ASTM D1051-06

(Specification)Standard Specification for Rubber Insulating Sleeves

Standard Specification for Rubber Insulating Sleeves

SCOPE

1.1 This specification covers manufacturing and testing of rubber insulating sleeves for protection of workers from electrical shock.

1.2 Two types of sleeves are provided and are designated as Type I, nonresistant to ozone, and Type II, resistant to ozone.

1.3 Five classes of sleeves, differing in electrical characteristics, are provided and are designated as Class 0, Class 1, Class 2, Class 3, and Class 4.

1.4 Two styles of sleeves, differing in configuration, are provided and are designated as Style A, straight taper, and Style B, curved elbow.

1.5 The values stated in SI units are to be regarded as the standard. See ASTM SI 10.

The following safety hazards caveat pertains only to the test methods portion, Sections 16-19, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety hazards statements are given in 18.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1051 – 06

Standard Specification for

1

Rubber Insulating Sleeves

This standard is issued under the fixed designation D 1051; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 518 Test Method for Rubber Deterioration—Surface

Cracking

1.1 This specification covers manufacturing and testing of

D 570 Test Method for Water Absorption of Plastics

rubber insulating sleeves for protection of workers from

D 573 Test Method for Rubber—Deterioration in an Air

electrical shock.

Oven

1.2 Two types of sleeves are provided and are designated as

D 624 Test Method for Tear Strength of Conventional

Type I, nonresistant to ozone, and Type II, resistant to ozone.

Vulcanized Rubber and Thermoplastic Elastomers

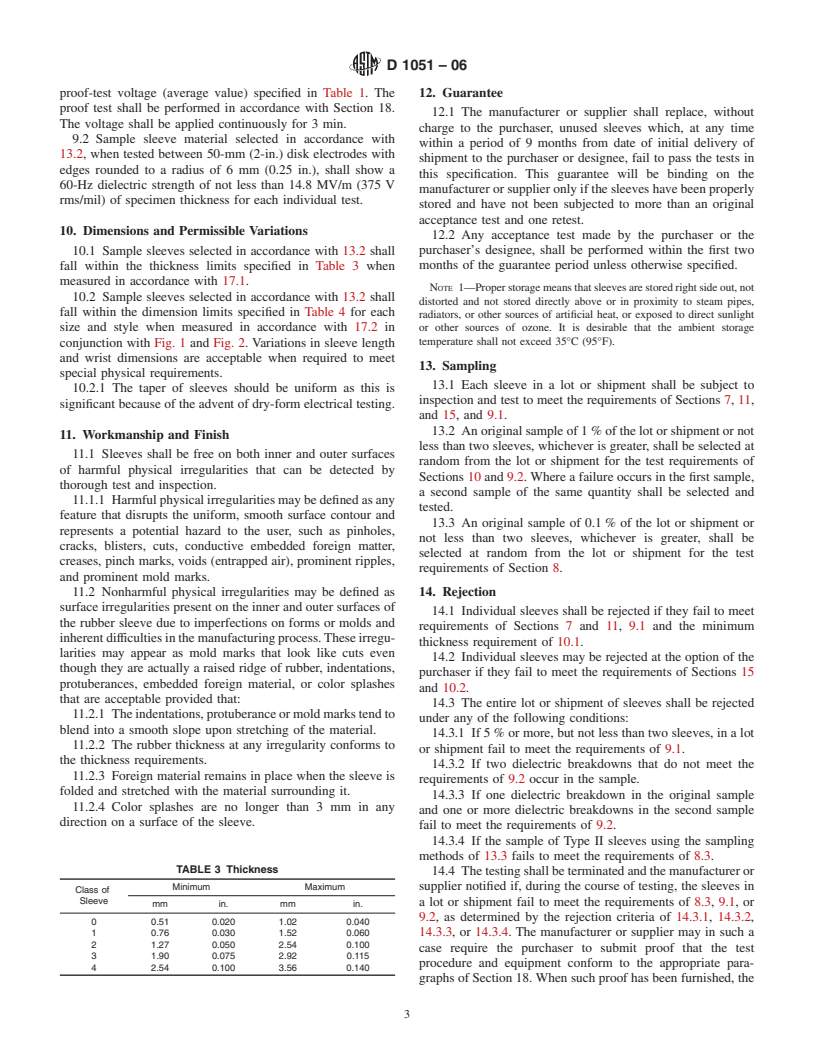

1.3 Five classes of sleeves, differing in electrical character-

D 1149 Test Method for Rubber Deterioration—Surface

istics, are provided and are designated as Class 0, Class 1,

Ozone Cracking in a Chamber

Class 2, Class 3, and Class 4.

D 1415 Test Method for Rubber Property—International

1.4 Two styles of sleeves, differing in configuration, are

Hardness

provided and are designated as Style A, straight taper, and

D 2240 Test Method for Rubber Property—Durometer

Style B, curved elbow.

Hardness

1.5 The values stated in SI units are to be regarded as the

D 2865 Practice for Calibration of Standards and Equip-

standard. See ASTM SI 10.

ment for Electrical Insulating Materials Testing

1.6 The following safety hazards caveat pertains only to the

F 819 Terminology Relating to Electrical Protective Equip-

test methods portion, Sections 16-19, of this specification: This

ment for Workers

standard does not purport to address all of the safety concerns,

SI 10 Standard for Use of the International System of Units

if any, associated with its use. It is the responsibility of the user

(SI): The Modern Metric System

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

3. Terminology

tions prior to use. Specific safety hazards statements are given

3.1 Definitions:

in 18.2.

3.1.1 color splash—a splash, smear, or streak of contrasting

2. Referenced Documents color evident on the inside or outside of the sleeves that was

2

deposited during the dripping operation and is vulcanized into

2.1 ASTM Standards:

the sleeve as part of the homogeneous compound.

D 149 Test Method for Dielectric Breakdown Voltage and

3.1.2 halogenation treatment—exposure of the entire sleeve

Dielectric Strength of Solid Electrical Insulating Materials

surface area to a halogen for the purpose of reducing surface

at Commercial Power Frequencies

friction.

D 297 Test Methods for Rubber Products—Chemical

3.1.3 user—the employer or entity purchasing the equip-

Analysis

ment to be utilized by workers for their protection; in the

D 412 Test Methods for Vulcanized Rubber and Thermo-

absence of such an employer or entity, the individual purchas-

plastic Elastomers—Tension

ing and utilizing the protective equipment.

3.1.4 For definitions of other terms, refer to Terminology

1

This specification is under the jurisdiction of ASTM Committee F18 on

F 819.

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.15 on Worker Personal Equipment. This standard replacesANSI

4. Significance and Use

Standard J6.5, which is no longer available.

4.1 This specification covers the minimum electrical,

Current edition approved Nov. 1, 2006. Published December 2006. Originally

approved in 1949. Last previous edition approved in 2002 as D 1051 – 02.

chemical, and physical properties guaranteed by the manufac-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

turer and the detailed procedures by which such properties are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to be determined. The purchaser at his option may perform or

Standards volume information, refer to the standard’s Document Summary page on

have performed any of these tests in order to verify the

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 1051 – 06

guarantee. Claims for failure to meet the specification are manufacturers; it signifies only that, if made, they shall

subject to verification by the manufacturer. conform to the details of this specification.

4.2 Sleeves are used for personal protection; therefore,

7. Manufacture and Marking

when authorizing their use, a margin of safety shall be allowed

betwe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.