ASTM E2653-08

(Practice)Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Fire Test Method with Fewer Than Six Participating Laboratories

Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Fire Test Method with Fewer Than Six Participating Laboratories

SIGNIFICANCE AND USE

ASTM regulations require precision statements in all test methods in terms of repeatability and reproducibility. This practice is used when the number of participating laboratories or materials being tested, or both, in a precision study is less than the number specified by Practice E 691. When possible, it is strongly recommended that a full E 691 standard protocol be followed to determine test method precision. Precision results produced by the procedures presented in this standard will not have the same degree of accuracy as results generated by a full E 691 protocol. This procedure will allow for the development of useful precision results when a full compliment of laboratories is not available for interlaboratory testing.

This practice is based on recommendations for interlaboratory studies and data analysis presented in Practice E 691. This practice does not concern itself with the development of test methods but with a standard means for gathering information and treating the data needed for developing a precision statement for a fire test method when a complete E 691 interlaboratory study and data analysis are not possible.

SCOPE

1.1 This practice describes the techniques for planning, conducting, analyzing, and treating results of an interlaboratory study (ILS) for estimating the precision of a fire test method when fewer than six laboratories are available to meet the recommended minimum requirements of Practice E 691. Data obtained from an interlaboratory study are useful in identifying variables that require modifications for improving test method performance and precision.

1.2 Precision estimates developed using this practice will not be statistically equivalent to precision estimates produced by Practice E 691 because a small number of laboratories are used. The smaller number of participating laboratories will seriously reduce the value of precision estimates reported by this practice. However, under circumstances where only a limited number of laboratories are available to participate in an ILS, precision estimates developed by this practice will provide the user with useful information concerning precision for a test method.

1.3 A minimum of three qualified laboratories is required for conducting an ILS using this practice. If six or more laboratories are available to participate in an ILS for a given fire test method, Practice E 691 shall be used for conducting the ILS.

1.4 Since the primary purpose of this practice is the development of the information needed for a precision statement, the experimental design in this practice will not be optimum for evaluating all materials, test methods, or as a tool for individual laboratory analysis.

1.5 Because of the reduced number of participating laboratories a Laboratory Monitor shall be used in the ILS. See Standard Guide E 2335.

1.6 Field of Application—This practice is concerned with test methods that yield numerical values or a series of numerical values for different fire-test response properties. The numerical values mentioned above are typically the result of calculations from a set of measurements.

1.7 This practice includes design information suitable for use with the development of interlaboratory studies for test methods that have categorization (go-no-go) allocation test results. However, it does not provide a recommended statistical practice for evaluating the go-no-go data.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2653–08

Standard Practice for

Conducting an Interlaboratory Study to Determine the

Precision of a Fire Test Method with Fewer Than Six

Participating Laboratories

This standard is issued under the fixed designation E 2653; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This practice includes design information suitable for

use with the development of interlaboratory studies for test

1.1 This practice describes the techniques for planning,

methods that have categorization (go-no-go) allocation test

conducting,analyzing,andtreatingresultsofaninterlaboratory

results.However,itdoesnotprovidearecommendedstatistical

study (ILS) for estimating the precision of a fire test method

practice for evaluating the go-no-go data.

when fewer than six laboratories are available to meet the

1.8 This standard does not purport to address all of the

recommended minimum requirements of Practice E 691. Data

safety concerns, if any, associated with its use. It is the

obtainedfromaninterlaboratorystudyareusefulinidentifying

responsibility of the user of this standard to establish appro-

variables that require modifications for improving test method

priate safety and health practices and determine the applica-

performance and precision.

bility of regulatory limitations prior to use.

1.2 Precision estimates developed using this practice will

not be statistically equivalent to precision estimates produced

2. Referenced Documents

by Practice E 691 because a small number of laboratories are

2.1 ASTM Standards:

used. The smaller number of participating laboratories will

E 176 Terminology of Fire Standards

seriously reduce the value of precision estimates reported by

E 177 Practice for Use of the Terms Precision and Bias in

this practice. However, under circumstances where only a

ASTM Test Methods

limited number of laboratories are available to participate in an

E 178 Practice for Dealing With Outlying Observations

ILS, precision estimates developed by this practice will pro-

E 456 Terminology Relating to Quality and Statistics

vide the user with useful information concerning precision for

E 691 Practice for Conducting an Interlaboratory Study to

a test method.

Determine the Precision of a Test Method

1.3 A minimum of three qualified laboratories is required

E 1169 Practice for Conducting Ruggedness Tests

for conducting an ILS using this practice. If six or more

E 2335 Guide for Laboratory Monitors

laboratories are available to participate in an ILS for a given

fire test method, Practice E 691 shall be used for conducting

3. Terminology

the ILS.

3.1 Definitions—For formal definitions of statistical terms,

1.4 Since the primary purpose of this practice is the devel-

seeTerminologyE 456.Forformaldefinitionsoffireterms,see

opmentoftheinformationneededforaprecisionstatement,the

Terminology E 176.

experimental design in this practice will not be optimum for

3.2 Definitions of Terms Specific to This Standard:

evaluatingallmaterials,testmethods,orasatoolforindividual

3.2.1 test method and protocol—in this practice, the term

laboratory analysis.

“test method” is used both for the actual measurement process

1.5 Because of the reduced number of participating labora-

and for the written description of the process, while the term

tories a Laboratory Monitor shall be used in the ILS. See

“protocol” is used for the directions given to the laboratories

Standard Guide E 2335.

for conducting the ILS.

1.6 Field of Application—This practice is concerned with

3.2.2 repeatability and reproducibility—these terms deal

test methods that yield numerical values or a series of

with the variability of test results obtained under specified

numerical values for different fire-test response properties.The

laboratory conditions. Repeatability concerns the variability

numerical values mentioned above are typically the result of

between independent test results obtained within a single

calculations from a set of measurements.

1 2

This practice is under the jurisdiction of ASTM Committee E05 on Fire For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Standards and is the direct responsibility of Subcommittee E05.15 on Furnishings contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Contents. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2008. Published November 2008. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2653–08

laboratory in the shortest practical period of time by a single followed to determine test method precision. Precision results

operator with a specific set of test apparatus using test produced by the procedures presented in this standard will not

specimens(ortestunits)takenatrandomfromasinglequantity have the same degree of accuracy as results generated by a full

of homogeneous material obtained or prepared for the ILS. E 691 protocol. This procedure will allow for the development

Reproducibility deals with the variability between single test of useful precision results when a full compliment of labora-

results obtained in different laboratories, each of which has tories is not available for interlaboratory testing.

applied the test method to test specimens (or test units) taken 5.2 This practice is based on recommendations for inter-

at random from a single quantity of homogeneous material laboratory studies and data analysis presented in Practice

obtained or prepared for the ILS. E 691. This practice does not concern itself with the develop-

3.3 For further discussion of the terms discussed above, see ment of test methods but with a standard means for gathering

Practice E 177 and the formal definitions in Terminology information and treating the data needed for developing a

E 456. precision statement for a fire test method when a complete

E 691 interlaboratory study and data analysis are not possible.

4. Summary of Practice

PLANNING THE ILS

4.1 The procedure presented in this practice consists of

three basic steps: planning the interlaboratory study, guiding

6. Planning

thetestingphaseofthestudy,andanalyzingthetestresultdata.

6.1 Task Group—Either the task group that developed the

The analysis evaluates the consistency of the data through the

test method or a special task group appointed for the purpose

use of numerical estimates of precision of the test method

must have overall responsibility for the ILS, including funding

pertaining to both within-laboratory repeatability and between-

whereappropriate,staffing,thedesignoftheILS,anddecision-

laboratory reproducibility.

making with regard to questionable data. The task group shall

4.2 Planning of the interlaboratory study will include a

decideonthenumberoflaboratories,materials,andtestresults

review of the test procedure to be used in the interlaboratory

for each material. In addition, it shall specify any special

study.This review will identify portions of the test method that

calibration procedures and the repeatability conditions to be

appear to contribute to a loss in precision. Special interlabora-

specified in the protocol.

tory instructions or modifications to the test method wording

6.2 ILS Coordinator—The task group must appoint one

are made as needed to clarify these sections and often result in

individual to act as overall coordinator for conducting the ILS.

a modification to the test method following the interlaboratory

Thecoordinatorwillsupervisethedistributionofmaterialsand

study.

protocols to the laboratories and receive the test result reports

4.3 A manager for the interlaboratory study and an inter-

from the laboratories. Scanning the reports for gross errors and

laboratory test monitor shall be selected. The same person is

checking with the laboratories, when such errors are found,

allowed to conduct both functions.

will also be the responsibility of the coordinator. The coordi-

4.4 Parties conducting an interlaboratory precision study of

nator will consult as needed with a statistician in questionable

a test method will acquire participation agreements with as

cases.

manylaboratoriesaspossiblethatarewillingtotakepartinthe

6.3 Laboratory Monitor—The task group must appoint one

interlaboratory study and have the capability to run the test

individual to act as a laboratory monitor for the ILS. The

method of interest. A minimum of three laboratories shall

laboratorymonitorwilldevelopanILSchecklistspecifictothe

participateintheprecisionstudy.Precisionresultswillincrease

test method, inspect the test laboratories for equipment con-

in quality with a larger number of participating laboratories.

formity and operator training, verify compatibility of the data

4.5 The types of materials and number of test specimens

acquisition system, and based on the Checklist and inspection

shall be selected for the interlaboratory study. No less than

results report to the sponsoring ASTM Subcommittee. Com-

three test specimens shall be selected for the interlaboratory

pletedetailsforthefunctionofalaboratorymonitorarelocated

study, and they shall be selected to reflect the range of

in Guide E 2335.

performance of test specimens normally evaluated by the test

6.4 Statistician—The task group shall obtain the assistance

method.Aminimum of three replicates shall be tested for each

of a person skilled in the use of statistical procedures, the test

test material selected. If a standard reference material is

method being studied, and with the materials being tested in

available for the test method, the material shall be included as

order to ensure that the requirements in this practice are met in

a specimen in the interlaboratory study. If a standard reference

an efficient and effective manner. This person will conduct the

material is not available, a test specimen that consistently

data analysis using procedures given in this standard and will

produces low variability test results shall be selected as a

assist the task group in interpreting results from the data

reference material for the interlaboratory study.

analysis.

5. Significance and Use

7. Basic Design

5.1 ASTM regulations require precision statements in all

test methods in terms of repeatability and reproducibility. This 7.1 Keep the ILS design simple in order to obtain estimates

practice is used when the number of participating laboratories of within-and between-laboratory variability that are free of

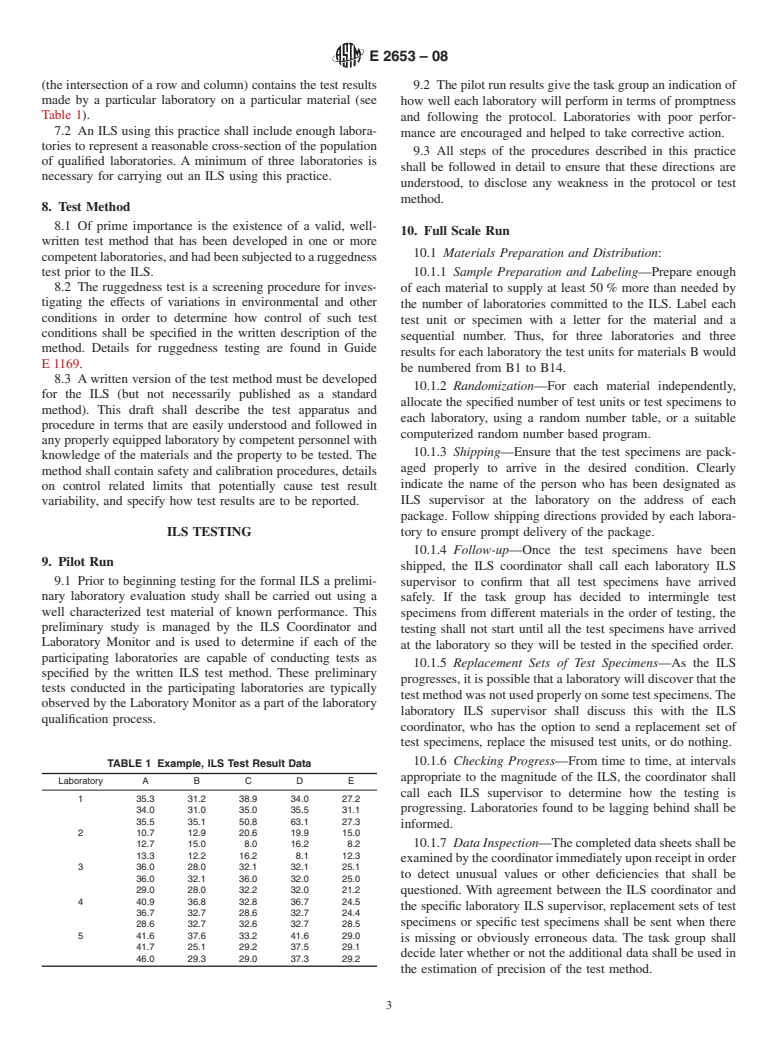

or materials being tested, or both, in a precision study is less secondary effects. The basic design is represented by a two-

than the number specified by Practice E 691. When possible, it way classification table in which the rows represent the

is strongly recommended that a full E 691 standard protocol be laboratories, the columns represent the materials, and the cell

E2653–08

(the intersection of a row and column) contains the test results 9.2 The pilot run results give the task group an indication of

made by a particular laboratory on a particular material (see how well each laboratory will perform in terms of promptness

Table 1).

and following the protocol. Laboratories with poor perfor-

7.2 An ILS using this practice shall include enough labora-

mance are encouraged and helped to take corrective action.

tories to represent a reasonable cross-section of the population

9.3 All steps of the procedures described in this practice

of qualified laboratories. A minimum of three laboratories is

shall be followed in detail to ensure that these directions are

necessary for carrying out an ILS using this practice.

understood, to disclose any weakness in the protocol or test

method.

8. Test Method

8.1 Of prime importance is the existence of a valid, well-

10. Full Scale Run

written test method that has been developed in one or more

10.1 Materials Preparation and Distribution:

competentlaboratories,andhadbeensubjectedtoaruggedness

test prior to the ILS. 10.1.1 Sample Preparation and Labeling—Prepare enough

8.2 The ruggedness test is a screening procedure for inves-

of each material to supply at least 50 % more than needed by

tigating the effects of variations in environmental and other

the number of laboratories committed to the ILS. Label each

conditions in order to determine how control of such test

test unit or specimen with a letter for the material and a

conditions shall be specified in the written description of the

sequential number. Thus, for three laboratories and three

method. Details for ruggedness testing are found in Guide

results for each laboratory the test units for materials B would

E 1169.

be numbered from B1 to B14.

8.3 Awritten version of the test method must be developed

10.1.2 Randomization—For each material independently,

for the ILS (but not necessarily published as a standard

allocate the specified number of test units or test specimens to

method). This draft shall describe the test apparatus and

each laboratory, using a random number table, or a suitable

procedure in terms that are easily understood and followed in

computerized random number based program.

any properly equipped laboratory by competent personnel with

10.1.3 Shipping—Ensure that the test specimens are pack-

knowledge of the materials and the property to be tested. The

aged properly to arrive in the desired condition. Clearly

method shall contain safety and calibration procedures, details

indicate the name of the person who has been designated as

on control related limits that potentially cause test result

ILS supervisor at the laboratory on the address of each

variability, and specify how test results are to be reported.

package. Follow shipping directions provided by each labora-

ILS TESTING tory to ensure prompt delivery of the package.

10.1.4 Follow-up—Once the test specimens have been

9. Pilot Run

shipped, the ILS coordinator shall call each laboratory ILS

9.1 Prior to beginning testing for the formal ILS a prelimi- supervisor to confirm that all test specimens have arrived

nary laboratory evaluation study shall be carried out using a

safely. If the task group has decided to intermingle test

well characterized test material of known performance. This

specimens from different materials in the order of testing, the

preliminary study is managed by the ILS Coordinator and

testing shall not start until all the test specimens have arrived

Laboratory Monitor and is used to determine if each of the

at the laboratory so they will be tested in the specified ord

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.