ASTM B488-01

(Specification)Standard Specification for Electrodeposited Coatings of Gold for Engineering Uses

Standard Specification for Electrodeposited Coatings of Gold for Engineering Uses

SCOPE

1.1 This specification covers requirements for electrodeposited gold coatings that contain not less than 99.00 mass % gold and that are used for engineering applications.

1.2 Specifically excluded from this specification are autocatalytic, immersion, and vapor deposited gold coatings.

1.3 Gold coatings conforming to this specification are employed for their corrosion and tarnish resistance (including resistance to fretting corrosion and catalytic polymerization), bondability, low and stable contact resistance, solderability, and infrared reflectivity. Several types of coatings, differing in gold purity and hardness, are covered by this specification.

1.4 The values stated in SI units are to be regarded as the standard. Values provided in parentheses are for information only.

1.5 The following hazards caveat pertains only to the test methods section, Section 9, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 488 – 01

Standard Specification for

1

Electrodeposited Coatings of Gold for Engineering Uses

This standard is issued under the fixed designation B 488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope B 322 Practice for Cleaning Metals Prior to Electroplating

B 343 Practice for Preparation of Nickel for Electroplating

1.1 This specification covers requirements for electrodepos-

3

with Nickel

ited gold coatings that contain not less than 99.00 mass % gold

3

B 374 Terminology Relating to Electroplating

and that are used for engineering applications.

B 481 Practice for Preparation of Titanium and Titanium

1.2 Specifically excluded from this specification are auto-

3

Alloys for Electroplating

catalytic, immersion, and vapor deposited gold coatings.

B 482 Practice for Preparation of Tungsten and Tungsten

1.3 Gold coatings conforming to this specification are em-

3

Alloys for Electroplating

ployed for their corrosion and tarnish resistance (including

B 487 Test Method for Measurement of Metal and Oxide

resistance to fretting corrosion and catalytic polymerization),

Coating Thicknesses by Microscopical Examination of a

bondability, low and stable contact resistance, solderability,

3

Cross Section

and infrared reflectivity. Several types of coatings, differing in

B 489 Practice for Bend Test for Ductility of Electrodepos-

gold purity and hardness, are covered by this specification.

ited and Autocatalytically Deposited Metal Coatings on

1.4 The values stated in SI units are to be regarded as the

3

Metals

standard. Values provided in parentheses are for information

B 499 Test Method for Measurement of Coating Thick-

only.

nessesbytheMagneticMethod:NonmagneticCoatingson

1.5 The following hazards caveat pertains only to the test

3

Magnetic Basis Metals

methods section, Section 9, of this specification: This standard

B 504 Test Method for Measurement of Thickness of Me-

does not purport to address all of the safety concerns, if any,

3

tallic Coatings by the Coulometric Method

associated with its use. It is the responsibility of the user of this

B 507 PracticeforDesignofArticlestoBeElectroplatedon

standard to establish appropriate safety and health practices

3

Racks

and determine the applicability of regulatory limitations prior

B 542 Terminology Relating to Electrical Contacts and

to use.

4

Their Use

2. Referenced Documents

B 558 Practice for Preparation of NickelAlloys for Electro-

3

plating

2.1 ASTM Standards:

2

B 567 Test Method for Measurement of Coating Thickness

B 32 Specification for Solder Metal

3

by the Beta Backscatter Method

B 183 Practice for Preparation of Low-Carbon Steel for

3

B 568 Test Method for Measurement of Coating Thickness

Electroplating

3

by X-Ray Spectrometry

B 242 Practice for Preparation of High-Carbon Steel for

3

3

B 571 Test Methods for Adhesion of Metallic Coatings

Electroplating

B 578 Test Method for Microhardness of Electroplated

B 253 Guide for Preparation of Aluminum Alloys for Elec-

3

3

Coatings

troplating

B 602 Test Method for Attribute Sampling of Metallic and

B 254 Practice for Preparation of and Electroplating on

3

3

Inorganic Coatings

Stainless Steel

B 678 Test Method for Solderability of Metallic Coated

B 281 Practice for Preparation of Copper and Copper Base

3

3

Products

Alloys for Electroplating and Conversion Coatings

B 697 Guide for Selection of Sampling Plans for Inspection

3

of Electrodeposited Metallic and Inorganic Coatings

1

This specification is under the jurisdiction of ASTM Committee B08 on

B 735 Test Method for Porosity in Gold Coatings on Metal

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee 3

Substrates by Nitric Acid Vapor

B08.08 on Engineering Coatings.

Current edition approved Oct. 10, 2001. Published October 2001. Originally

published as B 488 – 68. Last previous edition B 488 – 95.

2

Annual Book of ASTM Standards, Vol 02.04.

3 4

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 03.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

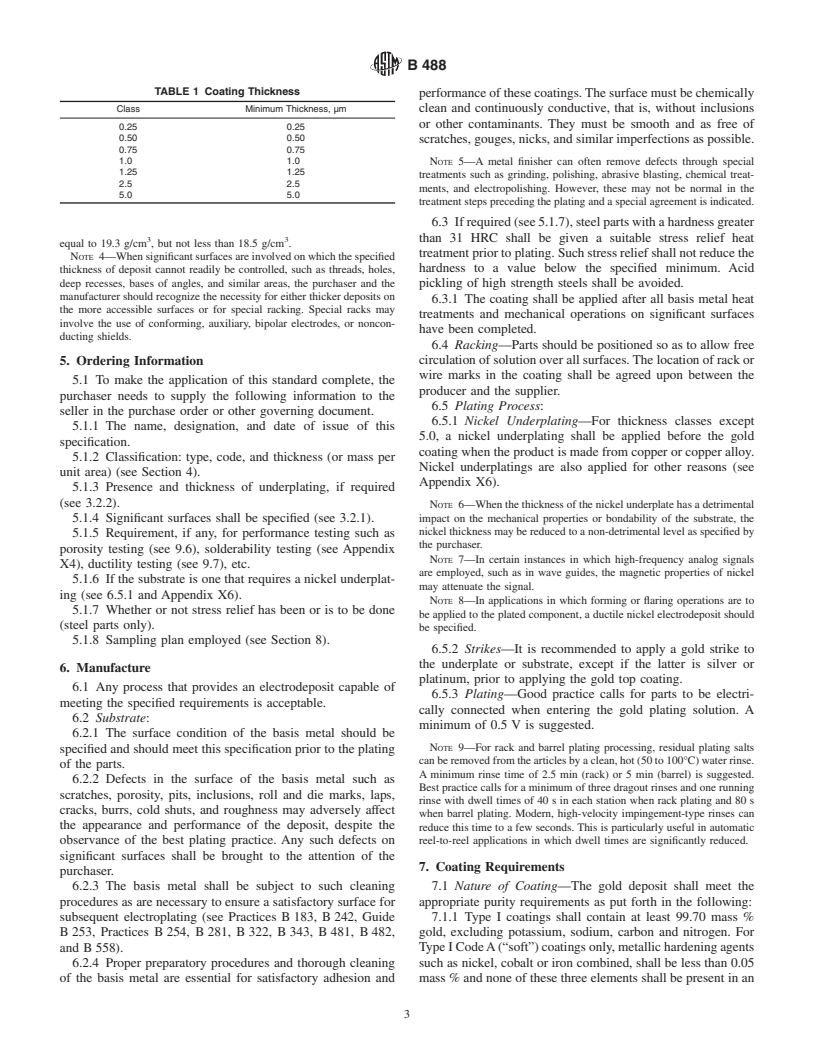

B 488

B 741 Test Methods for Porosity in Gold Coatings on Metal 4.1.3 a numeral designating thickness in micrometres in

3

Substrates by Paper Electrography accordance with 4.3.

B 748 Test Method for Measurement of Thickness of Me- 4.2 Purity and Hardness:

tallic Coatings by Measurement of Cross Section with a 4.2.1 Purity—The issue of this sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.