ASTM A2-90(1997)

(Specification)Standard Specification for Carbon Steel Girder Rails of Plain, Grooved, and Guard Types

Standard Specification for Carbon Steel Girder Rails of Plain, Grooved, and Guard Types

SCOPE

1.1 This specification covers carbon steel girder rails of three classes based on type or type and weight, and chemistry defined as follows and in Table 1:

1.1.1 Unless otherwise specified by the purchaser, girder-guard rails shall be Class A.

1.1.2 Plain and grooved-girder rails under 135 lb/yd (67.1 kg/m) in weight shall be specified by the purchaser as either Class A or Class B.

1.1.3 Plain and grooved-girder rails of 135 lb/yd in weight and heavier shall be Class C, unless otherwise specified.

1.2 The values states in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 2 – 90 (Reapproved 1997) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Carbon Steel Girder Rails of Plain, Grooved, and Guard Types

This standard is issued under the fixed designation A 2; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

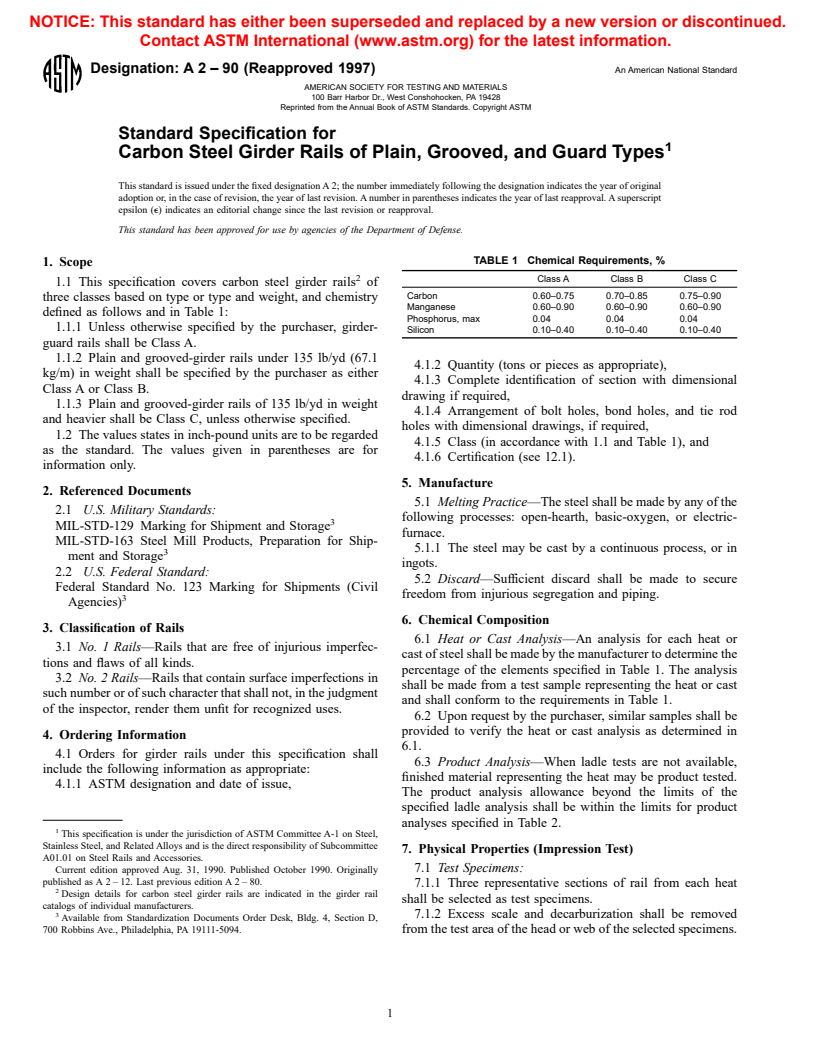

TABLE 1 Chemical Requirements, %

1. Scope

Class A Class B Class C

1.1 This specification covers carbon steel girder rails of

Carbon 0.60–0.75 0.70–0.85 0.75–0.90

three classes based on type or type and weight, and chemistry

Manganese 0.60–0.90 0.60–0.90 0.60–0.90

defined as follows and in Table 1:

Phosphorus, max 0.04 0.04 0.04

1.1.1 Unless otherwise specified by the purchaser, girder-

Silicon 0.10–0.40 0.10–0.40 0.10–0.40

guard rails shall be Class A.

1.1.2 Plain and grooved-girder rails under 135 lb/yd (67.1

4.1.2 Quantity (tons or pieces as appropriate),

kg/m) in weight shall be specified by the purchaser as either

4.1.3 Complete identification of section with dimensional

Class A or Class B.

drawing if required,

1.1.3 Plain and grooved-girder rails of 135 lb/yd in weight

4.1.4 Arrangement of bolt holes, bond holes, and tie rod

and heavier shall be Class C, unless otherwise specified.

holes with dimensional drawings, if required,

1.2 The values states in inch-pound units are to be regarded

4.1.5 Class (in accordance with 1.1 and Table 1), and

as the standard. The values given in parentheses are for

4.1.6 Certification (see 12.1).

information only.

5. Manufacture

2. Referenced Documents

5.1 Melting Practice—The steel shall be made by any of the

2.1 U.S. Military Standards:

following processes: open-hearth, basic-oxygen, or electric-

MIL-STD-129 Marking for Shipment and Storage

furnace.

MIL-STD-163 Steel Mill Products, Preparation for Ship-

5.1.1 The steel may be cast by a continuous process, or in

ment and Storage

ingots.

2.2 U.S. Federal Standard:

5.2 Discard—Sufficient discard shall be made to secure

Federal Standard No. 123 Marking for Shipments (Civil

freedom from injurious segregation and piping.

Agencies)

6. Chemical Composition

3. Classification of Rails

6.1 Heat or Cast Analysis—An analysis for each heat or

3.1 No. 1 Rails—Rails that are free of injurious imperfec-

cast of steel shall be made by the manufacturer to determine the

tions and flaws of all kinds.

percentage of the elements specified in Table 1. The analysis

3.2 No. 2 Rails—Rails that contain surface imperfections in

shall be made from a test sample representing the heat or cast

such number or of such character that shall not, in the judgment

and shall conform to the requirements in Table 1.

of the inspector, render them unfit for recognized uses.

6.2 Upon request by the purchaser, similar samples shall be

provided to verify the heat or cast analysis as determined in

4. Ordering Information

6.1.

4.1 Orders for girder rails under this specification shall

6.3 Product Analysis—When ladle tests are not available,

include the following information as appropriate:

finished material representing the heat may be product tested.

4.1.1 ASTM designation and date of issue,

The product analysis allowance beyond the limits of the

specified ladle analysis shall be within the limits for product

analyses specified in Table 2.

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

7. Physical Properties (Impression Test)

A01.01 on Steel Rails and Accessories.

7.1 Test Specimens:

Current edition approved Aug. 31, 1990. Published October 1990. Originally

published as A 2 – 12. Last previous edition A2–80.

7.1.1 Three representative sections of rail from each heat

Design details for carbon steel girder rails are indicated in the girder rail

shall be selected as test specimens.

catalogs of individual manufacturers.

7.1.2 Excess scale and decarburization shall be removed

Available from Standardization Documents Order Desk, Bldg. 4, Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094. from the test area of the head or web of the selected specimens.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A2

TABLE 2 Product Analysis—Allowance Beyond Limits of

8.2 Weight—The weight of the rails per yard as calculated,

Specified Chemical Analysis

shall be maintained as nearly as possible after conforming to

Allowance Under Minumum Allowance Over Maximum

the requirements specified in 8.1.

Limit, % Limit, %

8.3 Length:

Carbon 0.04 0.04

8.3.1 Unless otherwise specified, the standard length of rail

Manganese 0.06 0.06

shall be 39 ft (11.9 m) where measured at a temperature of

Phosphorus . . . 0.008

A

Silicon 0.02 0.02 60°F (15°C).

A

Continuously cast allowances shall be 0.05 % over maximum for silicon. 8.3.2 All standard 39-ft lengths may be specified; or

8.3.3 Standard 39-ft lengths with up to 11 % of the entire

order in lengths shorter than standard, varying by 1 ft (0.3 m)

7.2 Procedure:

from 38 to 24 ft (11.6 to 7.3 m) may be specified; or

7.2.1 Subject the head of each test specimen to a pressure of

8.3.4 Length variations other than those described in 8.3.3

100 000 lb (45 359 kg) for a period of 15 s, applied through a

may be established by agreement between the purchaser and

hardened steel ball 0.75 in. (19.05 mm) in diameter.

manufacturer.

7.2.2 Test Balls—The steel test ball shall have a minimum 7

8.3.5 A variation of ⁄16 in. (11 mm) from the specified

Brinell hardness of 600 and be able to withstand surface attack

length of individual rails will be permitted.

with an American Swiss Pillar File No. 2.

8.4 End Finish:

7.2.3 Permissible Variation in Test Balls—The test ball

8.4.1 Rails shall be milled, abrasive wheel cut, or ground to

diameter shall be within a variation of 60.002 in. (0.051 mm) 1

length, with a variation in end squareness of not more than ⁄32

from the standard size, and the permanent deformation under

in. (0.8 mm) allowed.

the required loading shall not be greater than 0.003 in. (0.076

8.4.2 Harmful burrs on the ends shall be removed.

mm).

8.5 Drilling:

7.3 Requirements—The average depth of the impressions

8.5.1 Circular holes for joint bar bolts, bonds, and tie rods

obtained on the head of the three specimens shall not be more

shall be drilled to conform to the drawings and dimensions

than 0.1496 in. (3.8 mm) for Class A rails, 0.1378 in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.