ASTM D1776-08

(Practice)Standard Practice for Conditioning and Testing Textiles

Standard Practice for Conditioning and Testing Textiles

ABSTRACT

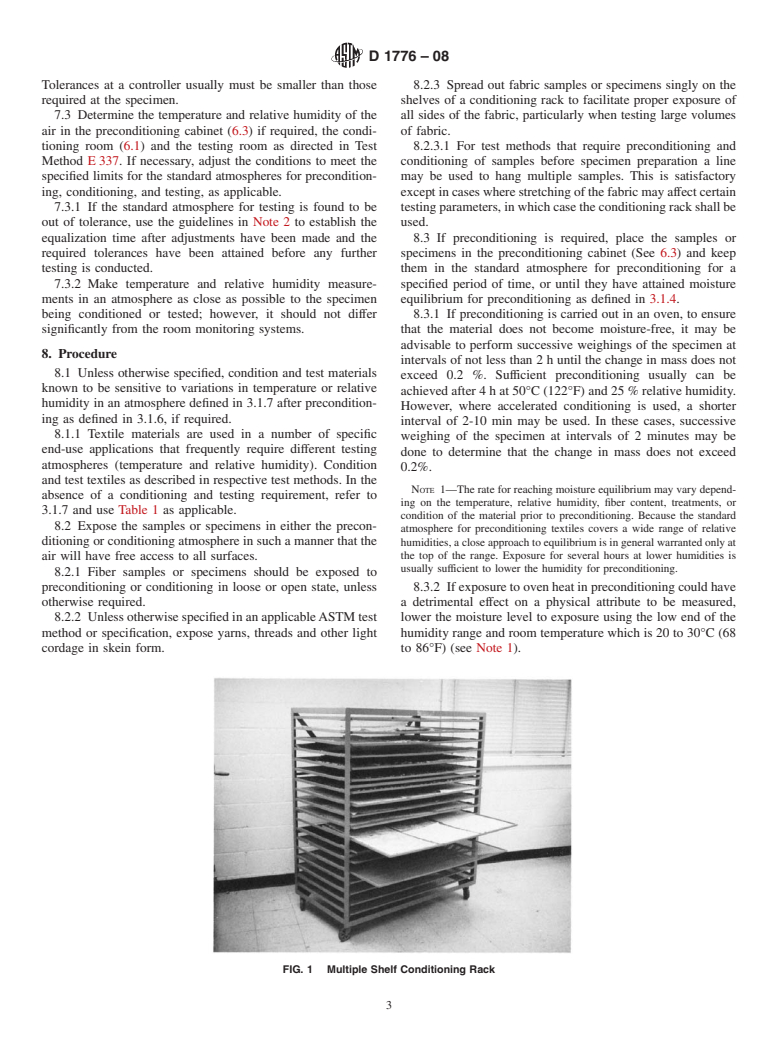

This practice covers the conditioning and testing of textiles in those instances where such conditioning is specified in a test method. Because prior exposure of textiles to high or low humidity may affect the equilibrium moisture pick-up, a procedure also is given for preconditioning the material when specified. The equipments to be used in the conditioning and testing of textiles shall include conditioning room or chamber, psychrometer ventilated by aspiration, preconditioning cabinet, room, or suitable container, balance, and multiple shelf conditioning rack. The conditioning room or chamber shall consist of equipment for maintaining the standard atmosphere for testing textiles throughout the room or chamber within the tolerances given and including facilities for circulating air over all surfaces of the exposed sample or specimen and equipment for recording the temperature and relative humidity of the air in the conditioning room or chamber. Samples or specimens requiring preconditioning shall be brought to a relatively low moisture content in a specified atmosphere. Samples or specimens requiring conditioning shall be brought to moisture equilibrium for testing in the standard atmosphere for testing textiles, or when required.

SCOPE

1.1 This practice covers the conditioning and testing of textiles when conditioning is specified in a test method. Because prior exposure of textiles to high or low humidity may affect moisture pick-up equilibrium, a procedure also is given for preconditioning the material when required.

1.2 The values stated the text are in SI units. Inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance to a specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 1776–08

Standard Practice for

1

Conditioning and Testing Textiles

This standard is issued under the fixed designation D 1776; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ISO 139 Textiles Standard Atmosphere for Conditioning

3

and Testing

1.1 This practice covers the conditioning and testing of

textiles when conditioning is specified in a test method.

3. Terminology

Becausepriorexposureoftextilestohighorlowhumiditymay

3.1 Definitions:

affect moisture pick-up equilibrium, a procedure also is given

3.1.1 accelerated conditioning, n— a process that uses

for preconditioning the material when required.

humidity generation and precise temperature controls to rap-

1.2 The values stated the text are in SI units. Inch-pound

idly bring a textile to equilibrium in a standard atmosphere.

units are shown in parentheses. The values stated in each

3.1.1.1 Discussion—Accelerated conditioning may be

system are not exact equivalents; therefore, each system shall

achieved in closed cabinets, rooms or process lines designed

be used independently of the other. Combining values from the

such that equilibrium can be achieved in a much shorter time,

two systems may result in nonconformance to a specification.

such as 2 to 10 minutes, compared to typical conditioning

1.3 This standard does not purport to address all of the

times.

safety concerns, if any, associated with its use. It is the

3.1.2 moisture content, n—that part of the total mass of a

responsibility of the user of this standard to establish appro-

material that is absorbed or adsorbed water, expressed as a

priate safety and health practices and determine the applica-

percentage of the total mass.

bility of regulatory limitations prior to use.

3.1.2.1 Discussion—The total mass is the original mass

2. Referenced Documents comprising the dry substance plus any water present.The word

2

water as used in these definitions refers to the compound

2.1 ASTM Standards:

chemically defined as H O. The terms water and moisture

2

D 123 Terminology Relating to Textiles

frequently are used interchangeably in the literature and the

D 618 Practice for Conditioning Plastics for Testing

trade, but the term moisture is sometimes considered to include

D 885 Test Methods for Tire Cords, Tire Cord Fabrics, and

other volatile matter.

Industrial Filament Yarns Made from Manufactured

3.1.3 moisture equilibrium, n— the state of condition a

Organic-Base Fibers

textile reaches when it no longer takes up moisture from, or

D 1776 Practice for Conditioning and Testing Textiles

gives up moisture to, the surrounding atmosphere.

D 4920 Terminology Relating to Conditioning, Chemical,

3.1.3.1 Discussion—Superficial equilibrium is reached very

and Thermal Properties

rapidly when air comes into contact with the outer surfaces of

D 7269 Test Methods for Tensile Testing of Aramid Yarns

a textile. Moisture equilibrium can be reached in a reasonable

E 337 Test Method for Measuring Humidity with a Psy-

timeonlyiftheairtowhichthesampleisexposedisinmotion.

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

Moisture equilibrium, with air temperature (in motion) and

peratures)

relative humidity controlled to prescribed levels, is achieved

2.2 ISO Standard:

when successive weighings do not show a progressive change

in mass greater than the tolerance established for the textile.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

3.1.4 moisture equilibrium, for preconditioning, n—the

is the direct responsibility of Subcommittee D13.51 on Conditioning and, Chemical

moisture state of a textile sample(s) or specimen(s) reached

and Thermal Properties.

after exposure to moving air in the standard atmosphere for

Current edition approved Aug. 1, 2008. Published October 2008. Originally

approved in 1998. Last previous edition approved in 2004 as D 1776–04.

preconditioning.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer tot he standard’s Document summary page on Available fromAmerican National Standards Institute, 11 W. 42nd Street, 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 1776–08

3.1.5 moisture equilibrium, for testing, n—the state of a and products, and among different laboratories, it is necessary

textile sample(s) or specimen (s) reaches after exposure to to

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 1776–04 Designation:D 1776–08

Standard Practice for

1

Conditioning and Testing Textiles

This standard is issued under the fixed designation D 1776; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This practice covers the conditioning and testing of textiles in those instances where such when conditioning is specified

in a test method. Because prior exposure of textiles to high or low humidity may affect the equilibrium moisture pick-up

equilibrium, a procedure also is given for preconditioning the material when specified.required.

1.2 The values stated in either SI units or inch-pound units the text are to be regarded separately as the standard. Within the

text, the inch-pound in SI units. Inch-pound units are shown in parentheses. The values stated in each system are not exact

equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result

in nonconformance with theto a specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D123Terminology Relating to Textiles

D578Specification for Glass Fiber Strands

D 123 Terminology Relating to Textiles

D 618Practice for Conditioning Plastics and Electrical Insulating Materials for Testing Practice for Conditioning Plastics for

Testing

D 885 Test Methods for Tire Cords, Tire Cord Fabrics, and Industrial Filament Yarns and Cords Made from Man-

MadeManufactured Organic-Base Fibers

D 1776Practice for Conditioning Textiles for Testing

D4920Terminology Relating to Moisture in Textiles Practice for Conditioning and Testing Textiles

D 4920 Terminology Relating to Conditioning, Chemical, and Thermal Properties

D 7269 Test Methods for Tensile Testing of Aramid Yarns

E 337 Test Method for Measuring Humidity Withwith a Psychrometer (the Measurement of Wet- and Dry-Bulb Temperatures)

2.2 ISO Standard:

3

ISO 139 Textiles Standard Atmosphere for Conditioning and Testing

3. Terminology

3.1 Definitions:

3.1.1 accelerated conditioning, n— a process that uses humidity generation and precise temperature controls to rapidly bring

a textile to equilibrium in a standard atmosphere.

3.1.1.1 Discussion—Accelerated conditioning may be achieved in closed cabinets, rooms or process lines designed such that

equilibrium can be achieved in a much shorter time, such as 2 to 10 minutes, compared to typical conditioning times.

3.1.2 moisture content, n—that part of the total mass of a material that is absorbed or adsorbed water, expressed as a percentage

of the total mass.

3.1.1.1

1

This practice is under the jurisdiction ofASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.51 on Conditioning and, Chemical and

Thermal Properties.

Current edition approvedMarch 1, 2004. Published March 2004. Originally approved in 1998. Last previous edition approved in 1998 as D1776–98.

Current edition approved Aug. 1, 2008. Published October 2008. Originally approved in 1998. Last previous edition approved in 2004 as D 1776–04.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer tot he standard’s Document summary page on the ASTM website.

3

Available from American National Standards Institute, 11 W. 42nd Street, 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 1776–08

3.1.2.1 Discussion—The total mass is the original mass comprising the dry substance plus any water present. The word water

as used in these definitions refers to the compound chemically defined as H O. The terms water and moisture frequently are used

2

interchangeably in the literature and the trade, but the term moisture is sometimes considered to include other volatile

material.matter.

3.1.23.1.3 moisture

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.