ASTM D7741-11

(Test Method)Standard Test Method for Measurement of Apparent Viscosity of Asphalt-Rubber or Other Asphalt Binders by Using a Rotational Hand Held Viscometer

Standard Test Method for Measurement of Apparent Viscosity of Asphalt-Rubber or Other Asphalt Binders by Using a Rotational Hand Held Viscometer

SIGNIFICANCE AND USE

This test is primarily used for field production control of Asphalt-Rubber (A-R) and other high viscosity binders; however the test can also be used in a laboratory setting.

A hand held rotational viscometer is used to measure the apparent viscosity of a completed blend of A-R or high viscosity binder. A rotor (spindle), turning at constant speed, is inserted in the liquid binder to be measured. The resistance to movement of the spindle (torque) caused by the viscosity of the surrounding liquid is measured using a special mechanism to obtain direct readings in Pa·s or cP.

Note 1—Spindle generally made of stainless steel, although another metal such as brass could be used.

The measured apparent viscosity is used to control the production of the A-R or other high viscosity binder, to assess the uniformity of the binder produced or for other related purposes.

As the spindle turns in the A-R or other high viscosity binder, it has a tendency to “drill” into the sample (i.e., for A-R, the spindle spins the rubber particles out of the measurement area). Consequently, the apparent viscosity drops to reflect only the liquid phase of the high viscosity binder. Therefore, the peak viscosity measurement value is recorded to reflect the viscosity of the blended material.

SCOPE

1.1 The use of high viscosity asphalt binders like Asphalt-Rubber is becoming more common in the United States and worldwide. Specifications such as Specification D6114 note the need for field control of the apparent viscosity and require the use of a field production rotational viscometer. The testing of Asphalt-Rubber Binder for use in Asphalt- Rubber Hot Mix and for Asphalt-Rubber Membrane is necessary to ensure consistent mix properties that will ensure good performance of these materials. Logistics of field applications limits the use of conventional laboratory controls and testing equipment. This test, using a hand held rotational viscometer can be conducted in either the field or laboratory to determine the apparent viscosity of Asphalt-Rubber and other high viscosity binders for field production control and to assess the uniformity of the binder produced or for other related purposes.

1.2 Asphalt-Rubber Binder consists of a blend of paving grade asphalt cement and crumb rubber as described in Specification D6114. Other high viscosity asphalt binders may consist of asphalts modified with polymer or fiber or both. Testing is performed following the specified reaction time, if any, within the production process. Control of the raw materials is separate from the test.

1.3 The values stated in SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; each system shall be used independently of the other. Combining values from the two systems may result in non-compliance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7741–11

Standard Test Method for

Measurement of Apparent Viscosity of Asphalt-Rubber or

Other Asphalt Binders by Using a Rotational Hand Held

Viscometer

This standard is issued under the fixed designation D7741; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 The use of high viscosity asphalt binders like Asphalt- 2.1 ASTM Standards:

Rubber is becoming more common in the United States and D6114 Specification for Asphalt-Rubber Binder

worldwide.SpecificationssuchasSpecificationD6114notethe

3. Significance and Use

need for field control of the apparent viscosity and require the

use of a field production rotational viscometer. The testing of 3.1 This test is primarily used for field production control of

Asphalt-Rubber (A-R) and other high viscosity binders; how-

Asphalt-Rubber Binder for use in Asphalt- Rubber Hot Mix

and for Asphalt-Rubber Membrane is necessary to ensure ever the test can also be used in a laboratory setting.

3.2 Ahand held rotational viscometer is used to measure the

consistent mix properties that will ensure good performance of

these materials. Logistics of field applications limits the use of apparent viscosity of a completed blend of A-R or high

viscosity binder.Arotor (spindle), turning at constant speed, is

conventional laboratory controls and testing equipment. This

test, using a hand held rotational viscometer can be conducted inserted in the liquid binder to be measured. The resistance to

movementofthespindle(torque)causedbytheviscosityofthe

in either the field or laboratory to determine the apparent

viscosity of Asphalt-Rubber and other high viscosity binders surrounding liquid is measured using a special mechanism to

obtain direct readings in Pa·s or cP.

for field production control and to assess the uniformity of the

binder produced or for other related purposes.

NOTE 1—Spindle generally made of stainless steel, although another

1.2 Asphalt-Rubber Binder consists of a blend of paving

metal such as brass could be used.

grade asphalt cement and crumb rubber as described in

3.3 The measured apparent viscosity is used to control the

Specification D6114. Other high viscosity asphalt binders may

production of the A-R or other high viscosity binder, to assess

consist of asphalts modified with polymer or fiber or both.

the uniformity of the binder produced or for other related

Testing is performed following the specified reaction time, if

purposes.

any, within the production process. Control of the raw materi-

3.4 As the spindle turns in the A-R or other high viscosity

als is separate from the test.

binder,ithasatendencyto“drill”intothesample(i.e.,forA-R,

1.3 The values stated in SI units or inch-pound units are to

the spindle spins the rubber particles out of the measurement

be regarded separately as standard. The values stated in each

area).Consequently,theapparentviscositydropstoreflectonly

systemmaynotbeexactequivalents;eachsystemshallbeused

the liquid phase of the high viscosity binder. Therefore, the

independently of the other. Combining values from the two

peak viscosity measurement value is recorded to reflect the

systems may result in non-compliance with the standard.

viscosity of the blended material.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Apparatus

responsibility of the user of this standard to establish appro-

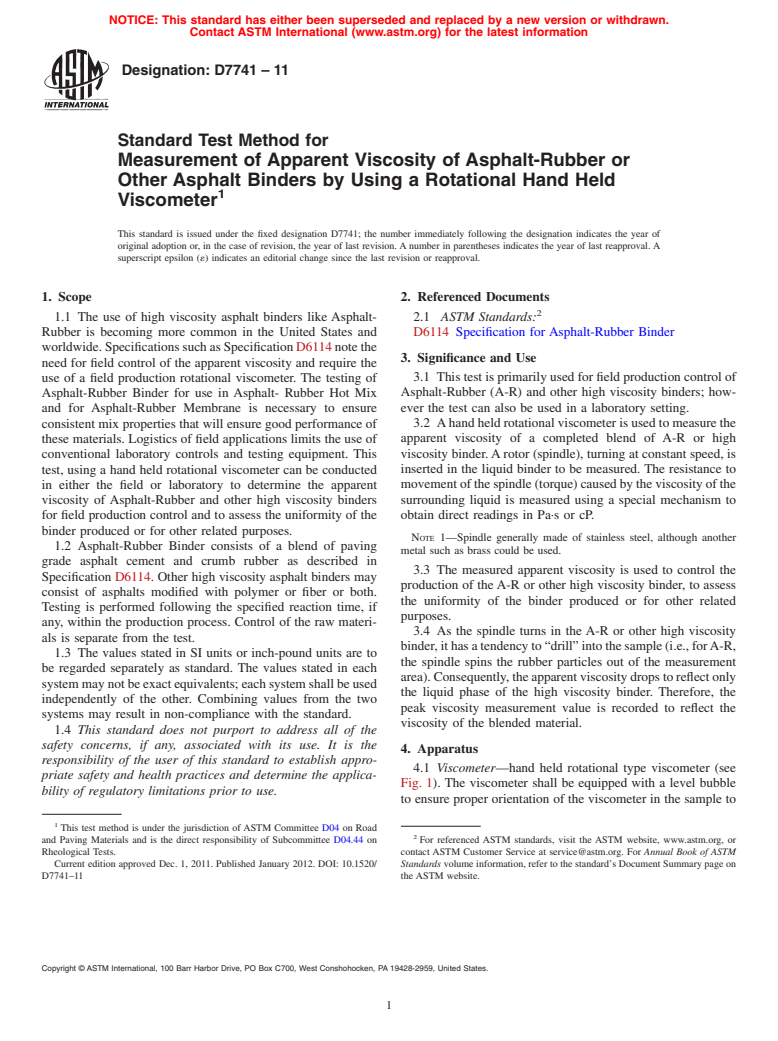

4.1 Viscometer—hand held rotational type viscometer (see

priate safety and health practices and determine the applica-

Fig. 1). The viscometer shall be equipped with a level bubble

bility of regulatory limitations prior to use.

to ensure proper orientation of the viscometer in the sample to

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Rheological Tests. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2011. Published January 2012. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

D7741–11

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7741–11

FIG. 1

be tested. Spindle (rotor) speed typically 62.5 rpm, however

may vary with different manufacturers.

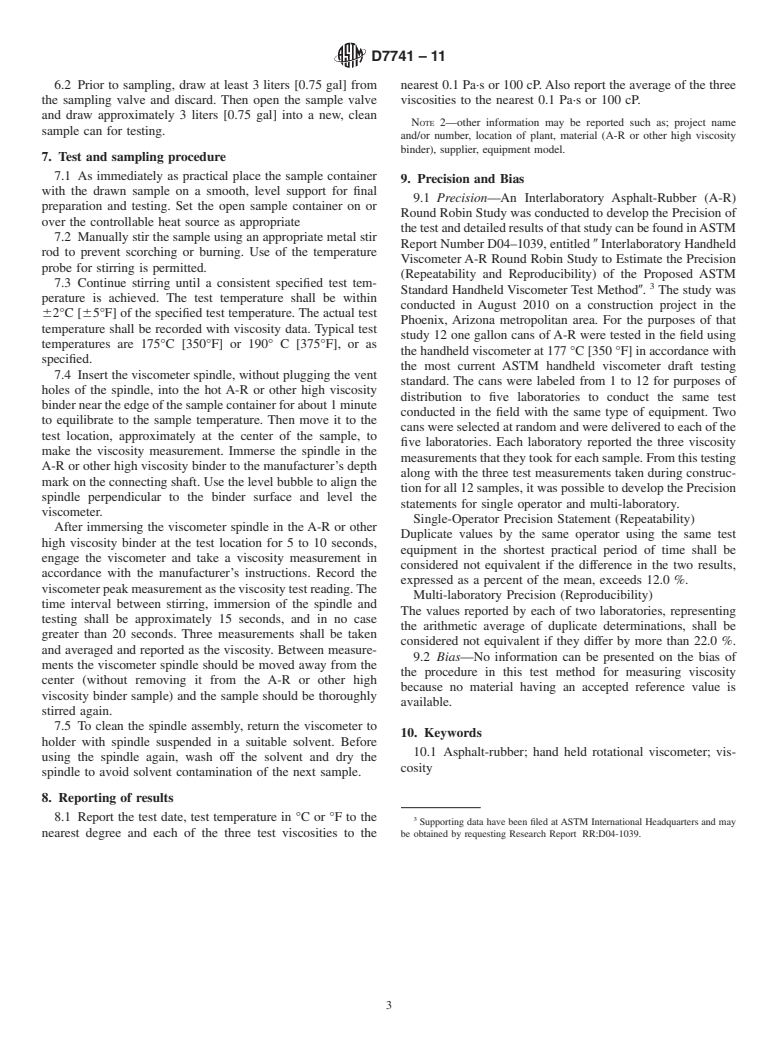

4.2 Spindle (Rotor)—Diameter - 24 6 1.1 mm. [1.0 6 0.05

inch]; Height - 53 6 0.1 mm [2 6 .005 inch] or equivalent (see

Fig. 2).

4.3 Thermometer—Digital with metal jacket probe, 1 de-

gree °C [2 degree °F] precision.

4.4 SampleCan—4liter[1gallon]metalcanwithwirebale.

4.5 Viscosity Standard Oils—Calibrated in absolute viscos-

ity in Pa·s [centipoises cP] and in the range of 1.0 to 5.0 Pa·s

[1000 to 5000 cP].

4.6 Controllable heat source, such as a hot plate, gas stove

or burner, etc., to maintain the test temperature of the A-R or

high viscosity binder sample during viscosity measurement.

4.7 Viscometer holder—clean metal can or some type of

frame where the viscometer can be stored between tests.

5. Calibration Verification

5.1 Calibration of the rotational viscometer shall be verified

FIG. 2

prior to use at each site per manufacturer’s instructions using

the reference viscosity standard oils.

Obtain the sample from an appropriate sample valve located to

6. Sampling

intercept the normal flow of material during production.

6.1 The sample shall consist of at least 3 liters [0.75 gal] of Perform sampling and testing in close proximity to the plant

the completed mixture of A-R or other high viscosity binder. operation to avoid undue temperature loss during handling.

D7741–11

6.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.