ASTM F2892-11

(Specification)Standard Specification for Performance Requirements for Soft Toe Protective Footwear (Non-Safety / Non-Protective Toe)

Standard Specification for Performance Requirements for Soft Toe Protective Footwear (Non-Safety / Non-Protective Toe)

ABSTRACT

This specification provides certification of protective footwear. It includes performance requirements for footwear to protect workers' feet from a variety of workplace hazards.

SCOPE

1.1 The principle purpose of this specification is the certification of protective footwear. Certification must be performed by independent third party laboratories in order for footwear to bare the ASTM marking.

1.2 The specification contains performance requirements for footwear to protect workers' feet from the following hazards by providing: (1) conductive properties (Cd) which reduce hazards that may result from static electricity buildup; and reduce the possibility of ignition of explosives and volatile chemicals; (2) electric hazard protection (EH), to protect the wearer when accidental contact by stepping on live electric wires; (3) static dissipative properties (SD) to reduce hazards due to excessively low footwear electrical resistance that may exist where SD footwear is required; (4) puncture resistance (PR) footwear devices.

1.3 This specification covers minimum requirements for the performance of footwear to provide protection against a variety of workplace hazards other than the toe area that can potentially result in injury.

1.4 This specification is not intended to serve as a detailed manufacturing or purchasing specification, but can be referenced in purchase contracts to ensure that minimum performance requirements are met.

1.5 Controlled laboratory tests used to determine compliance with the performance requirements of this specification shall not be deemed as establishing performance levels for all situations to which individuals may be exposed.

1.6 Any changes to the original components of safety footwear such as replacing or adding after market footbeds/inserts could cause failure to any or all parts, or a combination thereof, of this specification rendering the ASTM Soft Toe Protective Footwear label invalid.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2892 −11

Standard Specification for

Performance Requirements for Soft Toe Protective Footwear

(Non-Safety / Non-Protective Toe)

This standard is issued under the fixed designation F2892; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

CurrentASTM standards F2412 and F2413 provide test methods and performance requirements for

footwear requiring a protective safety toe cap. In industry there are many jobs that do not require toe

protection from impact or compression. This committee has developed non-safety toe cap (soft toe)

requirements to allow manufacturers to demonstrate the performance level of non-safety toe cap (soft

toe) footwear.

1. Scope 1.6 Any changes to the original components of safety

footwear such as replacing or adding after market footbeds/

1.1 The principle purpose of this specification is the certi-

inserts could cause failure to any or all parts, or a combination

ficationofprotectivefootwear.Certificationmustbeperformed

thereof, of this specification rendering the ASTM Soft Toe

by independent third party laboratories in order for footwear to

Protective Footwear label invalid.

bare the ASTM marking.

1.7 The values stated in SI units are to be regarded as

1.2 Thespecificationcontainsperformancerequirementsfor

standard. No other units of measurement are included in this

footwear to protect workers’ feet from the following hazards

standard.

by providing: (1) conductive properties (Cd) which reduce

1.8 This standard does not purport to address all of the

hazards that may result from static electricity buildup; and

safety concerns, if any, associated with its use. It is the

reduce the possibility of ignition of explosives and volatile

responsibility of the user of this standard to establish appro-

chemicals; (2) electric hazard protection (EH), to protect the

priate safety and health practices and determine the applica-

wearer when accidental contact by stepping on live electric

bility of regulatory limitations prior to use.

wires; (3) static dissipative properties (SD) to reduce hazards

due to excessively low footwear electrical resistance that may

2. Referenced Documents

exist where SD footwear is required; (4) puncture resistance

(PR) footwear devices. 2.1 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

1.3 This specification covers minimum requirements for the

F1646 Terminology Relating to Safety and Traction for

performanceoffootweartoprovideprotectionagainstavariety

Footwear

of workplace hazards other than the toe area that can poten-

F2412 Test Methods for Foot Protection

tially result in injury.

F2413 Specification for Performance Requirements for Pro-

1.4 This specification is not intended to serve as a detailed

tective (Safety) Toe Cap Footwear

manufacturing or purchasing specification, but can be refer- 3

2.2 Federal Standards:

enced in purchase contracts to ensure that minimum perfor-

29 CFR 1910.132 Personal Protective Equipment–General

mance requirements are met.

Requirements

1.5 Controlled laboratory tests used to determine compli-

29 CFR 1910.136 Personal Protective Equipment–Occupa-

ance with the performance requirements of this specification tional Foot Protection

shall not be deemed as establishing performance levels for all

situations to which individuals may be exposed.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This specification is under the jurisdiction of ASTM Committee F13 on Standards volume information, refer to the standard’s Document Summary page on

Pedestrian/Walkway Safety and Footwear and is the direct responsibility of the ASTM website.

Subcommittee F13.30 on Footwear. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Current edition approved July 1, 2011. Published August 2011. DOI: 10.1520/ Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

F2892-11. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2892 − 11

2.3 Canadian Standards Association Standard 4.1.4 Puncture resistance footwear devices, (PR).

CAN/CSA Z195 Protective Footwear

4.2 Any changes to the original components of the soft toe

protective footwear such as replacing or adding after market

3. Terminology

footbeds/inserts could cause failure to any or all parts, or a

3.1 Definitions:

combination thereof, of this standard rendering the ASTM

3.1.1 box toes, n—are semi-rigid materials which can be

MARKING INVALID. Soft Toe Protective footwear speci-

molded to the shape of the last during shoe making. This

mens or samples shall be retested for any of the following

provides the reinforcement and shape retention on the critical

changes.

area of the toe of the footwear.

4.2.1 Changeinconstructionmethodusedtomakefootwear

3.1.2 insert/footbed/sockliner, (all removable), n—footbed

or change in factory in which footwear is produced.

normally made of a foam product with leather or fabric cover

4.2.2 Change in the upper or insole material thickness

shapedtocovertheentireinsolewhichcanbeinsertedbetween

greater than 25 %, change to the soling system, or a change in

the foot and insole board.

the hardness of the outsole.

3.1.3 insole, n—foundation of the shoe; the inner sole of the

4.2.3 Change in shape of last used in the manufacturing of

shoe which is next to the foot, under the sockliner or the insert,

footwear.

onto which the upper is lasted.

4.2.4 Change in material or supplier of protective insole.

3.1.4 last, n—solid hinged form, in the general shape of a

foot, around which footwear is constructed.

5. Performance Requirements for Foot Protection

3.1.5 lasting, v—building of footwear around a specific last.

5.1 Conductive Protective Footwear (Cd):

3.1.6 lining, n—term used to describe all components that

NOTE 1—Conductive footwear is not intended to be worn by personnel

can be used to construct the interior of the upper part of the

working near open electrical circuits.

footwear.

5.1.1 Conductive protective footwear shall be constructed

3.1.7 product category, n—description for a type of foot-

and manufactured to provide protection for the wearer through

wear designed and manufactured for a specific hazard or

conductance with a maximum 500 000 ohm resistance, against

hazards.

hazards that may result from static electricity buildup, thus

3.1.8 protective footwear, n—footwear that is designed,

reducingthepossibilityofignitionofanexplosioninsituations

constructed, and classified to protect the wearer from a

such as munitions manufacture.

potential hazard or hazards.

5.1.1.1 Footwear shall dissipate static electricity from the

3.1.9 quarter, n—entire back portion of the footwear upper.

body to reduce the possibility of ignition of volatile com-

3.1.10 size, n—length and breadth measurements of foot-

pounds.

wear determined by using a specific grading; the American

5.1.1.2 Footwear shall be of a construction that facilitates a

system of footwear grading.

stable electrically conductive path. All external components

3.1.11 socklining (non-removable), n—material placed over

shall be made of non metallic materials.

the insole, footbed or insert which maybe imprinted with a

5.1.2 Conductive protective footwear shall be determined

brand name or other designation.

by evaluating three specimens in accordance with Test Meth-

ods F2412.

3.1.12 soft toe (absence of protective toe cap), n—which are

commonly called box toe in footwear industry.

5.1.3 The specimens shall demonstrate resistance between 0

and 500 000 ohms.

3.1.13 soling material, n—exterior bottom platform of the

footwear; the bottom surface. 5.1.4 Any specimen or sample of conductive footwear that

does not meet the performance requirement constitutes a non

3.1.14 upper, n—parts of a shoe or boot that are above the

compliance for the product category.

bottom of the foot.

5.2 Electric Hazard Resistant Footwear (EH):

4. Significance and Use

NOTE 2—Electrical hazard protection is severely deteriorated in the

4.1 This specification contains requirements to evaluate the

followingconditions:excessivewearonthesolingmaterialorexposureto

performance of footwear for the following:

wet and humid environments, or both. Work footwear can become

4.1.1 Conductive properties which reduce hazards that may

contaminated with conductive materials. For example, soles can pick up

result from static electricity buildup, and reduce the possibility

metal shavings etc. which may reduce the effectiveness of the protection.

In step potential environments, dielectric overshoes should be used.

of ignition of explosives and volatile chemicals, (Cd).

4.1.2 Electric hazard by stepping on live wire (EH).

5.2.1 Electric hazard footwear shall be constructed, and

4.1.3 Static dissipative (SD) properties to reduce hazards

manufactured so that the footwear outsole can provide a

due to excessively low footwear electrical resistance that may

SECONDARY SOURCE OF ELECTRIC HAZARD PRO-

exist

...

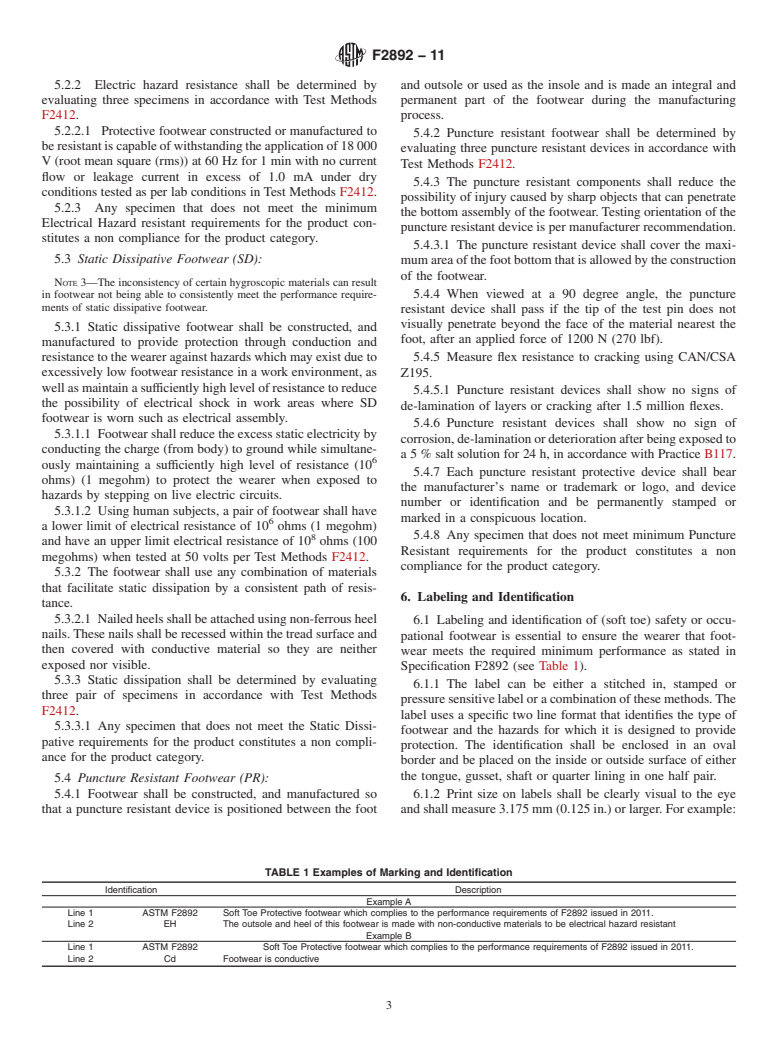

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.