ASTM D605-82(2012)

(Specification)Standard Specification for Magnesium Silicate Pigment (Talc)

Standard Specification for Magnesium Silicate Pigment (Talc)

ABSTRACT

This specification establishes the properties and requirements for pigments that consist substantially of natural hydrous magnesium silicate (talc), and can be suitably processed to what is commercially known as paint pigment quality. Specimens shall be suitably sampled and tested, and should conform to specified requirements as to combined magnesium and calcium silicates content, calcium oxide content, aluminum and iron oxides content, loss on ignition, moisture and other volatile material, color, coarse particles, water-soluble matter, oil absorption, consistency, and fineness.

SCOPE

1.1 This specification covers pigments that consist substantially of natural hydrous magnesium silicate, and is restricted to those minerals that conform to the chemical limits prescribed herein and can be suitably processed to what is commercially known as paint pigment quality.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following hazard caveat applies to the test method portion of this specification only. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D605 −82 (Reapproved 2012)

Standard Specification for

Magnesium Silicate Pigment (Talc)

This standard is issued under the fixed designation D605; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

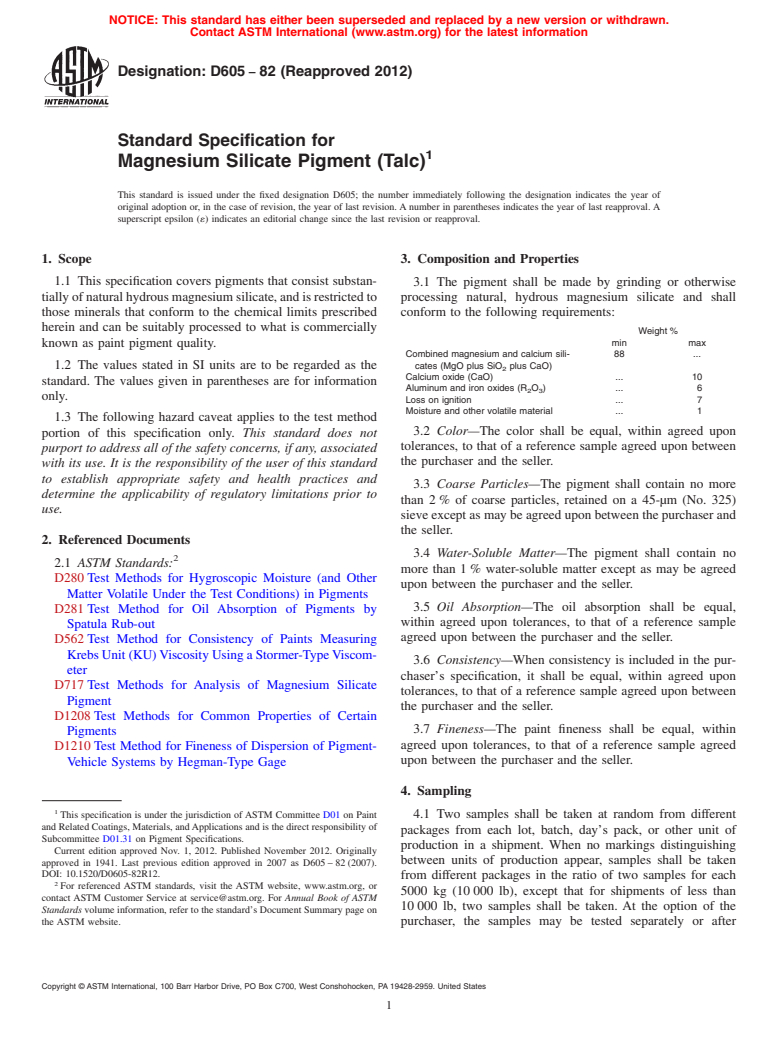

1. Scope 3. Composition and Properties

1.1 This specification covers pigments that consist substan- 3.1 The pigment shall be made by grinding or otherwise

tiallyofnaturalhydrousmagnesiumsilicate,andisrestrictedto

processing natural, hydrous magnesium silicate and shall

those minerals that conform to the chemical limits prescribed conform to the following requirements:

herein and can be suitably processed to what is commercially

Weight %

min max

known as paint pigment quality.

Combined magnesium and calcium sili- 88 .

cates (MgO plus SiO plus CaO)

1.2 The values stated in SI units are to be regarded as the

Calcium oxide (CaO) . 10

standard. The values given in parentheses are for information

Aluminum and iron oxides (R O ) . 6

2 3

only.

Loss on ignition . 7

Moisture and other volatile material . 1

1.3 The following hazard caveat applies to the test method

3.2 Color—The color shall be equal, within agreed upon

portion of this specification only. This standard does not

tolerances, to that of a reference sample agreed upon between

purport to address all of the safety concerns, if any, associated

the purchaser and the seller.

with its use. It is the responsibility of the user of this standard

to establish appropriate safety and health practices and

3.3 Coarse Particles—The pigment shall contain no more

determine the applicability of regulatory limitations prior to

than 2 % of coarse particles, retained on a 45-µm (No. 325)

use.

sieve except as may be agreed upon between the purchaser and

the seller.

2. Referenced Documents

3.4 Water-Soluble Matter—The pigment shall contain no

2.1 ASTM Standards:

more than 1 % water-soluble matter except as may be agreed

D280 Test Methods for Hygroscopic Moisture (and Other

upon between the purchaser and the seller.

Matter Volatile Under the Test Conditions) in Pigments

3.5 Oil Absorption—The oil absorption shall be equal,

D281 Test Method for Oil Absorption of Pigments by

within agreed upon tolerances, to that of a reference sample

Spatula Rub-out

agreed upon between the purchaser and the seller.

D562 Test Method for Consistency of Paints Measuring

KrebsUnit(KU)ViscosityUsingaStormer-TypeViscom-

3.6 Consistency—When consistency is included in the pur-

eter

chaser’s specification, it shall be equal, within agreed upon

D717 Test Methods for Analysis of Magnesium Silicate

tolerances, to that of a reference sample agreed upon between

Pigment

the purchaser and the seller.

D1208 Test Methods for Common Properties of Certain

3.7 Fineness—The paint fineness shall be equal, within

Pigments

agreed upon tolerances, to that of a reference sample agreed

D1210 Test Method for Fineness of Dispersion of Pigment-

upon between the purchaser and the seller.

Vehicle Systems by Hegman-Type Gage

4. Sampling

This specification is under the jurisdiction of ASTM Committee D01 on Paint

4.1 Two samples shall be taken at random from different

and Related Coatings, Materials, andApplications and is the direct responsibility of

packages from each lot, batch, day’s pack, or other unit of

Subcommittee D01.31 on Pigment Specifications.

production in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.