ASTM C898-95

(Guide)Standard Guide for Use of High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane With Separate Wearing Course

Standard Guide for Use of High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane With Separate Wearing Course

SCOPE

1.1 This guide describes the use of a high solids content, cold liquid-applied elastomeric waterproofing membrane that meets the criteria in Specification C 836, in a waterproofing system subject to hydrostatic pressure for building decks over occupied space where the membrane is covered with a separate protective wearing course.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 898 – 95

Standard Guide for Use of

High Solids Content, Cold Liquid-Applied Elastomeric

Waterproofing Membrane with Separate Wearing Course

This standard is issued under the fixed designation C 898; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1752 Specification for Preformed Sponge Rubber and

Cork Expansion Joint Fillers for Concrete Paving and

1.1 This guide describes the use of a high solids content,

Structural Construction

cold liquid-applied elastomeric waterproofing membrane in a

D 3253 Specification for Vulcanized Rubber Sheeting for

waterproofing system subject to hydrostatic pressure for build-

Pond, Canal, and Reservoir Lining

ing decks over occupied space where the membrane is covered

2.2 American Concrete Institute Standard:

with a separate protective wearing course.

301-72 (1975) Specifications for Structural Concrete for

1.2 The values stated in SI units are to be regarded as the

Buildings

standard. The values given in parentheses are for information

only.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Refer to Terminology C 717 for definitions of the

safety concerns, if any, associated with its use. It is the

following terms used in this guide: bond breaker; cellular; cold

responsibility of the user of this standard to establish appro-

joint; compatibility; compound; construction joint; control

priate safety and health practices and determine the applica-

joint; creep; dry film thickness; elastomer; expansion joint;

bility of regulatory limitations prior to use.

gasket; isolation joint; joint; laitance; primer; reglet; reinforced

2. Referenced Documents joint; sealant; spalling; waterproofing.

3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.2.1 cold-applied—capable of being applied without heat-

C 33 Specification for Concrete Aggregates

ing as contrasted to hot-applied. Cold-applied products are

C 136 Test Method for Sieve Analysis of Fine and Coarse

furnished in a liquid state, whereas hot-applied products are

Aggregates

furnished as solids that must be heated to liquefy them.

C 717 Terminology of Building Seals and Sealants

3.2.2 curing time—the period between application and the

C 755 Practice for Selection of Vapor Retarders for Thermal

time when the material reaches its design physical properties.

Insulations

3.2.3 deflection—the deviation of a structural element from

C 836 Specification for High Solids Content, Cold Liquid-

its original shape or plane due to physical loading, temperature

Applied Elastomeric Waterproofing Membrane for Use

gradients, or rotation of its supports.

with Separate Wearing Course

3.2.4 drainage board—see prefabricated drainage compos-

C 920 Specification for Elastomeric Joint Sealants

ite, the preferred term.

C 962 Guide for Use of Elastomeric Joint Sealants

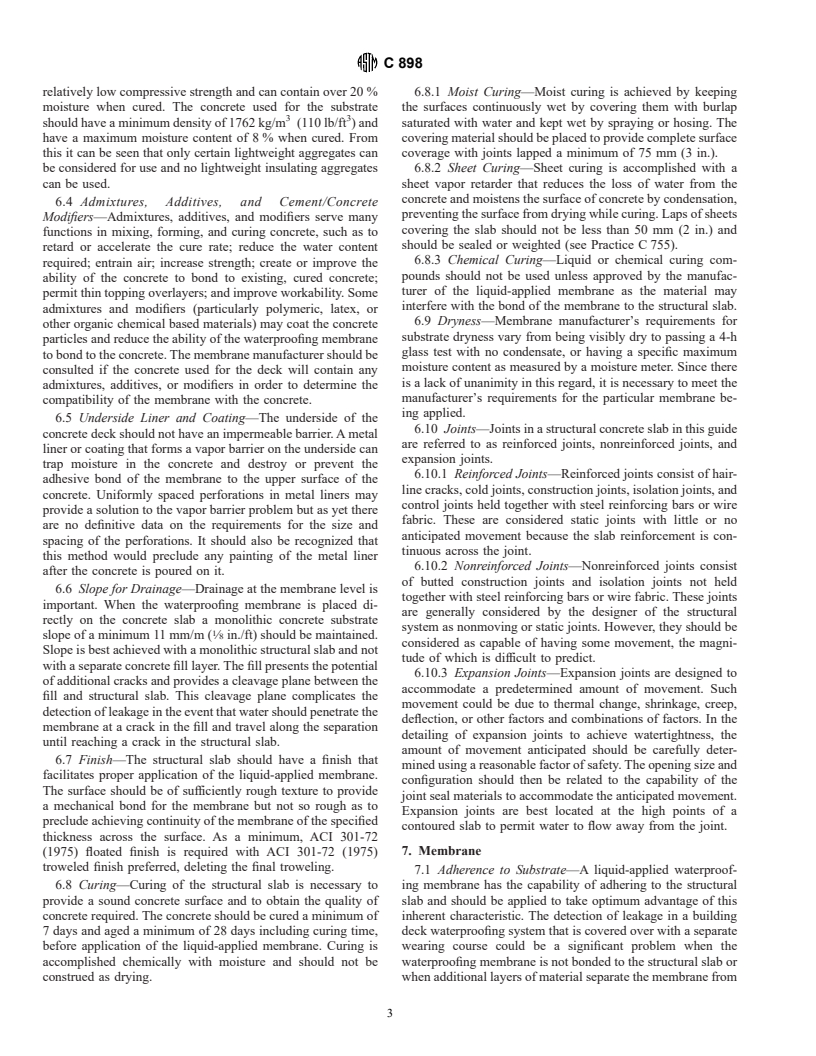

3.2.5 drainage course—see percolation layer and Fig. 1.

D 1056 Specification for Flexible Cellular Materialsù-

6 3.2.6 finish wearing surface—see traffıc surface.

Sponge or Expanded Rubber

3.2.7 flashing—a generic term describing the transitional

D 1751 Specification for Preformed Expansion Joint Fillers

area between the waterproofing membrane and surfaces above

for Concrete Paving and Structural Construction (Nonex-

the wearing surface of the building deck; a terminal closure or

truding and Resilient Bituminous Types)

barrier to prevent ingress of water into the system.

3.2.8 floated finish—a concrete finish provided by consoli-

dating and leveling the concrete with only a power driver or

This guide is under the jurisdiction of ASTM Committee C-24 on Building

Seals and Sealants and is the direct responsibility of Subcommittee C24.80 on

hand float, or both. A floated finish is coarser than a troweled

Building Deck Waterproofing Systems.

finish. For specifications, see ACI 301-72 (1975).

Current edition approved Dec. 10, 1995. Published February 1996. Originally

3.2.9 freeze-thaw cycle—the freezing and subsequent thaw-

published as C 898 – 78. Last previous edition C 898 – 89.

Annual Book of ASTM Standards, Vol 04.02.

ing of a material.

Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 04.06.

Discontinued. See 1992 Annual Book of ASTM Standards, Vol 04.07. Replaced

by C 1193. Discontinued. See 1988 Annual Book of ASTM Standards, Vol 04.09.

6 9

Annual Book of ASTM Standards, Vol 08.01. Available from American Concrete Institute, P.O. Box 19150 Redford Station,

Annual Book of ASTM Standards, Vol 04.03. Detroit, MI 48219.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 898

of the waterproofing system as well as guide specifications.

The intent of Sections 5-14 is to provide information and

guidelines for consideration of the designer of the waterproof-

ing system. The intent of the remaining sections is to provide

minimum guide specifications for the use of purchaser and

seller in contract documents. Where the state of the art is such

that criteria for a particular condition is not as yet firmly

established or has numerous variables that require consider-

ation, reference is made to the applicable portion of Sections

5-14 that covers the particular area of concern.

DESIGN CONSIDERATIONS

5. General

5.1 Major Components, Subsystems, and Features—The

major components to be considered for a building deck

waterproofing system are the structural building deck or

substrate to be waterproofed, waterproofing membrane, protec-

tion of the membrane, drainage, insulation, and wearing course

(see Fig. 1). Additional features to be considered are membrane

terminal conditions and expansion joints.

5.2 Compatibility—It is essential that all components and

contiguous elements be compatible and coordinated to form a

totally integrated waterproofing system.

FIG. 1 Basic Components of Cold Liquid-Applied Elastomeric

6. Substrate

Membrane Waterproofing System with Separate Wearing Course

6.1 General—The building deck or substrate referred to in

this guide is reinforced cast-in-place structural concrete. Pre-

3.2.10 grout—concrete containing no coarse aggregates; a

cast concrete slabs pose more technical problems than cast-in-

thin mortar.

place concrete, and the probability of lasting watertightness is

3.2.11 percolation layer (drainage course)—a layer of

greatly diminished and difficult to achieve because of the

washed gravel or of a manufactured drainage media that allows

multitude of joints which have the capability of movement and

water to filter through to the drain (see Fig. 1).

must be treated accordingly. Moving joints are critical features

3.2.12 prefabricated drainage composite—proprietary de-

of waterproofing systems and are more critical when sealed at

vices to facilitate drainage, usually a composite laminate of

the membrane level than at a higher level with the use of

more than one material including filter fabric.

integral concrete curbs. Such curbs are impractical with precast

3.2.13 protection board—see protection course.

concrete slabs and necessitate an even more impractical drain

3.2.14 protection course—semi-rigid sheet material placed

in each slab. Other disadvantages of precast concrete slabs are

on top of the waterproofing membrane to protect it against

their inflexibility in achieving contoured slope to drains and the

damage during subsequent construction and to provide a

difficulty of coordinating the placement of such drains.

protective barrier against compressive and shearing forces

6.2 Strength—The strength of concrete is a factor to be

induced by materials placed above it (see Fig. 1).

considered with respect to the liquid-applied membrane insofar

3.2.15 structural slab—a horizontal, supporting, cast-in-

as it relates to finish, bond strength, and continuing integrity

place, concrete building deck. See Fig. 1.

(absence of cracks and other defects that could affect the

3.2.16 traffıc surface—a surface exposed to traffic, either

integrity of the membrane after installation).

pedestrian or vehicular, also described as finish wearing

6.3 Density and Moisture Content—Density of concrete and

surface.

moisture content when cured are interrelated and can affect

3.2.17 troweled finish—a concrete finish provided by

adhesion of the membrane to the substrate with an excessively

smoothing the surface with power driven or hand trowels or

high moisture content, moisture may condense at the mem-

both, after the float finishing operation. A troweled finish is

brane and concrete interface and cause membrane delamina-

smoother than the floated finish. For specifications, see ACI

tion. This is particularly so if the top surface is cooler than the

301-72 (1975).

concrete below. Lower moisture contents are achieved with the

3.2.18 wearing surface—see traffıc surface.

use of hard, dense, stone aggregate. This type of coarse

3.2.19 wet-film thickness—the thickness of a liquid coating

aggregate will generally provide structural concrete with a

as it is applied.

moisture content from 3 to 5 % when cured. Lightweight

3.2.20 wet-film gage—a gage for measuring the thickness of

aggregate, such as expanded shale, will generally provide

a wet film.

lightweight structural concrete with a moisture content from 5

4. Significance and Use

to 20 % when cured. Lightweight insulating concrete made

4.1 This guide provides design considerations for the design with a weaker expanded aggregate, such as perlite, has a

C 898

relatively low compressive strength and can contain over 20 % 6.8.1 Moist Curing—Moist curing is achieved by keeping

moisture when cured. The concrete used for the substrate the surfaces continuously wet by covering them with burlap

3 3

should have a minimum density of 1762 kg/m (110 lb/ft ) and saturated with water and kept wet by spraying or hosing. The

have a maximum moisture content of 8 % when cured. From covering material should be placed to provide complete surface

this it can be seen that only certain lightweight aggregates can coverage with joints lapped a minimum of 75 mm (3 in.).

be considered for use and no lightweight insulating aggregates 6.8.2 Sheet Curing—Sheet curing is accomplished with a

can be used. sheet vapor retarder that reduces the loss of water from the

concrete and moistens the surface of concrete by condensation,

6.4 Admixtures, Additives, and Cement/Concrete

preventing the surface from drying while curing. Laps of sheets

Modifiers—Admixtures, additives, and modifiers serve many

covering the slab should not be less than 50 mm (2 in.) and

functions in mixing, forming, and curing concrete, such as to

should be sealed or weighted (see Practice C 755).

retard or accelerate the cure rate; reduce the water content

6.8.3 Chemical Curing—Liquid or chemical curing com-

required; entrain air; increase strength; create or improve the

pounds should not be used unless approved by the manufac-

ability of the concrete to bond to existing, cured concrete;

turer of the liquid-applied membrane as the material may

permit thin topping overlayers; and improve workability. Some

interfere with the bond of the membrane to the structural slab.

admixtures and modifiers (particularly polymeric, latex, or

6.9 Dryness—Membrane manufacturer’s requirements for

other organic chemical based materials) may coat the concrete

substrate dryness vary from being visibly dry to passing a 4-h

particles and reduce the ability of the waterproofing membrane

glass test with no condensate, or having a specific maximum

to bond to the concrete. The membrane manufacturer should be

moisture content as measured by a moisture meter. Since there

consulted if the concrete used for the deck will contain any

is a lack of unanimity in this regard, it is necessary to meet the

admixtures, additives, or modifiers in order to determine the

manufacturer’s requirements for the particular membrane be-

compatibility of the membrane with the concrete.

ing applied.

6.5 Underside Liner and Coating—The underside of the

6.10 Joints—Joints in a structural concrete slab in this guide

concrete deck should not have an impermeable barrier. A metal

are referred to as reinforced joints, nonreinforced joints, and

liner or coating that forms a vapor barrier on the underside can

expansion joints.

trap moisture in the concrete and destroy or prevent the

6.10.1 Reinforced Joints—Reinforced joints consist of hair-

adhesive bond of the membrane to the upper surface of the

line cracks, cold joints, construction joints, isolation joints, and

concrete. Uniformly spaced perforations in metal liners may

control joints held together with steel reinforcing bars or wire

provide a solution to the vapor barrier problem but as yet there

fabric. These are considered static joints with little or no

are no definitive data on the requirements for the size and

anticipated movement because the slab reinforcement is con-

spacing of the perforations. It should also be recognized that

tinuous across the joint.

this method would preclude any painting of the metal liner

6.10.2 Nonreinforced Joints—Nonreinforced joints consist

after the concrete is poured on it.

of butted construction joints and isolation joints not held

6.6 Slope for Drainage—Drainage at the membrane level is

together with steel reinforcing bars or wire fabric. These joints

important. When the waterproofing membrane is placed di-

are generally considered by the designer of the structural

rectly on the concrete slab a monolithic concrete substrate

system as nonmoving or static joints. However, they should be

slope of a minimum 11 mm/m ( ⁄8 in./ft) should be maintained.

considered as capable of having some movement, the magni-

Slope is best achieved with a monolithic structural slab and not

tude of which is difficult to predict.

with a separate concrete fill layer. The fill presents the potential

6.10.3 Expansion Joints—Expansion joints are designed to

of additional cracks and provides a cleavage plane between the

accommodate a predetermined amount of movement. Such

fill and structural slab. This cleavage plane complicates the

movement could be due to thermal change, shrinkage, creep,

detection of leakage in the event that water should penetrate the

deflection, or other factors and combinations of factors. In the

membrane at a crack in the fill and travel along the separation

detailing of expansion joints to achieve watertightness, the

until reaching a crack in the structural slab.

amount of movement anticipated should be carefully deter-

6.7 Finish—The structural slab should have a finish

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.