ASTM D8292-20

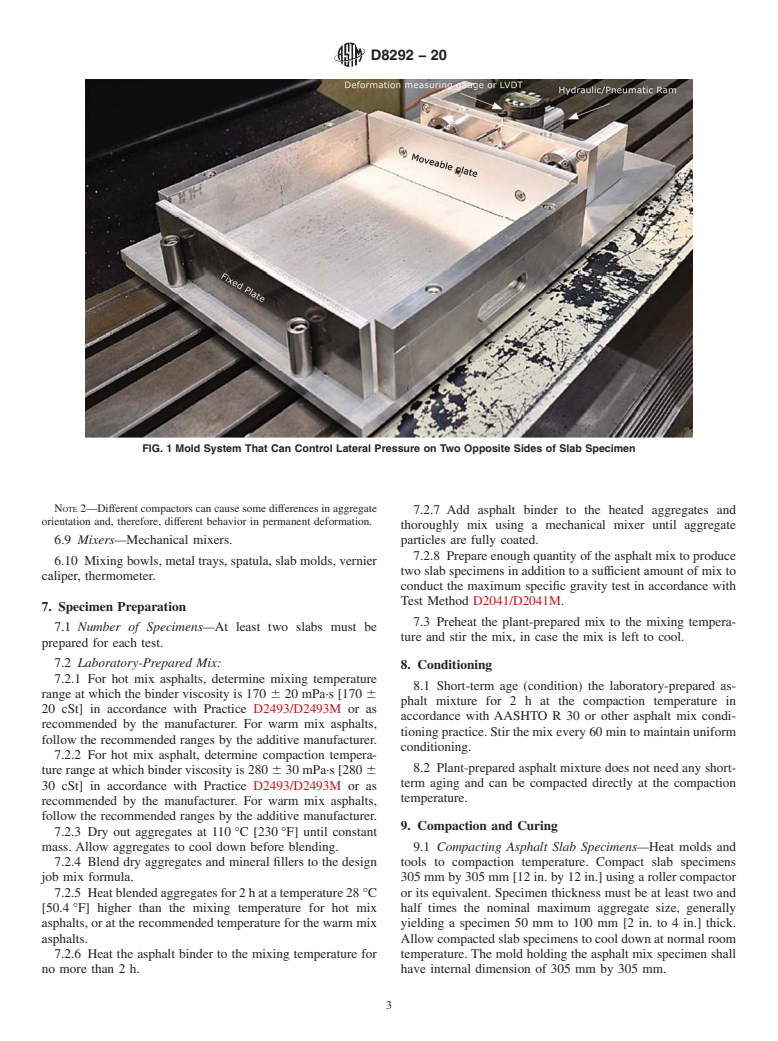

(Test Method)Standard Test Method for Permanent Deformation Behavior and Rutting Resistance of Compacted Asphalt Mix in the Modified Loaded Wheel Tracker Test Utilizing Controlled Confining Pressure

Standard Test Method for Permanent Deformation Behavior and Rutting Resistance of Compacted Asphalt Mix in the Modified Loaded Wheel Tracker Test Utilizing Controlled Confining Pressure

SIGNIFICANCE AND USE

5.1 This test method measures the permanent deformation behavior and rutting resistance of an asphalt mixture specimen.

5.2 This method can also measure moisture susceptibility of an asphalt mixture specimen if required by the agency.

Note 1: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method describes a procedure for testing permanent deformation behavior and rutting resistance of compacted asphalt mixtures using a modified version of a loaded wheel tracker device2 utilizing controlled confining pressure. The test specimen is tested either dry or moisture conditioned. A laboratory roller compactor or its equivalent is used to prepare test slabs of 305 mm by 305 mm [12 in. by 12 in.] and thickness 50 mm, 75 mm, or 100 mm [2 in., 3 in., or 4 in.] depending on the nominal maximum aggregate size. The thickness of the specimen must be at least two and half times the nominal maximum aggregate size. Alternatively, saw-cut slab specimens with dimensions 305 mm by 305 mm [12 in. by 12 in.] and thickness 50 mm to 100 mm [2 in. to 4 in.] may be secured from the field.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 Since a precision estimate for this standard has not been fully developed, the test method is to be used for research and informational purposes only. Therefore, this standard should not be used for acceptance or rejection of a material for purchasing purposes.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D8292 −20

Standard Test Method for

Permanent Deformation Behavior and Rutting Resistance of

Compacted Asphalt Mix in the Modified Loaded Wheel

1

Tracker Test Utilizing Controlled Confining Pressure

This standard is issued under the fixed designation D8292; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method describes a procedure for testing

responsibility of the user of this standard to establish appro-

permanent deformation behavior and rutting resistance of

priate safety, health, and environmental practices and deter-

compacted asphalt mixtures using a modified version of a

2 mine the applicability of regulatory limitations prior to use.

loaded wheel tracker device utilizing controlled confining

1.6 This international standard was developed in accor-

pressure. The test specimen is tested either dry or moisture

dance with internationally recognized principles on standard-

conditioned. A laboratory roller compactor or its equivalent is

ization established in the Decision on Principles for the

used to prepare test slabs of 305 mm by 305 mm [12 in. by

Development of International Standards, Guides and Recom-

12 in.] and thickness 50 mm, 75 mm, or 100 mm [2 in., 3 in.,

mendations issued by the World Trade Organization Technical

or 4 in.] depending on the nominal maximum aggregate size.

Barriers to Trade (TBT) Committee.

The thickness of the specimen must be at least two and half

times the nominal maximum aggregate size. Alternatively,

2. Referenced Documents

saw-cut slab specimens with dimensions 305 mm by 305 mm

3

2.1 ASTM Standards:

[12 in. by 12 in.] and thickness 50 mm to 100 mm [2 in. to

D8 Terminology Relating to Materials for Roads and Pave-

4 in.] may be secured from the field.

ments

1.2 Units—The values stated in either SI units or inch-

D2041/D2041M Test Method for Theoretical Maximum

pound units are to be regarded separately as standard. The

Specific Gravity and Density of Asphalt Mixtures

values stated in each system may not be exact equivalents;

D2493/D2493M Practice for Viscosity-Temperature Chart

therefore,eachsystemshallbeusedindependentlyoftheother.

for Asphalt Binders

Combining values from the two systems may result in noncon-

D2726/D2726M Test Method for Bulk Specific Gravity and

formance with the standard.

Density of Non-Absorptive Compacted Asphalt Mixtures

1.3 The text of this standard references notes and footnotes

D3203/D3203M Test Method for PercentAir Voids in Com-

which provide explanatory material. These notes and footnotes

pacted Asphalt Mixtures

(excluding those in tables and figures) shall not be considered

D3666 Specification for Minimum Requirements for Agen-

as requirements of the standard.

cies Testing and Inspecting Road and Paving Materials

D5361/D5361M Practice for Sampling Compacted Asphalt

1.4 Since a precision estimate for this standard has not been

Mixtures for Laboratory Testing

fully developed, the test method is to be used for research and

D6027/D6027M Practice for Calibrating Linear Displace-

informational purposes only. Therefore, this standard should

ment Transducers for Geotechnical Purposes

not be used for acceptance or rejection of a material for

D6857/D6857M Test Method for Maximum Specific Grav-

purchasing purposes.

ity and Density of Asphalt Mixtures Using Automatic

Vacuum Sealing Method

D8079 Practice for Preparation of Compacted Slab Asphalt

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.20 on Mix Samples Using a Segmented Rolling Compactor

Mechanical Tests of Asphalt Mixtures.

E1 Specification for ASTM Liquid-in-Glass Thermometers

Current edition approved Feb. 1, 2020. Published February 2020. DOI: 10.1520/

D8292-20.

2

The modified wheel tracker is covered by a patent. Interested parties are invited

3

to submit information regarding the identification of an alternative(s) to this For referenced ASTM standards, visit the ASTM website, www.astm.org, or

patented item to theASTM International Headquarters.Your comments will receive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

careful consideration at a meeting of the responsible technical committee, which Standards volume information, refer to the standard’s Document Summary

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.