TLV) as established by

each individual at least once every three years or use statistical

the American Conference of Governmental Industrial Hygien-

random sampling.

ists (ACGIH) for quartz is 0.1 mg/m and the TLV is 0.05

4.2.9 When monitoring indicates levels in excess of the

mg/m for cristobalite and tridymite.

PEL, appropriate NIOSH-approved respirators shall be worn

4.1.4 The Recommended Exposure Limit (REL) (see

until at least three consecutive measurements, taken on differ-

NIOSH Criteria Document ) as established by the National

ent days on the same worker and his/her replacement, or both

whose sample exceeded the PEL, are below the PEL. A root

Available from Superintendent of Documents, U. S. Government Printing

cause analysis should be conducted for all exposures in excess

Office, Washington, DC 20402.

of the PEL that can not be accounted for. Root cause analysis

Available from National Institute for Occupational Safety and Health, Division

involves investigating cause(s) for the excessive exposure,

of Physical Sciences and Engineering, Cincinnati, OH.

Available fromAmerican Conference of Governmental and Industrial Hygien-

providing remedies, and conducting follow-up sampling to

ists, 1014 Broadway, Cincinnati, OH 45202.

document that exposures are below the PEL.

Available from HL7, 900 Victors Way, Ste 122, Ann Arbor, MI 48108.

4.2.10 Measurementofworkeroccupationalexposuresshall

Criteria for a Recommended Standard: Occupational Exposure to Crystalline

Silica, Publication No. 75-120, 1974. be within the worker’s breathing zone and shall meet the

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E 1132 – 99a

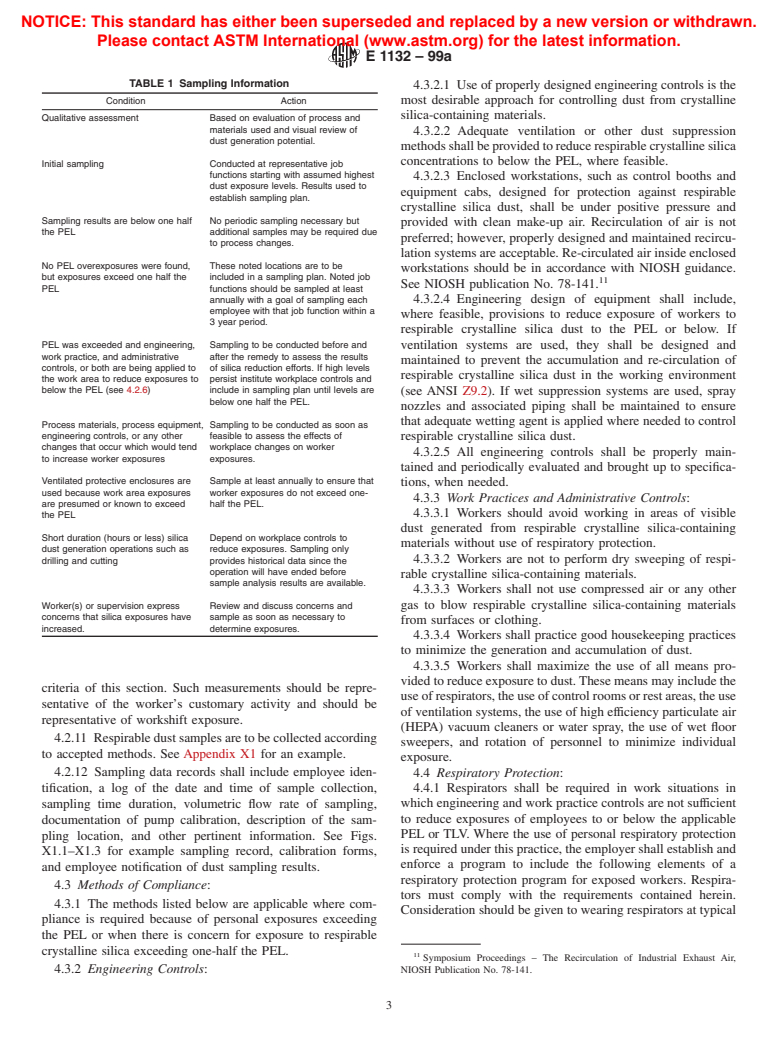

TABLE 1 Sampling Information

4.3.2.1 Use of properly designed engineering controls is the

Condition Action most desirable approach for controlling dust from crystalline

silica-containing materials.

Qualitative assessment Based on evaluation of process and

materials used and visual review of

4.3.2.2 Adequate ventilation or other dust suppression

dust generation potential.

methodsshallbeprovidedtoreducerespirablecrystallinesilica

concentrations to below the PEL, where feasible.

Initial sampling Conducted at representative job

functions starting with assumed highest

4.3.2.3 Enclosed workstations, such as control booths and

dust exposure levels. Results used to

equipment cabs, designed for protection against respirable

establish sampling plan.

crystalline silica dust, shall be under positive pressure and

Sampling results are below one half No periodic sampling necessary but

provided with clean make-up air. Recirculation of air is not

the PEL additional samples may be required due

preferred; however, properly designed and maintained recircu-

to process changes.

lation systems are acceptable. Re-circulated air inside enclosed

No PEL overexposures were found, These noted locations are to be

workstations should be in accordance with NIOSH guidance.

but exposures exceed one half the included in a sampling plan. Noted job

See NIOSH publication No. 78-141.

PEL functions should be sampled at least

annually with a goal of sampling each 4.3.2.4 Engineering design of equipment shall include,

employee with that job function within a

where feasible, provisions to reduce exposure of workers to

3 year period.

respirable crystalline silica dust to the PEL or below. If

PEL was exceeded and engineering, Sampling to be conducted before and ventilation systems are used, they shall be designed and

work practice, and administrative after the remedy to assess the results

maintained to prevent the accumulation and re-circulation of

controls, or both are being applied to of silica reduction efforts. If high levels

respirable crystalline silica dust in the working environment

the work area to reduce exposures to persist institute workplace controls and

below the PEL (see 4.2.6) include in sampling plan until levels are

(see ANSI Z9.2). If wet suppression systems are used, spray

below one half the PEL.

nozzles and associated piping shall be maintained to ensure

that adequate wetting agent is applied where needed to control

Process materials, process equipment, Sampling to be conducted as soon as

engineering controls, or any other feasible to assess the effects of

respirable crystalline silica dust.

changes that occur which would tend workplace changes on worker

4.3.2.5 All engineering controls shall be properly main-

to increase worker exposures exposures.

tained and periodically evaluated and brought up to specifica-

Ventilated protective enclosures are Sample at least annually to ensure that

tions, when needed.

used because work area exposures worker exposures do not exceed one-

4.3.3 Work Practices and Administrative Controls:

are presumed or known to exceed half the PEL.

4.3.3.1 Workers should avoid working in areas of visible

the PEL

dust generated from respirable crystalline silica-containing

Short duration (hours or less) silica Depend on workplace controls to

materials without use of respiratory protection.

dust generation operations such as reduce exposures. Sampling only

4.3.3.2 Workers are not to perform dry sweeping of respi-

drilling and cutting provides historical data since the

operation will have ended before

rable crystalline silica-containing materials.

sample analysis results are available.

4.3.3.3 Workers shall not use compressed air or any other

gas to blow respirable crystalline silica-containing materials

Worker(s) or supervision express Review and discuss concerns and

concerns that silica exposures have sample as soon as necessary to

from surfaces or clothing.

increased. determine exposures.

4.3.3.4 Workers shall practice good housekeeping practices

to mini

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.