ASTM D6295/D6295M-98

(Test Method)Standard Test Method for Dispensability of Light-Duty Pressure-Sensitive Film Tape

Standard Test Method for Dispensability of Light-Duty Pressure-Sensitive Film Tape

SCOPE

1.1 This test method covers the measurement of the force and elongation required to dispense pressure-sensitive film tape on a 1-in. core intended for office and stationery applications from a desk-top dispenser.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6295/D 6295M – 98

Standard Test Method for

Dispensability of Light–Duty Pressure–Sensitive Film Tape

This standard is issued under the fixed designation D 6295/D 6295M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope from a roll using specific test conditions and specific blade

described in this test method.

1.1 This test method covers the measurement of the force

and elongation required to dispense pressure-sensitive film tape

4. Significance and Use

on a 1-in. core intended for office and stationery applications

4.1 Pressure-sensitive film tapes are supplied in roll form.

from a desk-top dispenser.

For such a tape to be useful a strip of the tape must be easily

1.2 The values stated in either SI or inch-pound units are to

dispensed or severed from the roll by means of a cutter found

be regarded separately as standard. The values stated in each

on most dispensers. This test method is a means of measuring

system are not exact equivalents; therefore, each system must

the ease of this severing or dispensing of the tape.

be used independently of the other.

4.2 This test method provides information that can be used

1.3 This standard does not propose to address all of the

in material specifications for product design and quality

safety concerns, if any, associated with its use. It is the

assurance applications. It can be used in comparing different

responsibility of the user of this standard to establish appro-

tape products on specific dispensing blades.

priate safety and health practices and determine the applica-

4.3 This test method may be suited for office and stationery

bility of regulatory limitations prior to use.

and tapes with acetate, cellophane, or light-duty plastic back-

2. Referenced Documents ings. Some tapes may be shown to be difficult to dispense

under these conditions yet are readily dispensable with other

2.1 ASTM Standards:

dispensing systems.

D 996 Terminology of Packaging and Distribution Environ-

ments

NOTE 1—Backings described in CID A-A-113 are typical backings.

D 3715/D 3715M Practice for Quality Assurance of

5. Apparatus

Pressure-Sensitive Tapes

D 4332 Practice for Conditioning Containers, Packages or

5.1 Tension Tester—A constant-rate-of-extension (CRE)

Packaging Components for Testing

type with load cell capacity such that the maximum expected

E 122 Practice for Choice of Sample Size to Estimate a

dispensing force does not exceed 90 % of its normal limit. A

Measure of Quality for a Lot or Process

means of moving the stressing clamp at a uniform rate of 250

2.2 Commercial Item Description (CID):

mm/min or 10 in./min. Test information should be displayed

A-A-113 Tape, Pressure-Sensitive Adhesive

graphically with a sampling rate of at least 100 data points per

second.

3. Terminology

5.2 Blade—Manufactured in accordance with information

3.1 Definitions—Terminology found in Terminology D 996

given in Fig. 1.

shall apply.

NOTE 2—The blade used in models C-15, C-38, C-40, and C-41

3.2 Definitions of Terms Specific to This Standard:

dispensers meets these requirements. This blade has been found to be

3.2.1 dispensability—the initial force and elongation re-

suitable for this testing.

quired to sever or cut off a strip of pressure-sensitive film tape

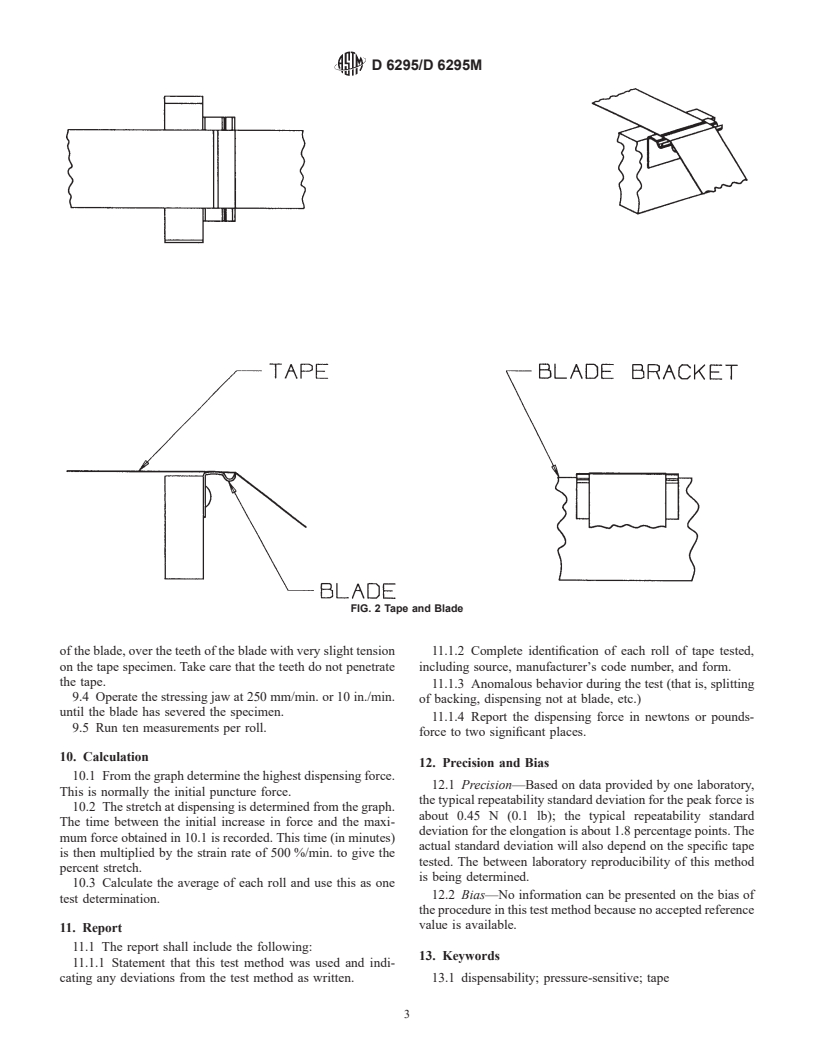

5.3 Blade Support Fixture—The test fixture, as shown in

Figs. 2 and 3, shall have a means of rigidly mounting the blade

This test method is under the jurisdiction of ASTM Committee D-10 on

in the tensile tester so that the land portion faces at 30° down

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

from the vertical and rotates the blade 10° from the horizontal.

Labels.

Current edition approved August 10, 1998. Published December 1998.

Annual Book of ASTM Standards, Vol 15.09.

Annual Book of ASTM Standards, Vol 14.02.

Available from General Services Administration, Federal Supply Service

Specifications Section (3FP-E), Suite 8100, 470 East L’Enfant Plaza, SW, Wash- Available from Chemsultants International, 9349 Hamilton Dr., Mentor, OH

ington, DC 20407. 44061–1118.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6295/D 6295M

FIG. 1 Blade

5.4 Blade Change—In the normal course of events the blade 8. Conditioning

should be changed at least every 1000 uses or when there is

8.1 Condition the sample rolls of tape in the standard

evidence of damage or wear. A new blade should be used for

con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.