ASTM A269/A269M-15

(Specification)Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ABSTRACT

This specification covers nominal-wall-thickness, seamless and welded austenitic steel tubing for general corrosion-resisting and low- or high-temperature service. All material shall be furnished in the heat-treated condition. The steel shall conform to the chemical composition requirements. Different mechanical test requirements that includes, flaring test, flange test, hardness test, and reverse flattening test are presented. Also, each tube shall be subjected to the non-destructive electric test or the hydrostatic test. Finally the hardness requirements for different grades of tubes are highlighted.

SCOPE

1.1 This specification covers grades of nominal-wall-thickness, stainless steel tubing for general corrosion-resisting and low- or high-temperature service, as designated in Table 1.

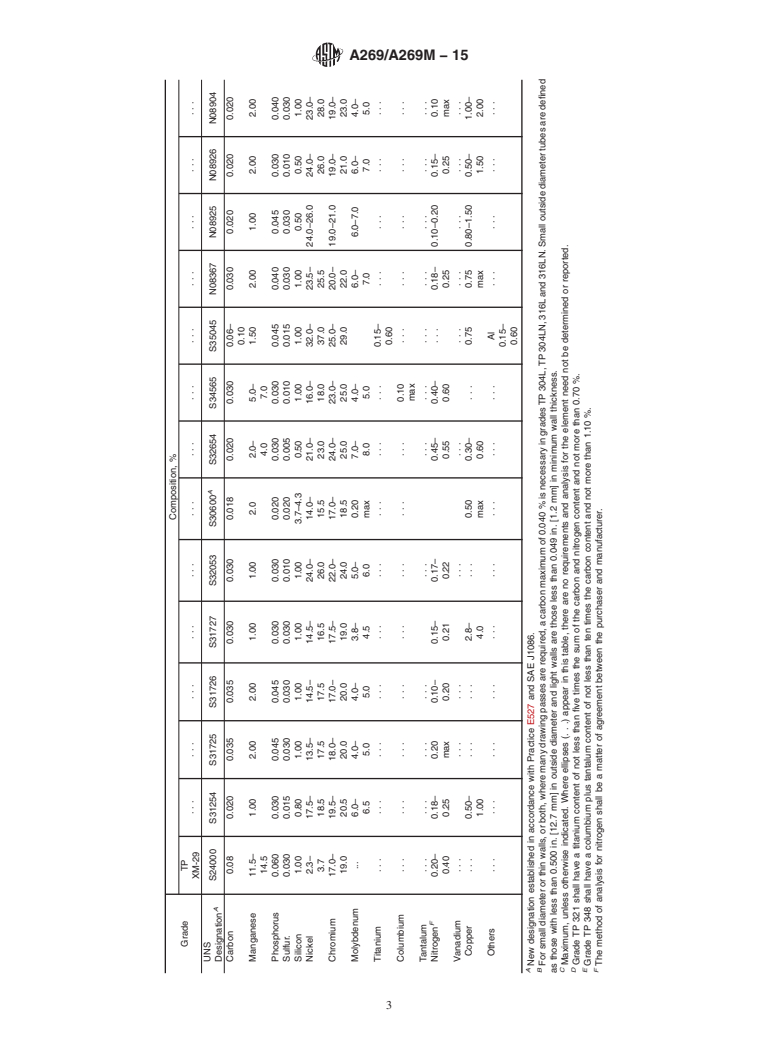

Grade

Composition, %

TP

XM-29

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

UNS DesignationA

S24000

S31254

S31725

S31726

S31727

S32053

S30600A

S32654

S34565

S35045

N08367

N08925

N08926

N08904

Carbon

0.08

0.020

0.035

0.035

0.030

0.030

0.018

0.020

0.030

0.06–

0.10

0.030

0.020

0.020

0.020

Manganese

11.5–

14.5

1.00

2.00

2.00

1.00

1.00

2.0

2.0–

4.0

5.0–

7.0

1.50

2.00

1.00

2.00

2.00

Phosphorus

0.060

0.030

0.045

0.045

0.030

0.030

0.020

0.030

0.030

0.045

0.040

0.045

0.030

0.040

Sulfur.

0.030

0.015

0.030

0.030

0.030

0.010

0.020

0.005

0.010

0.015

0.030

0.030

0.010

0.030

Silicon

1.00

0.80

1.00

1.00

1.00

1.00

3.7–4.3

0.50

1.00

1.00

1.00

0.50

0.50

1.00

Nickel

2.3–

3.7

17.5–

18.5

13.5–

17.5

14.5–

17.5

14.5–

16.5

24.0–

26.0

14.0–

15.5

21.0–

23.0

16.0–

18.0

32.0–

37.0

23.5–

25.5

24.0–26.0

24.0–

26.0

23.0–

28.0

Chromium

17.0–

19.0

19.5–

20.5

18.0–

20.0

17.0–

20.0

17.5–

19.0

22.0–

24.0

17.0–

18.5

24.0–

25.0

23.0–

25.0

25.0–

29.0

20.0–

22.0

19.0–21.0

19.0–

21.0

19.0–

23.0

Molybdenum

...

6.0–

6.5

4.0–

5.0

4.0–

5.0

3.8–

4.5

5.0–

6.0

0.20

max

7.0–

8.0

4.0–

5.0

6.0–

7.0

6.0–7.0

6.0–

7.0

4.0–

5.0

Titanium

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

0.15–

0.60

. . .

. . .

. . .

. . .

Columbium

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

0.10

max

. . .

. . .

. . .

. . .

. . .

Tantalum

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

NitrogenF

0.20–

0.40

0.18–

0.25

0.20

max

0.10–

0.20

0.15–

0.21

0.17–

0.22

0.45–

0.55

0.40–

0.60

. . .

0.18–

0.25

0.10–0.20

0.15–

0.25

0.10

max

Vanadium

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

Copper

. . .

0.50–

1.00

. . .

. . .

2.8–

4.0

. . .

0.50

max

0.30–

0.60

. . .

0.75

0.75

max

0.80–1.50

0.50–

1.50

1.00–

2.00

Others

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

Al

0.15–

0.60

. . .

. . .

. . .

. . .(A) New designation established in accordance with Practice E527 and SAE J1086.(B) For small diameter or thin walls, or both, where many drawing passes are required, a carbon maximum of 0.040 % is necessary in grades TP 304L, TP 304LN, 316L and 316LN. Small outside diameter tubes are defined as those with less than 0.500 in. [12.7 mm] in outside diameter and light walls are those less than 0.049...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A269/A269M −15

StandardSpecification for

Seamless and Welded Austenitic Stainless Steel Tubing for

1

General Service

This standard is issued under the fixed designationA269/A269M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* A480/A480M Specification for General Requirements for

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

1.1 This specification covers grades of nominal-wall-

Sheet, and Strip

thickness, stainless steel tubing for general corrosion-resisting

A632 Specification for Seamless and Welded Austenitic

and low- or high-temperature service, as designated in Table 1.

Stainless Steel Tubing (Small-Diameter) for General Ser-

1.2 The tubing sizes and thicknesses usually furnished to

vice

1

this specification are ⁄4 in. [6.4 mm] in inside diameter and

A1016/A1016M Specification for General Requirements for

larger and 0.020 in. [0.51 mm] in nominal wall-thickness and

Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless

heavier.

Steel Tubes

E527 Practice for Numbering Metals and Alloys in the

1.3 Mechanical property requirements do not apply to

1

tubing smaller than ⁄8 in. [3.2 mm] in inside diameter or 0.015 Unified Numbering System (UNS)

in. [0.38 mm] in thickness.

2.2 ASME Piping Code:

3

ASME B31.3 Process Piping

NOTE 1—Additional testing requirements may apply for use in ASME

B31.3 applications.

2.3 Other Standard:

1.4 Optional supplementary requirements are provided and,

SAE J1086 Practice for Numbering Metals and Alloys

4

when one or more of these are desired, each shall be so stated

(UNS)

in the order.

3. Ordering Information

1.5 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. Within the text, SI

3.1 Orders for material under this specification should

units are shown in brackets. The values stated in each system

include the following, as required, to describe the desired

may not be exact equivalents; therefore, each system shall be

material adequately:

used independently of the other. Combining values from the

3.1.1 Quantity (feet, metres, or number of lengths),

two systems may result in non-conformance with the standard.

3.1.2 Name of material (seamless or welded tubes),

Theinch-poundunitsshallapplyunlessthe“M”designationof

3.1.3 Grade (Table 1),

this specification is specified in the order.

3.1.4 Size (outside diameter and nominal wall thickness),

3.1.5 Length (specific or random),

2. Referenced Documents

3.1.6 Optional requirements (heat treatment, see Section 6;

2

2.1 ASTM Standards:

hydrostatic or nondestructive electric test, see Section 10),

A262 Practices for Detecting Susceptibility to Intergranular

3.1.7 Test report required (see Section on Inspection of

Attack in Austenitic Stainless Steels

Specification A1016/A1016M),

3.1.8 Specification designation, and

3.1.9 Special requirements and any supplementary require-

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

ments selected.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved Sept. 1, 2015. Published September 2015. Originally

ɛ1

approved in 1944. Last previous edition approved in 2014 as A269–14 . DOI:

3

10.1520/A0269_A0269M-15. Available from American Society of Mechanical Engineers (ASME), ASME

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A269/A269M−15

2

C

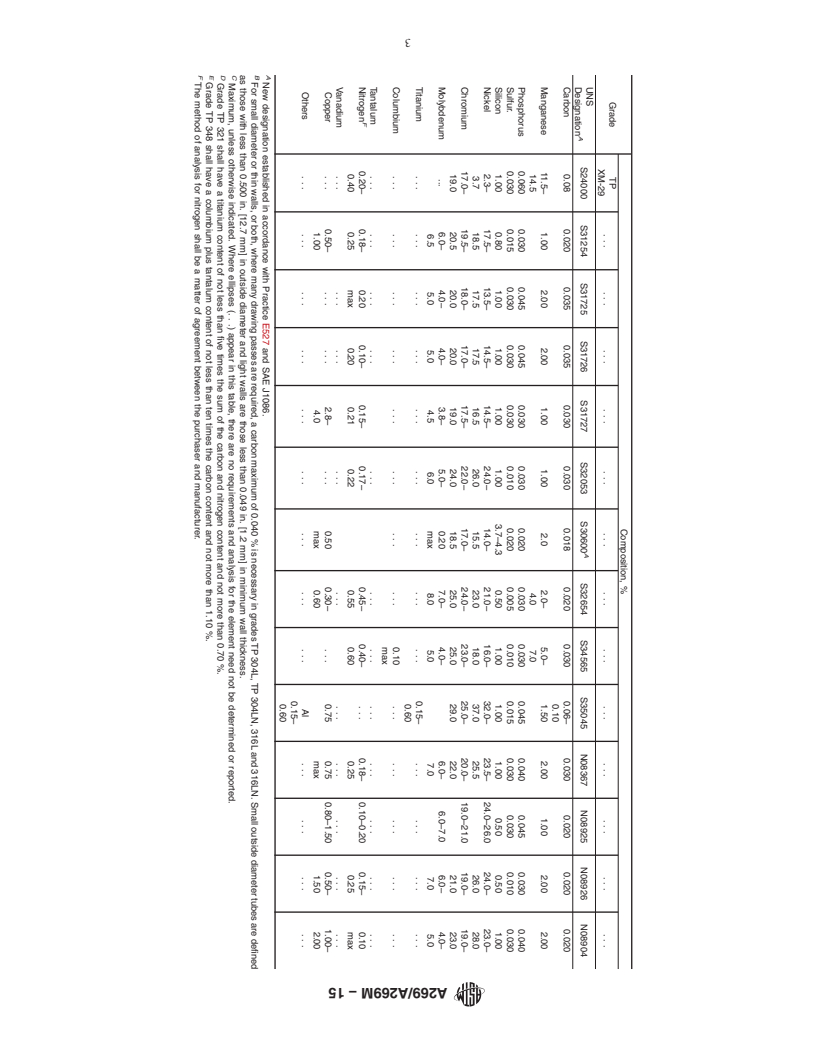

TABLE 1 Chemical Requirements %

Composition, %

Grade TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP

...

201 201LN 304 304L 304LN 316 316L 316LN . 317 321 347 348 XM-10 XM-11 XM-15 XM-19

UNS

S20100 S20153 S30400 S30403 S30453 S31600 31603 S31653 S31655 S31700 S31730 S32100 S34700 S34800 S21900 S21904 S38100 S20910

A

Designation

B B B B

Carbon 0.15 0.03 0.08 0.035 0.035 0.08 0.035 0.035 0.030 0.08 0.030 0.08 0.08 0.08 0.08 0.0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A269/A269M − 14 A269/A269M − 15

Standard Specification for

Seamless and Welded Austenitic Stainless Steel Tubing for

1

General Service

This standard is issued under the fixed designation A269/A269M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Editorial corrections made throughout in June 2014.

1. Scope*

1.1 This specification covers grades of nominal-wall-thickness, stainless steel tubing for general corrosion-resisting and low-

or high-temperature service, as designated in Table 1.

1

1.2 The tubing sizes and thicknesses usually furnished to this specification are ⁄4 in. [6.4 mm] in inside diameter and larger and

0.020 in. [0.51 mm] in nominal wall-thickness and heavier.

1

1.3 Mechanical property requirements do not apply to tubing smaller than ⁄8 in. [3.2 mm] in inside diameter or 0.015 in. [0.38

mm] in thickness.

NOTE 1—Additional testing requirements may apply for use in ASME B31.3 applications.

1.4 Optional supplementary requirements are provided and, when one or more of these are desired, each shall be so stated in

the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard. The

inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

2. Referenced Documents

2

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A480/A480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

A632 Specification for Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) for General Service

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.2 ASME Piping Code:

3

ASME B31.3 Process Piping

2.3 Other Standard:

4

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

3. Ordering Information

3.1 Orders for material under this specification should include the following, as required, to describe the desired material

adequately:

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved May 1, 2014Sept. 1, 2015. Published May 2014September 2015. Originally approved in 1944. Last previous edition approved in 20132014 as

ɛ1

A269–13.–14 . DOI: 10.1520/A0269_A0269M-14E01.10.1520/A0269_A0269M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

4

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A269/A269M − 15

2

C

TABLE 1 Chemical Requirements %

Composition, %

Grade TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP TP

. . .

201 201LN 304 304L 304LN 316 316L 316LN . . . 317 321 347 348 XM-10 XM-11 XM-15 XM-19

UNS

S20100 S20153 S30400 S30403 S30453 S31600 31603 S31653 S31655 S31700 S31730 S32100 S34700 S34800 S21900 S21904 S38100 S20910

A

Designation

B B B B

Carbon 0.15 0.03 0.08 0.035 0.035 0.08 0.035 0.035 0.030 0.08 0.030 0.08 0.08 0.08 0.08 0.04 0.08 0.06

Manganese 5.5– 6.4– 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 8.00– 8.00– 2.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.