ASTM D81-87(2003)

(Specification)Standard Specification for Basic Carbonate White Lead Pigment

Standard Specification for Basic Carbonate White Lead Pigment

SCOPE

1.1 This specification covers the material commercially known as basic carbonate white lead, used as a pigment and in putty. The pigment may be purchased in the dry form or as a paste in oil.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 81 – 87 (Reapproved 2003)

Standard Specification for

Basic Carbonate White Lead Pigment

ThisstandardisissuedunderthefixeddesignationD 81;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

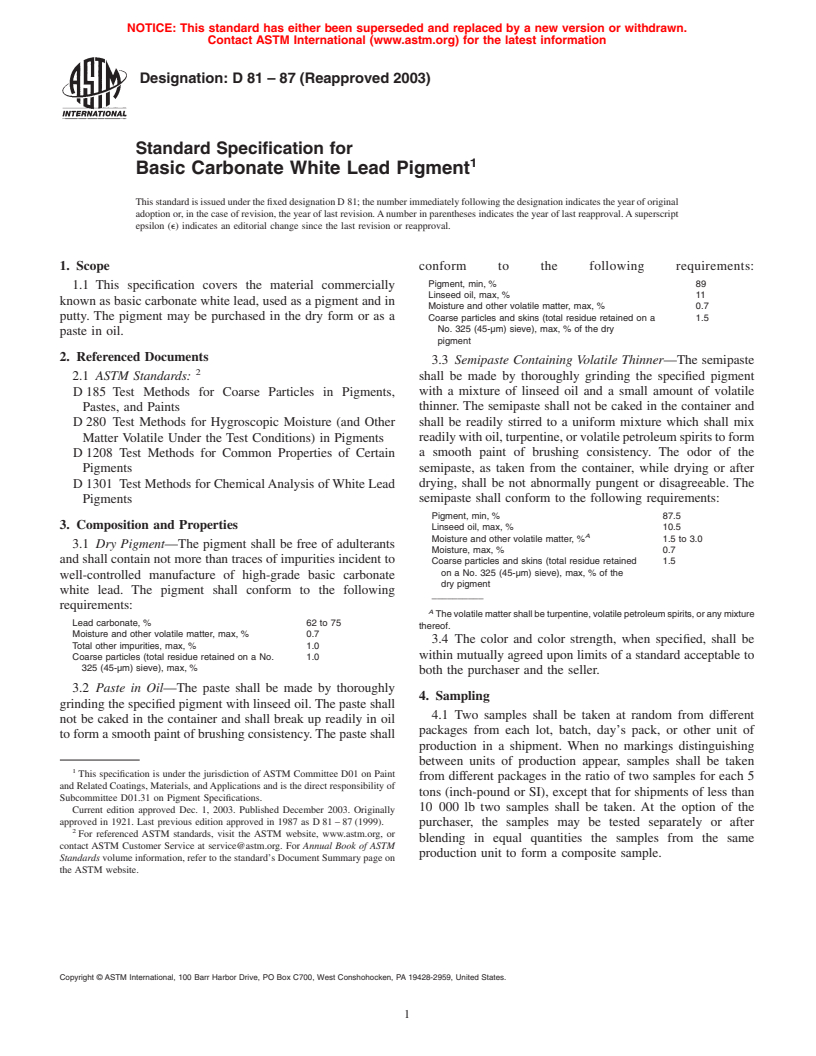

1. Scope conform to the following requirements:

Pigment, min, % 89

1.1 This specification covers the material commercially

Linseed oil, max, % 11

known as basic carbonate white lead, used as a pigment and in

Moisture and other volatile matter, max, % 0.7

putty. The pigment may be purchased in the dry form or as a

Coarse particles and skins (total residue retained on a 1.5

No. 325 (45-µm) sieve), max, % of the dry

paste in oil.

pigment

2. Referenced Documents

3.3 Semipaste Containing Volatile Thinner—The semipaste

shall be made by thoroughly grinding the specified pigment

2.1 ASTM Standards:

D 185 Test Methods for Coarse Particles in Pigments, with a mixture of linseed oil and a small amount of volatile

thinner. The semipaste shall not be caked in the container and

Pastes, and Paints

D 280 Test Methods for Hygroscopic Moisture (and Other shall be readily stirred to a uniform mixture which shall mix

readilywithoil,turpentine,orvolatilepetroleumspiritstoform

Matter Volatile Under the Test Conditions) in Pigments

D 1208 Test Methods for Common Properties of Certain a smooth paint of brushing consistency. The odor of the

semipaste, as taken from the container, while drying or after

Pigments

D 1301 Test Methods for ChemicalAnalysis of White Lead drying, shall be not abnormally pungent or disagreeable. The

semipaste shall conform to the following requirements:

Pigments

Pigment, min, % 87.5

3. Composition and Properties

Linseed oil, max, % 10.5

A

Moisture and other volatile matter, % 1.5to3.0

3.1 Dry Pigment—The pigment shall be free of adulterants

Moisture, max, % 0.7

and shall contain not more than traces of impurities incident to

Coarse particles and skins (total residue retained 1.5

on a No. 325 (45-µm) sieve), max, % of the

well-controlled manufacture of high-grade basic carbonate

dry pigment

white lead. The pigment shall conform to the following

__________

requirements:

A

The volatile matter shall be turpentine, volatile petroleum spirits, or any mixture

Lead carbonate, % 62 to 75

thereof.

Moisture and other volatile matter, max, % 0.7

3.4 The color and color strength, when specified, shall be

Total other impurities, max, % 1.0

within mutually agreed upon limits of a standard acceptable to

Coarse particles (total residue retained on a No. 1.0

325 (45-µm) sieve), max, %

both the purchaser and the seller.

3.2 Paste in Oil—The paste shall be made by thoroughly

4. Sampling

grinding the specified pigment with linseed oil. The paste shall

4.1 Two samples shall be taken at random from different

not be caked in the container and shall break up readily in oil

packages from each lot, batch, day’s pack, or other unit of

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.