ASTM D6411/D6411M-99(2005)

(Specification)Standard Specification for Slicone Rubber Room Temperature Vulcanizing Low Outgassing Materials

Standard Specification for Slicone Rubber Room Temperature Vulcanizing Low Outgassing Materials

ABSTRACT

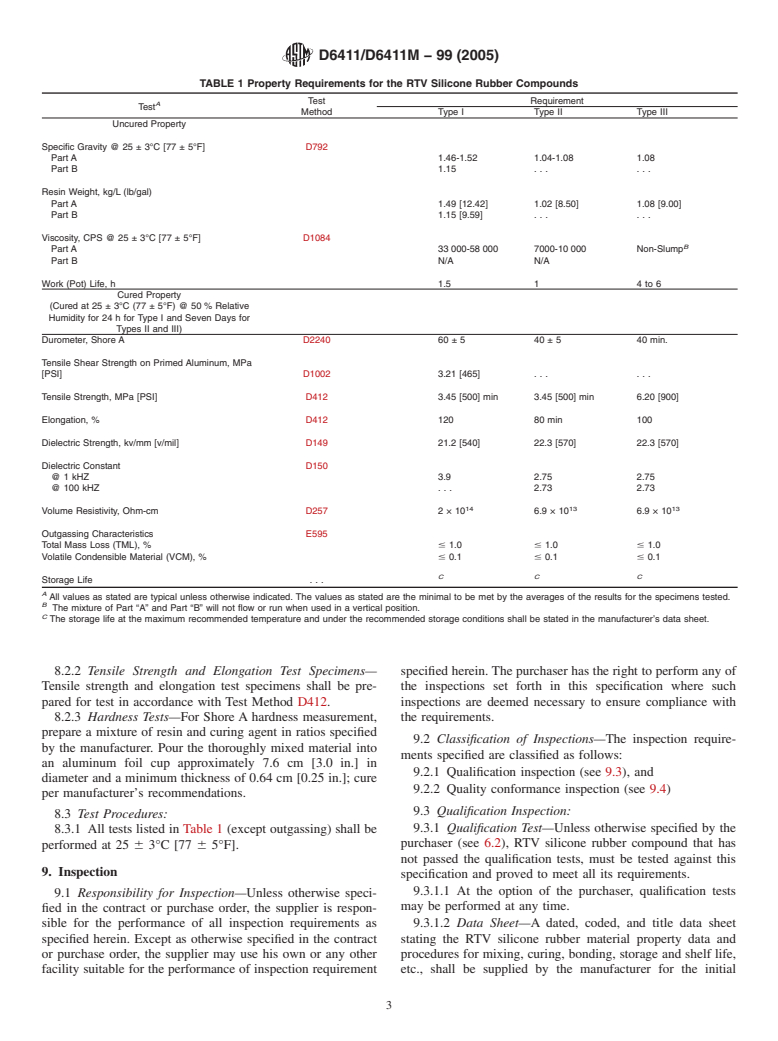

This specification covers a two-part flowable space grade silicone rubber room temperature vulcanizing (RTV) adhesive or compound. This specification provides material requirements and testing procedures to differentiate between the physical, mechanical, electrical, and adhesive bonding properties of three types of RTV silicone rubber compounds. RTV low volatile silicone rubber compounds shall be classified as type I, type II, and type III. The silicone rubber material shall be tested for specific gravity, resin weight, viscosity, humidity, work life, tensile shear strength, tensile strength, elongation, dielectric strength, dielectric constant, volume resistivity, outgassing characteristics, total mass loss, volatile condensable material, and storage life.

SCOPE

1.1 The specification covers a two-part flowable space grade room temperature vulcanizing (RTV) silicone rubber adhesive or compound. The material is specifically designed for applications requiring extreme low temperature, low outgassing and minimal volatile condensibles under extreme operating conditions. The RTV silicone rubber should be suitable for withstanding environmental exposure to temperatures from -115 to 200C (-175 to 392F). The material should also withstand the combination of stress, temperature, and relative humidity expected to be encountered in service. The RTV silicone rubber may be used as a sealing, caulking, potting or bonding material for applications on metal, plastics, rubber, glass, and ceramic products. Types I and II are often used as coatings.

1.2 The values stated in SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.3 The following precautionary statement refers to the test method portion only, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6411/D6411M −99(Reapproved2005)

Standard Specification For

Silicone Rubber Room Temperature Vulcanizing Low

Outgassing Materials

This standard is issued under the fixed designation D6411/D6411M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D149 Test Method for Dielectric Breakdown Voltage and

DielectricStrengthofSolidElectricalInsulatingMaterials

1.1 Thespecificationcoversatwo-partflowablespacegrade

at Commercial Power Frequencies

room temperature vulcanizing (RTV) silicone rubber adhesive

D150 Test Methods forAC Loss Characteristics and Permit-

or compound. The material is specifically designed for appli-

tivity (Dielectric Constant) of Solid Electrical Insulation

cations requiring extreme low temperature, low outgassing and

D257 Test Methods for DC Resistance or Conductance of

minimal volatile condensibles under extreme operating condi-

Insulating Materials

tions. The RTV silicone rubber should be suitable for with-

D412 Test Methods forVulcanized Rubber andThermoplas-

standing environmental exposure to temperatures from –115 to

tic Elastomers—Tension

200°C (–175 to 392°F).The material should also withstand the

D792 Test Methods for Density and Specific Gravity (Rela-

combination of stress, temperature, and relative humidity

tive Density) of Plastics by Displacement

expectedtobeencounteredinservice.TheRTVsiliconerubber

D907 Terminology of Adhesives

may be used as a sealing, caulking, potting or bonding material

D1002 Test Method for Apparent Shear Strength of Single-

for applications on metal, plastics, rubber, glass, and ceramic

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

products. Types I and II are often used as coatings.

sion Loading (Metal-to-Metal)

1.2 The values stated in SI units or inch-pound units are to

D1084 Test Methods for Viscosity of Adhesives

be regarded separately as standard. Within the text, the

D2240 Test Method for Rubber Property—Durometer Hard-

inch-pound units are shown in brackets. The values stated in

ness

each system are not exact equivalents; therefore, each system

D2651 GuideforPreparationofMetalSurfacesforAdhesive

must be used independently of the other. Combining values

Bonding

from the two systems may result in nonconformance with this

D3951 Practice for Commercial Packaging

specification.

E595 Test Method for Total Mass Loss and Collected Vola-

1.3 The following precautionary statement refers to the test tile Condensable Materials from Outgassing in a Vacuum

method portion only, Section 8, of this specification: This

Environment

standard does not purport to address all of the safety concerns, 2.2 National Aeronautics and Space Administration (NASA)

if any, associated with its use. It is the responsibility of the user

JSC SP-R-0022 General Specification, Vacuum Stability

of this standard to establish appropriate safety and health Requirement of Polymeric Material for Spacecraft Appli-

practices and determine the applicability of regulatory limita-

cation

tions prior to use. MSFC-HDBK-527/JSC-09604 Material Selection List for

Hardware Systems

2. Referenced Documents

GSFC RP 1124 Outgassing Data for Selecting Spacecraft

2.1 ASTM Standards:

Materials

B209 Specification for Aluminum and Aluminum-Alloy

NOTE1—Copiesofspecifications,standards,drawingsandpublications

Sheet and Plate

required by suppliers in connection with specific purchases should be

obtained from the purchaser or as directed by his contracting officer.

This specification is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of subcommittee D14.80 on Metal 3. Terminology

Bonding Adhesives.

3.1 Definitions:

Current edition approved April 1, 2005. Published May 2005. Originally

approved in 1999. Last previous edition approved in 1999 as D6411/D6411M - 99. 3.1.1 Many terms in this specification are defined in Termi-

DOI: 10.1520/D6411_D6411M-99R05.

nology D907.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Unless otherwise indicated, copies of the above documents are available from

the ASTM website. a NASA installation library or document repository.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6411/D6411M−99(2005)

3.1.2 lot, n—a specific material that can be identified by the 6.1.7 Storage conditions.

place of manufacture, quantity and type of raw materials and

6.2 Qualification—In case the RTV silicone rubber com-

process conditions used.

pound(s) that are qualified/approved at the time set for opening

3.2 Definitions of Terms Specific to This Standard: of bids, the procurement documents should state that the

3.2.1 RTV, adj—room temperature vulcanizing. awards will be forthcoming.

3.2.2 RTV Silicone Rubber Compound, n—a silicone resin

7. Test Requirements

base (A) and a silicone resin curing agent (B) when mixed in a

proper ratio results in a rubbery compound. A RTV silicone

7.1 Material—The RTV silicone rubber compound, when

rubber compound that is manufactured by a unique combina-

tested per Section 8, shall meet the physical, mechanical and

tion of raw silicone materials and manufacturing process that

electrical, and outgassing requirements as specified in Table 1.

conforms to a given set of physical and performance properties

The silicone rubber compound shall not have a detrimental

and is identified by specific name, number, or alphanumeric

effect on surfaces being in contact or bonded over the range of

designation.

temperaturesatwhichtheRTVsiliconerubbercompoundswill

be used.

NOTE 2—A“curing agent” is commonly used with this type of silicone

rubber compound. The term “accelerator” or “catalyst” is synonymous

7.2 Qualification—Qualification shall only apply to the

with “curing agent.”

formulation on which the qualification tests have been made;

any changes by the manufacturer in formulation or method of

4. Significance and Use

manufacturing, shall be cause of designating the RTV silicone

4.1 General—This specification provides material require-

rubber compound as a new product. The new product shall be

ments and testing procedures to differentiate between the

givenanewcodenumberandshallberequalifiedandapproved

physical, mechanical, electrical, adhesive bonding properties

until it has been shown to meet the requirements of this

of three types of RTV silicone rubber compounds.

specification.

4.2 Thephysical,mechanicalandelectricalpropertiesofthe

7.3 Working Characteristics:

RTV silicone rubber are tested and measured to provide

7.3.1 Application—The RTV silicone rubber compound

specific data on requirements for qualification and lot accep-

shall be suitable for application to surfaces in accordance with

tance of separate ingredients comprising the RTV silicone

the manufacturer’s instructions.

rubber compounds and the properties resulting from the cured

7.3.2 Curing—The time, temperature, and pressure used to

mixture.

cure the RTVsilicone rubber compound shall be in accordance

with the manufacturer’s recommendation.

NOTE 3—Because of the many number of adherend materials bonded

with RTV silicone rubber material, testing by this specification will only

evaluate the RTV silicone rubber material under a given set of conditions.

8. Test Methods

8.1 Qualification Tests—For qualification, the RTV silicone

5. Classification

rubber compound shall be tested using the tests described in

5.1 The RTV low volatile silicone rubber compounds shall

this section.All tests specified in Table 1 shall be performed at

be furnished as one of the following types:

room temperature, 25 6 3°C [77 6 5°F] with the exception of

5.1.1 Type I—Alow viscosity, two-part system consists of a

the outgassing test.

silicone resin base (A) and a liquid curing agent (B) when

8.2 Preparation of Test Specimens—Prepare at least ten

mixed and cured results in a Shore A hardness of 60.

specimens for each separate test as follows:

5.1.2 Type II—A medium viscosity, two-part system con-

8.2.1 Tensile Shear Strength Specimens:

sists of a silicone resin base (A) and a liquid curing agent (B)

8.2.1.1 Adherend—The metal substrate shall be 6061-T6 or

when mixed and cured results in a Shore A hardness of 40.

2024-T3 aluminum alloy in accordance with Specification

5.1.3 Type III—A medium viscosity thixotropic, two-part

B209.

system consists of a silicone resin base (A) and a liquid curing

8.2.1.2 Surface Preparation—Clean and etch in accordance

agent (B) when mixed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.