ASTM F2413-05

(Specification)Standard Specification for Performance Requirements for Foot Protection

Standard Specification for Performance Requirements for Foot Protection

ABSTRACT

This specification covers the minimum design, performance, testing, and classification requirements, and prescribes fit, function, and performance criteria for footwear designed to be worn to provide protection against a variety of workplace hazards that can potentially result in injury. It is not the intention of this specification to serve as a detailed manufacturing or purchasing specification, but can be referenced in purchase contracts to ensure that minimum performance requirements are met. Footwear conforming to this specification shall meet the performance requirements for the following: impact resistance for the toe area of footwear; compression resistance for the toe area of footwear; metatarsal protection that reduces the chance of injury to the metatarsal bones at the top of the foot; conductive properties which reduce hazards that may result from static electricity buildup, and reduce the possibility of ignition of explosives and volatile chemicals; electric shock resistance; static dissipative (SD) properties to reduce hazards due to excessively low footwear resistance that may exist where SD footwear is required; puncture resistance of footwear bottoms; chain saw cut resistance; and dielectric insulation.

SCOPE

1.1 This specification covers minimum requirements for the design, performance, testing, and classification of footwear designed to provide protection against a variety of workplace hazards that can potentially result in injury.

1.2 The objective of this specification is to prescribe fit, function, and performance criteria for footwear that is intended to be worn to reduce injuries.

1.3 This specification is not intended to serve as a detailed manufacturing or purchasing specification, but can be referenced in purchase contracts to ensure that minimum performance requirements are met.

1.4 Controlled laboratory tests used to determine compliance with the performance requirements of this specification shall not be deemed as establishing performance levels for all situations to which individuals may be exposed.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2413 – 05

Standard Specification for

Performance Requirements for Foot Protection

This standard is issued under the fixed designation F2413; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

For more than sixty years, the predecessor to this specification, ANSI Z41, established the

performance criteria for a wide range of footwear to protect from hazards that affect the personal

safety of workers.

The value of these standards was recognized early in the history of Occupational Safety and Health

Administration (OSHA) and incorporated as a reference standard in the Code of Federal Regulations

(CFR) 1910.

The specification contains performance requirements for footwear to protect workers’ feet from the

following hazards by providing: (1) impact resistance for the toe area of footwear; (2) compression

resistance for the toe area of the footwear; (3) metatarsal impact protection that reduces the chance of

injury to the metatarsal bones at the top of the foot; (4) conductive properties which reduce hazards

that may result from static electricity buildup; and reduce the possibility of ignition of explosives and

volatile chemicals; (5) electric shock resistance, to protect the wearer when accidental contact is made

with live electric wires; (6) static dissipative (SD) properties to reduce hazards due to excessively low

footwear resistance that may exist where SD footwear is required; (7) puncture resistance of footwear

bottoms; (8) chain saw cut resistance; and (9) dielectric insulation.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This specification covers minimum requirements for the

bility of regulatory limitations prior to use.

design, performance, testing, and classification of footwear

designed to provide protection against a variety of workplace

2. Referenced Documents

hazards that can potentially result in injury.

2.1 ASTM Standards:

1.2 The objective of this specification is to prescribe fit,

B117 Practice for Operating Salt Spray (Fog) Apparatus

function, and performance criteria for footwear that is intended

F1116 Test Method for Determining Dielectric Strength of

to be worn to reduce injuries.

Dielectric Footwear

1.3 This specification is not intended to serve as a detailed

F1117 Specification for Dielectric Footwear

manufacturing or purchasing specification, but can be refer-

F1818 Specification for Foot Protection for Chain Saw

enced in purchase contracts to ensure that minimum perfor-

Users

mance requirements are met.

F2412 Test Methods for Foot Protection

1.4 Controlled laboratory tests used to determine compli-

2.2 Federal Standards:

ance with the performance requirements of this specification

CFR 1910.132 Personal Protective Equipment–General Re-

shall not be deemed as establishing performance levels for all

quirements

situations to which individuals may be exposed.

CFR 1910.136 Personal Protective Equipment–Occupa-

1.5 The values stated in SI units are to be regarded as the

tional Foot Protection

standard. The values given in parentheses are for information

2.3 Canadian Standards Association Standard:

only.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction of ASTM Committee F13 on the ASTM website.

Pedestrian/Walkway Safety and Footwear and is the direct responsibility of AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Subcommittee F13.30 on Footwear. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Current edition approved March 1, 2005. Published March 2005. DOI: 10.1520/ Available from Canadian Standards Association (CSA), 178 Rexdale Blvd.,

F2413-05. Toronto, ON Canada M9W1R3.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2413 – 05

CAN/CSA Z195 Protective Footwear 4.1.6 Static dissipative (SD) properties to reduce hazards

due to excessively low footwear resistance that may exist

where SD footwear is required,

3. Terminology

4.1.7 Puncture resistance of footwear bottoms,

3.1 Definitions:

4.1.8 Chain saw cut resistance, and

3.1.1 footwear, n—wearing apparel for the feet (such as

4.1.9 Dielectric insulation.

shoes, boots, slippers, or overshoes) excluding hosiery.

3.1.1.1 Discussion—Thistermcanrefertoeitherleftfootor

5. Performance Requirements and Workmanship

right foot units or pairs.

3.1.2 insert, n—footbed normally made of a foam product

5.1 Impact Resistant Footwear:

with leather or fabric cover shaped to cover the entire insole

5.1.1 Impact resistant footwear shall also meet the require-

which can be inserted between the foot and insole board.

ments of 5.2 for compression resistant footwear.

3.1.3 insole, n—foundation of the shoe; the inner sole of the

5.1.2 Footwear shall be designed, constructed, and manu-

shoewhichisnexttothefoot,underthesocklinerortheinsert,

factured so that a protective toe cap is an integral and

onto which the upper is lasted.

permanent part of the footwear.

3.1.4 last, n—solid hinged form, in the general shape of a

5.1.3 The workmanship in the production and assembly of

foot, around which footwear is constructed.

the footwear shall ensure that the footwear provides function-

3.1.5 lasting, v—building of footwear around a specific foot

ality to the wearer.

form.

5.1.4 Classification shall be determined by evaluating three

3.1.6 lining, n—term used to describe all components that

specimens in accordance with Test Methods F2412. The

can be used to construct the interior of the upper part of the

product classification for impact resistance represents the

footwear.

minimum force required for each classification that results in

3.1.7 outsole and heel, n—exterior bottom platform of the

the toe area of the footwear having a minimum interior height

footwear; the bottom surface.

clearance of 12.7 mm (0.50 in.) in men’s footwear and 11.9

3.1.8 product category, n—description for a type of foot-

mm (0.468 in.) in women’s footwear.

wear designed and manufactured for a specific hazard or

5.1.4.1 Impact resistance of footwear shall be classified as

hazards.

follows:

3.1.9 product classification, n—footwear manufactured to

(1) Class 75 product classification men’s footwear shall

meet a minimum performance requirement for a specific

demonstrate a minimum interior height clearance of 12.7 mm

hazard or hazards.

(0.50 in.) during exposure to impact energy of 101.7 J (75

3.1.10 protective footwear, n—footwear that is designed,

ft-lbf).

constructed, and classified to protect the wearer from a

(2) Class 75 product classification women’s footwear shall

potential hazard or hazards.

demonstrate a minimum interior height clearance of 11.9 mm

3.1.11 protective toe cap, n—component designed to pro-

(0.468 in.) during exposure to impact energy of 101.7 J (75

vide toe protection that is an integral and permanent part of the

ft-lbf).

footwear.

(3) Class 50 product classification men’s footwear shall

3.1.12 quarter, n—entire back portion of the footwear

demonstrate a minimum interior height clearance of 12.7 mm

upper.

(0.50 in.) during exposure to impact energy of 67.8 J (50

3.1.13 shall, v—mandatory action.

ft-lbf).

3.1.14 should, v—advisory comment.

(4) Class 50 product classification women’s footwear shall

3.1.15 size, n—length and breadth measurements of foot-

demonstrate a minimum interior height clearance of 11.9 mm

wear determined by using a specific grading; the American

(0.468 in.) during exposure to impact energy of 67.8 J (50

system of footwear grading.

ft-lbf).

3.1.16 socklining, n—material placed over the insole which

5.1.4.2 Any specimen that does not meet the minimum

is imprinted with a brand name or other designation.

impact performance requirements for the product classification

3.1.17 upper, n—parts of a shoe or boot that are above the

constitutes failure for the product category.

sole.

5.1.4.3 Protective toe footwear specimens or samples shall

be retested for classification for any of the following changes:

4. Significance and Use

(1) Change in material used to make protective toe cap,

changeinprotectivecapmanufacturer,orchangesinthedesign

4.1 This specification contains requirements to evaluate the

of the toe cap.

performance of footwear for the following:

4.1.1 Impact resistance for the toe area of footwear, (2) Change in construction method used to make footwear.

(3) Change in the upper or insole material thickness greater

4.1.2 Compression resistance for the toe area of footwear,

4.1.3 Metatarsal protection that reduces the chance of injury than 25 %, change to the soling system, or a change in the

hardness of the outsole.

to the metatarsal bones at the top of the foot,

4.1.4 Conductive properties which reduce hazards that may (4) Shape of last used in the manufacturing of footwear.

result from static electricity buildup, and reduce the possibility 5.2 Compression Resistant Footwear:

of ignition of explosives and volatile chemicals,

5.2.1 Compression resistant footwear shall also meet the

4.1.5 Electric shock resistance, requirements of 5.1 for impact resistant footwear.

F2413 – 05

5.2.2 Footwear shall be designed, constructed, and manu-

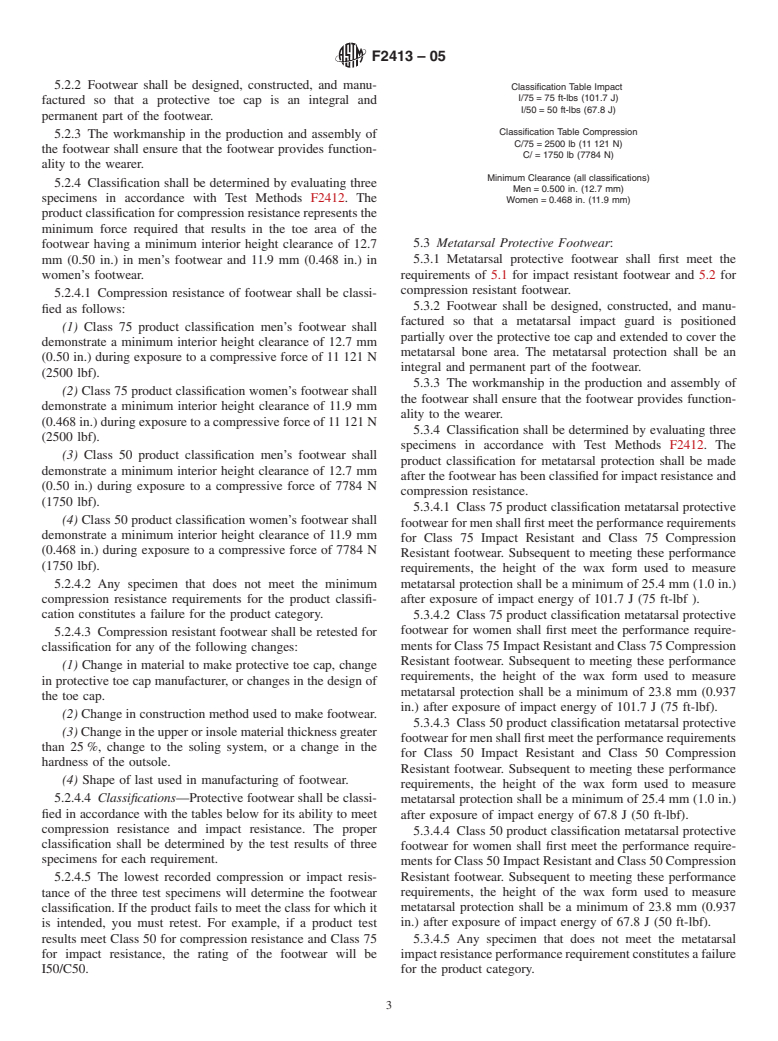

Classification Table Impact

I/75 = 75 ft-lbs (101.7 J)

factured so that a protective toe cap is an integral and

I/50 = 50 ft-lbs (67.8 J)

permanent part of the footwear.

Classification Table Compression

5.2.3 The workmanship in the production and assembly of

C/75 = 2500 lb (11 121 N)

the footwear shall ensure that the footwear provides function-

C/ = 1750 lb (7784 N)

ality to the wearer.

Minimum Clearance (all classifications)

5.2.4 Classification shall be determined by evaluating three

Men = 0.500 in. (12.7 mm)

specimens in accordance with Test Methods F2412. The

Women = 0.468 in. (11.9 mm)

product classification for compression resistance represents the

minimum force required that results in the toe area of the

5.3 Metatarsal Protective Footwear:

footwear having a minimum interior height clearance of 12.7

5.3.1 Metatarsal protective footwear shall first meet the

mm (0.50 in.) in men’s footwear and 11.9 mm (0.468 in.) in

women’s footwear. requirements of 5.1 for impact resistant footwear and 5.2 for

compression resistant footwear.

5.2.4.1 Compression resistance of footwear shall be classi-

5.3.2 Footwear shall be designed, constructed, and manu-

fied as follows:

factured so that a metatarsal impact guard is positioned

(1) Class 75 product classification men’s footwear shall

partially over the protective toe cap and extended to cover the

demonstrate a minimum interior height clearance of 12.7 mm

metatarsal bone area. The metatarsal protection shall be an

(0.50 in.) during exposure to a compressive force of 11 121 N

integral and permanent part of the footwear.

(2500 lbf).

5.3.3 The workmanship in the production and assembly of

(2) Class 75 product classification women’s footwear shall

the footwear shall ensure that the footwear provides function-

demonstrate a minimum interior height clearance of 11.9 mm

ality to the wearer.

(0.468 in.) during exposure to a compressive force of 11 121 N

5.3.4 Classification shall be determined by evaluating three

(2500 lbf).

specimens in accordance with Test Methods F2412. The

(3) Class 50 product classification men’s footwear shall

product classification for metatarsal protection shall be made

demonstrate a minimum interior height clearance of 12.7 mm

after the footwear has been classified for impact resistance and

(0.50 in.) during exposure to a compressive force of 7784 N

compression resistance.

(1750 lbf).

5.3.4.1 Class 75 product classification metatarsal protective

(4) Class 50 product classification women’s footwear shall

footwearformenshallfirstmeettheperformancerequirements

demonstrate a minimum interior height clearance of 11.9 mm

for Class 75 Impact Resistant and Class 75 Compression

(0.468 in.) during exposure to a compressive force of 7784 N

Resistant footwear. Subsequent to meeting these performance

(1750 lbf).

requirements, the height of the wax form used to measure

5.2.4.2 Any specimen that does not meet the minimum metatarsal protection shall be a minimum of 25.4 mm (1.0 in.)

compression resistance requirements for the product classifi- after exposure of impact energy of 101.7 J (75 ft-lbf ).

cation constitutes a failure for the product category. 5.3.4.2 Class 75 product classification metatarsal protective

footwear for women shall first meet the performance require-

5.2.4.3 Compression resistant footwear shall be retested for

ments for Class 75 Impact Resistant and Class 75 Compression

classification for any of the following changes:

Resistant footwear. Subsequent to meeting these performance

(1) Change in material to make protective toe cap, change

requirements, the height of the wax form used to measure

in protective toe cap manufacturer, or changes in the design of

metatarsal protection shall be a minimum of 23.8 mm (0.937

the toe cap.

in.) after exposure of impact energy of 101.7 J (75 ft-lbf).

(2) Change in construction method used to make footwear.

5.3.4.3 Class 50 product classification metatarsal protective

(3) Change in the upper or insole material thickness greater

footwearformenshallfirstmeettheperformancerequirements

than 25 %, change to the soling system, or a change in the

for Class 50 Impact Resistant and Class 50 Compression

hardness of the outsole.

Resistant footwear. Subsequent to meeting these performance

(4) Shape of last used in manufacturing of footwear.

requirements, the height of the wax form used to measure

5.2.4.4 Classifications—Protective footwear shall be classi-

metatarsal protection shall be a minimum of 25.4 mm (1.0 in.)

fied in accordance with the tables below for its ability to meet

after exposure of impact energy of 67.8 J (50 ft-lbf).

compression resistance and impact resistance. The proper

5.3.4.4 Class 50 product classification metatarsal protective

classification shall be determined by the test results of three

footwear for women shall first meet the performance require-

specimens for each requirement.

ments for Class 50 Impact Resistant and Class 50 Compression

5.2.4.5 The lowest recorded compression or impact resis- Resi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.