ASTM E2178-03

(Test Method)Standard Test Method for Air Permeance of Building Materials

Standard Test Method for Air Permeance of Building Materials

SIGNIFICANCE AND USE

The purpose of this test is to measure the air permeance of flexible sheet or rigid panel-type materials. The results of this test may be useful in determining suitability of that material as a component of an air retarder system.

This method does not address the installed air leakage performance of building materials. The installed performance of air retarder materials and air retarder systems in low-rise framed wall construction is addressed in Specification E 1677.

SCOPE

1.1 This test method is to determine the air permeance of building materials at various pressure differentials with the intent of determining an assigned air permeance rate of the material at the reference pressure difference (P) of 75 Pa.

1.2 The method is intended to assess flexible sheet or rigid panel-type materials using a 1 m 1 m specimen size.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurements are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E2178 – 03

Standard Test Method for

1

Air Permeance of Building Materials

This standard is issued under the fixed designation E2178; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 This method does not address the installed air leakage

performance of building materials. The installed performance

1.1 This test method is to determine the air permeance of

of air retarder materials and air retarder systems in low-rise

building materials at various pressure differentials with the

framed wall construction is addressed in Specification E1677.

intent of determining an assigned air permeance rate of the

material at the reference pressure difference (DP)of75Pa.

5. Sampling

1.2 The method is intended to assess flexible sheet or rigid

5.1 The number of specimens to be tested shall be suitable

panel-type materials usinga1m 3 1 m specimen size.

to establish an air leakage rate which is representative of the

1.3 The values stated in SI units are to be regarded as

product. In no case shall less than five specimens be tested.

standard. No other units of measurements are included in this

standard.

NOTE 1—Because of the variability in the manufacture of a product, the

1.4 This standard does not purport to address all of the number of specimens to be tested may vary from product to product.

Certain materials may have standard methods for sampling that shall be

safety concerns, if any, associated with its use. It is the

used to sample these materials.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

6. Test Apparatus

bility of regulatory limitations prior to use.

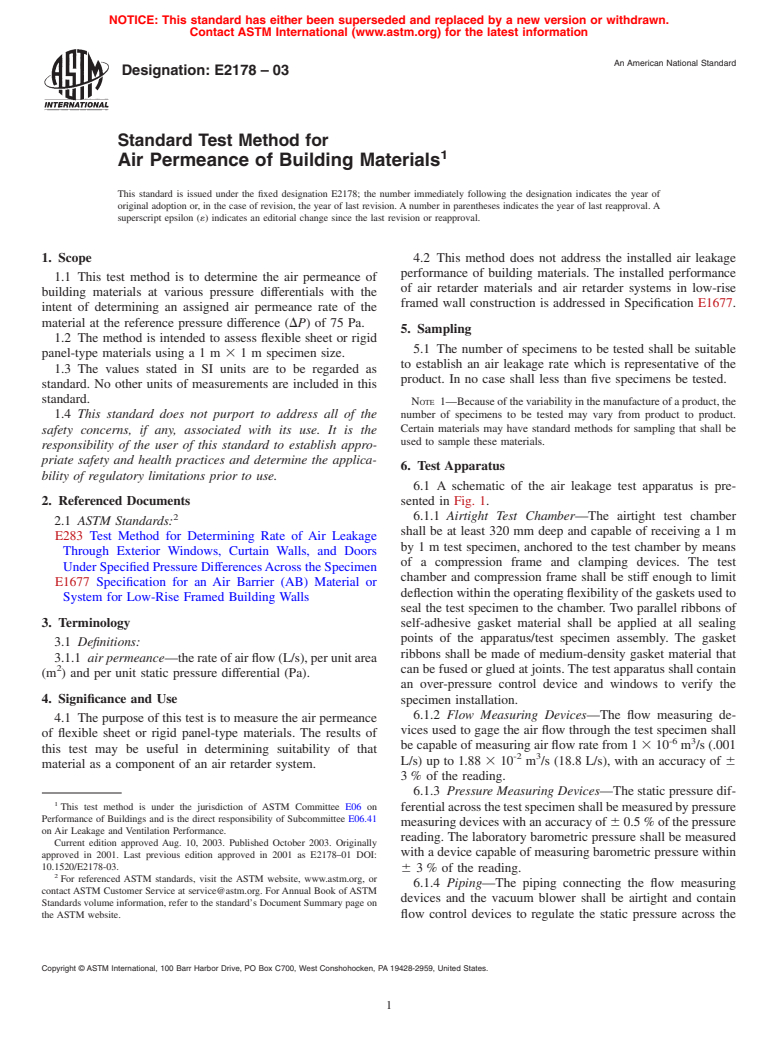

6.1 A schematic of the air leakage test apparatus is pre-

2. Referenced Documents sented in Fig. 1.

2 6.1.1 Airtight Test Chamber—The airtight test chamber

2.1 ASTM Standards:

shall be at least 320 mm deep and capable of receivinga1m

E283 Test Method for Determining Rate of Air Leakage

by 1 m test specimen, anchored to the test chamber by means

Through Exterior Windows, Curtain Walls, and Doors

of a compression frame and clamping devices. The test

Under Specified Pressure DifferencesAcross the Specimen

chamber and compression frame shall be stiff enough to limit

E1677 Specification for an Air Barrier (AB) Material or

deflection within the operating flexibility of the gaskets used to

System for Low-Rise Framed Building Walls

seal the test specimen to the chamber. Two parallel ribbons of

3. Terminology self-adhesive gasket material shall be applied at all sealing

points of the apparatus/test specimen assembly. The gasket

3.1 Definitions:

ribbons shall be made of medium-density gasket material that

3.1.1 air permeance—therateofairflow(L/s),perunitarea

2

can be fused or glued at joints. The test apparatus shall contain

(m ) and per unit static pressure differential (Pa).

an over-pressure control device and windows to verify the

4. Significance and Use

specimen installation.

6.1.2 Flow Measuring Devices—The flow measuring de-

4.1 The purpose of this test is to measure the air permeance

vices used to gage the air flow through the test specimen shall

of flexible sheet or rigid panel-type materials. The results of

-6 3

be capable of measuring air flow rate from 1 3 10 m /s (.001

this test may be useful in determining suitability of that

-2 3

L/s) up to 1.88 3 10 m /s (18.8 L/s), with an accuracy of 6

material as a component of an air retarder system.

3 % of the reading.

6.1.3 Pressure Measuring Devices—The static pressure dif-

1

This test method is under the jurisdiction of ASTM Committee E06 on ferentialacrossthetestspecimenshallbemeasuredbypressure

Performance of Buildings and is the direct responsibility of Subcommittee E06.41

measuring devices with an accuracy of 6 0.5 % of the pressure

on Air Leakage and Ventilation Performance.

reading. The laboratory barometric pressure shall be measured

Current edition approved Aug. 10, 2003. Published October 2003. Originally

with a device capable of measuring barometric pressure within

approved in 2001. Last previous edition approved in 2001 as E2178–01 DOI:

10.1520/E2178-03.

6 3 % of the reading.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.4 Piping—The piping connecting the flow measuring

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

devices and the vacuum blower shall be airtight and contain

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. flow control devices to regulate the static pressure across

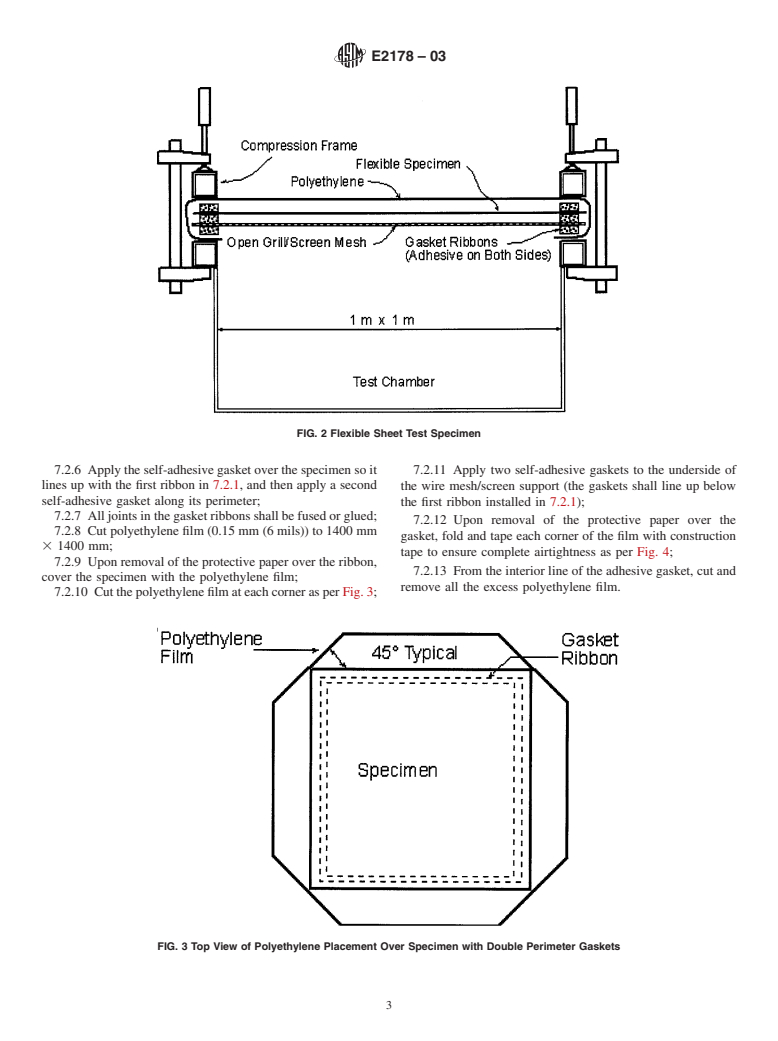

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.