ASTM C341-96

(Test Method)Standard Test Method for Length Change of Drilled or Sawed Specimens of Hydraulic-Cement Mortar and Concrete

Standard Test Method for Length Change of Drilled or Sawed Specimens of Hydraulic-Cement Mortar and Concrete

SCOPE

1.1 This test method covers the determination of the length changes of drilled or sawed specimens of hydraulic-cement mortar and concrete due to causes other than externally applied forces and temperature changes. It can be readily adapted, if desired, to studies of length change involving different schedules or environmental treatment than the standard procedures prescribed by this test method.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 341 – 96

Standard Test Method for

Length Change of Drilled or Sawed Specimens of Hydraulic-

Cement Mortar and Concrete

This standard is issued under the fixed designation C 341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the length 4.1 Measurements of length change permit assessment of

changes of drilled or sawed specimens of hydraulic-cement the potential for volumetric expansion or contraction of drilled

mortar and concrete due to causes other than externally applied or sawed specimens of hydraulic-cement mortar, and concrete

forces and temperature changes. It can be readily adapted, if due to various causes other than externally applied forces and

desired, to studies of length change involving different sched- temperature changes. This test method is particularly useful for

ules or environmental treatment than the standard procedures comparative evaluation of this potential in different mortar or

prescribed by this test method. concrete specimens.

1.2 The values stated in inch-pound units are to be regarded

5. Apparatus

as the standard.

1.3 This standard does not purport to address all of the 5.1 Length Comparator—The length comparator shall gen-

erally conform to the requirements of Specification C 490,

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- except that it should be constructed to accommodate the

specimens to be tested under this test method, which may have

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. gage lengths of 3 in. (75 mm) or more.

5.1.1 Gage Studs in Ends of Specimens—When the com-

2. Referenced Documents

parator is to be used to measure between gage studs in the ends

2.1 ASTM Standards: of specimens, the gage length for computing percentage length

A 276 Specification for Stainless Steel Bars and Shapes change shall be considered to be the distance between the

C 42 Test Method for Obtaining and Testing Drilled Cores innermost ends of the gage studs, and the contact terminals of

and Sawed Beams of Concrete the comparator shall be plane, polished, heat-treated surfaces

C 157 Test Method for Length Change of Hardened as described in Specification C 490. Fig. 3 of Specification

Hydraulic-Cement Mortar and Concrete C 490 shows one type of comparator which has been found

C 490 Practice for Use of Apparatus for the Determination suitable for such specimens. A horizontal comparator may be

of Length Change of Hardened Cement Paste, Mortar, and desirable for specimens that are considered too large to be

Concrete handled by the type of comparator illustrated in Fig. 3 of

Specification C 490.

3. Terminology

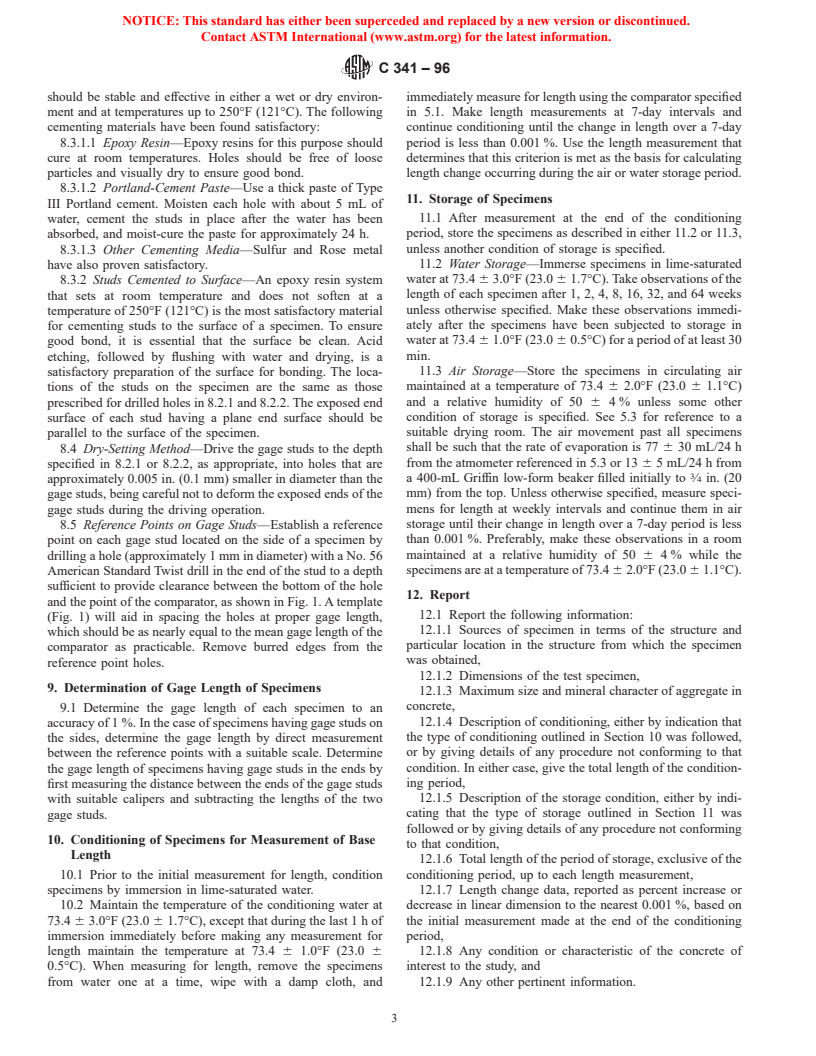

5.1.2 Gage Studs on Sides of Specimen—When the com-

3.1 Definition of Term—The term “length change,” as used parator is to be used to measure between gage studs on the

here, is defined as an increase or decrease in a linear dimension

sides of specimens, the contact terminals shall be conical,

of a test specimen which has been caused to change by any heat-treated surfaces as shown in Fig. 1, which illustrates a

factor other than externally applied forces and temperature

type of comparator that has been found satisfactory for this

changes. type of specimen. In this case, the gage length shall be the

distance between the reference points located in the exposed

ends of the gage studs (see 5.2).

This test method is under the jurisdiction of ASTM Committee C-9 on Concrete

5.2 Gage Studs—Gage studs shall be Type 316 stainless

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.68 on

steel, meeting Specification A 276.

Volume Change.

Current edition approved Nov. 10, 1996. Published January 1997. Originally 5.2.1 For Ends of Specimens—Gage studs that are to be

published as C 341 – 54 T. Last previous edition C 341 – 89.

located in the ends of specimens shall have a rounded surface

Annual Book of ASTM Standards, Vol 01.05.

to provide point contact with the terminals of the comparator.

Annual Book of ASTM Standards, Vol 04.02.

The types of studs described in Specification C 490 are suitable

Annual Book of ASTM Standards, Vol 04.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C341–96

FIG. 1 Type of Suitable Extensometer for Measurement of Length Change of Specimens Having Gage Studs on Sides

for insertion in drilled holes. Spherical studs having a diameter 8. Setting Gage Studs

1 3

of ⁄4 to ⁄8 in. (6 to 10 mm), or studs that are sections of spheres

8.1 Gage studs may either be dry-set or cemented in drilled

of similar diameter, are suitable for cementing to the ends of

holes, or cemented directly to the surface of the specimen.

specimens.

8.2 Drilling Holes—For gage studs that are to be cemented,

5.2.2 For Sides of Specimens—The exposed end of gage

holes should be drilled (Note 1) only slightly larger than the

studs that are to be located on the sides of specimens shall have

studs. For gage studs that are to be dry-set, holes should be

3 1

a plane surface with a diameter or diagonal of ⁄8 to ⁄2 in. (10

drilled about 0.005 in. (0.1 mm) smaller in diameter than the

to 13 mm). For dry setting, the length of the stud shall be ⁄2 to

studs. In the case of small specimens, take care that the

⁄8 in. (13 to 16 mm). Shorter lengths of stud, including plane

specimens are not damaged by the drilling operation. The

disks, may be satisfactory for studs that are to be cemented.

location and depth of holes shall be as given in 8.2.1 and 8.2.2.

5.3 Drying Room and Controls—A drying room and con-

NOTE 1—Carbide-tipped masonry drills have been found most suitable

trols as described in Test Method C 157 shall be used for

for this purpose.

storing specimens in air.

8.2.1 For Gage Studs in Ends of Specimen—Drill holes in

6. Sampling

the ends of a specimen so that their longitudinal axes coincide

6.1 Samples shall be obtained in accordance with the with the longitudinal axis of the specimen. The depth of the

section on Sampling of Test Method C 42. holes should be such that the gage studs will project from ⁄8 in.

to ⁄16 in. (3 to 5 mm) beyond the ends of the specimen.

7. Test Specimens

8.2.2 For Gage Studs in Sides of Specimen—Drill a pair of

holes in each of two opposite sides of the specimen to

7.1 Test specimens shall be either cores or rectangular

compensate for warping and to provide a better average for

prisms that have been drilled or sawed from existing concrete

length change. Position both pairs of holes in a plane contain-

or mortar structures and are free from reinforcing steel, visible

ing the longitudinal axis of the specimen and space to conform

cracks, or other structural defects. They may be of any size but

to the length of the comparator. The center of each hole should

specimens that are to be compared should not differ in their

be at least 1 in. (approximately 25 mm) from the end of the

cross-sectional dimensions by more than 10 % or in length by

specimen. The depth of the holes should preferably be such that

more than 20 %. The gage length shall be at least six times the

the top surfaces of the gage studs can be set about 0.1 in. (3

maximum nominal size of the coarse aggregate but not less

mm) below the surface of the specimen.

than 3 in. (75 mm), and that the minimum cross-sectional

8.3 Cementing Methods:

dimension be at least three times the maximum nominal size of

the coarse aggregate but not less than 2 in. (50 mm). When the 8.3.1 Studs Set in Holes—Position gage studs in holes at the

gage studs are to be located on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.