ASTM D1709-03

(Test Method)Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

SCOPE

1.1 These test methods cover the determination of the energy that causes plastic film to fail under specified conditions of impact of a free-falling dart. This energy is expressed in terms of the weight (mass) of the missile falling from a specified height which would result in 50 % failure of specimens tested.

1.2 Two test methods are described:

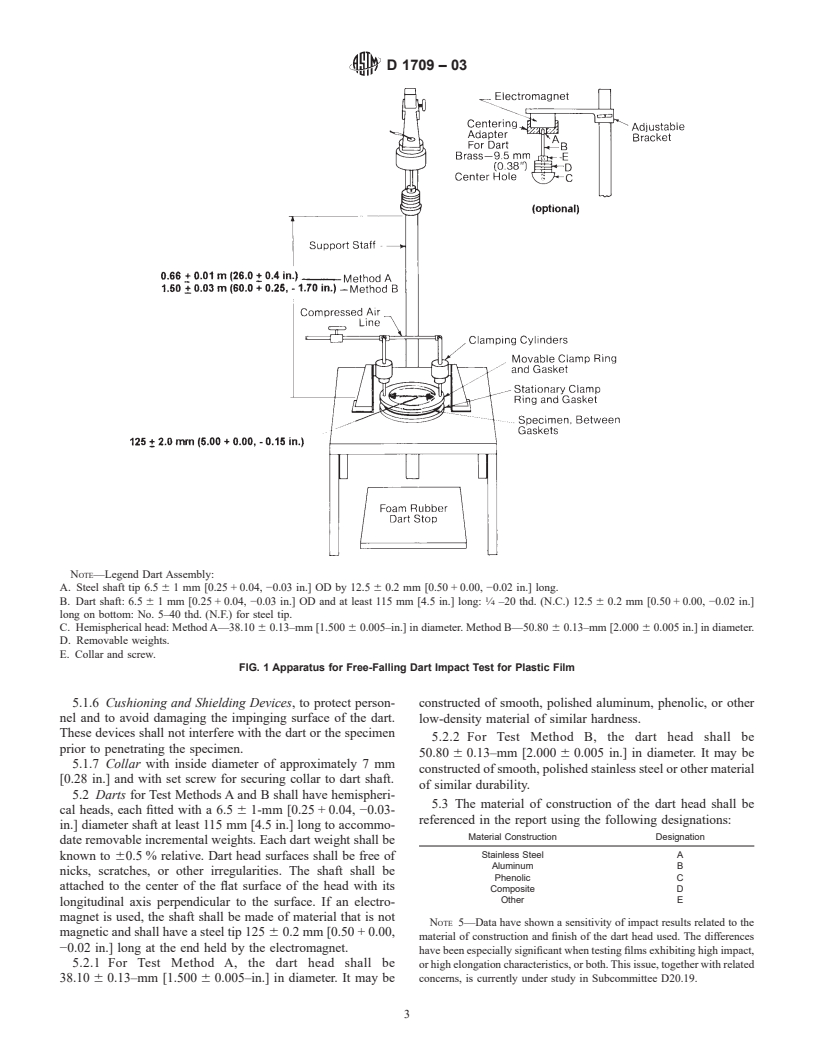

1.2.1 Test Method A employs a dart with a 38.10 ± 0.13-mm [1.500 ± 0.005-in.] diameter hemispherical head dropped from a height of 0.66 ± 0.01 m [26.0 ± 0.4 in.]. This test method may be used for films whose impact resistances require masses of about 50 g or less to about 2 kg to fracture them.

1.2.2 Test Method B employs a dart with a 50.80 ± 0.13-mm [2.000 ± 0.005-in.] diameter hemispherical head dropped from a height of 1.50 ± 0.03 m [60.0 + 0.25, -1.70 in.]. Its range of applicability is from about 0.3 kg to about 2 kg.

1.3 Two testing techniques are described:

1.3.1 The standard technique is the staircase method. By this technique, a uniform missile weight increment is employed during test and the missile weight is decreased or increased by the uniform increment after test of each specimen, depending upon the result (fail or not fail) observed for the specimen.

1.3.2 The alternative technique provides for testing specimens in successive groups of ten. One missile weight is employed for each group and missile weight is varied in uniform increments from group to group.

1.3.3 The staircase technique and the alternative technique give equivalent results both as to the values of impact failure weight which are obtained and as to the precisions with which they are determined.

1.4 The values stated in SI units are to be regarded as standard. The values stated in parentheses are for information only.

Note 1—Tests on materials that do not break, for any reason, are not considered to be valid. It has been noted that certain materials may stretch so far as to bottom out at the base of certain test instruments without actually rupturing. Subcommittee D20.19 is currently considering methods for testing these materials. Anyone interested in participating in a Task Group should contact the Chairman of Subcommittee D20.19 through ASTM International Headquarters.

Note 2—This test method is technically equivalent to ISO 7765-1: 1988, with the exception of a larger tolerance on the drop height in Test Method B. Also, the ISO method does not allow the alternative testing technique described in Section 11 of this test method.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1709 – 03

Standard Test Methods for

Impact Resistance of Plastic Film by the Free-Falling Dart

1

Method

This standard is issued under the fixed designation D 1709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

actually rupturing. Subcommittee D20.19 is currently considering meth-

1. Scope*

ods for testing these materials. Anyone interested in participating in a Task

1.1 These test methods cover the determination of the

Group should contact the Chairman of Subcommittee D20.19 through

energy that causes plastic film to fail under specified conditions

ASTM International Headquarters.

of impact of a free-falling dart. This energy is expressed in

NOTE 2—This test method is technically equivalent to ISO 7765-1:

terms of the weight (mass) of the missile falling from a 1988, with the exception of a larger tolerance on the drop height in Test

Method B. Also, the ISO method does not allow the alternative testing

specified height which would result in 50 % failure of speci-

technique described in Section 11 of this test method.

mens tested.

1.2 Two test methods are described:

1.5 This standard does not purport to address the safety

1.2.1 Test Method A employs a dart with a 38.10 6 0.13- concerns, if any, associated with its use. It is the responsibility

mm [1.500 6 0.005-in.] diameter hemispherical head dropped

of the user of this standard to establish appropriate safety and

from a height of 0.66 6 0.01 m [26.0 6 0.4 in.]. This test health practices and determine the applicability of regulatory

method may be used for films whose impact resistances require

limitations prior to use.

masses of about 50 g or less to about 2 kg to fracture them.

2. Referenced Documents

1.2.2 Test Method B employs a dart with a 50.80 6 0.13-

mm [2.000 6 0.005-in.] diameter hemispherical head dropped 2.1 ASTM Standards:

from a height of 1.50 6 0.03 m [60.0 + 0.25, −1.70 in.]. Its D 374 Test Methods for Thickness of Solid Electrical Insu-

2

range of applicability is from about 0.3 kg to about 2 kg. lation

3

1.3 Two testing techniques are described: D 618 Practice for Conditioning Plastics for Testing

3

1.3.1 The standard technique is the staircase method. By D 883 Terminology Relating to Plastics

this technique, a uniform missile weight increment is employed D 1248 Specification for Polyethylene Plastics Extrusion

3

during test and the missile weight is decreased or increased by Materials for Wire and Cable

the uniform increment after test of each specimen, depending D 3420 Test Method for Dynamic Ball Burst (Pendulum)

4

upon the result (fail or not fail) observed for the specimen. Impact Resistance of Plastic Film

1.3.2 The alternative technique provides for testing speci- D 4272 Test Method for Total Energy Impact of Plastic

4

mens in successive groups of ten. One missile weight is Films by Dart Drop

employed for each group and missile weight is varied in E 177 Practice for Use of the Terms Precision and Bias in

5

uniform increments from group to group. ASTM Test Methods

1.3.3 The staircase technique and the alternative technique E 691 Practice for Conducting an Interlaboratory Study to

5

give equivalent results both as to the values of impact failure Determine the Precision of a Test Method

weight which are obtained and as to the precisions with which 2.2 ISO Standard:

they are determined. ISO 7765:1988 Plastic Film and Sheeting—Determination

1.4 The values stated in SI units are to be regarded as of Impact Resistance by the Free Falling Dart Method—

6

standard. The values stated in parentheses are for information Part 1: Staircase Method

only.

3. Terminology

NOTE 1—Tests on materials that do not break, for any reason, are not

3.1 Definitions—For definitions related to plastics, see

considered to be valid. It has been noted that certain materials may stretch

Terminology D 883.

so far as to bottom out at the base of certain test instruments without

2

Annual Book of ASTM Standards, Vol 10.01.

1 3

These test methods are under the jurisdiction of ASTM Committee D20 on Annual Book of ASTM Standards, Vol 08.01.

4

Plastics and are the direct responsibility of Subcommittee D20.19 on Film and Annual Book of ASTM Standards, Vol 08.02.

5

Sheeting. Annual Book of ASTM Standards, Vol 14.02.

6

Current edition approved March 10, 2003. Published April 2003. Originally Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

approved in 1959. Last previous edition approved in 2001 as D 1709 – 01. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM Internat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.