ASTM D6637-01

(Test Method)Standard Test Method for Determining Tensile Properties of Geogrids by the Single or Multi-Rib Tensile Method

Standard Test Method for Determining Tensile Properties of Geogrids by the Single or Multi-Rib Tensile Method

SIGNIFICANCE AND USE

The determination of the tensile force-elongation values of geogrids provides index property values. This test method shall be used for quality control and acceptance testing of commercial shipments of geogrids.

In cases of dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using student’t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing began. If a bias is found, either its cause must be found and corrected or the purchaser and supplier must agree to interpret future test results in light of the known bias.

All geogrids can be tested by any of these methods. Some modification of techniques may be necessary for a given geogrid depending upon its physical make-up. Special adaptations may be necessary with strong geogrids, multiple layered geogrids, or geogrids that tend to slip in the clamps or those which tend to be damaged by the clamps.

SCOPE

1.1 These test methods cover the determination of the tensile strength properties of geogrids by subjecting strips of varying width to tensile loading.

1.2 Three alternative procedures are provided to determine the tensile strength, as follows:

1.2.1 Method A--Testing a single geogrid rib in tension (N or lbf).

1.2.2 Method B--Testing multiple geogrid ribs in tension (kN/m or lbf/ft).

1.2.3 Method C--Testing multiple layers of multiple geogrid ribs in tension (kN/m or lbf/ft)

1.3 This test method is intended for quality control and conformance testing of geogrids.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound values stated in parentheses are provided for information only.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6637–01

Standard Test Method for

Determining Tensile Properties of Geogrids by the Single or

Multi-Rib Tensile Method

This standard is issued under the fixed designation D 6637; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 atmosphere for testing geosynthetics, n—air main-

tained at a relative humidity of 50 to 70 % and a temperature

1.1 These test methods cover the determination of the

of 21 6 2°C (70 6 4°F).

tensile strength properties of geogrids by subjecting strips of

3.1.2 breaking force, (F), n—the force at failure.

varying width to tensile loading.

3.1.3 corresponding force, n—synonym for force at speci-

1.2 Three alternative procedures are provided to determine

fied elongation.

the tensile strength, as follows:

3.1.4 force at specified elongation, FASE, n—a force asso-

1.2.1 Method A—Testing a single geogrid rib in tension (N

ciated with a specific elongation on the force-elongation curve.

or lbf).

(synonym for corresponding force.)

1.2.2 Method B—Testing multiple geogrid ribs in tension

3.1.5 force-elongation curve, n—in a tensile test, a graphi-

(kN/m or lbf/ft).

cal representation of the relationship between the magnitude of

1.2.3 Method C—Testing multiple layers of multiple geo-

an externally applied force and the change in length of the

grid ribs in tension (kN/m or lbf/ft)

specimen in the direction of the applied force. (synonym for

1.3 This test method is intended for quality control and

stress-strain curve.)

conformance testing of geogrids.

3.1.6 geogrid, n—a geosynthetic formed by a regular net-

1.4 The values stated in SI units are to be regarded as the

work of integrally connected elements with aperetures greater

standard. The inch-pound values stated in parentheses are

than 6.35 mm ( ⁄4 inch) to allow interlocking with surrounding

provided for information only.

soil, rock, earth, and other surrounding materials to primarily

1.5 This standard may involve hazardous materials, opera-

function as reinforcement. (D 5262)

tions, and equipment. This standard does not purport to

3.1.7 integral, adj—in geosynthetics, forming a necessary

address all of the safety concerns, if any, associated with its

part of the whole; a constituent.

use. It is the responsibility of the user of this standard to

3.1.8 geosynthetic, n—a product manufactured from poly-

establish appropriate safety and health practices and deter-

meric material used with soil, rock, earth, or other geotechnical

mine the applicability of regulatory limitations prior to use.

engineering related material as an integral part of a man made

2. Referenced Documents project, structure, or system.

3.1.9 index test, n—a test procedure which may contain

2.1 ASTM Standards:

known bias, but which may be used to establish an order for a

D 76 Specifications for Tensile Testing Machines for Tex-

set of specimens with respect to the property of interest.

tiles

3.1.10 junction, n—the point where geogrid ribs are inter-

D 123 Terminology Relating to Textiles

connected to provide structure and dimensional stability.

D 1909 Table of Commercial Moisture Regains for Textile

3.1.11 rib , n—for geogrids, the continuous elements of a

Fibers

geogrid which are either in the machine or cross-machine

D 4354 Practice for Sampling of Geosynthetics for Testing

direction as manufactured.

D 4439 Terminology for Geosynthetics

3.1.12 rupture, n—for geogrids, the breaking or tearing

3. Terminology

apart of ribs.

3.1.13 tensile, adj—capable of tensions, or relating to ten-

3.1 Definitions:

sion of a material.

3.1.14 tensile strength, (a ), n—for geogrids the maximum

f

This test method is under the jurisdiction of ASTM Committee D35 on

resistance to deformation developed for a specific material

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

cal Properties. whensubjectedtotensionbyanexternalforce.Tensilestrength

Current edition approved Feb. 10, 2001. Published May 2001.

of geogrids is the characteristic of a sample as distinct from a

Annual Book of ASTM Standards, Vol 07.01.

specimen and is expressed in force per unit width.

Annual Book of ASTM Standards, Vol 04.13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6637–01

3.1.15 tensile test, n—for geosynthetics, a test in which a geogrids, or geogrids that tend to slip in the clamps or those

material is stretched uniaxially to determine the force- which tend to be damaged by the clamps.

elongation characteristics, the breaking force, or the breaking

6. Apparatus

elongation.

3.1.16 tension, n—the force that produces a specified elon-

6.1 Testing Clamps—The clamps shall be sufficiently wide

gation.

to grip the entire width of the specimen (as determined by the

3.2 For definitions of other terms used in this test method,

test method) and with appropriate clamping power to prevent

refer to Terminologies D 123 and D 4439.

slipping or crushing (damage). For a given product, the same

clamps shall be used in testing methods A, B, and C prior to

4. Summary of Test Method

making any comparison between results.

4.1 Method A—In this method, a single, representative rib

6.1.1 Size of Jaw Faces—Each clamp shall have jaw faces

specimen of a geogrid is clamped and placed under a tensile

measuring wider than the width of the specimen.

force using a constant rate of extension testing machine. The

6.2 Tensile Testing Machine—A testing machine of the

tensile force required to fail (rupture) the specimen is recorded.

constant rate of extension type as described in Specification

The ultimate single rib tensile strength (N or lbf) is then

D 76 shall be used. The machine shall be equipped with a

determined based on the average of six single rib tensile tests.

device for recording the tensile force and the amount of

4.2 Method B—A relatively wide specimen is gripped

separation of the grips. Both of these measuring systems shall

across its entire width in the clamps of a constant rate of

be accurate to 6 1.0 % and, preferably, shall be external to the

extension type tensile testing machine operated at a prescribed

testing machine. The rate of separation shall be uniform and

rateofextension,applyingauniaxialloadtothespecimenuntil

capable of adjustment within the range of the test.

the specimen ruptures. Tensile strength (kN/m or lbf/ft),

6.3 Distilled Water and Nonionic Wetting Agent, shall be

elongation, and secant modulus of the test specimen can be

used for wet specimens only.

calculated from machine scales, dials, recording charts, or an

6.4 Extensometer—When required by the method, a device

interfaced computer.

capable of measuring the distance between two reference

4.3 Method C—A relatively wide, multiple layered speci-

points on the specimen without any damage to the specimen or

men is gripped across its entire width in the clamps of a

slippage, care being taken to ensure that the measurement

constantrateofextensiontypetensiletestingmachineoperated

represents the true movement of the reference points. Ex-

ataprescribedrateofextension,applyingauniaxialloadtothe

amples of extensometers include mechanical, optical, infrared

specimen until the specimen ruptures. Tensile strength (kN/m

or electrical devices.

or lbf/ft), elongation and secant modulus of the test specimen

can be calculated from machine scales, dials recording charts, 7. Sampling

or an interfaced computer.

7.1 Lot Sample—Divide the product into lots and take the

lot sample as directed in Practice D 4354.

5. Significance and Use

7.2 Laboratory Sample—For the laboratory sample, take a

5.1 The determination of the tensile force-elongation values

full roll width swatch long enough in the machine direction

of geogrids provides index property values. This test method

from each roll in the lot sample to ensure that the requirements

shall be used for quality control and acceptance testing of

in 8.1 can be met. The sample may be taken from the end

commercial shipments of geogrids.

portion of a roll provided there is no evidence it is distorted or

5.2 In cases of dispute arising from differences in reported

different from other portions of the roll.

test results when using this test method for acceptance testing

of commercial shipments, the purchaser and supplier should

8. Test Specimen

conduct comparative tests to determine if there is a statistical

8.1 Thespecimensshallconsistofthree(3)junctionsor300

bias between their laboratories. Competent statistical assis-

mm in length (12 in.), in order to establish a minimum

tance is recommended for the investigation of bias. As a

specimen length in the direction of the test (either the machine

minimum, the two parties should take a group of test speci-

or cross-machine direction). All specimens should be free of

mens which are as homogeneous as possible and which are

surface defects, etc., not typical of the laboratory sample. Take

from a lot of material of the type in question. The test

no specimens nearer the selvage edge along the geogrid than

specimens should then be randomly assigned in equal numbers

⁄10 the width of the sample.

to each laboratory for testing.The average results from the two

NOTE 1—If a comparison of one geogrid to another is to be made the

laboratories should be compared using student’s t-test for

length of each specimen shall be the same (as similar as possibly) and

unpaireddataandanacceptableprobabilitylevelchosenbythe

agreed upon by all parties.

twopartiesbeforethetestingbegan.Ifabiasisfound,eitherits

cause must be found and corrected or the purchaser and 8.2 Preparation:

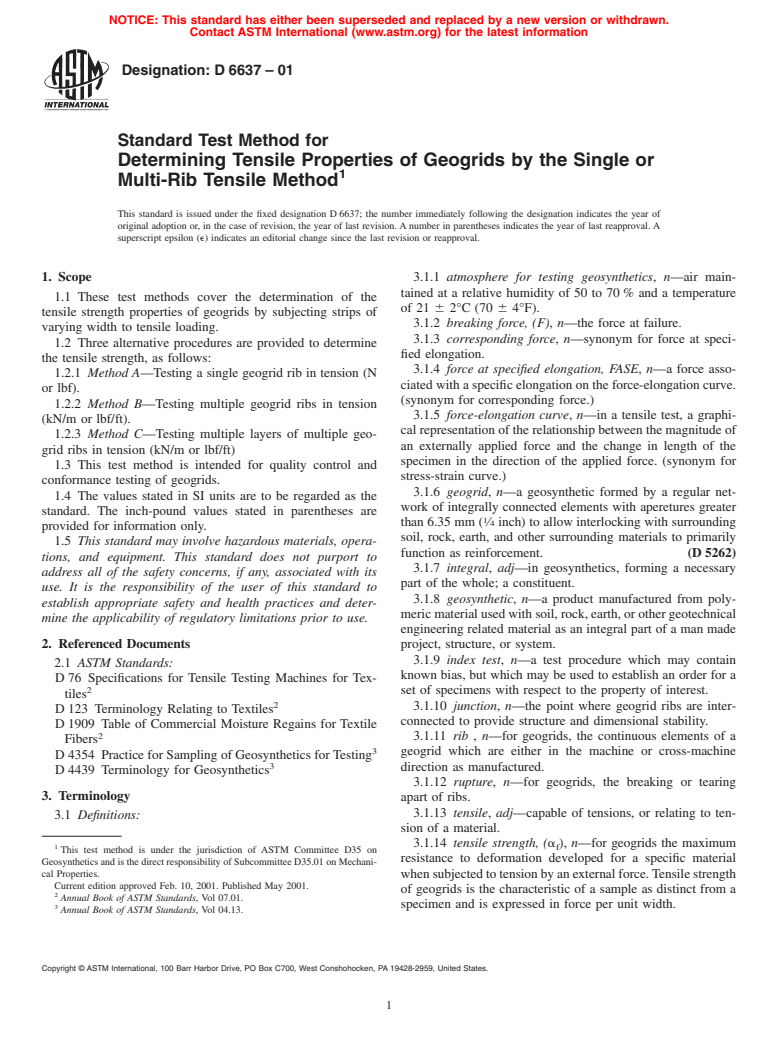

supplier must agree to interpret future test results in light of the 8.2.1 Method A—Prepare each finished specimen, as shown

known bias. in Fig. 1, to contain one rib in the cross-test wide by at least

5.3 All geogrids can be tested by any of these methods. three junctions (two apertures) long in the direction of the

Some modification of techniques may be necessary for a given testing, with the length dimension being designated and accu-

geogrid depending upon its physical make-up. Special adapta- rately cut parallel to the direction for which the tensile strength

tions may be necessary with strong geogrids, multiple layered is being measured.

D6637–01

n 5 ~tv/A! (1)

where:

n = number of test specimens (rounded upward to a whole

number),

v = reliable estimate of the coefficient of variation of

individual observations on similar materials in the

user’s laboratory under conditions of single-operator

precision, %,

t = the value of Student’s t for one-sided limits, a 95 %

FIG. 1 Specimen Dimensions for Method A probability level, and the degrees of freedom associ-

ated with the estimate of v, and;

A = 5.0 % of the average, the value of allowable variation.

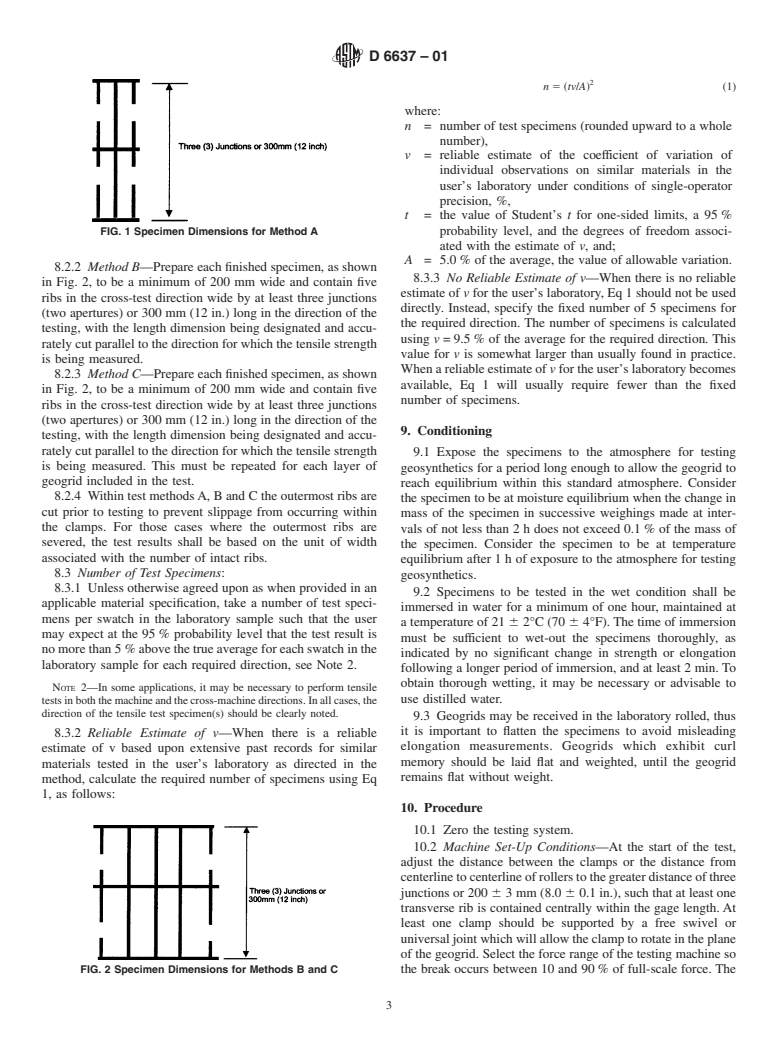

8.2.2 Method B—Prepare each finished specimen, as shown

8.3.3 No Reliable Estimate of v—When there is no reliable

in Fig. 2, to be a minimum of 200 mm wide and contain five

estimate of v for the user’s laboratory, Eq 1 should not be used

ribs in the cross-test direction wide by at least three junctions

directly. Instead, specify the fixed number of 5 specimens for

(two apertures) or 300 mm (12 in.) long in the direction of the

the required direction. The number of specimens is calculated

testing, with the length dimension being designated and accu-

using v = 9.5 % of the average for the required direction. This

rately cut parallel to the direction for which the tensile strength

value for v is somewhat larger than usually found in practice.

is being measured.

When a reliable estimate of v for the user’s laboratory becomes

8.2.3 Method C—Prepare each finished specimen, as shown

available, Eq 1 will usually require fewer than the fixed

in Fig. 2, to be a minimum of 200 mm wide and contain five

number of specimens.

ribs in the cross-test direction wide by at least three junctions

(two apertures) or 300 mm (12 in.) long in the direction of the

9. Conditioning

testing, with the length dimension being designated and accu-

rately cut parallel to the direction for which the tensile strength

9.1 Expose the specimens to the atmosphere for testing

is being measured. This must be repeated for each layer of

geosynthetics for a period long enough to allow the geogrid to

geogrid included in the test.

reach equilibrium within this standard atmosphere. Consider

8.2.4 Within test methodsA, B and C the outermost ribs are

the specimen to be at moisture equilibrium when the change in

cut prior to testing to prevent slippage from occurring within

mass of the specimen in successive weighings made at inter-

the clamps. For those cases where the outermost ribs are

vals of not less than 2 h does not exceed 0.1 % of the mass of

severed, the test results shall be based on the unit of width

the specimen. Consider the specimen to be at temperature

associated with the number of intact ribs.

equilibrium after1hof exposure to the atmosphere for testing

8.3 Number of Test Specimens:

geosynthetics.

8.3.1 Unless otherwise agreed upon as when provided in an

9.2 Specimens to be tested in the wet condition shall be

applicable material specification, take a number of test speci-

immersed in water for a minimum of one hour, maintained at

mens per swatch in the laboratory sample such that the user

a temperature of 21 6 2°C (70 6 4°F). The time of immersion

may expect at the 95 % probability level that the test result is

must be sufficient to wet-out the specimens thoroughly, as

nomorethan5 %abovethetrueaverageforeachswatchinthe

indicated by no significant change in strength or elongation

laboratory sample for each required direction, see Note 2.

following a longer period of immersion, and at least 2 min. To

obtain thorough wetting, it may be necessary or advisable to

NOTE 2—In some applications, it may be necessary to perform tensile

use distilled water.

testsinboththemachineandthecross-machinedirections.Inallcases,the

direction of the tensile test specimen(s) should be clearly noted.

9.3 Geogrids may be received in the laboratory rolled, thus

it is important to flatten the specimens to avoid misleading

8.3.2 Reliable Estimate of v—When there is a reliable

elongation measurements. Geogrids which exhibit curl

estimate of v based upon extensive past records for similar

memory should be laid flat and weighted, until the geogrid

materials tested in the user’s laboratory as directed in the

remains flat without weight.

method, calculate the required number of specimens using Eq

1, as follows:

10. Proc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.