ASTM C690-09(2019)

(Test Method)Standard Test Method for Particle Size Distribution of Alumina or Quartz Powders by Electrical Sensing Zone Technique

Standard Test Method for Particle Size Distribution of Alumina or Quartz Powders by Electrical Sensing Zone Technique

SIGNIFICANCE AND USE

3.1 This test method is useful to both sellers and purchasers of alumina and quartz powders for determining particle size distributions for materials specifications, manufacturing control, and development and research.

SCOPE

1.1 This test method, one of several found valuable for the measurement of particle size, covers the determination of the particle size distribution of alumina or quartz powders (0.6 to 56.0 μm) using electrical sensing zone particle size analyzers. These instruments use an electric current path of small dimensions which is modulated by individual particle passage through an aperture, and produces individual pulses of amplitude proportional to the particle volume.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C690 − 09 (Reapproved 2019)

Standard Test Method for

Particle Size Distribution of Alumina or Quartz Powders by

Electrical Sensing Zone Technique

This standard is issued under the fixed designation C690; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Significance and Use

1.1 This test method, one of several found valuable for the 3.1 This test method is useful to both sellers and purchasers

measurement of particle size, covers the determination of the of alumina and quartz powders for determining particle size

particle size distribution of alumina or quartz powders (0.6 to distributions for materials specifications, manufacturing

56.0 µm) using electrical sensing zone particle size analyzers. control, and development and research.

These instruments use an electric current path of small dimen-

4. Apparatus

sions which is modulated by individual particle passage

through an aperture, and produces individual pulses of ampli-

4.1 Electrical Sensing Zone Particle Counter.

tude proportional to the particle volume.

4.2 Aperture Tubes, diameter ranging from approximately

1.2 The values stated in SI units are to be regarded as

30 to 140 µm. The diameter required is dependent upon the

standard. No other units of measurement are included in this

particle size distribution of the sample. Generally any given

standard.

tube will cover a particle size range from 2 to 60 % of its

1.3 This standard does not purport to address all of the aperture diameter.

safety concerns, if any, associated with its use. It is the

NOTE 1—In certain cases, apertures up to 300 µm are usable.

responsibility of the user of this standard to establish appro-

4.3 Sample Beaker, capable of maintaining all particles

priate safety, health, and environmental practices and deter-

uniformly in suspension (for example, round-bottom).

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

4.4 Blender,capacity1-Lglasscontainer.Ameanstocontrol

dance with internationally recognized principles on standard- speed is required.

ization established in the Decision on Principles for the

4.5 Beakers, 100, 500, and 1000-mL.

Development of International Standards, Guides and Recom-

4.6 Pipet.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4.7 Wash Bottles.

4.8 Membrane Filtering Device, rated at 0.45-µm filters or

2. Summary of Test Method

finer.

2.1 A carefully dispersed, dilute suspension of the powder

inabeakerfilledwithanelectrolyteisplacedontheinstrument

5. Reagents

sample stand. The suspension is forced through a restricting

5.1 Purity of Reagents—Reagent grade chemicals shall be

aperture. Each particle passing generates an electric pulse that

used in all tests. Unless otherwise indicated, it is intended that

is recorded on an electronic counter.

all reagents shall conform to the specifications of the Commit-

2.2 The instrument response is essentially related to particle

tee onAnalytical Reagents of theAmerican Chemical Society,

volume (liquid displacement). Equivalent spherical diameter is

where such specifications are available. Other grades may be

commonly used to express the particle size. (Comparisons with

used, provided it is first ascertained that the reagent is of

other techniques have been found to be good for spherical

sufficiently high purity to permit its use without lessening the

particles; for non-spherical particles results may differ.)

accuracy of the determination.

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Whitewares and Related Productsand is the direct responsibility of Subcommittee Reagent Chemicals, American Chemical Society Specifications , American

C21.04 on Raw Materials. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Current edition approved Oct. 1, 2019. Published October 2019. Originally listed by the American Chemical Society, see Analar Standards for Laboratory

approved in 1971. Last previous edition approved in 2014 as C690 – 09 (2014). Chemicals, VWR International Ltd., U.K., and the United States Pharmacopoeia,

DOI: 10.1520/C0690-09R19. USPC, Rockville, MD.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C690 − 09 (2019)

maintainauniformparticlesuspensionwhilewithdrawingthesample.The

5.2 Dispersing Media—Ten percent solution of purified or

pipet should deliver all of the withdrawn slurry to ensure a representative

reagent grade sodium hexametaphosphate in distilled water

transfer of sample in the event of any size classification during the

twice filtered through the membrane filtering device.

transfer.

NOTE 2—Deionized water may be substituted for distilled water.

6.6 Place the sample beaker in position on the sample stand.

NOTE 3—This liquid should not be retained longer than 1 month and

6.7 Adjust the speed of the stirrer to furnish sufficient

should not be pH modified or heated.

agitation to maintain a uniform particle suspension, but below

5.3 Electrolyte—Dissolve 10.0 g of reagent grade sodium

air bubble generation speeds.

chloride (NaCl) in 1000 mL of distilled water and filter twice

through the membrane filtering device. 6.8 Use the apparatus control software to set the measure-

ment parameters. Make three measurements in which each

5.4 Wash Water—Distilled water twice filtered through the

measurement counts and measures at least 5000 particles.

membrane filtering device.

Average the particle size distribution from the three measure-

5.5 Calibration Particles—NIST or NIST traceable mono-

ments and report the statistical parameters from the averaged

sized particle standards.

results.

6. Procedure

6.9 Precautions:

6.9.1 Before each analysis, using wash bottle and filtered

6.1 Summary—Disperse the test powder in the electrolyte

wash water, wash all surfaces coming in contact with sample.

with a blender. Transfer a representative portion

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C690 − 09 (Reapproved 2019)

Standard Test Method for

Particle Size Distribution of Alumina or Quartz Powders by

Electrical Sensing Zone Technique

This standard is issued under the fixed designation C690; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Significance and Use

1.1 This test method, one of several found valuable for the 3.1 This test method is useful to both sellers and purchasers

measurement of particle size, covers the determination of the of alumina and quartz powders for determining particle size

particle size distribution of alumina or quartz powders (0.6 to distributions for materials specifications, manufacturing

56.0 µm) using electrical sensing zone particle size analyzers. control, and development and research.

These instruments use an electric current path of small dimen-

sions which is modulated by individual particle passage 4. Apparatus

through an aperture, and produces individual pulses of ampli-

4.1 Electrical Sensing Zone Particle Counter.

tude proportional to the particle volume.

4.2 Aperture Tubes, diameter ranging from approximately

1.2 The values stated in SI units are to be regarded as

30 to 140 µm. The diameter required is dependent upon the

standard. No other units of measurement are included in this

particle size distribution of the sample. Generally any given

standard.

tube will cover a particle size range from 2 to 60 % of its

1.3 This standard does not purport to address all of the aperture diameter.

safety concerns, if any, associated with its use. It is the

NOTE 1—In certain cases, apertures up to 300 µm are usable.

responsibility of the user of this standard to establish appro-

4.3 Sample Beaker, capable of maintaining all particles

priate safety, health, and environmental practices and deter-

uniformly in suspension (for example, round-bottom).

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor- 4.4 Blender, capacity 1-L glass container. A means to control

dance with internationally recognized principles on standard-

speed is required.

ization established in the Decision on Principles for the

4.5 Beakers, 100, 500, and 1000-mL.

Development of International Standards, Guides and Recom-

4.6 Pipet.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4.7 Wash Bottles.

4.8 Membrane Filtering Device, rated at 0.45-µm filters or

2. Summary of Test Method

finer.

2.1 A carefully dispersed, dilute suspension of the powder

in a beaker filled with an electrolyte is placed on the instrument

5. Reagents

sample stand. The suspension is forced through a restricting

5.1 Purity of Reagents—Reagent grade chemicals shall be

aperture. Each particle passing generates an electric pulse that

used in all tests. Unless otherwise indicated, it is intended that

is recorded on an electronic counter.

all reagents shall conform to the specifications of the Commit-

2.2 The instrument response is essentially related to particle

tee on Analytical Reagents of the American Chemical Society,

volume (liquid displacement). Equivalent spherical diameter is

where such specifications are available. Other grades may be

commonly used to express the particle size. (Comparisons with

used, provided it is first ascertained that the reagent is of

other techniques have been found to be good for spherical

sufficiently high purity to permit its use without lessening the

particles; for non-spherical particles results may differ.)

accuracy of the determination.

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic

Whitewares and Related Productsand is the direct responsibility of Subcommittee Reagent Chemicals, American Chemical Society Specifications , American

C21.04 on Raw Materials. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Current edition approved Oct. 1, 2019. Published October 2019. Originally listed by the American Chemical Society, see Analar Standards for Laboratory

approved in 1971. Last previous edition approved in 2014 as C690 – 09 (2014). Chemicals, VWR International Ltd., U.K., and the United States Pharmacopoeia,

DOI: 10.1520/C0690-09R19. USPC, Rockville, MD.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C690 − 09 (2019)

maintain a uniform particle suspension while withdrawing the sample. The

5.2 Dispersing Media—Ten percent solution of purified or

pipet should deliver all of the withdrawn slurry to ensure a representative

reagent grade sodium hexametaphosphate in distilled water

transfer of sample in the event of any size classification during the

twice filtered through the membrane filtering device.

transfer.

NOTE 2—Deionized water may be substituted for distilled water.

6.6 Place the sample beaker in position on the sample stand.

NOTE 3—This liquid should not be retained longer than 1 month and

6.7 Adjust the speed of the stirrer to furnish sufficient

should not be pH modified or heated.

agitation to maintain a uniform particle suspension, but below

5.3 Electrolyte—Dissolve 10.0 g of reagent grade sodium

air bubble generation speeds.

chloride (NaCl) in 1000 mL of distilled water and filter twice

through the membrane filtering device. 6.8 Use the apparatus control software to set the measure-

ment parameters. Make three measurements in which each

5.4 Wash Water—Distilled water twice filtered through the

measurement counts and measures at least 5000 particles.

membrane filtering device.

Average the particle size distribution from the three measure-

5.5 Calibration Particles—NIST or NIST traceable mono-

ments and report the statistical parameters from the averaged

sized particle standards.

results.

6. Procedure

6.9 Precautions:

6.9.1 Before each analysis, using wash bottle and filtered

6.1 Summary—Disperse the test powder in the electrolyte

wash water, wash all surfaces coming in contact with sample.

with a blender. Transfer a representative portion to the sample

6.9.2 Ensure that the calibration of the instrument

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C690 − 09 (Reapproved 2014) C690 − 09 (Reapproved 2019)

Standard Test Method for

Particle Size Distribution of Alumina or Quartz Powders by

Electrical Sensing Zone Technique

This standard is issued under the fixed designation C690; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method, one of several found valuable for the measurement of particle size, covers the determination of the particle

size distribution of alumina or quartz powders (0.6 to 56.0 μm) using electrical sensing zone particle size analyzers. These

instruments use an electric current path of small dimensions which is modulated by individual particle passage through an aperture,

and produces individual pulses of amplitude proportional to the particle volume.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Summary of Test Method

2.1 A carefully dispersed, dilute suspension of the powder in a beaker filled with an electrolyte is placed on the instrument

sample stand. The suspension is forced through a restricting aperture. Each particle passing generates an electric pulse that is

recorded on an electronic counter.

2.2 The instrument response is essentially related to particle volume (liquid displacement). Equivalent spherical diameter is

commonly used to express the particle size. (Comparisons with other techniques have been found to be good for spherical particles;

for non-spherical particles results may differ.)

3. Significance and Use

3.1 This test method is useful to both sellers and purchasers of alumina and quartz powders for determining particle size

distributions for materials specifications, manufacturing control, and development and research.

4. Apparatus

4.1 Electrical Sensing Zone Particle Counter.

4.2 Aperture Tubes, diameter ranging from approximately 30 to 140 μm. The diameter required is dependent upon the particle

size distribution of the sample. Generally any given tube will cover a particle size range from 2 to 60 % of its aperture diameter.

NOTE 1—In certain cases, apertures up to 300 μm are usable.

4.3 Sample Beaker, capable of maintaining all particles uniformly in suspension (for example, round-bottom).

4.4 Blender, capacity 1-L glass container. A means to control speed is required.

4.5 Beakers, 100, 500, and 1000-mL.

4.6 Pipet.

4.7 Wash Bottles.

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Productsand is the direct responsibility of Subcommittee C21.04

on Raw Materials.

Current edition approved Dec. 1, 2014Oct. 1, 2019. Published December 2014October 2019. Originally approved in 1971. Last previous edition approved in 20092014

as C690 – 09.C690 – 09 (2014). DOI: 10.1520/C0690-09R14.10.1520/C0690-09R19.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C690 − 09 (2019)

4.8 Membrane Filtering Device, rated at 0.45-μm filters or finer.

5. Reagents

5.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

5.2 Dispersing Media—Ten percent solution of purified or reagent grade sodium hexametaphosphate in distilled water twice

filtered through the membrane filtering device.

NOTE 2—Deionized water may be substituted for distilled water.

NOTE 3—This liquid should not be retained longer than 1 month and should not be pH modified or heated.

5.3 Electrolyte—Dissolve 10.0 g of reagent grade sodium chloride (NaCl) in 1000 mL of distilled water and filter twice through

the membrane filtering device.

5.4 Wash Water—Distilled water twice filtered through the membrane filtering device.

5.5 Calibration Particles—NIST or NIST traceable monosized particle standards.

6. Procedure

6.1 Summary—Disperse the test powder in the electrolyte with a blender. Transfer a representative portion to the sample beaker

that contains filtered electrolyte. Place sample beaker in the apparatus and obtain particle size distribution in a chosen size range.

Obtain relative weight fraction by assuming constant particle density.

6.2 Precalibrate the aperture and electrolyte combination following the manufacturer’s instruction manual.

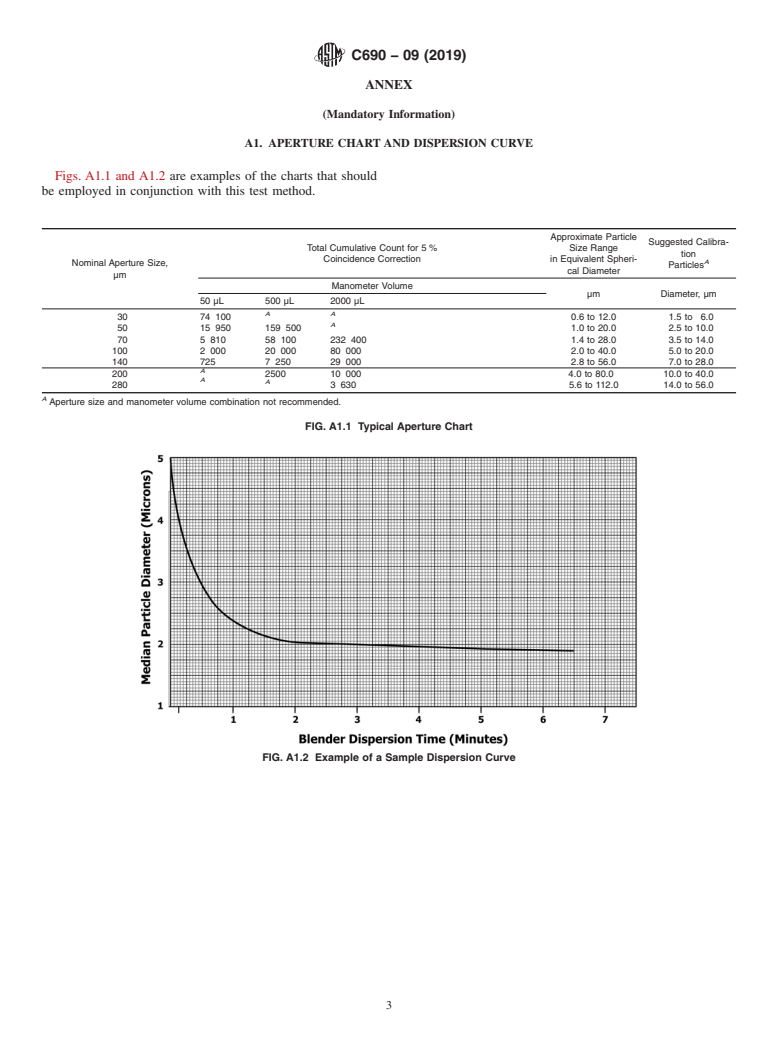

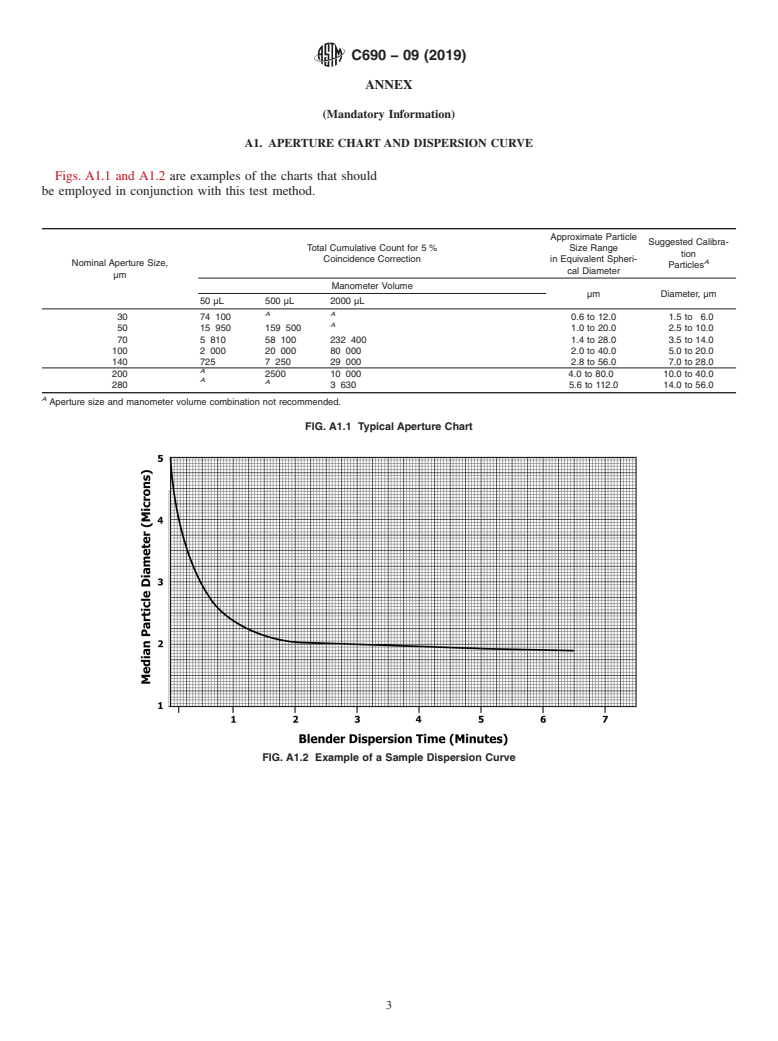

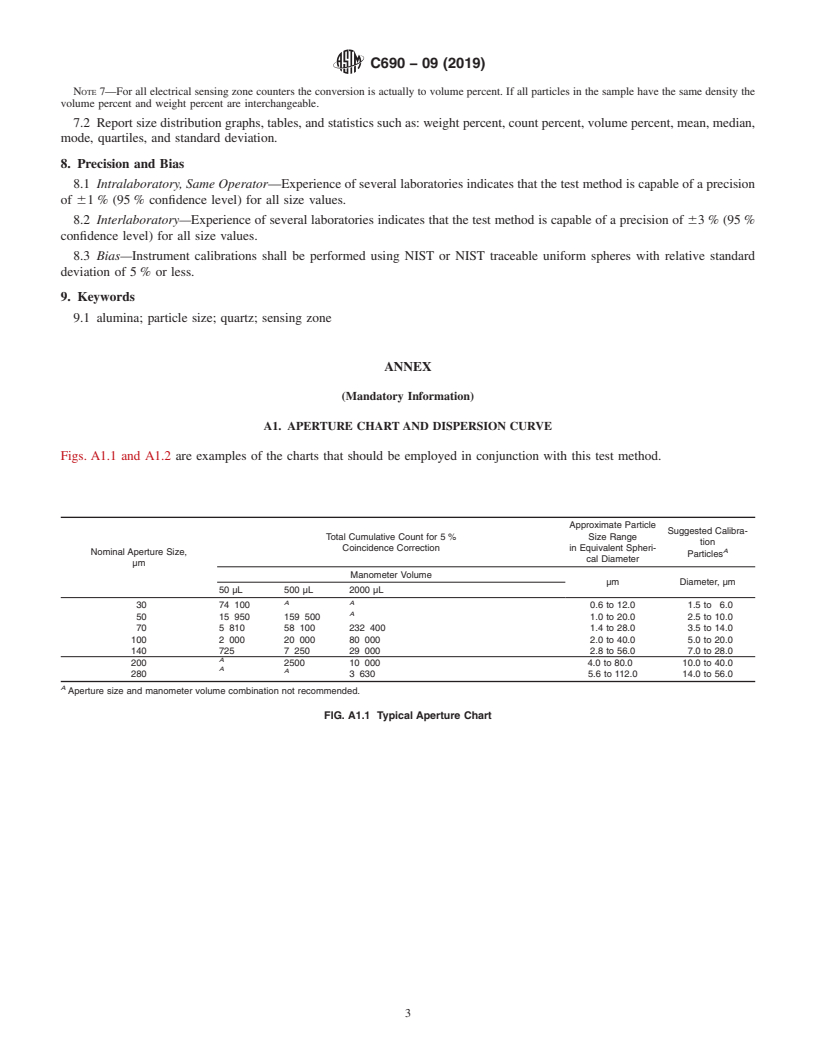

NOTE 4—Calibration should be performed in accordance with the instruction manual. Monosized NIST or NIST traceable calibration standards should

be selected from Fig. A1.1. Mutual agreement on the source and size of calibration standards is necessary for interlaboratory comparisons.

6.3 Check background counts by filling the sample beaker with filtered electrolyte and taking counts without any sample added.

Follow 6.6, 6.7, and 6.8.

6.4 Disperse approximately 0.7 g of sample in 200 mL of electrolyte containing 5 drops of dispersing media, by mixing at high

speed on the blender or its equivalent for 5 min.

NOTE 5—The proper dispersion conditions for a given mixer or blender should be predetermined by obtaining a time-speed versus median diameter

curve (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.