ASTM F2225-15(2020)

(Specification)Standard Safety Specification for Consumer Trampoline Enclosures

Standard Safety Specification for Consumer Trampoline Enclosures

ABSTRACT

This safety specification covers the performance and safety requirements intended to reduce the potential hazards associated with the manufacture and assembly of components, maintenance, use, and labeling of consumer trampoline enclosures. This specification is applicable to trampoline enclosures to be sold as an accessory to or packaged with trampolines of a minimum bed size of 3300 in.2 (2.1 m2); a minimum height of 20 in. (510 mm); intended for the purpose of continuous, vertical jumping activities; and intended for consumer use.

SCOPE

1.1 This safety specification covers the components, assembly, use, labeling, and performance requirements of consumer trampoline enclosures (see Safety Specification F381).

1.2 This specification is applicable to trampoline enclosures to be sold as an accessory to or packaged with trampolines of (1) a minimum bed size of 3300 in.2 (2.1 m2), (2) a minimum height of 20 in. (510 mm), (3) intended for the purpose of continuous, vertical jumping activities, and (4) intended for consumer use.

1.3 This specification includes the following sections and selected subsections:

Section

Scope

1

Referenced Documents

2

Terminology

3

Components

4

General Requirements

5

Performance Requirements

6

Performance Tests

6

Information Packet

7

Product Marking

8

Packaging and Package Marking

9

1.4 This specification does not purport to address all of the hazards that may be associated with trampolines or trampoline enclosures, or both. The standard’s existence alone will not necessarily prevent injuries. Like other physical activities, trampoline use involves the risk of injury, particularly if the equipment is used improperly. Similarly, the use of a trampoline enclosure alone will not necessarily prevent all injuries.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 The following precautionary caveat pertains only to the test methods portion of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2225 −15 (Reapproved 2020) An American National Standard

Standard Safety Specification for

Consumer Trampoline Enclosures

This standard is issued under the fixed designation F2225; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environ-

1.1 This safety specification covers the components,

mental practices and determine the applicability of regulatory

assembly, use, labeling, and performance requirements of

limitations prior to use.

consumer trampoline enclosures (see Safety Specification

1.7 This international standard was developed in accor-

F381).

dance with internationally recognized principles on standard-

1.2 This specification is applicable to trampoline enclosures

ization established in the Decision on Principles for the

to be sold as an accessory to or packaged with trampolines of

Development of International Standards, Guides and Recom-

2 2

(1) a minimum bed size of 3300 in. (2.1 m ), (2) a minimum

mendations issued by the World Trade Organization Technical

height of 20 in. (510 mm), (3) intended for the purpose of

Barriers to Trade (TBT) Committee.

continuous, vertical jumping activities, and (4) intended for

2. Referenced Documents

consumer use.

2.1 ASTM Standards:

1.3 This specification includes the following sections and

D638 Test Method for Tensile Properties of Plastics

selected subsections:

D2240 Test Method for Rubber Property—Durometer Hard-

Section

ness

Scope 1

Referenced Documents 2

F381 Safety Specification for Components, Assembly, Use,

Terminology 3

and Labeling of Consumer Trampolines

Components 4

General Requirements 5 F1077 Guide for Selection of Committee F16 Fastener

Performance Requirements 6

Specifications (Withdrawn 2014)

Performance Tests 6

2.2 ANSI Standard:

Information Packet 7

Product Marking 8 Z535.4 Product Safety Signs and Labels

Packaging and Package Marking 9

2.3 Federal Standards:

1.4 This specification does not purport to address all of the 16 CFR 1500 Hazardous Substances Act Regulations

hazards that may be associated with trampolines or trampoline

16 CFR 1500.48 Technical Requirements for Determining a

enclosures, or both. The standard’s existence alone will not

Sharp Point in Toys and Other Articles Intended for Use

necessarily prevent injuries. Like other physical activities,

by Children Under 8 Years of Age

trampoline use involves the risk of injury, particularly if the

16 CFR 1500.49 Technical Requirements for Determining a

equipment is used improperly. Similarly, the use of a trampo- Sharp Metal or Glass Edge in Toys and Other Articles

line enclosure alone will not necessarily prevent all injuries.

Intended for Use by Children Under 8 Years of Age

2.4 AATCC Standard:

1.5 The values stated in inch-pound units are to be regarded

AATCC 169 Weather Resistance of Textiles: Xenon Lamp

as standard. The values given in parentheses are mathematical

Exposure

conversions to SI units that are provided for information only

and are not considered standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1.6 The following precautionary caveat pertains only to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

test methods portion of this specification. This standard does

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

not purport to address all of the safety concerns, if any,

The last approved version of this historical standard is referenced on

www.astm.org.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

This safety specification is under the jurisdiction ofASTM Committee F08 on 4th Floor, New York, NY 10036.

Sports Equipment, Playing Surfaces, and Facilities and is the direct responsibility of Available from Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA

Subcommittee F08.17 on Trampolines and Related Equipment. 15250–7954.

Current edition approved April 1, 2020. Published April 2020. Originally Available from American Association of Textile Chemists and Colorists

approved in 2003. Last previous edition approved in 2015 as F2225 – 15. DOI: (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

10.1520/F2225-15R20. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2225−15 (2020)

3. Terminology 5.4 All fasteners shall be manufactured in accordance with

Section 5.4.2 of Guide F1077. All fasteners, connecting, and

3.1 Definitions of Terms Specific to This Standard:

covering devices shall be inherently corrosion resistant or be

3.1.1 attachment system, n—the complete manner in which

provided with corrosion resistant coating.

certain components are connected.

5.4.1 When installed in accordance with the manufacturer’s

3.1.2 barrier, n—an enclosing device constructed of netting,

instructions, fasteners, lock washers, self-locking nuts, or other

fabric, or other material that is intended to prevent both

lockingmeansshallbeprovidedforallnutsandboltstoprotect

inadvertent and deliberate attempts to pass through the device.

them from unintentional loosening. Hardware in moving joints

3.1.3 barrier height, n—the distance from the bed surface at

shall also be secured against unintentional loosening.

rest to the upper edge of the barrier measured at a support.

5.4.2 There shall be no accessible sharp points or edges on

3.1.4 barriersystem,n—anenclosingdevicethatisintended

fasteners. A cut-off bolt end projecting beyond the face of the

to prevent both inadvertent and deliberate attempts to pass

nut shall be free of burrs, sharp points, and sharp edges. An

through the device forming the enclosure suspended from or

accessible bolt end shall not extend more than two full threads

attached, or both, to enclosure support (frame).

beyond the face of a nut.

3.1.5 enclosure, n—equipment which reduces the risk of the

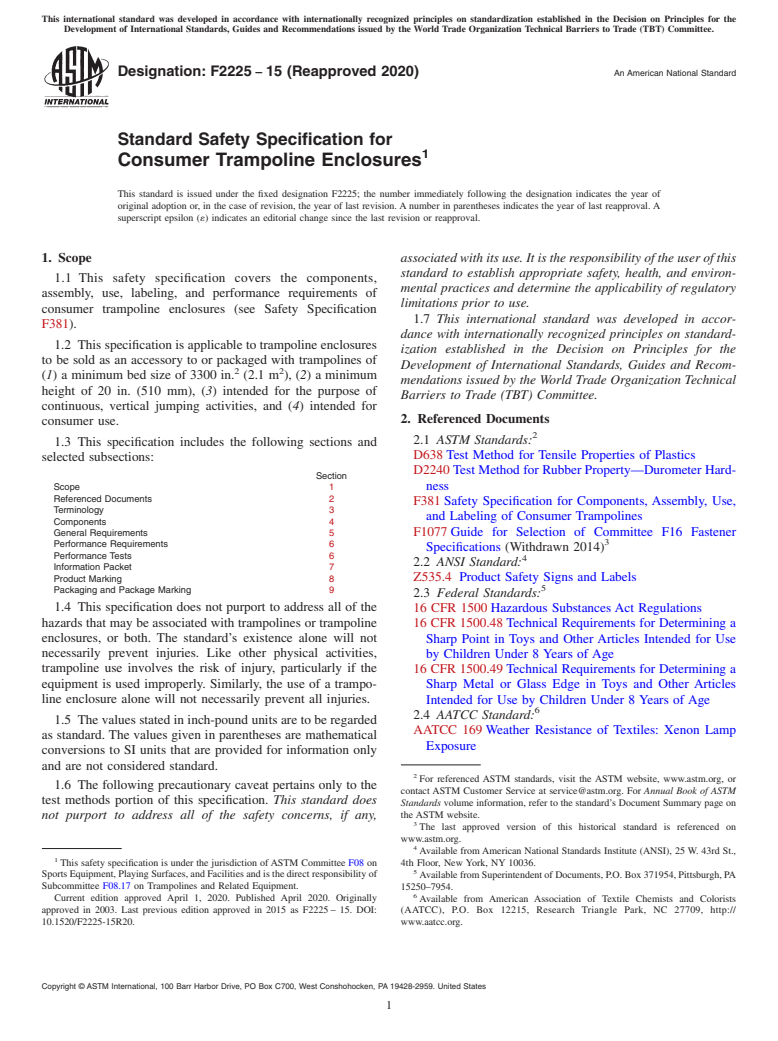

5.5 Connecting devices such as but not limited to S-hooks

user falling off the trampoline.

and C-hooks shall be properly closed. These connectors are

3.1.6 enclosure support (frame) attachment system, n—the

considered closed when there is no gap or space greater than

framework constructed of supportive materials from which the

0.04 in. (1 mm) when measured with a feeler gage.

enclosure barrier is suspended or attached, or both, and the

manner in which components are connected. 5.5.1 S-hook connectors are subject to the following addi-

tional requirements: (1) No portion of the closed end of an

3.1.7 maximum specified user weight, n—maximum weight

S-hook upper loop may project beyond the vertical boundary

of a user as specified by the manufacturer. The manufacturer

established by the upper loop; (2) an S-hook upper loop may

shall ensure the maximum specified user weight meets the

align with, may partially overlap, or may completely overlap

requirements of Safety Specification F381 Section 6 for the

the connector body. If the upper loop completely overlaps the

trampoline on which the enclosure is mounted.

connector body, it must not extend past the connector body, or

3.1.8 upright pole caps, n—covering cap on exposed enclo-

(3) an S-hook lower loop must align with the connector body

sure support (frame) pole ends to prevent cuts, abrasion or

and not overlap in any way. (See Fig. 1.)

impalement.

5.6 The enclosure barrier shall be a durable weather resis-

4. Components

tant fabric suitable for extended outdoor life. Materials used in

4.1 A trampoline enclosure system when offered for sale

the barrier and any fabric, cord, or webbing connections

shall include the following components:

supporting the barrier that are normally exposed to sunlight

4.1.1 Enclosure support system padding and upright pole

shall be made of ultraviolet (UV) resistant materials.

caps,

4.1.2 Enclosure support (frame) and attachment system, 5.7 Support (frame) members exposed to contact during

4.1.3 Enclosure barrier,

foreseeable usage shall be padded.The top end of such support

4.1.4 Enclosure barrier attachment system,

(frame) members shall be capped.

4.1.5 Information packet/user manual, and

5.8 The barrier attachment system shall include (1) upper

4.1.6 Suitable on-product and on-package warnings.

attachment to upright supports (frame), and (2) lower attach-

5. General Requirements ment to trampoline bed or trampoline frame top rails. The

barrier attachment system shall be of sufficient strength and

5.1 The barrier height shall have the following minimums:

durability to withstand tearing, deformation or failure as a

5.1.1 For round trampolines with bed diameter at less than

result of the loads outlined in 6.1 (Performance Requirement

10 ft (2.5 m) – 60 in. (1.5 m).

Test #1).

5.1.2 For round trampolines with a bed diameter of 10 ft

(2.5 m) (or more) – 72 in. (1.8 m).

5.9 Enclosure Openings—The enclosure barrier shall in-

5.1.3 For rectangular trampolines—one-half the length of

clude an opening allowing entry and exit of the user from the

the longest bed dimension, but not less than 60 in. (1.5 m)

jumping surface. This opening, when closed according to the

minimum barrier height.

manufacturer’s instructions, shall be of sufficient strength and

5.2 The enclosure support (frame) system and barrier ma-

durability to withstand, without tearing, deformation or failure,

terials shall be of sufficient strength and rigidity to hold the

adirectimpactoftheloadsatthepointoftheopeningand8in.

enclosure barrier in place and withstand the loads outlined in

to the left and to the right of the opening (outlined in 6.1,

Performance Requirement Test #1.

Performance Requirement Test #1) with no penetration of any

portion of the test load beyond the outer edges of the opening

5.3 Support attachment system and hardware shall be sub-

ject to ready assembly by the original retail consumer and shall or any opening of the barrier itself. If the enclosure barrier

opening is overlapped, the opening point is considered the

meet the requirements set forth in 6.1 (Performance Require-

ment Test #1). midsection of the overlap.

F2225−15 (2020)

FIG. 1Requirements for Connecting Devices

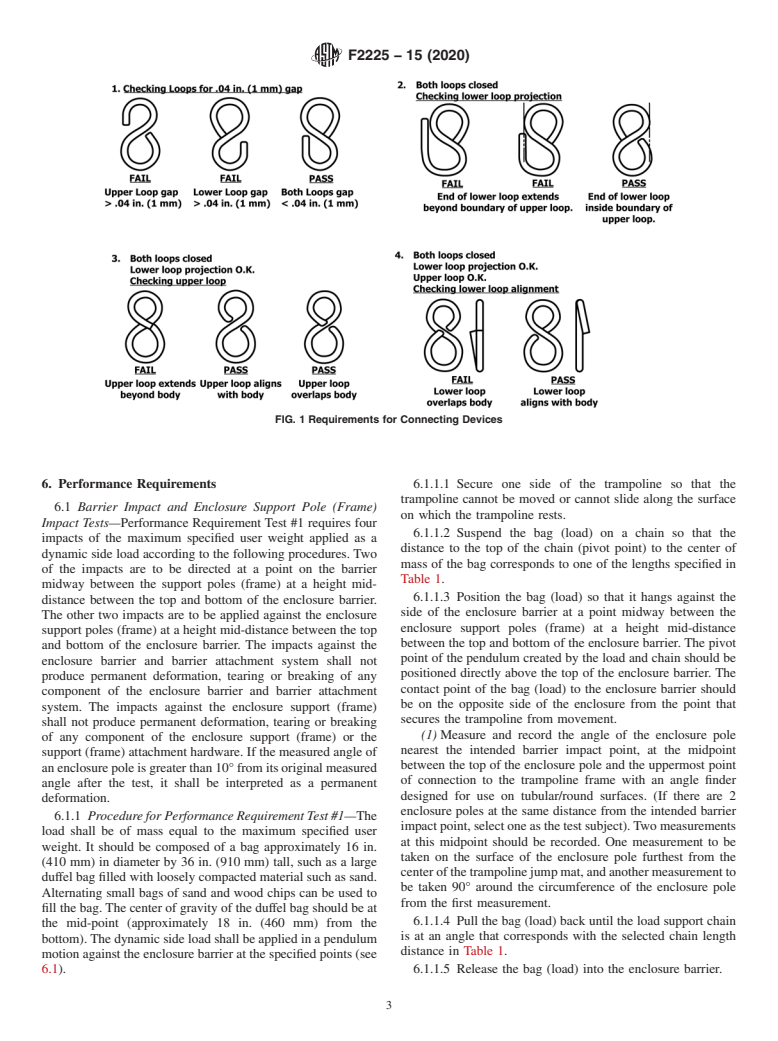

6. Performance Requirements 6.1.1.1 Secure one side of the trampoline so that the

trampoline cannot be moved or cannot slide along the surface

6.1 Barrier Impact and Enclosure Support Pole (Frame)

on which the trampoline rests.

Impact Tests—Performance Requirement Test #1 requires four

6.1.1.2 Suspend the bag (load) on a chain so that the

impacts of the maximum specified user weight applied as a

distance to the top of the chain (pivot point) to the center of

dynamic side load according to the following procedures. Two

mass of the bag corresponds to one of the lengths specified in

of the impacts are to be directed at a point on the barrier

Table 1.

midway between the support poles (frame) at a height mid-

6.1.1.3 Position the bag (load) so that it hangs against the

distance between the top and bottom of the enclosure barrier.

side of the enclosure barrier at a point midway between the

The other two impacts are to be applied against the enclosure

enclosure support poles (frame) at a height mid-distance

support poles (frame) at a height mid-distance between the top

between the top and bottom of the enclosure barrier. The pivot

and bottom of the enclosure barrier. The impacts against the

point of the pendulum created by the load and chain should be

enclosure barrier and barrier attachment system shall not

positioned directly above the top of the enclosure barrier. The

produce permanent deformation, tearing or breaking of any

contact point of the bag (load) to the enclosure barrier should

component of the enclosure barrier and barrier attachment

be on the opposite side of the enclosure from the point that

system. The impacts against the enclosure support (frame)

secures the trampoline from movement.

shall not produce permanent deformation, tearing or breaking

(1) Measure and record the angle of the enclosure pole

of any component of the enclosure support (frame) or the

nearest the intended barrier impact point, at the midpoint

support (frame) attachment hardware. If the measured angle of

between the top of the enclosure pole and the uppermost point

anenclosurepoleisgreaterthan10°fromitsoriginalmeasured

of connection to the trampoline frame with an angle finder

angle after the test, it shall be interpreted as a permanent

designed for use on tubular/round surfaces. (If there are 2

deformation.

enclosure poles at the same distance from the intended barrier

6.1.1 ProcedureforPerformanceRequirementTest#1—The

impactpoint,selectoneasthetestsubject).Twomeasurements

load shall be of mass equal to the maximum specified user

at this midpoint should be recorded. One measurement to be

weight. It should be composed of a bag approximately 16 in.

taken on the surface of the enclosure pole furthest from the

(410 mm) in diameter by 36 in. (910 mm) tall, such as a large

centerofthetrampolinejumpmat,andanothermeasurementto

duffel bag filled with loosely compacted material such as sand.

be taken 90° around the circumference of the enclosure pole

Alternating small bags of sand and wood chips can be used to

from the first measurement.

fill the bag. The center of gravity of the duffel bag should be at

6.1.1.4 Pull the bag (load) back until the load support chain

the mid-point (approximately 18 in. (460 mm) from the

is at an angle that corresponds with the selected chain length

bottom).The dynamic side load shall be applied in a pendulum

distance in Table 1.

motion against the enclosure barrier at the specified points (see

6.1). 6.1.1.5 Release the bag (load) into the enclosure barrier.

F2225−15 (2020)

TABLE 1 Length to Center of Mass and Angle

to the right, as measured from the inside of the enclosure, from

Pendulum Length to Pendulum Length to Pendulum Angle the enclosure opening as established in 6.1.1.11.

Center of the Mass Center of the Mass Relative to

6.1.1.15 Repeat the test methods in 6.1.1.12 and 6.1.1.13.

of Bag (feet) of Bag (metres) Vertical (degrees)

6.1.1.16 Repeat the preparation for impact tests as estab-

10 3.0 30.0

lished in 6.1.1.11, except the position of the bag (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.