ASTM D7310-21

(Practice)Standard Practice for Defect Detection and Rating of Plastic Films Using Optical Sensors

Standard Practice for Defect Detection and Rating of Plastic Films Using Optical Sensors

SIGNIFICANCE AND USE

4.1 Defects in film are not acceptable to the end-user as there is a reduction in the fitness-for-use in many applications. This document is intended to be a practice to assist users in the inspection, quantification and observation of defects.

4.2 This practice is applicable in a laboratory environment, continuous inspection as a quality control or as a research tool. It is also appropriate for use in any commercial process used to produce film including extrusion, calendaring, etc.

4.3 This practice is also suitable for use as an evaluation or screening tool for materials intended to be used in other processes where defects of this nature are critical, such as fiber spinning non-woven, etc.

4.4 Results achieved by different equipment, even from the same vendor in the same laboratory, are often not directly comparable as a bias exists that cannot be fully addressed through consistent operating conditions. Results frequently shift when analyzer components are upgraded. Additionally, results are often not directly comparable between different product types. All results are to be considered as relative values rather than absolute.

4.4.1 Therefore, it is not recommended to provide absolute results as part of a sales contract between the buyer and seller. For sales contracts, it is recommended to establish product grade designations based on the historical relationship of the absolute results reported, and fitness-for-use or based on a reference material agreed by both parties. This is attained by the collection of data over a time-period to establish acceptable control limits.

4.4.2 The defect size range of interest is usually different between resin supplier and converters. Total defect counts are not one to one comparable between small laboratory extrusion lines and commercial extrusion lines. Therefore, an individual correlation is the aim to get accepted results for fitness-for-use.

Note 2: This was tested on Brabender, Collin, Goettfert, and OCS s...

SCOPE

1.1 This practice intends to provide standardized approaches and criteria for the observation and reporting of defects in various types of plastic film, by means of an optical scanning system. Scope includes the in situ inspection of defects in films fabricated for specific applications after preparation of a suitable film from plastic resin.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7310 − 21

Standard Practice for

Defect Detection and Rating of Plastic Films Using Optical

1

Sensors

This standard is issued under the fixed designation D7310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

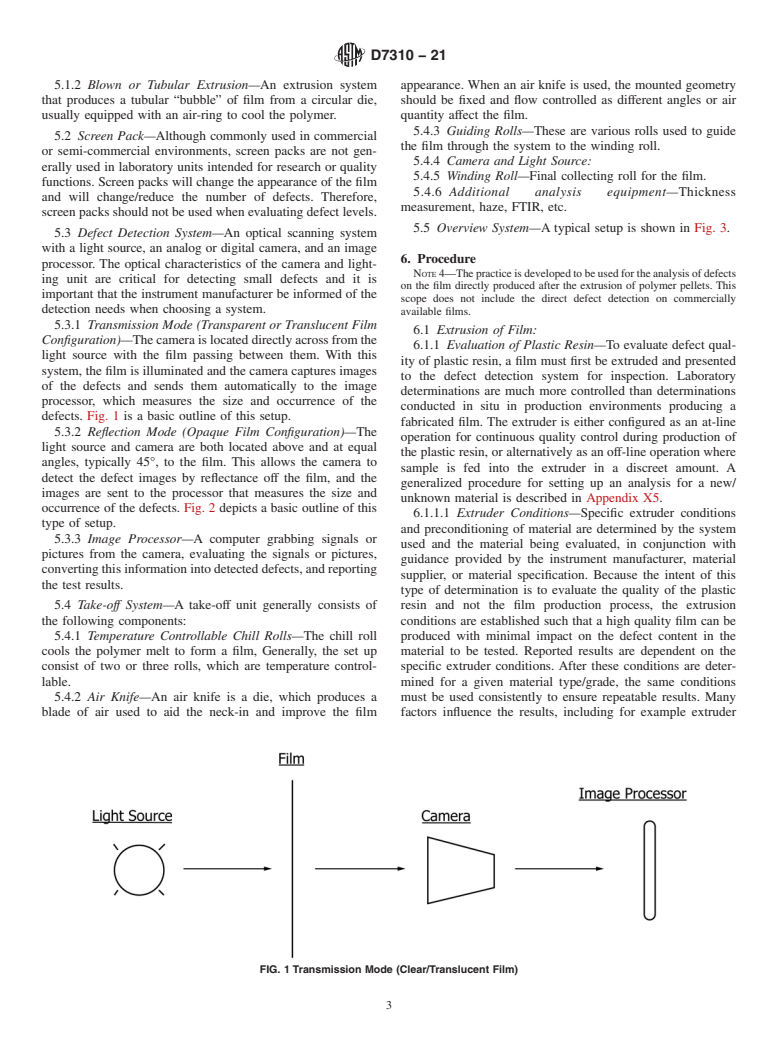

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 defect—for the purpose of this practice any entity in

1.1 This practice intends to provide standardized ap-

thefilmthatislargeenoughtobedetectedbyanopticalsensor

proaches and criteria for the observation and reporting of

and is either polymeric in nature or caused by degradation,

defects in various types of plastic film, by means of an optical

external contamination, undispersed additives or pigments, or

scanning system. Scope includes the in situ inspection of

similar sources.

defects in films fabricated for specific applications after prepa-

3.2.1.1 Discussion—In Appendix X1, some types of defects

ration of a suitable film from plastic resin.

are shown (cross-linked material, un-molten polymer, pin-

1.2 This standard does not purport to address all of the

holes). The defects can be classified in three groups:

safety concerns, if any, associated with its use. It is the

3.2.1.1 gel—particle of plastic material in the film matrix

responsibility of the user of this standard to establish appro-

not blended with the matrix and often acting as a miniature

priate safety, health, and environmental practices and deter-

lens. Several types of gels exist.

mine the applicability of regulatory limitations prior to use.

3.2.1.2 contamination—anyparticleinoronthefilmmatrix

NOTE 1—There is no known ISO equivalent to this standard.

affecting irradiated light differently than the matrix (dirt,

1.3 This international standard was developed in accor-

insects, oxidized additives or material, catalyst residues, solid

dance with internationally recognized principles on standard-

particles,metallicparticles,undispersedpigmentsoradditives,

ization established in the Decision on Principles for the

etc.).

Development of International Standards, Guides and Recom-

3.2.1.3 structural defect—visual deviation not caused by

mendations issued by the World Trade Organization Technical

gels or contaminations, for example, air bubbles, wrinkles, die

Barriers to Trade (TBT) Committee.

lines, film holes, sharkskin, arrowheads.

2. Referenced Documents

3.2.2 pixel

2 3.2.2.1 in a picture—smallest element of an image that can

2.1 ASTM Standards:

be individually processed by a video display system or a

D883Terminology Relating to Plastics

physical point in a raster image.

E456Terminology Relating to Quality and Statistics

3.2.2.1 Discussion—The greater the number of pixels per

E691Practice for Conducting an Interlaboratory Study to

area, the higher the resolution.

Determine the Precision of a Test Method

3.2.2.2 in a camera—smallest single photo-electrical detec-

E2587Practice for Use of Control Charts in Statistical

tor element of the camera sensor.

Process Control

3.2.3 effective pixel size—actualsizeoftheindividualpixels

3. Terminology

in the analyzed image.

3.1 Definitions—For definitions of terms that appear in this

3.2.3.1 Discussion—The effective pixel size of the optical

practice relating to plastics, refer to Terminology D883. system is determined by the physical pixel size of the sensor

and a magnification factor caused by the lens of the camera.

1 3.2.4 resolution

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

3.2.4.1 image—the detail an image holds, also called pixel

Products.

density.

Current edition approved Sept. 1, 2021. Published September 2021. Originally

3.2.4.1 Discussion—Higher resolution means more image

approved in 2007. Last previous edition approved in 2020 as D7310-20.

detail, often expressed in pixels per inch or dots per inch.

DOI:10.1520/D7310-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.4.2 camera—resolution of the sensor: the sheer number

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of pixels on the sensor; the amount of detail that a camera can

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. capture, measured in pixels (for example, 4k-camera).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7310 − 20 D7310 − 21

Standard Practice for

Defect Detection and Rating of Plastic Films Using Optical

1

Sensors

This standard is issued under the fixed designation D7310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice intends to provide standardized approaches and criteria for the observation and reporting of defects in various

types of plastic film, by means of an optical scanning system. Scope includes the in situ inspection of defects in films fabricated

for specific applications as well as after preparation of a suitable film sample to characterize defects within plastic granules

followed by inspection of the film sample.from plastic resin.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2587 Practice for Use of Control Charts in Statistical Process Control

3. Terminology

3.1 Definitions—For definitions of terms that appear in this practice relating to plastics, refer to Terminology D883.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 defect—for the purpose of this practice any entity in the film that is large enough to be detected by an optical sensor and

is either polymeric in nature or caused by degradation, external contamination, undispersed additives or pigments, or similar

sources.

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved May 15, 2020Sept. 1, 2021. Published August 2020September 2021. Originally approved in 2007. Last previous edition approved in 20112020

as D7310 - 11.D7310 - 20. DOI:10.1520/D7310-20.DOI:10.1520/D7310-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7310 − 21

3.2.1.1 Discussion—

In Appendix X1, some types of defects are shown (cross-linked material, un-molten polymer, pinholes). The defects can be

classified in three groups:

3.2.1.1 gel—particle of plastic material in the film matrix not blended with the matrix and often acting as a miniature lens.

Several types of gels exist.

3.2.1.2 contamination—any particle in or on the film matrix affecting irradiated light differently than the matrix (dirt, insects,

oxidized additives or material, catalyst residues, solid particles, metallic particles, undispersed pigments or additives, etc.).

3.2.1.3 structural defect—visual deviation not caused by gels or contaminations, for example, air bubbles, wrinkles, die lines,

film holes, sharkskin, arrowheads.

3.2.2 pixel

3.2.2.1 in a picture—smallest element of an image that can be individually processed by a video display system or a physical

point in a raster image.

3.2.2.1 Discussion—

The greater the number of pixels per area, the higher the resolution.

3.2.2.2 in a camera—smallest single photo-electrical detector element of the camera sensor.

3.2.3 effective pixel size—actual size of the individual pixels in the analyzed image.

3.2.3.1 Discussion—

The effective pixel size of the optical system is determined by the physical pixel size of the sensor and a magnification factor

caused by the lens of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.