ASTM E676-94(1998)

(Specification)Standard Specification for Interchangeable Taper-Ground Joints

Standard Specification for Interchangeable Taper-Ground Joints

SCOPE

1.1 This specification covers designations, dimensions, and tolerances for only the ground surfaces of interchangeable taper-ground joints for laboratory and industrial equipment in full-length, medium-length, short-length, and international-length (ISO K-6 series) grindings. Note 1-The dimensions pertaining to full-length, medium-length, and short-length joints, other than for the tolerance on length of grind, were taken directly from the now obsolete Commercial Standard CS 21. Note 2-Tolerances on the diameters of the international-length joints do not agree with those given in ISO Recommendation R383. These tolerances have been established to agree with those of CS 21 in order to prevent the negative projection (large end of inner joint being smaller than large end of outer joint) permitted by ISO. Note 3-Although glass is the most commonly used material for ground joints, other materials may be used as specified. Taper-ground joints constructed from glass should be of suitable chemical and thermal properties in accordance with Specification E438. Joints should be as free as possible of visible defects and conform to Specification E671.

1.2 The following precautionary caveat pertains only to the Test Method portion, Section 4, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: E 676 – 94 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Interchangeable Taper-Ground Joints

This standard is issued under the fixed designation E 676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 U.S. Department of Commerce Standard:

CS 21 Interchangeable Taper-Ground Joints, Stopcocks,

1.1 This specification covers designations, dimensions, and

Stoppers, and Spherical-Ground Joints

tolerances for only the ground surfaces of interchangeable

2.3 ISO Standard:

taper-ground joints for laboratory and industrial equipment in

R 383 Interchangeable Conical Ground Glass Joints

full-length, medium-length, short-length, and international-

length (ISO K-6 series) grindings.

3. Requirements

NOTE 1—The dimensions pertaining to full-length, medium-length, and

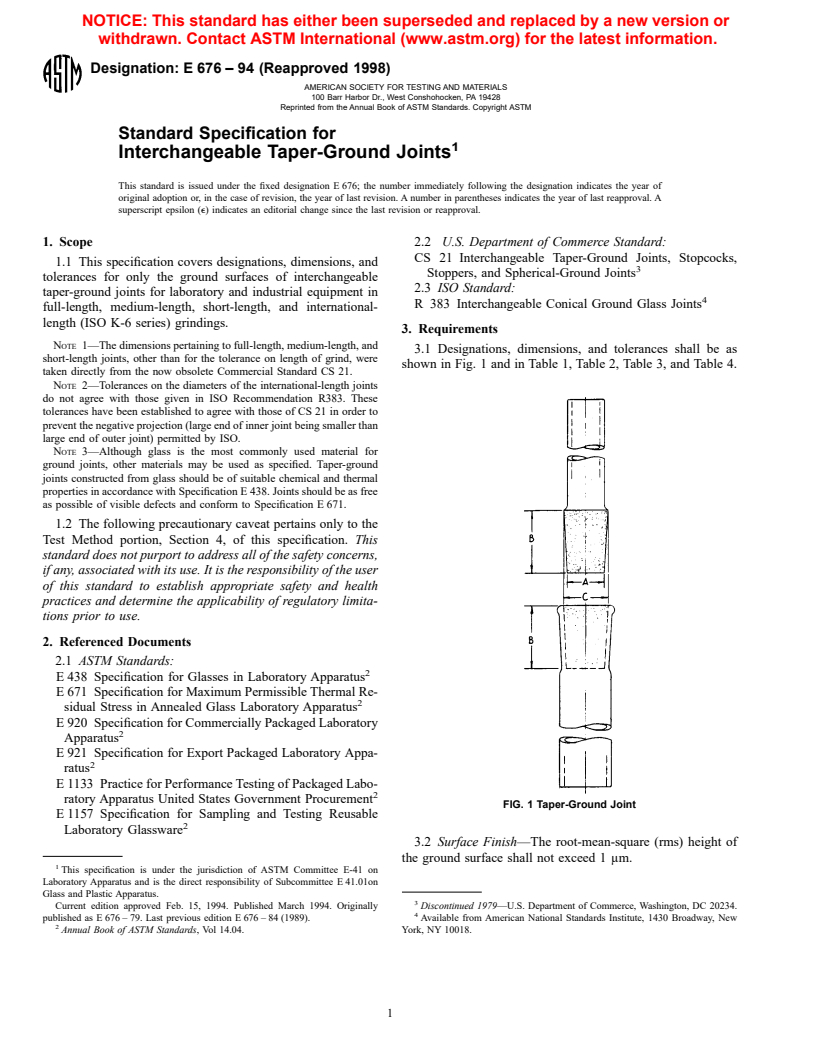

3.1 Designations, dimensions, and tolerances shall be as

short-length joints, other than for the tolerance on length of grind, were

shown in Fig. 1 and in Table 1, Table 2, Table 3, and Table 4.

taken directly from the now obsolete Commercial Standard CS 21.

NOTE 2—Tolerances on the diameters of the international-length joints

do not agree with those given in ISO Recommendation R383. These

tolerances have been established to agree with those of CS 21 in order to

prevent the negative projection (large end of inner joint being smaller than

large end of outer joint) permitted by ISO.

NOTE 3—Although glass is the most commonly used material for

ground joints, other materials may be used as specified. Taper-ground

joints constructed from glass should be of suitable chemical and thermal

properties in accordance with Specification E 438. Joints should be as free

as possible of visible defects and conform to Specification E 671.

1.2 The following precautionary caveat pertains only to the

Test Method portion, Section 4, of this specification. This

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

tions prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 438 Specification for Glasses in Laboratory Apparatus

E 671 Specification for Maximum Permissible Thermal Re-

sidual Stress in Annealed Glass Laboratory Apparatus

E 920 Specification for Commercially Packaged Laboratory

Apparatus

E 921 Specification for Export Packaged Laboratory Appa-

ratus

E 1133 Practice for Performance Testing of Packaged Labo-

ratory Apparatus United States Government Procurement

FIG. 1 Taper-Ground Joint

E 1157 Specification for Sampling and Testing Reusable

Laboratory Glassware

3.2 Surface Finish—The root-mean-square (rms) height of

the ground surface shall not exceed 1 μm.

This specification is under the jurisdiction of ASTM Committee E-41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E 41.01on

Glass and Plastic Apparatus.

Current edition approved Feb. 15, 1994. Published March 1994. Originally Discontinued 1979—U.S. Department of Commerce, Washington, DC 20234.

published as E 676 – 79. Last previous edition E 676 – 84 (1989). Available from American National Standards Institute, 1430 Broadway, New

Annual Book of ASTM Standards, Vol 14.04. York, NY 10018.

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

E 676

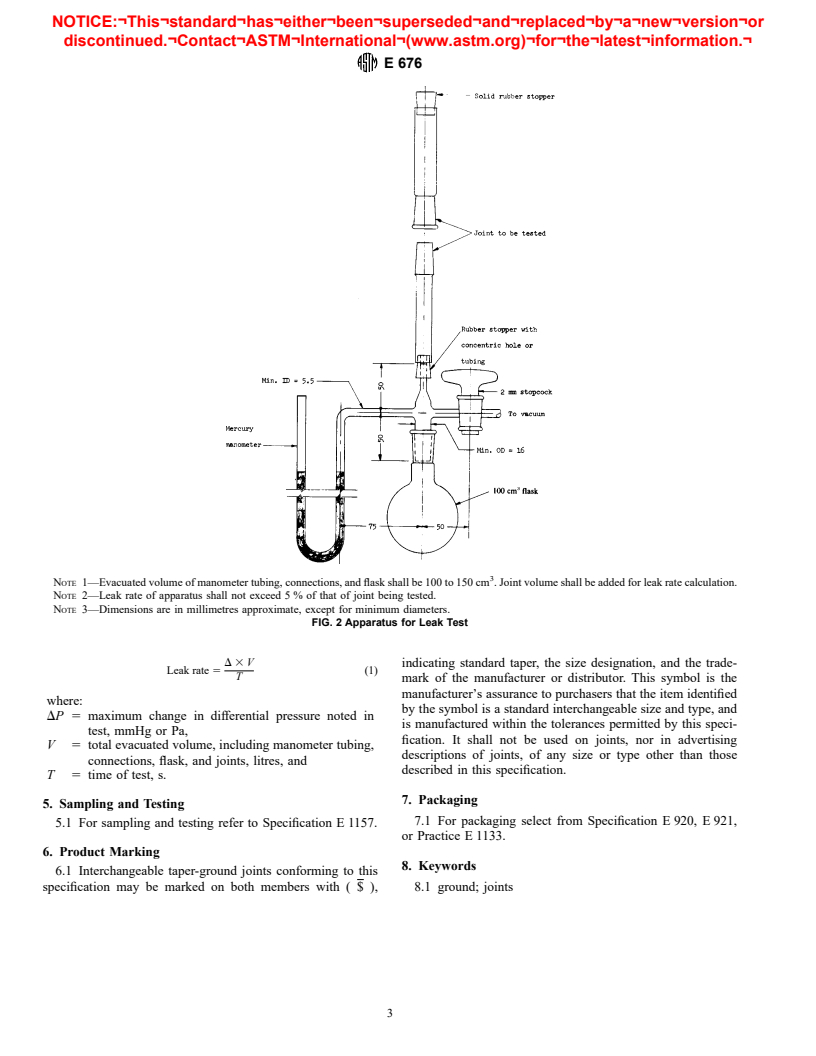

TABLE 1 Full-Length Taper-Ground Joints TABLE 3 Short-Length Taper-Ground Joints

Joint Size A B C Joint Size A B C

Designation Approximate Approxi- Diameter at Designation Approximate Approxi- Diameter at

Diameter at mate Length Large End Diameter at mate Length Large End

Small End, of Ground of Ground Small End, of Ground of Ground

A B A B

mm Zone, mm Zone, mm mm Zone, mm Zone, mm

7/25 5.0 25 7.5 5/8 4.2 8 5.0

10/30 7.0 30 10.0 7/10 6.5 10 7.5

12/30 9.5 30 12.5 10/7 9.3 7 10.0

14/35 11.0 35 14.5 10/10 9.0 10 10.0

19/38 15.0 38 18.8 12/10 11.5 10 12.5

24/40 20.0 40 24.0 14/10 13.5 10 14.5

29/42 25.0 42 29.2 19/10 17.8 10 18.8

34/45 30.0 45 34.5 24/12 22.8 12 24.0

40/50 35.0 50 40.0 29/12 28.0 12 29.2

45/50 40.0 50 45.0 34/12 33.3 12 34.5

50/50 45.0 50 50.0 40/12 38.8 12 40.0

55/50 50.0 50 55.0 45/12 43.8 12 45.0

60/50 55.0 50 60.0 50/12 48.8 12 50.0

71/60 65.0 60 71.0 55/12 53.8 12 55.0

103/60 97.0 60 103.0 60/12 58.8 12 60.0

71/15 69.5 15 71.0

A

A tolerance of 61.5 mm is allowed on both inner and outer members.

B A

A tolerance of + 0.15 mm is allowed on inner members, and a tolerance A tolerance of 61.5 mm is allowed on both inner and outer members.

B

of − 0.15 mm on outer members. A tolerance of + 0.15 mm is allowed on inner members, and a tolerance

of − 0.15 mm on outer members.

TABLE 2 Medium-Length Taper-Ground Joints

TABLE 4 International-Length Taper-Ground Joints

Joint Size A B C

Designation Approximate Approxi- Diameter at Joint Size A B C

Diameter at mate Length Large End Designation Approximate Approxi- Diameter at

Small End, of Ground of Ground Diameter at mate Length L

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.